Amino group-containing ionic liquid-modified graphene oxide-wrapped silica gel-based chromatographic filling material

A graphene-wrapped, ionic liquid technology, used in ion exchange, ion exchange regeneration, ion exchange treatment devices, etc., to achieve the effect of excellent chromatographic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

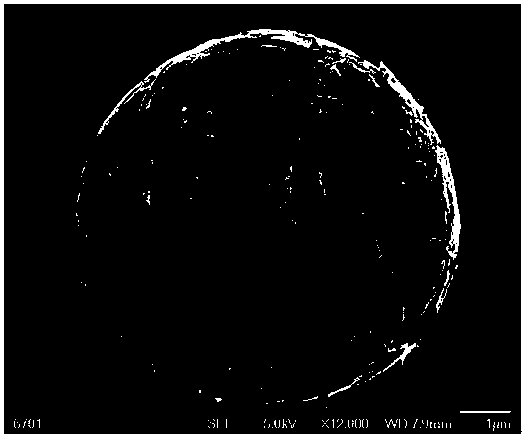

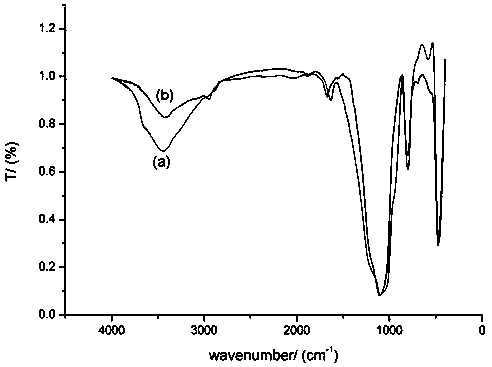

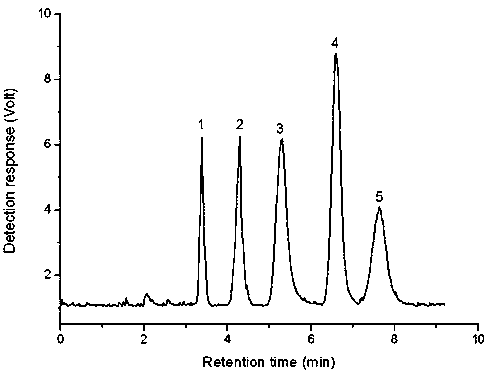

[0031] Example 1 Preparation of ionic liquid-modified graphene oxide-wrapped silica gel-based chromatographic material

[0032] Proceed as follows:

[0033] (1) Take 10g of silica gel and 100mL of hydrochloric acid with a mass fraction of 37%, mix the two evenly, let stand for acidification for 12h, then separate the silica gel, wash with distilled water until neutral, and finally vacuum dry at 120°C for 12h to obtain the surface 10g of silica gel containing silanol;

[0034] (2) Add 10g of silica gel containing silanol on the surface obtained above into 100ml of anhydrous toluene, after dispersing evenly, add 8g of 3-aminopropyltriethoxysilane, mix the mixture uniformly by ultrasonic, then heat at 120°C Reflux and react for 12 hours; after the reaction, wash the filler with toluene, ethanol, and methanol in sequence, and dry the washed filler at 120°C for 24 hours under vacuum at 0.06Mpa to obtain NH 2 / SiO 2 ;

[0035] (3) Get 0.1g of graphene oxide powder and disperse i...

Embodiment 2

[0038] Example 2 Preparation of ionic liquid-modified graphene oxide-wrapped silica gel-based chromatographic material

[0039] Proceed as follows:

[0040] (1) Take 10g of silica gel and 100mL of hydrochloric acid with a mass fraction of 37%, mix the two evenly, let it stand for acidification for 24 hours, then separate the silica gel, wash it with distilled water until it is neutral, and finally dry it in vacuum at 120°C for 24 hours to obtain the surface 10g of silica gel containing silanol;

[0041](2) Add 10g of silica gel containing silanol on the surface obtained above to 100ml of anhydrous toluene, after dispersing evenly, add 8g of 3-aminopropyltriethoxysilane, mix the mixture uniformly by ultrasonic, then heat and reflux at 150°C , reacted for 12h; after the reaction, wash the filler with toluene, ethanol and methanol in turn, and dry the washed filler at 120°C for 24h under vacuum at 0.06Mpa to obtain NH 2 / SiO 2 ;

[0042] (3) Take 0.1g of graphene oxide powder...

Embodiment 3

[0045] Example 3 Preparation of ionic liquid-modified graphene oxide-wrapped silica gel-based chromatographic material

[0046] Proceed as follows:

[0047] (1) Take 10g of silica gel and 100mL of hydrochloric acid with a mass fraction of 37%, mix the two evenly, let it stand for acidification for 24 hours, then separate the silica gel, wash it with distilled water until it is neutral, and finally dry it in vacuum at 120°C for 24 hours to obtain the surface 10g of silica gel containing silanol;

[0048] (2) Add 10g of silica gel containing silanol on the surface obtained above to 100ml of anhydrous toluene, after dispersing evenly, add 8g of 3-aminopropyltriethoxysilane, mix the mixture uniformly by ultrasonic, then heat and reflux at 150°C , reacted for 12h; after the reaction, wash the filler with toluene, ethanol and methanol in turn, and dry the washed filler at 120°C for 24h under vacuum at 0.06Mpa to obtain NH 2 / SiO 2 ;

[0049] (3) Take 0.02g of graphene oxide powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com