Airflow generating structure and the device thereof

A generation device and airflow technology, applied in the field of airflow generation structure and its application device, can solve the problems of poor air output efficiency, noise and vibration, and reduced service life of axial fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

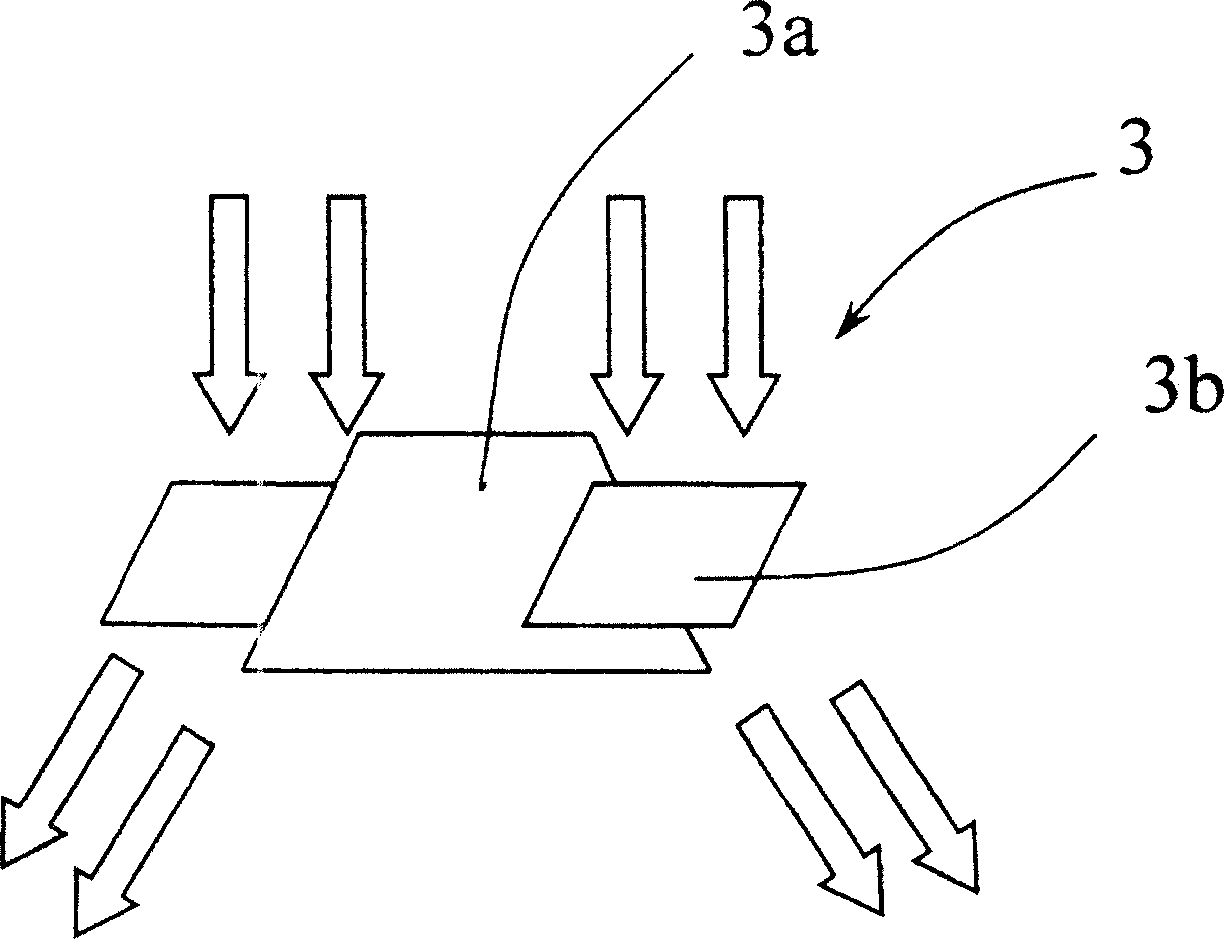

[0097] Please refer to Figure 5 and Figure 6 As shown, the first preferred embodiment of the present invention discloses an air flow generating structure 10 , which includes a hub portion 11 , a setting portion 12 , a plurality of spoilers 13 and a stabilizing ring 14 .

[0098] The hub 11 has a top end 111 and a bottom end 112, the top end 111 is generally convex, the bottom end 112 is concavely provided with a cavity 113, and the cavity 113 is inserted with an outwardly extending rotating shaft 15 ( spindle).

[0099] The setting portion 12 is roughly in the shape of a ring plate, which is integrally formed on the outer edge of the bottom end 112 of the hub portion 11 and extends outward along the radial direction of the hub portion 11. The setting portion 12 faces the hub portion 11. One side forms a setting surface 121 .

[0100] The two surfaces of each spoiler 13 are respectively a convex surface and a concave curved surface, so that its appearance presents a curved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com