Heat pipe sealing structure, and its pressing method and special mould

A heat pipe and sealing technology, which is applied to other manufacturing equipment/tools, forming tools, manufacturing tools, etc., can solve problems such as excessive extension of the metal nozzle, cracks at the seal, and shorten the life of the heat pipe, so as to increase the seal sealing Strength, increase the sealing pressure strength, and reduce the effect of structural damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

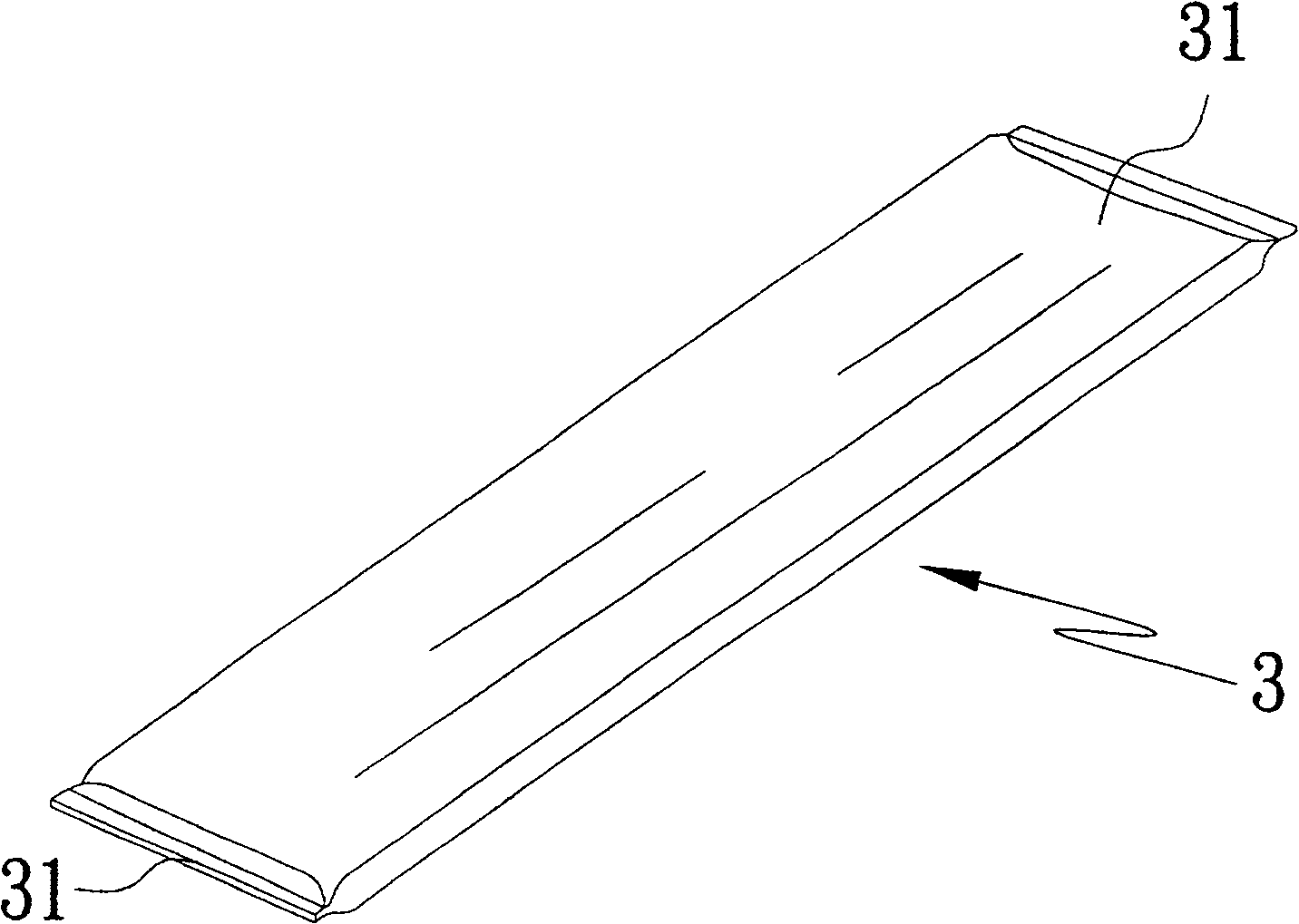

[0043] see Figure 4~7 As shown, a heat pipe sealing and pressing method of the present invention comprises the following steps: a. providing a mold 4 with first and second molds (left and right molds or male and female molds) 41, 42, the first One and two molds 41, 42 are embossed to form a plurality of convex surfaces 43 and depressions 44 (such as Figure 4 , 5 , shown in 6), and the embossing treatment on the surface of the first and second molds 41, 42 can be the first mold 41 or the second mold 42 alone (such as Figure 7 shown), or the first and second molds 41 and 42 all have embossing treatment, wherein the angle of the embossing pattern of the first and second mold surface embossing treatment is between 0 and 90 degrees, but at 45 degrees It is the best, and the design ratio and the depth of the depressions of the plurality of raised surfaces 43 and the depressions 44 are related to the pressing working conditions and metal materials;

[0044] b. Place the opening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com