Method for preparing polyvinyl imidazole type silica gel filler

A technology of polyvinylimidazole and vinylimidazole, which is applied in the field of preparation of high-performance liquid chromatography fillers, can solve problems such as single separation mechanism, impossibility of chromatographic application, difficult separation of samples, etc., and achieve stable chromatographic performance and superior chromatographic performance , synthetic reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

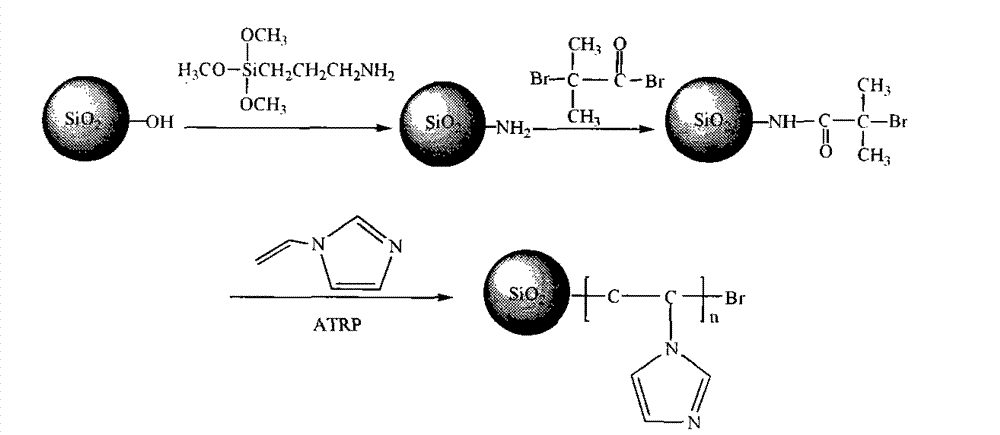

[0032] Embodiment 1: Preparation of poly-N-vinylimidazole grafted silica gel

[0033] Include the following steps A and B in turn:

[0034] A. Synthesis of brominated silica gel

[0035] Add 5.0g of aminopropyl silica gel to the reaction vessel, add 50ml of toluene, stir evenly, add 0.8ml of 2-bromoisobutyryl bromide and 0.6ml of triethylamine, and react at room temperature for 24h. Then, vacuum filter, wash with 200ml methanol, 300ml water, 200ml methanol successively, and then vacuum dry at 65°C for 12h to obtain brominated silica gel.

[0036] B. Synthesis of poly-N-vinylimidazole-grafted silica gel

[0037] Add 4.0g of brominated silica gel to the reaction vessel, add 20ml of N,N'-dimethylformamide as the reaction solvent, stir it evenly, add 20ml of N , N'-dimethylformamide solution, and then add 2ml of N-vinylimidazole, under the protection of high-purity nitrogen, heat and react at 45°C for 36h. Then cool to room temperature, filter with suction, wash with 200ml met...

Embodiment 2

[0038] Embodiment 2: Preparation of poly-N-vinylimidazole grafted silica gel

[0039] Include the following steps A and B in turn:

[0040] A. Synthesis of brominated silica gel

[0041] Add 5.0g of aminopropyl silica gel to the reaction vessel, add 60ml of toluene, stir evenly, add 1.2ml of 2-bromoisobutyryl bromide and 0.5ml of triethylamine, and react at room temperature for 12h. Then, vacuum filter, wash with 300ml methanol, 400ml water, 200ml methanol successively, and then vacuum dry at 65°C for 8h to obtain brominated silica gel.

[0042] B. Synthesis of poly-N-vinylimidazole-grafted silica gel

[0043] Add 4.0g of brominated silica gel to the reaction vessel, add 20ml of N,N'-dimethylformamide as the reaction solvent, stir it evenly, add 20ml of N , N'-dimethylformamide solution, and then added 4ml of N-vinylimidazole, protected by high-purity nitrogen, and heated at 80°C for 24h. Then cool to room temperature, filter with suction, wash with 300ml methanol, 400ml w...

Embodiment 3

[0044] Embodiment 3: Preparation of poly-N-vinylimidazole grafted silica gel

[0045] Include the following steps A and B in turn:

[0046] A. Synthesis of brominated silica gel

[0047] Add 5.0g of aminopropyl silica gel to the reaction vessel, add 50ml of toluene, stir evenly, add 0.7ml of 2-bromoisobutyryl bromide and 0.6ml of triethylamine, and react at room temperature for 36h. Then, vacuum filter, wash with 200ml methanol, 400ml water, 200ml methanol successively, and then vacuum dry at 65°C for 8h to obtain brominated silica gel.

[0048] B. Synthesis of poly-N-vinylimidazole-grafted silica gel

[0049] Add 4.0g of brominated silica gel to the reaction vessel, add 20ml of N,N'-dimethylformamide as the reaction solvent, stir it evenly, add 20ml of N with 160mg of cuprous bromide and 200mg of 2,2'-bipyridyl , N'-dimethylformamide solution, and then added 4ml of N-vinylimidazole, protected by argon, and heated at 130°C for 24h. Then cool to room temperature, filter wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com