Preparation method of high-elasticity crease-resistant silk shirt fabric

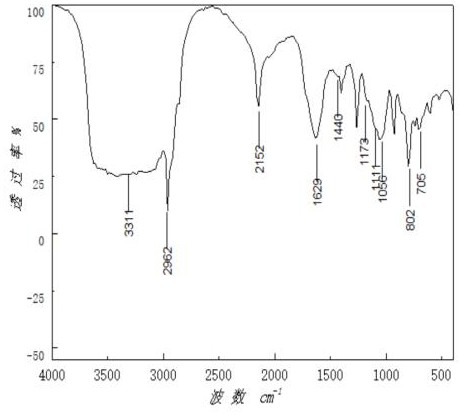

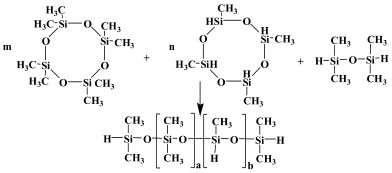

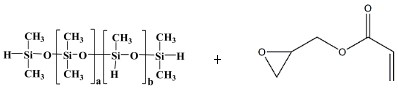

A silk and elasticity technology is applied in the field of preparation of high-elasticity anti-wrinkle silk shirting fabrics, which can solve the problems of harsh synthesis conditions, inability to achieve effective control of hydrogen content and molecular weight of target products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a high-elastic wrinkle-resistant silk shirting fabric, the specific scheme of which is:

[0035] Blending, according to the mass kg, 30kg silk fiber, 5kg polytrimethylene terephthalate fiber, 3kg cashmere fiber and 2kg camel hair are blended into silk blended fiber, and then warped to make base cloth; The yarn needs sizing, the temperature of the sizing tank is 50°C, the drying room is 90°C, and the sizing rate is 12.1%;

[0036] Refining, using a bath ratio of 1:20 to refine the base cloth, the refining temperature is 80°C, and the refining time is 30 minutes. The refining liquid composition includes 1.6g / L refining agent, 3.8g / L 30% hydrogen peroxide, 2.1 g / L etidronate, 0.8g / L sodium silicate, 1.2g / L sodium carbonate;

[0037] Finishing, the refined base fabric is treated in the anti-wrinkle finishing solution by two dipping and two rolling processes, then pre-baked at 80°C for 30s, and then heated to 100°C for 60s;

[0038] Water washing, the ...

Embodiment 2

[0049] A method for preparing a high-elastic wrinkle-resistant silk shirting fabric, the specific scheme of which is:

[0050] Blending, 40kg silk fiber, 8kg polytrimethylene terephthalate fiber, 6kg cashmere fiber and 5kg camel hair are blended into silk blended fiber, and then warped to make base cloth; the blended yarn before warping needs sizing, sizing The tank temperature is 55°C, the drying room is 100°C, and the sizing rate is 13.6%;

[0051] Refining, using a bath ratio of 1:30 to refine the base cloth, the refining temperature is 85 ° C, and the refining time is 40 minutes. The refining liquid composition includes 2.4g / L refining agent, 4.2g / L 30% hydrogen peroxide, 2.8 g / L etidronate, 1.8g / L sodium silicate, 2.1g / L sodium carbonate;

[0052] Finishing, the refined base fabric is treated with two dipping and two rolling processes in the anti-wrinkle finishing solution, then pre-baked at 90°C for 40s, and then heated to 110°C for 90s;

[0053] Water washing, the fir...

Embodiment 3

[0062] A method for preparing a high-elastic wrinkle-resistant silk shirting fabric, the specific scheme of which is:

[0063] Blending, 60kg silk fiber, 10kg polytrimethylene terephthalate fiber, 12kg cashmere fiber and 8kg camel hair are blended into silk blended fiber, and then warped to make base cloth; the blended yarn before warping needs sizing, sizing The tank temperature is 65°C, the drying room is 110°C, and the sizing rate is 14.9%;

[0064] Refining, using a bath ratio of 1:40 to refine the base cloth, the refining temperature is 95 ° C, and the refining time is 60 minutes. The refining liquid composition includes 3.8g / L refining agent, 5.6g / L 30% hydrogen peroxide, 3.6 g / L etidronate, 2.8g / L sodium silicate, 2.8g / L sodium carbonate;

[0065] Finishing, the refined base fabric is treated with two dipping and two rolling processes in the anti-wrinkle finishing solution, then pre-baked at 100°C for 60s, and then heated to 120°C for 120s;

[0066] Water washing, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com