Ride control constant contact side bearing arrangement

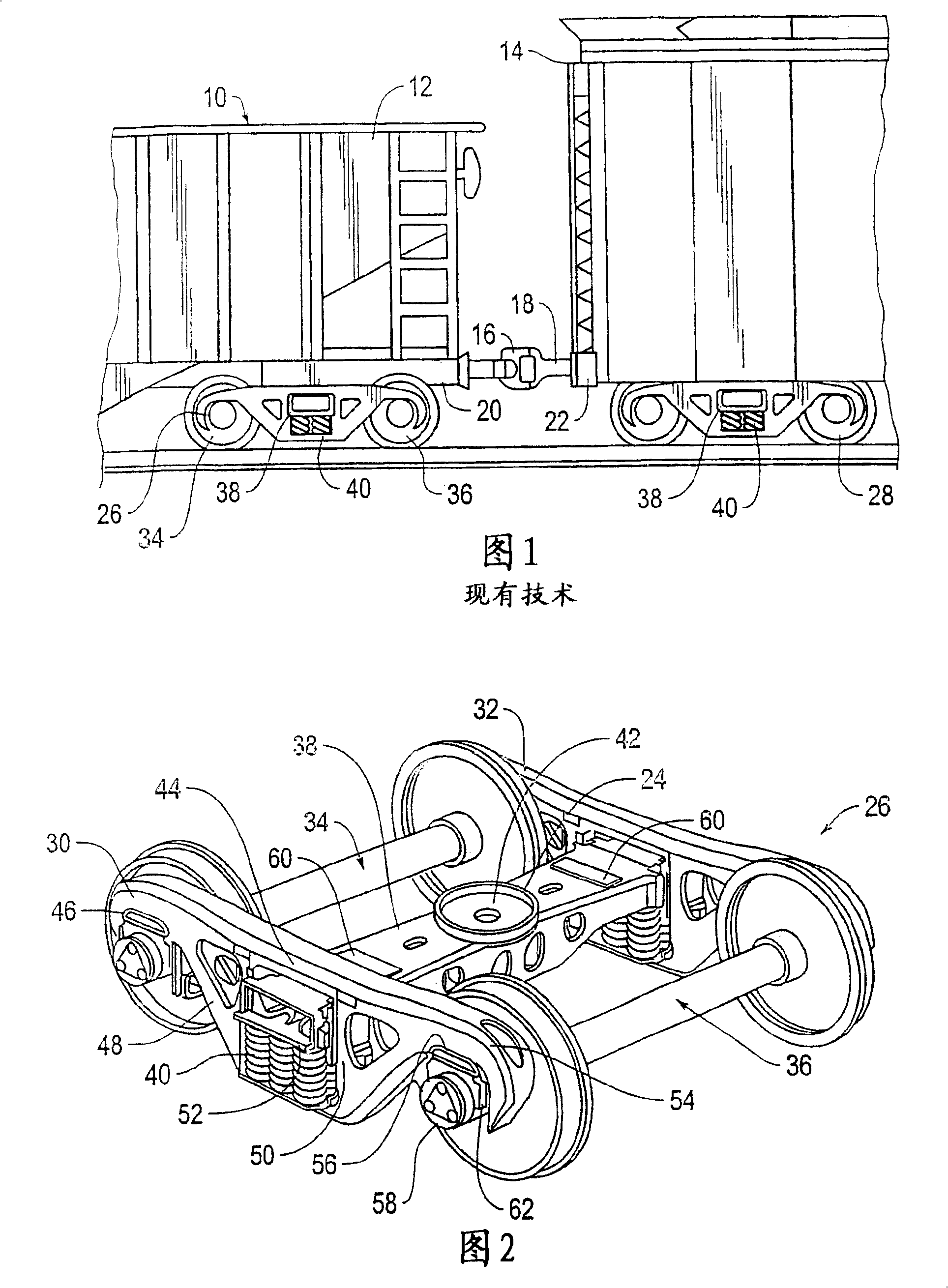

A long-stroke, basic-body technology, applied in the direction of the device that moves laterally between the chassis and the bogie, to reduce weight, improve inspection capabilities, and reduce the need for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

