Precision plastic mold

A precision plastic and mold technology, applied in the field of mold manufacturing, can solve problems such as increasing maintenance costs, affecting production progress, and being prone to breakage, reducing injection molding costs, reducing scrap rates, and saving materials and costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

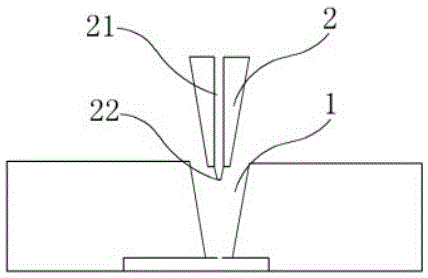

[0015] Such as figure 1 As shown, the mold insert of the present invention is provided with a casting cavity 1, and the casting cavity 1 is embedded with a casting core 2, and the casting core 2 is in interference fit with the casting cavity 1. Since the use environment of the casting cavity 1 is a high-temperature injection molding process, the tolerance of the interference fit of the casting core 2 needs to consider the expansion coefficient in a high-heat environment. In the solution of the present invention, the tolerance of the interference fit is set at 0.01 mm is the best.

[0016] The pouring core 2 also includes a pouring channel 21 and a pouring port 22 .

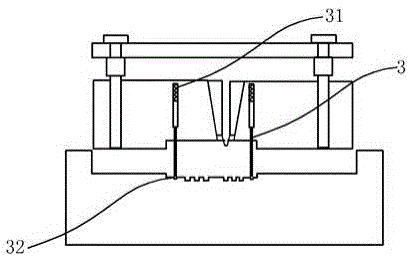

[0017] figure 2 It is a structural schematic diagram of the mold guide system of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com