Mounting method of large pressure machine foundation

An installation method and press technology, applied to presses, manufacturing tools, etc., can solve problems such as insufficient lifting capacity and small assembly space, and achieve the effect of reducing installation costs and solving small spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

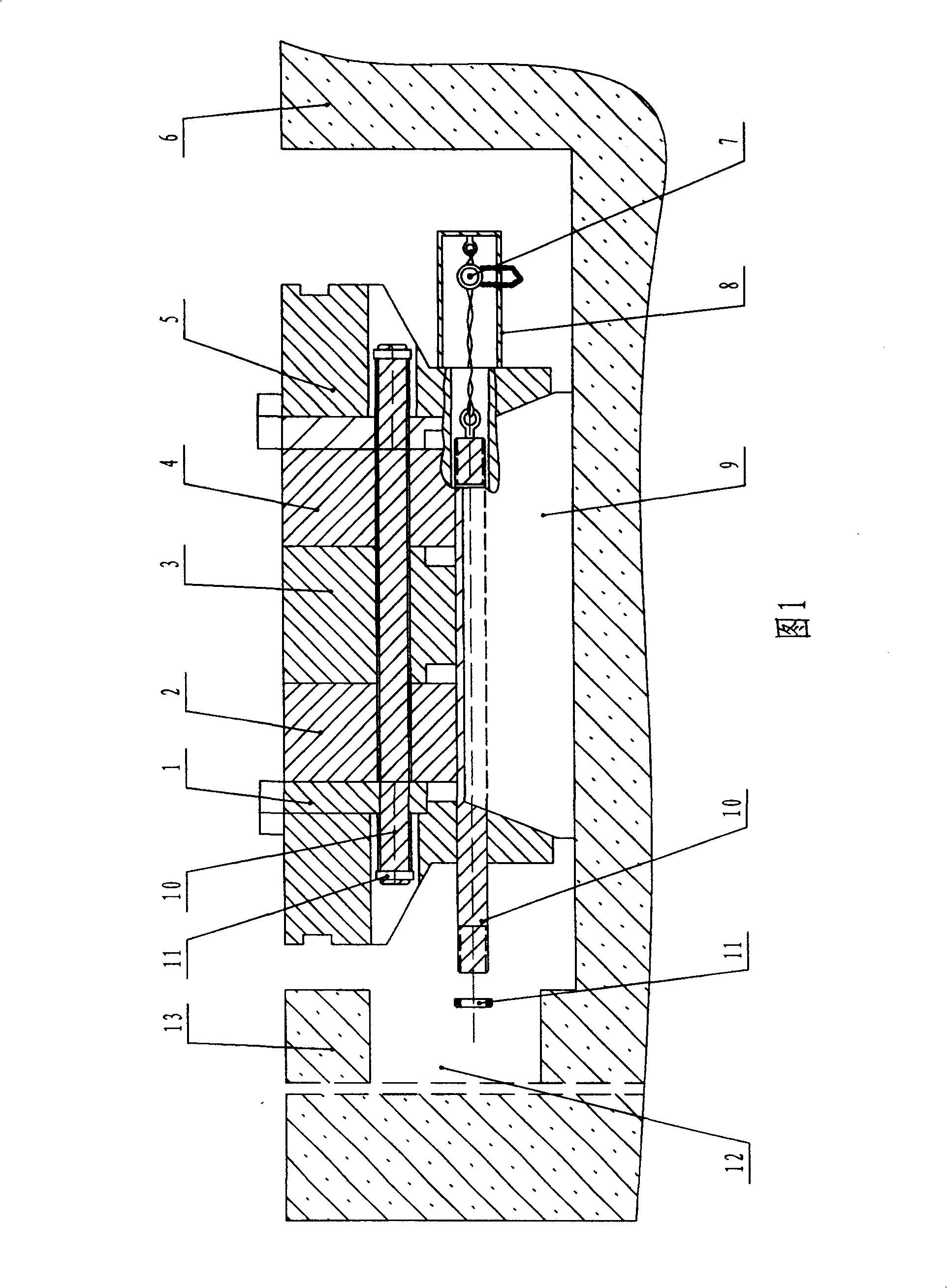

[0009] Referring to Fig. 1, the horizontal concrete foundation pit 12 is prefabricated at the lower part of the concrete foundation 13 on the left side of the large press, and the stud bolts of the six tie rods 10 are covered with protective sleeves, put into the horizontal concrete foundation pit 12, and the foundation beam 9 is put into the horizontal concrete foundation pit 12. Install on the concrete foundation, adjust the positioning; hoist the No. 2 base 2 into the foundation beam 9 for positioning, then hoist the No. 3 base 3 into the foundation beam 9 to align with the No. 2 base 2, and use the jack to move the No. 3 base 3 to the left Move and mortise with No. 2 base 2; hoist No. 4 base 4 into the foundation beam 9 to align with No. 3 base 3, use a jack to move No. 4 base 4 to the left, and mortise with No. 3 base 3; No. 1 base 1 is hoisted into the left side of No. 2 base 2 and the right side of the left concrete foundation 13, and the bottom of No. 1 base 1 is padded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com