Hand crimp connecting tool

A technology of crimping tools and crimping terminals, applied in the direction of connections, electrical components, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Next, embodiments of the present invention will be described.

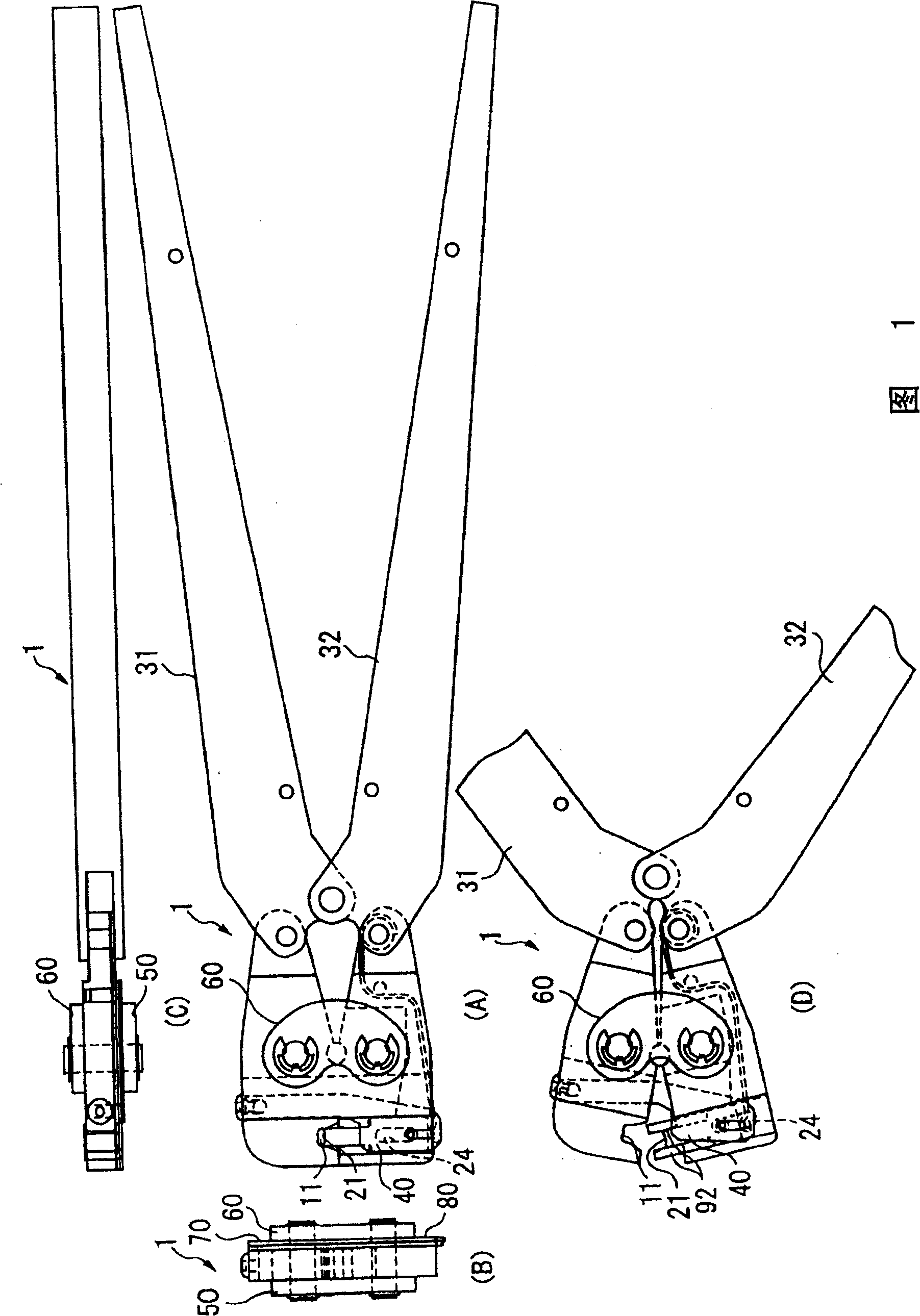

[0023] Fig. 1 is an overall structural view of the manual crimping tool of the present invention. In this FIG. 1 , FIG. 1(A) is a front view, FIG. 1(B) is a side view, and FIG. 1(C) is a top view. In addition, Fig. 1(D) is a front view showing a state in which the bead portion and the anvil are opened.

