Liquid phase chromatogram filler and method for synthesizing same

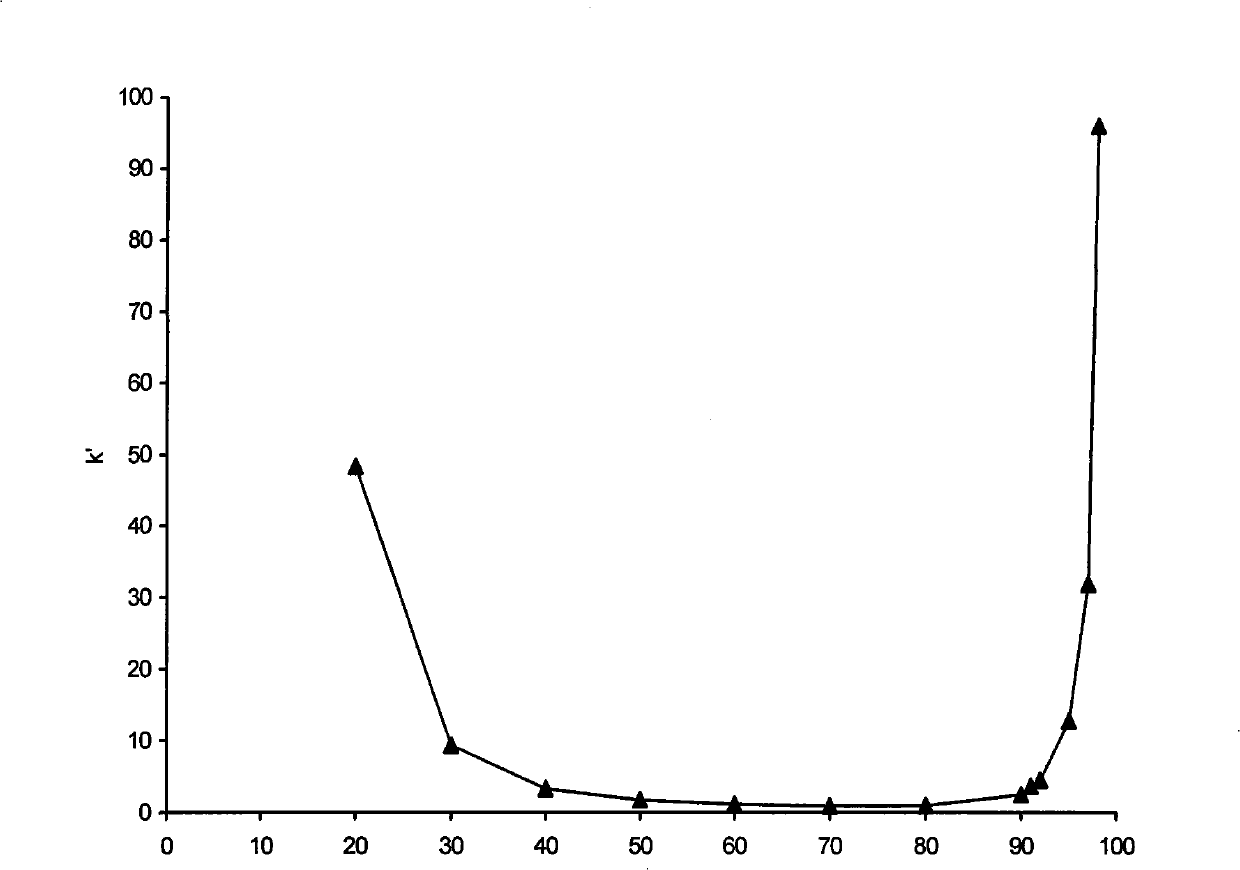

A liquid chromatography, normal phase technology, applied in the field of preparation of high performance liquid chromatography filling materials, can solve the problems of complex separation mechanism, poor stability and reproducibility, etc., and achieve superior chromatographic performance, strong adsorption and separation capacity, column Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

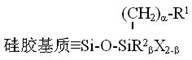

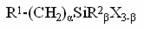

[0037] The synthesis method of the high-performance liquid chromatography packing of the present invention uses silica gel particles as a substrate, uses a polar fluorophenyl silylating reagent, and adopts a liquid phase reaction method to carry out surface treatment on the silica gel particles to obtain a bonded silica gel packing. After the material is further inertized, a new type of high performance liquid chromatography filler is prepared. The specific operation steps are as follows:

[0038] Synthesis of trimethoxysilylpropyl-2,3,4,5,6-pentafluorobenzamide: Weigh a certain amount of aminopropyltrimethoxysilane, put it into a three-necked flask, add dry toluene, Add appropriate acid chloride dropwise to triethylamine, pass through dry inert gas, and stir mechanically for 16 hours. The crude material was purified by distillation.

[0039] Synthesis of polar fluorophenyl silica gel: Add activated silica gel into the reactor, pass through dry inert gas, add xylene and pyri...

Embodiment 1

[0044] (1) Weigh 18 grams of aminopropyltrimethoxysilane, put it into a three-necked flask, install a condenser tube and a dropping funnel, feed dry argon, add 50 milliliters of dry toluene, 13 grams of triethylamine, drop 2 , 23 grams of 3,4,5,6-pentafluorobenzoyl chloride, mechanically stirred for 16 hours, and the crude material was purified by distillation.

[0045] (2) Weigh 10.0 grams of spherical silica gel (5 μm, 120 300m 2 / g, the metal impurity content is less than 30ppm), vacuum dried at 120°C for 24 hours, put it into the reactor after cooling, feed dry argon, install a condenser tube and a drying tube, add 50 milliliters of xylene, 4 milliliters of pyridine, and mechanically stir Evenly, then add 7 grams of silane synthesized in step (1), heat to reflux and react at a constant temperature for 24 hours, stop the reaction, vacuum filter, and use successively toluene, methylene chloride, acetone, methanol-water (1: 1, v / v), methanol wash.

[0046] (3) Take 10.0 ...

Embodiment 2

[0049] (1) Weigh 10.0 grams of spherical silica gel (5 μm, 120 300m 2 / g, the metal impurity content is less than 30ppm), vacuum dried at 120°C for 24 hours, put it into the reactor after cooling, feed dry argon, install a condenser tube and a drying tube, add 50 milliliters of xylene, 4 milliliters of pyridine, and mechanically stir Evenly, then add 3 grams of aminopropyltrimethoxysilane, heat to reflux and react at a constant temperature for 24 hours, stop the reaction, vacuum filter, and use toluene, dichloromethane, acetone, methanol-water (1:1, v / v), washing with methanol, and drying at 80° C. for 24 hours.

[0050] (2) Take by weighing 10.0 grams of dry aminopropyl bonded silica gel, put it into a reactor, feed dry argon, install a condenser tube and a drying tube, add 50 milliliters of toluene, 4 grams of triethylamine, drop 2, 8 grams of 3,4,5,6-pentafluorobenzoyl chloride, mechanically stirred for 16 hours. Stop the reaction, vacuum filter, wash with toluene, dic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com