Fixed disc type brake

A disc brake and fixed caliper technology, applied in the direction of brake discs, wheel hubs, vehicle components, etc., can solve the problems of large air passages, high thermal loads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

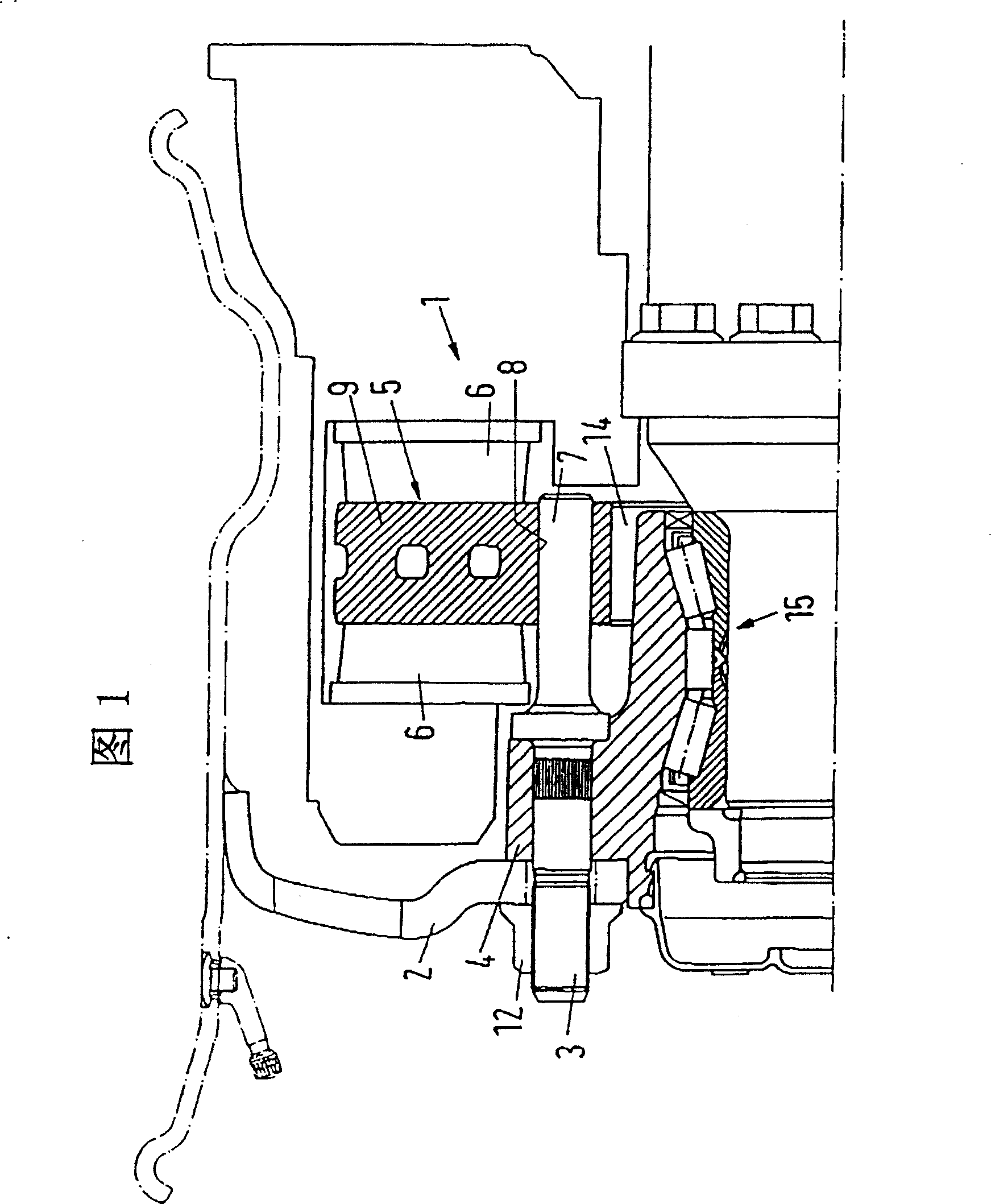

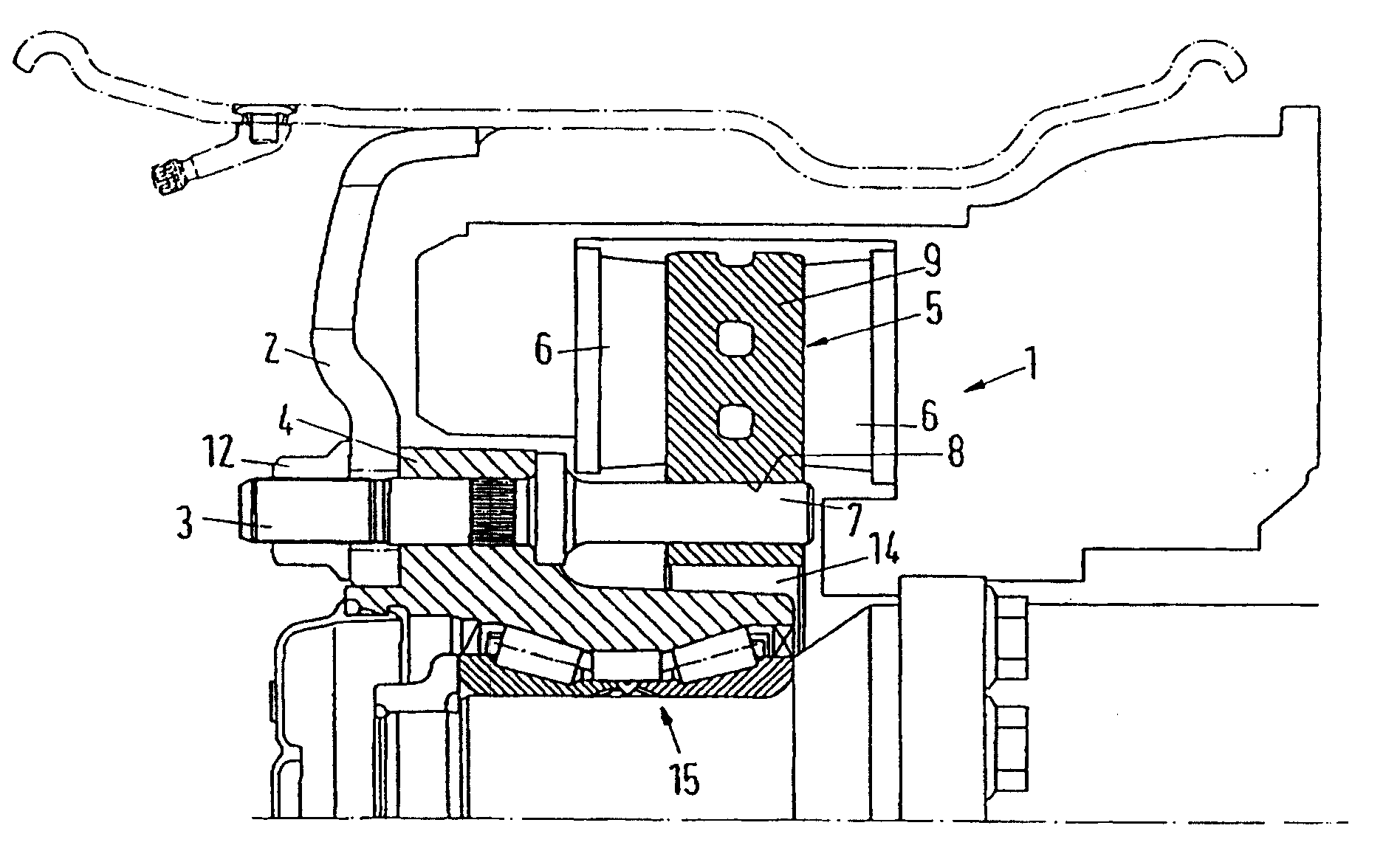

[0019] The fixed-caliper disc brake according to FIG. 1 is specified in particular for commercial vehicles, the wheels 2 of which are fastened to the wheel hub 4 by means of wheel bolts 3 and wheel nuts 12 .