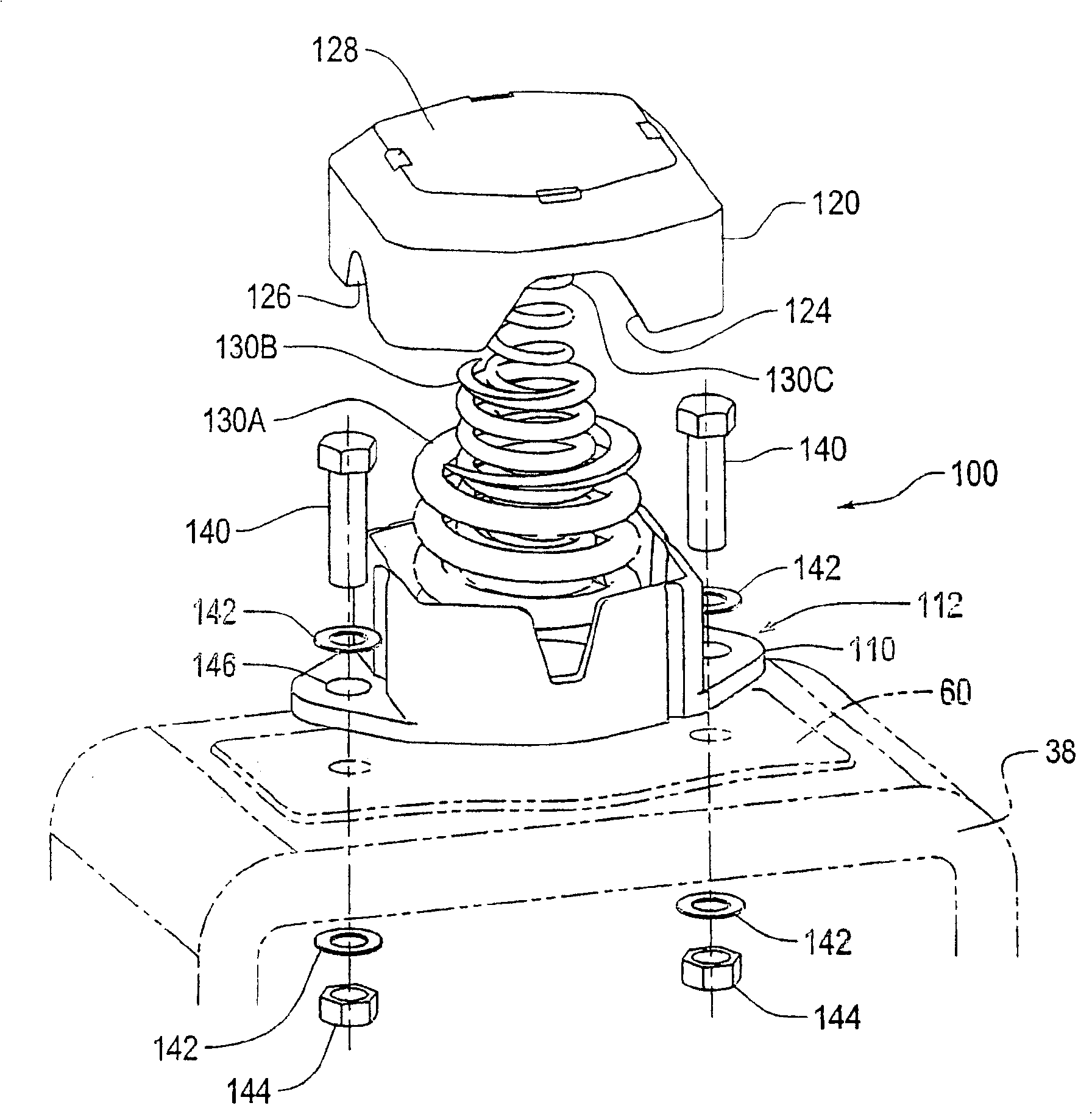

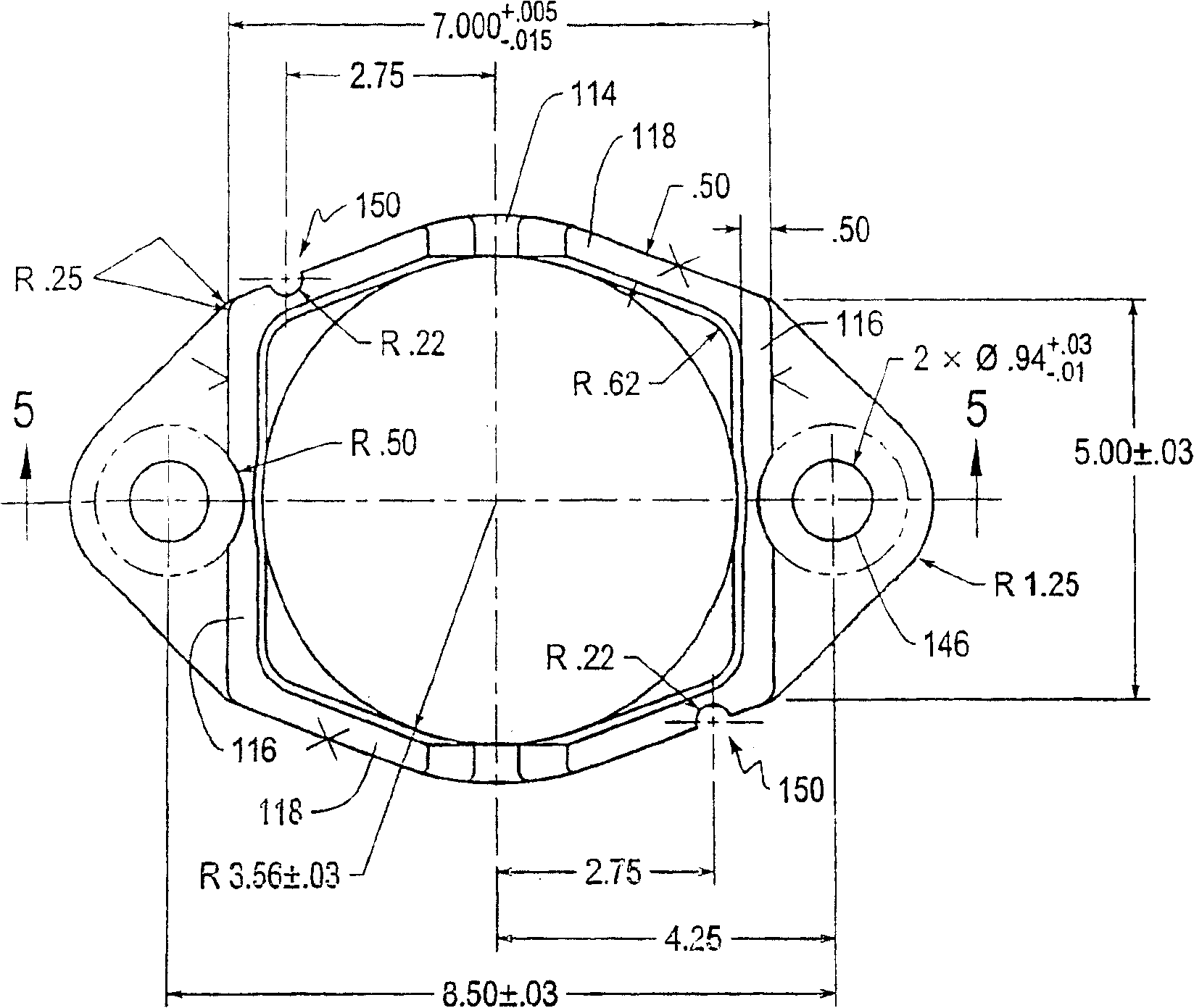

[0056] Refer to attached image 3 -8, The first embodiment according to the present invention will be described. Side bearing member 100 has a longitudinal major axis coincident with the longitudinal axis of the railroad car. That is, when the side bearing is mounted to the railcar truck backing plate 38 ( Figure 4 Only a portion is shown), the side bearing main shaft is perpendicular to the backing plate longitudinal axis. The main components of the side bearing component 100 include a base body 110, a cap 120, and one or more elastic actuating components 130, such as a spring or an elastomer element. In the exemplary embodiment, three springs are provided here as the actuating elements, an outer spring 130A, a middle spring 130B and an inner spring 130C, each having a different spring constant to provide an overall combined load rate.

[0057] The base body 110 is secured to the backing plate 38 by suitable means. As shown, the base 110 is bolted to the backing plate 38 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Load rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com