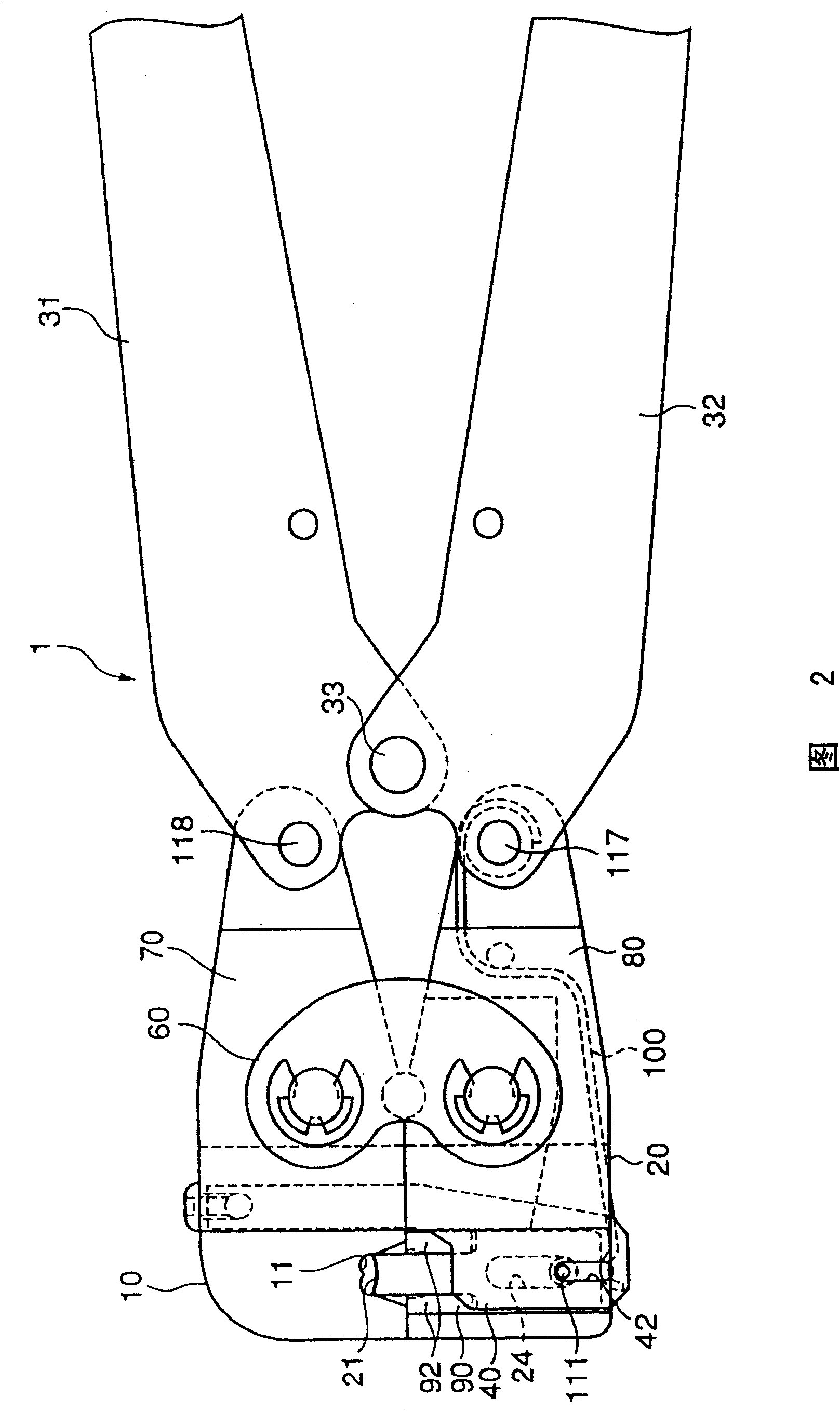

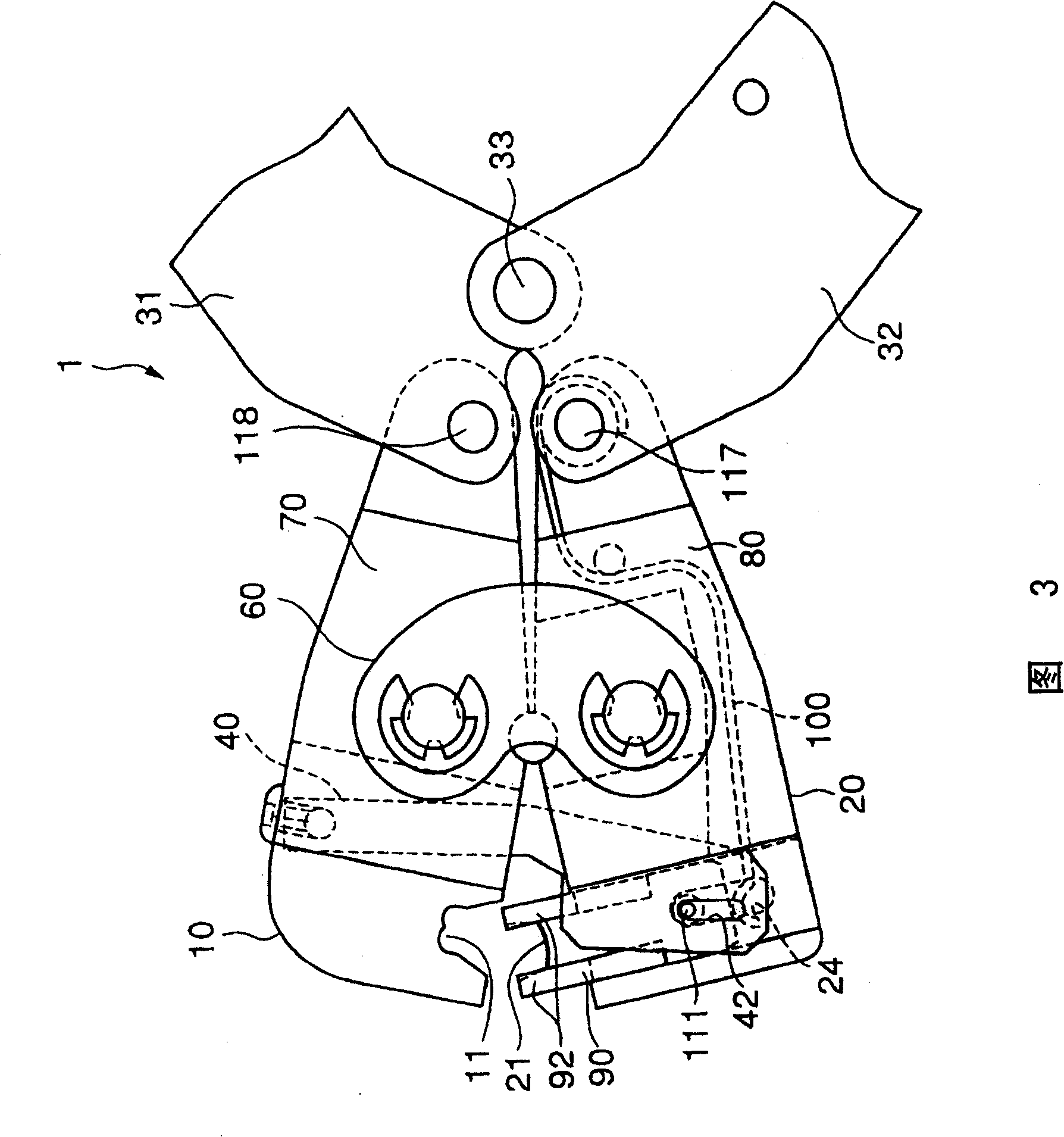

[0024] In addition, FIG. 2 is an enlarged front view of the first and second jaws in a closed state. Fig. 3 is an enlarged front view of first and second jaws in an open state.

[0025] In addition, FIG. 4 is an assembly view showing components of the manual crimping tool shown in FIGS. 1 to 3 . Figure 5 This is an enlarged view of a crimp terminal with only the crimp portion. Figure 6 It is an enlarged view of a slider used in the manual crimping tool shown in FIGS. 1 to 4 .

[0026] The manual crimping tool of this embodiment, even if Figure 5 Even the crimp terminal having the shape shown above, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com