Fan mechanism

A fan and fan frame technology, applied in the field of fan mechanism, can solve problems such as weak assembly, loud noise, and easy generation of gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

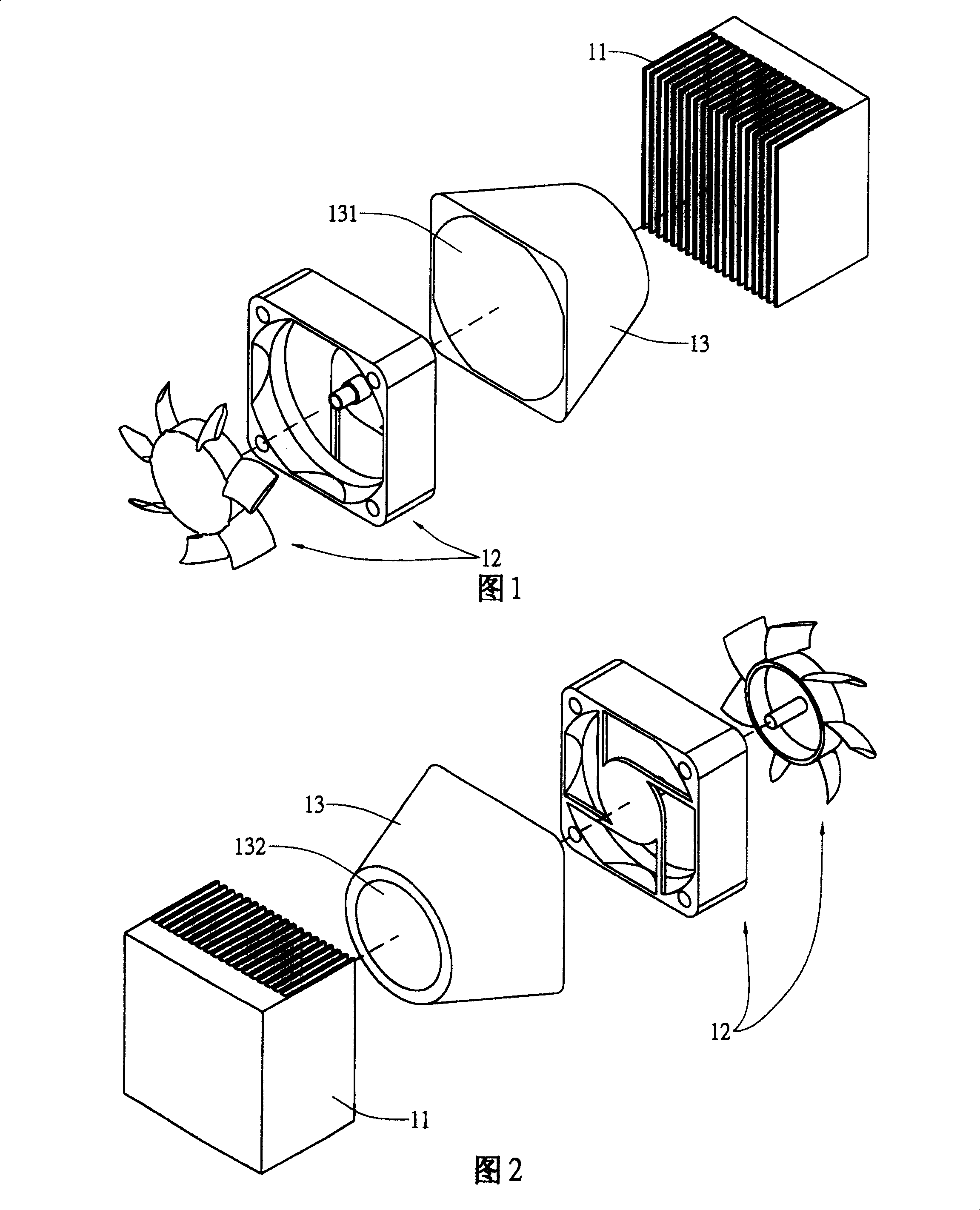

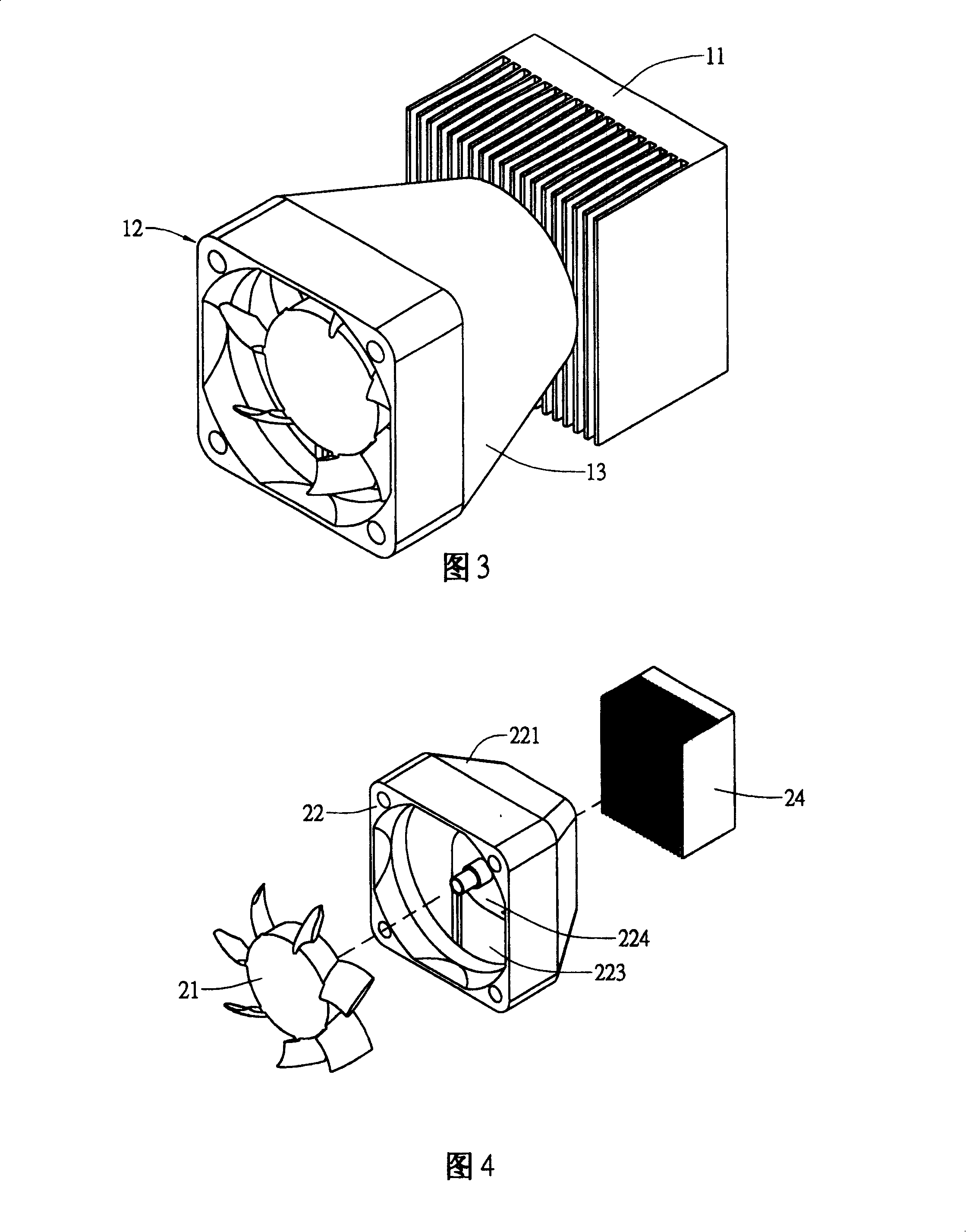

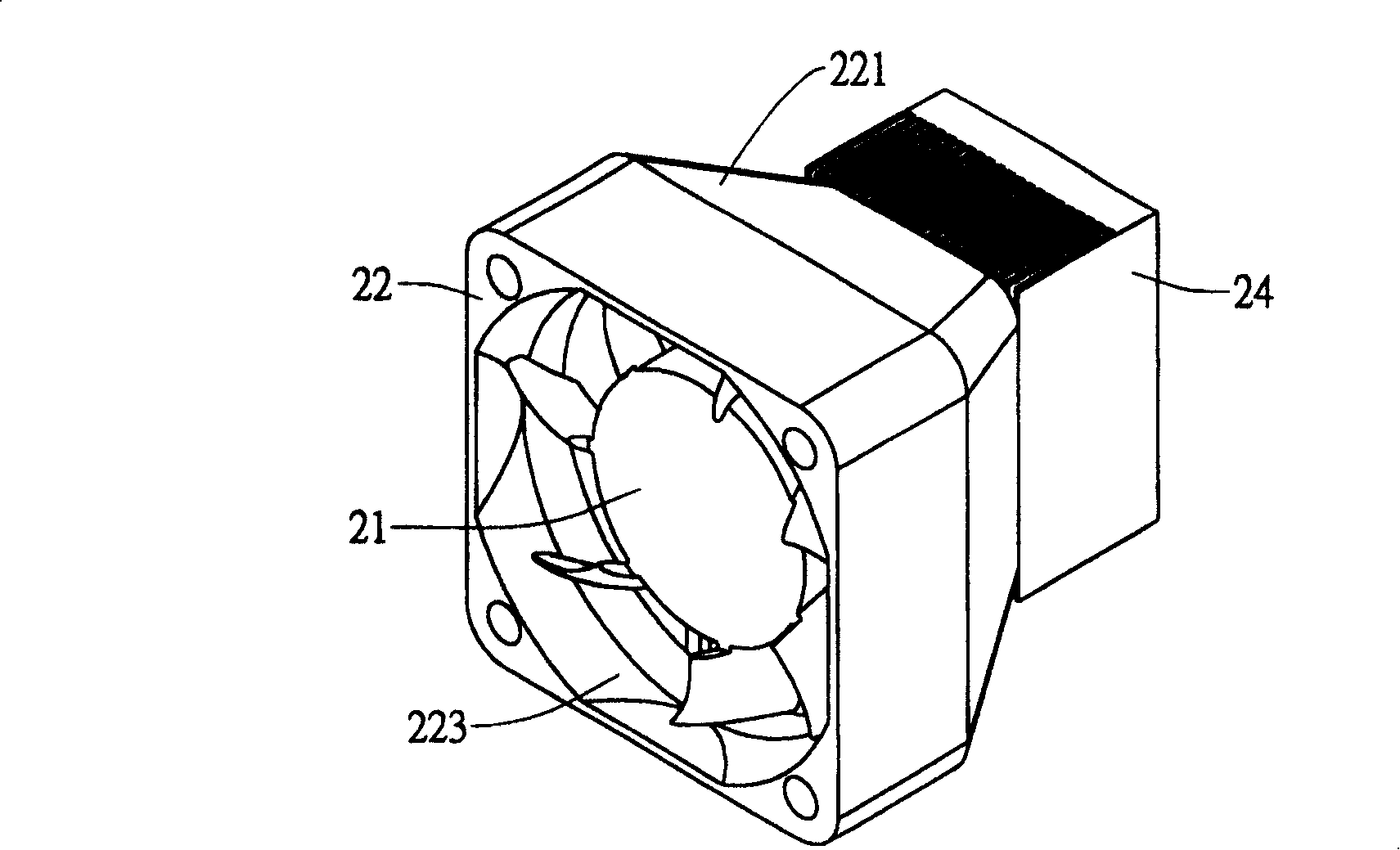

[0025] The present invention provides a fan mechanism, please refer to Figure 4, Figure 5 , Figure 6 The preferred embodiment of the present invention shown, as shown in the figure, at least includes a fan frame 22 and a fan wheel 21, wherein one side of the fan frame 22 is appropriately extended toward the center of the other side to form a tapered There is a tapered part 221, so that the tapered part 221 forms an air outlet 222 that is equal to the area of the heating element 24, and one side of the fan frame 22 is provided with an air inlet 223, and a hub seat 224 is provided in it to pivot the fan. wheel 21, and then the air outlet 222 of the fan frame 22 is connected to the heating element 24, and then the fan frame 22 and the fan wheel 21 which are larger than the area of the heating element 24 are connected to the heating element 24.

[0026] When the fan wheel 21 rotates, the guiding fluid enters through the air inlet 223 and blows to the heating element 24 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com