Fan unit

A fan and fan wheel technology, applied in the field of fans that can increase the air intake, can solve the problems of not being large enough, unable to effectively display the heat dissipation effect, and the area of the air inlet being limited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

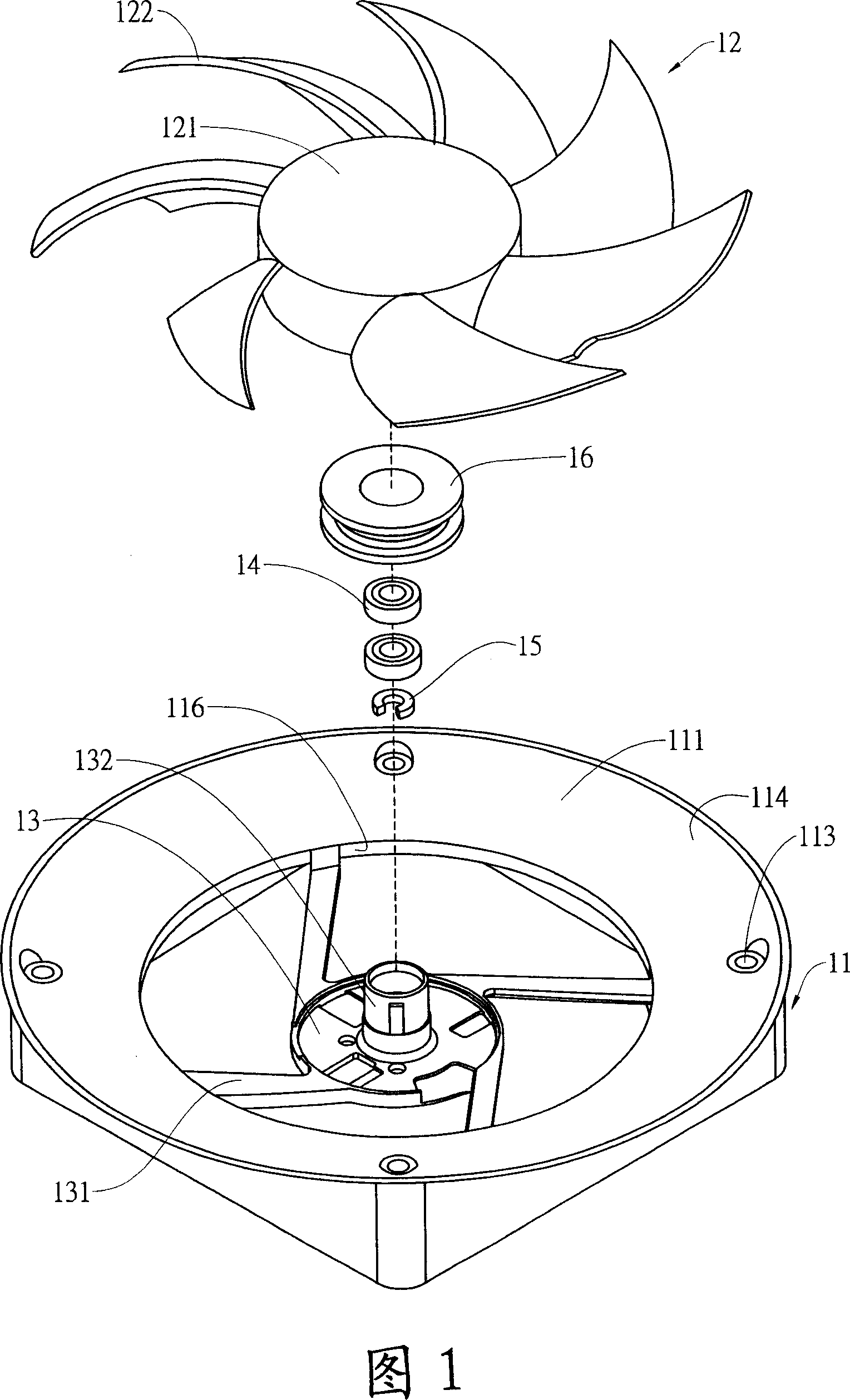

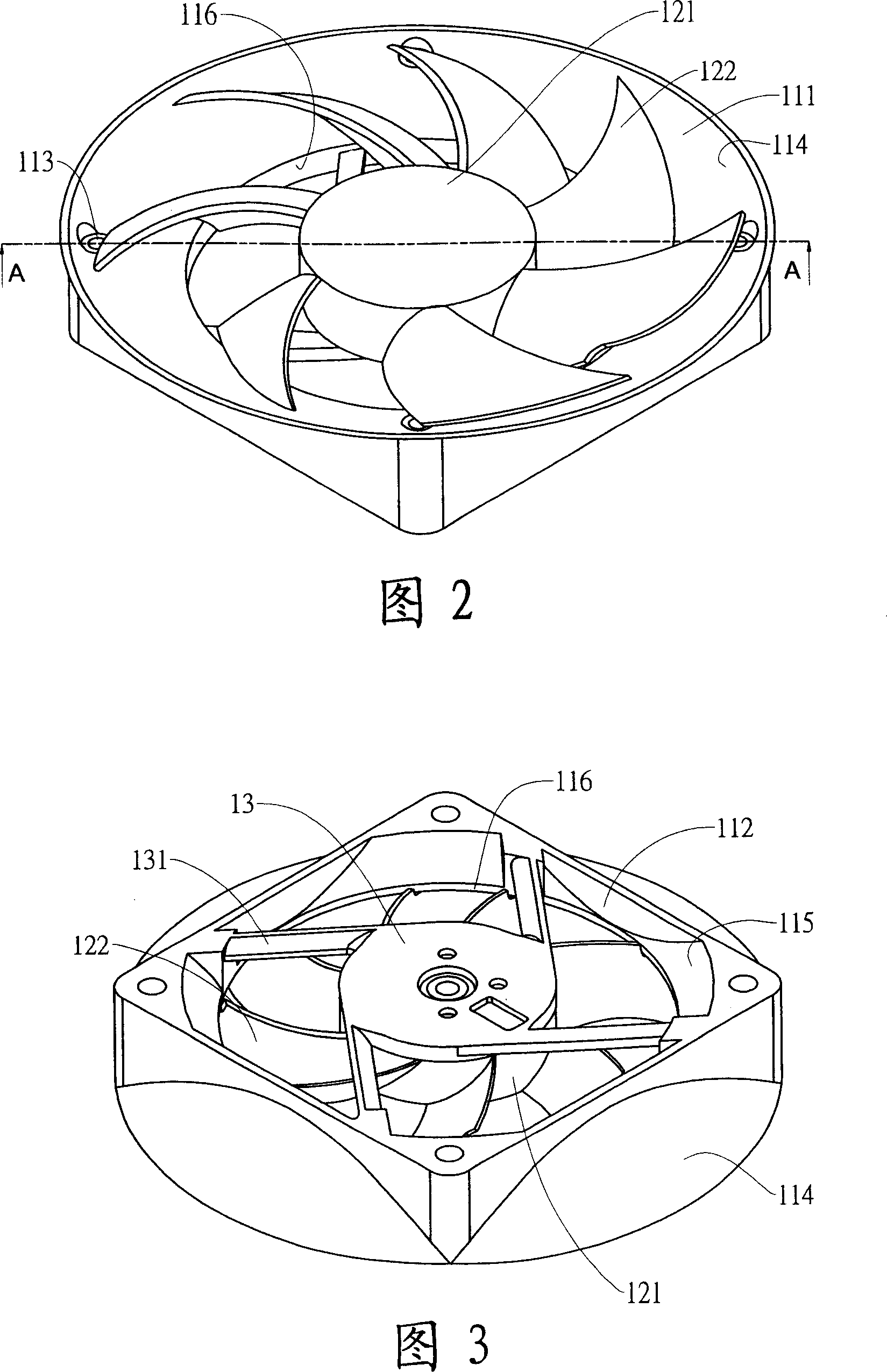

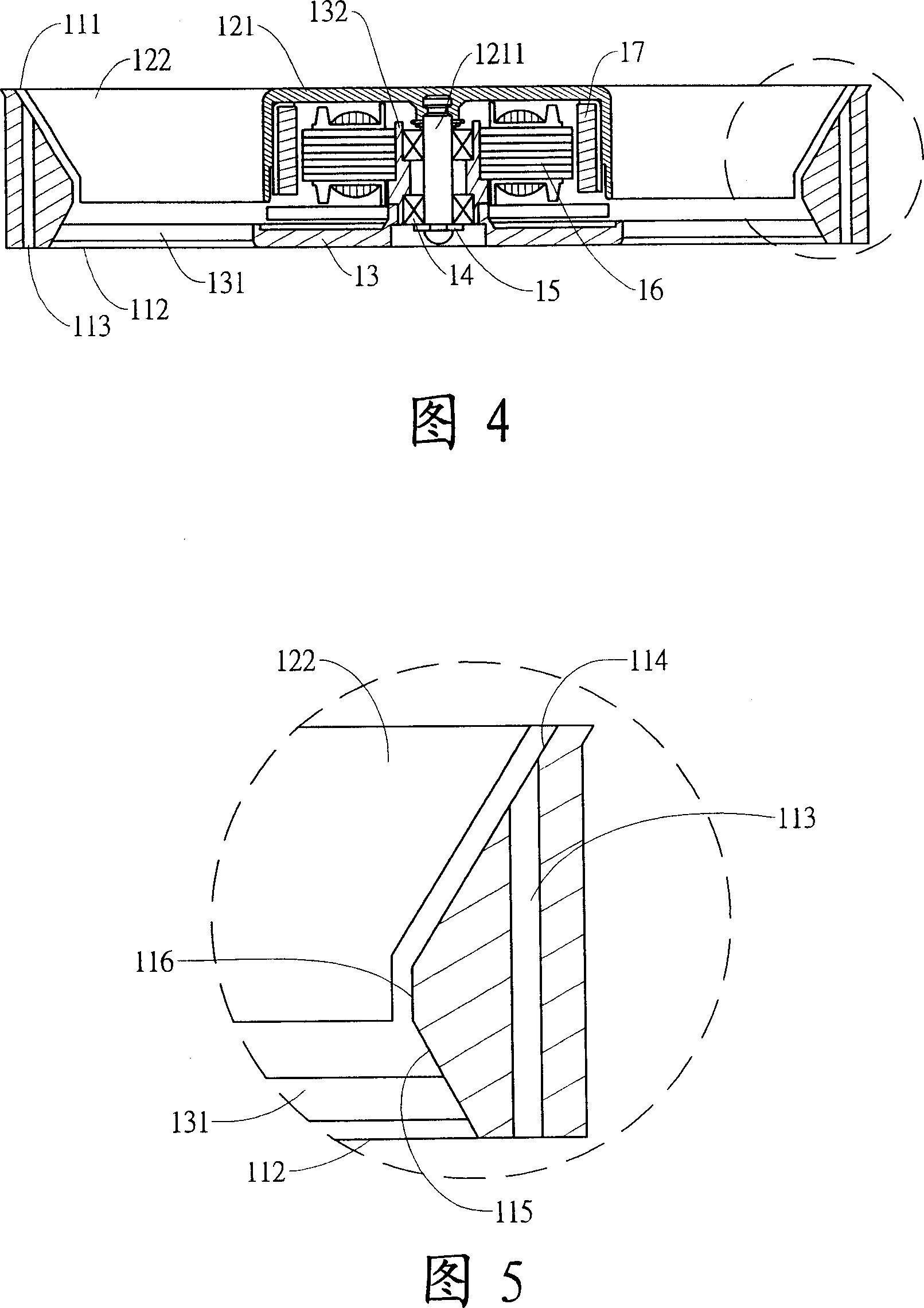

[0022] The present invention provides a fan unit, the accompanying drawings are preferred embodiments of the present invention, please refer to Figure 1 to Figure 4 shows the first preferred embodiment of the present invention, which at least includes a frame 11 and a fan wheel 12, wherein the frame body 11 has a flow channel through the frame body 11, and the flow channel forms a first through hole 111 and a second through hole 112 on both sides of the frame body 11, and a The through hole 113 is provided for the fixing assembly to pass through, and the inner side of the frame body 11 is formed at the first through hole 111, which is inclined from the outside of the frame body 11 to the inside of the frame body 11 and radially outward and extends at least beyond the frame body The first frame wall 114 of the through hole 113 of 11, and a second frame wall 115 inclined in the opposite direction to the first frame wall 114 is formed on the second through hole 112 side, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com