Base assembly for flat display and assembling method thereof

A flat-panel display and flat-panel display technology, applied in the direction of instruments, optics, electrical components, etc., can solve problems such as unusable, waste of materials, installation and disassembly, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the technical content of the present invention more clearly, the following preferred specific embodiments are specially cited as follows.

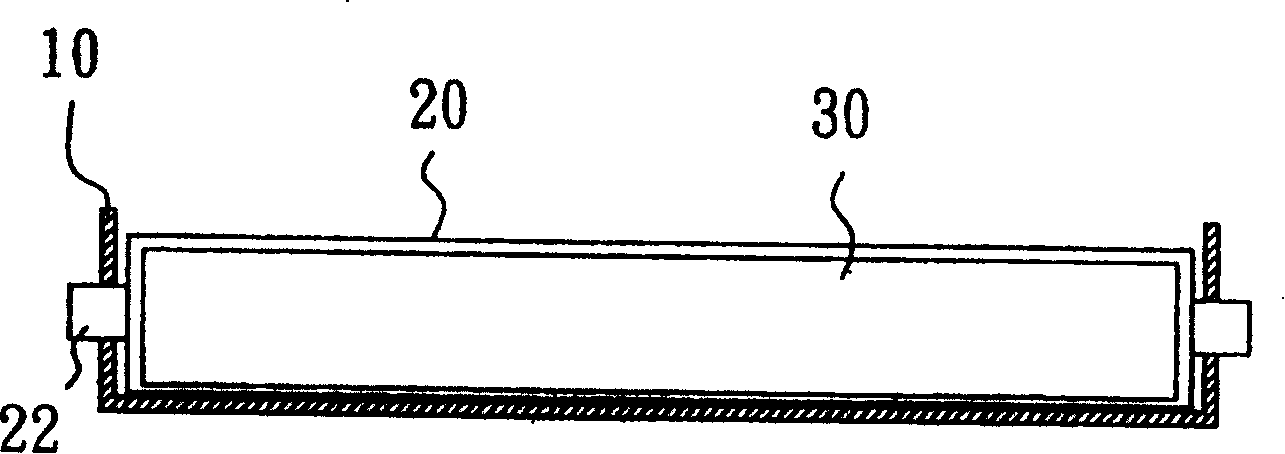

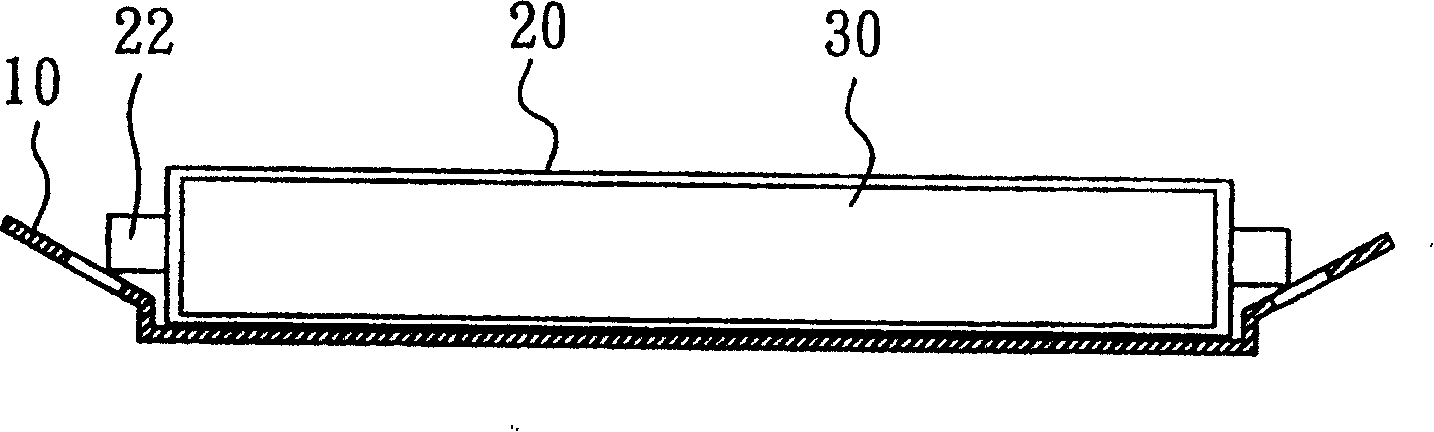

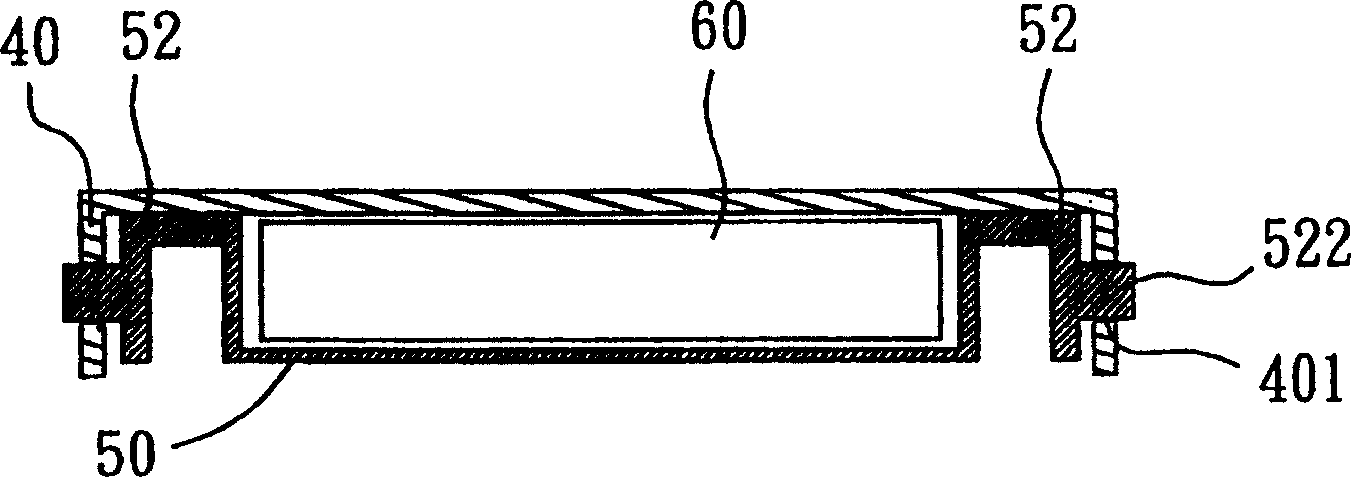

[0022] Please refer to FIG. 2(A), which is a cross-sectional view of a liquid crystal display device according to a preferred embodiment of the present invention. When the liquid crystal display panel module 60 is covered and fixed between the top case 40 and the main frame body 50, the main frame body 50 is locked with the top case body 40 by means of the joint unit 52 on its edge, and a backlight module. The coupling unit 52 includes a fastening portion 522 , and the fastening portion 522 can just be locked with the pre-aligned opening 401 formed on the periphery of the top case 40 . When it is desired to disassemble and separate the top case 40 from the main frame body 50, please refer to FIG. Breaking away from the opening 401 , the top case 40 and the main frame body 50 can be disassembled and separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com