Pipe clips

A technology for fixing hoops and pipes, which is applied in the direction of pipes/pipe joints/fittings, pipe brackets, mechanical equipment, etc. It can solve the problems of short life of pipe fixing hoops and inconvenient installation, and achieve convenient transportation management, transportation and use, and use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to understand the structural features and implementation methods of the present invention more intuitively and conveniently, the present invention will be described in further detail below with reference to the examples of the drawings:

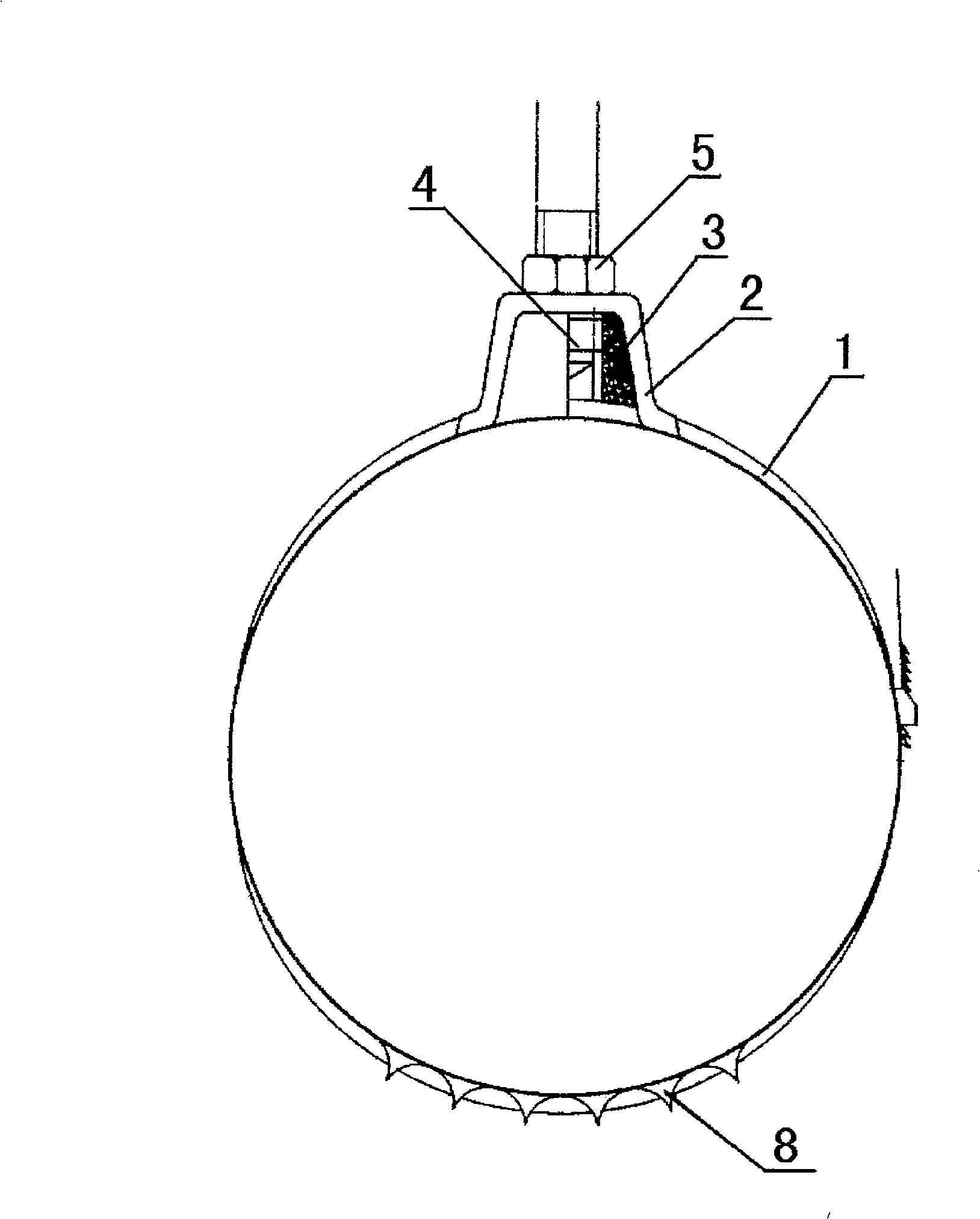

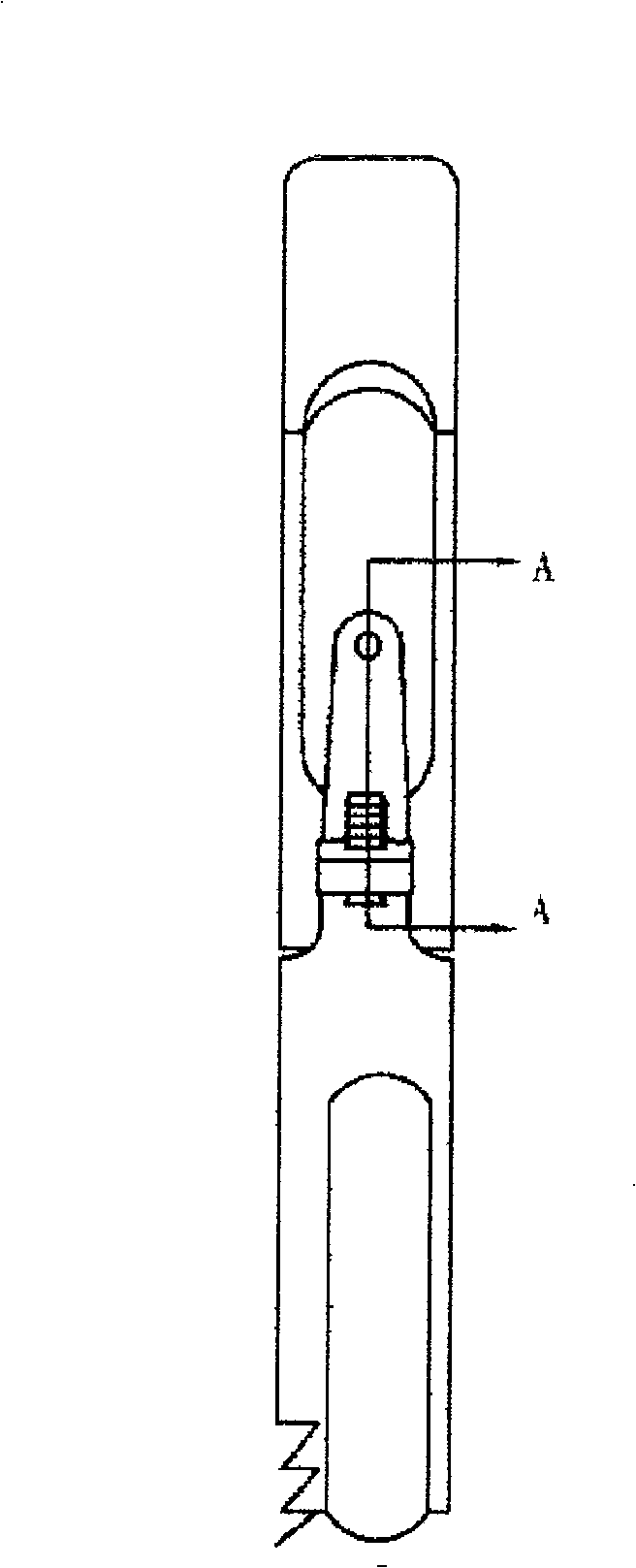

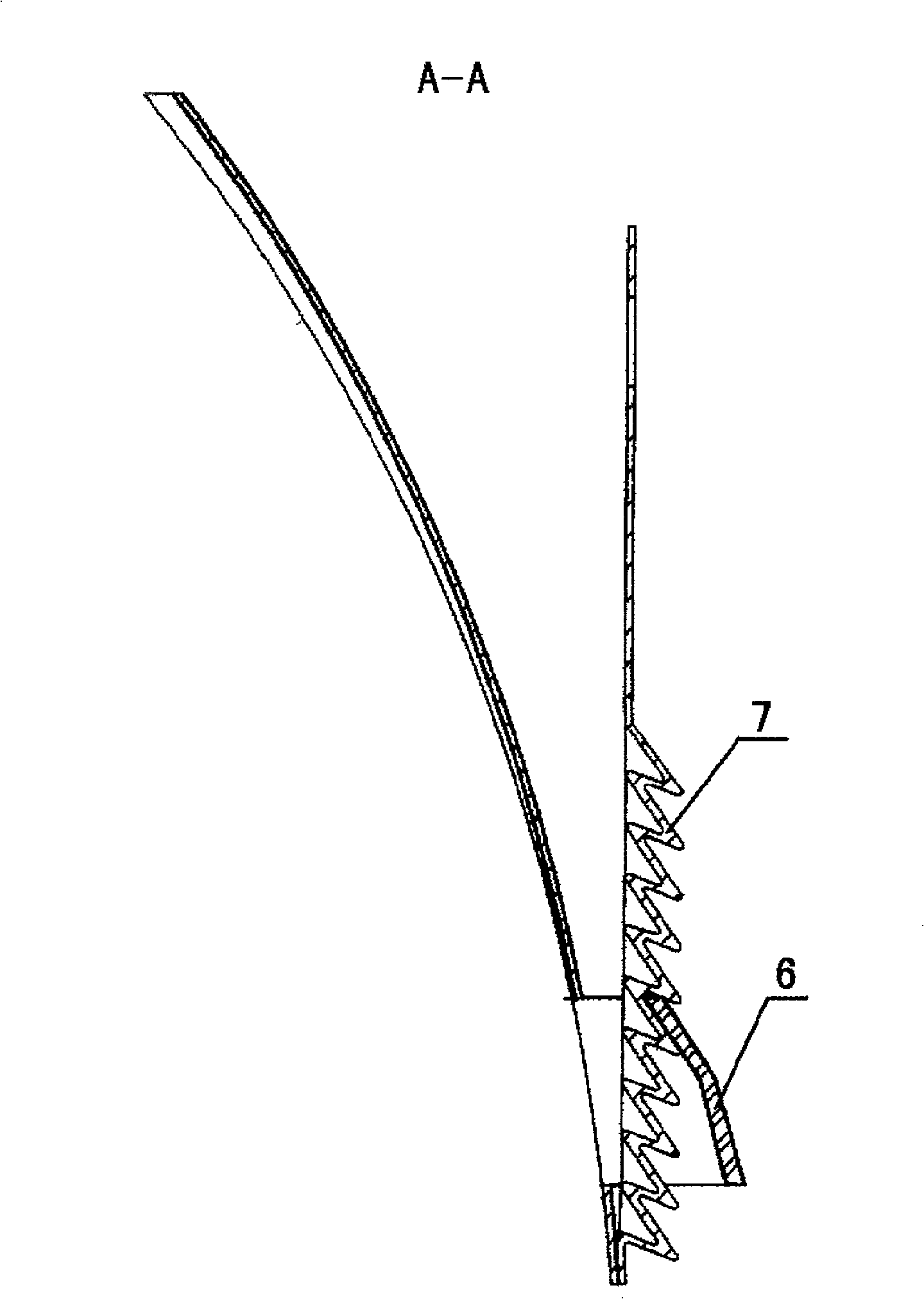

[0021] figure 1 , figure 2 with image 3 In the illustrated embodiment 1, the hoop body 1 of the pipe fixing hoop is made of a section of stainless steel belt with a width of 20 mm and a thickness of 0.5 mm. The hoop body 1 is provided with a section whose groove bottom protrudes from the inside to the outside. The bottom annular reinforcing groove has a central angle of 160°. The hoop body 1 is also provided with an upper annular reinforcing groove whose groove bottom protrudes from the inside to the outside. The bottom annular reinforcing groove The central angle of the groove length is also 160°, and the bending area is between the two annular reinforcement grooves. The two semicircles of the hoop body 1 can be opened and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com