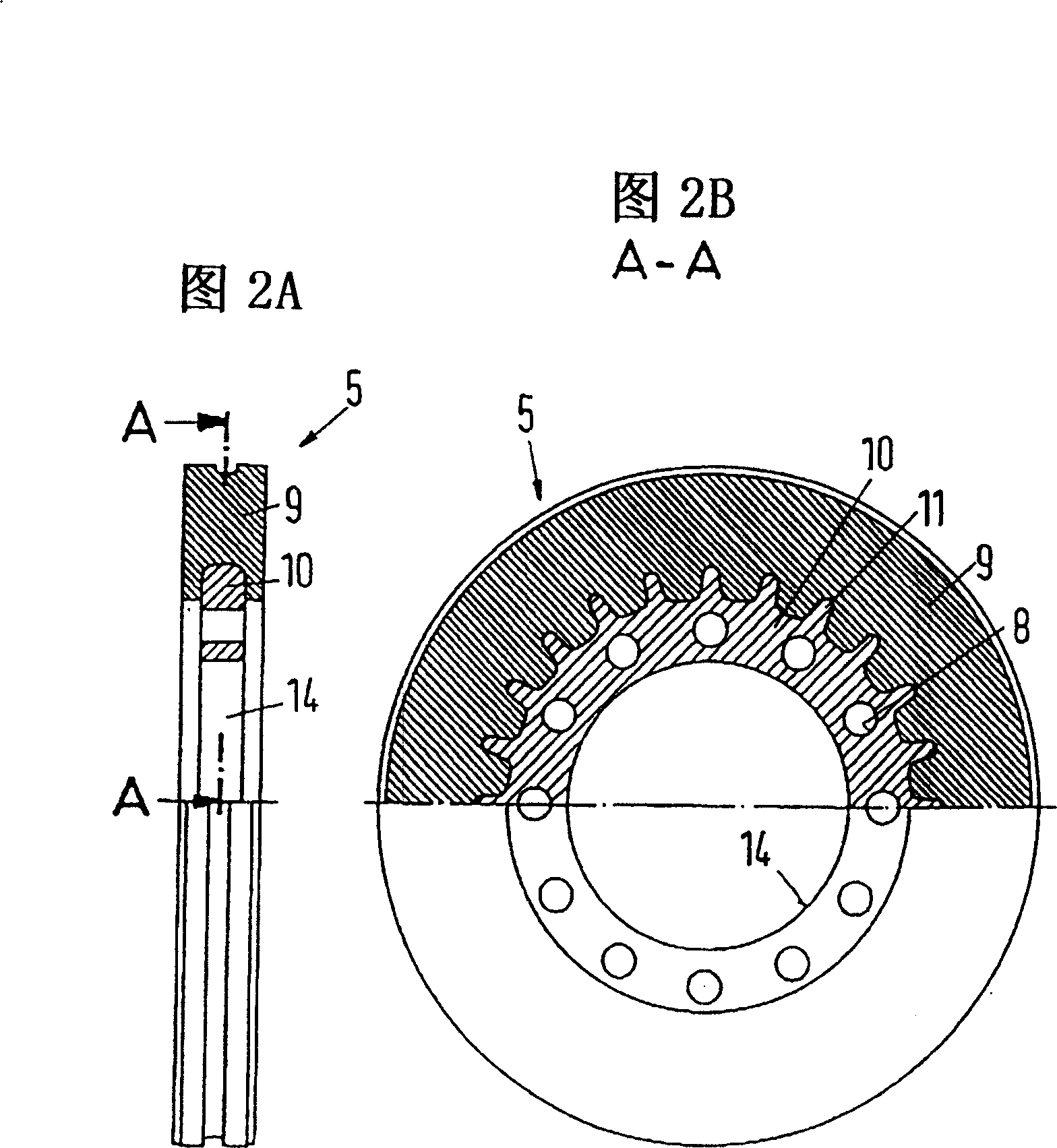

[0020] However, it can be seen in FIG. 1 that the conventional wheel stud 3 is not used, but that the wheel stud has a cylindrical stud extension 7 that is on the other side of a shoulder 13 by means of the shoulder and by means of the wheel. The nut 12 secures the wheel 2 to the hub 4 , and the bolt extension 7 projects into the hole 8 of the brake disc 5 . The screw extension 7 has a slight play in the bore 8 which on the one hand allows a certain thermal expansion of the brake disc 5 relative to the hub 4 at the braking temperature and on the other hand ensures a reliable axial guidance of the brake disc 5 , which is necessary because the brake disc material 9 is increasingly subject to wear during driving of the vehicle.

[0021] The individual brake pads 6 act on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com