Warehouse bottom material-flushing resisting method and control device

A technology of anti-shock and blanking, which is applied in the field of cement building materials, can solve the problems of harming the health of workers, the failure of equipment to operate, and affecting the working environment, etc., and achieve the effects of protecting the health of workers, simple structure, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

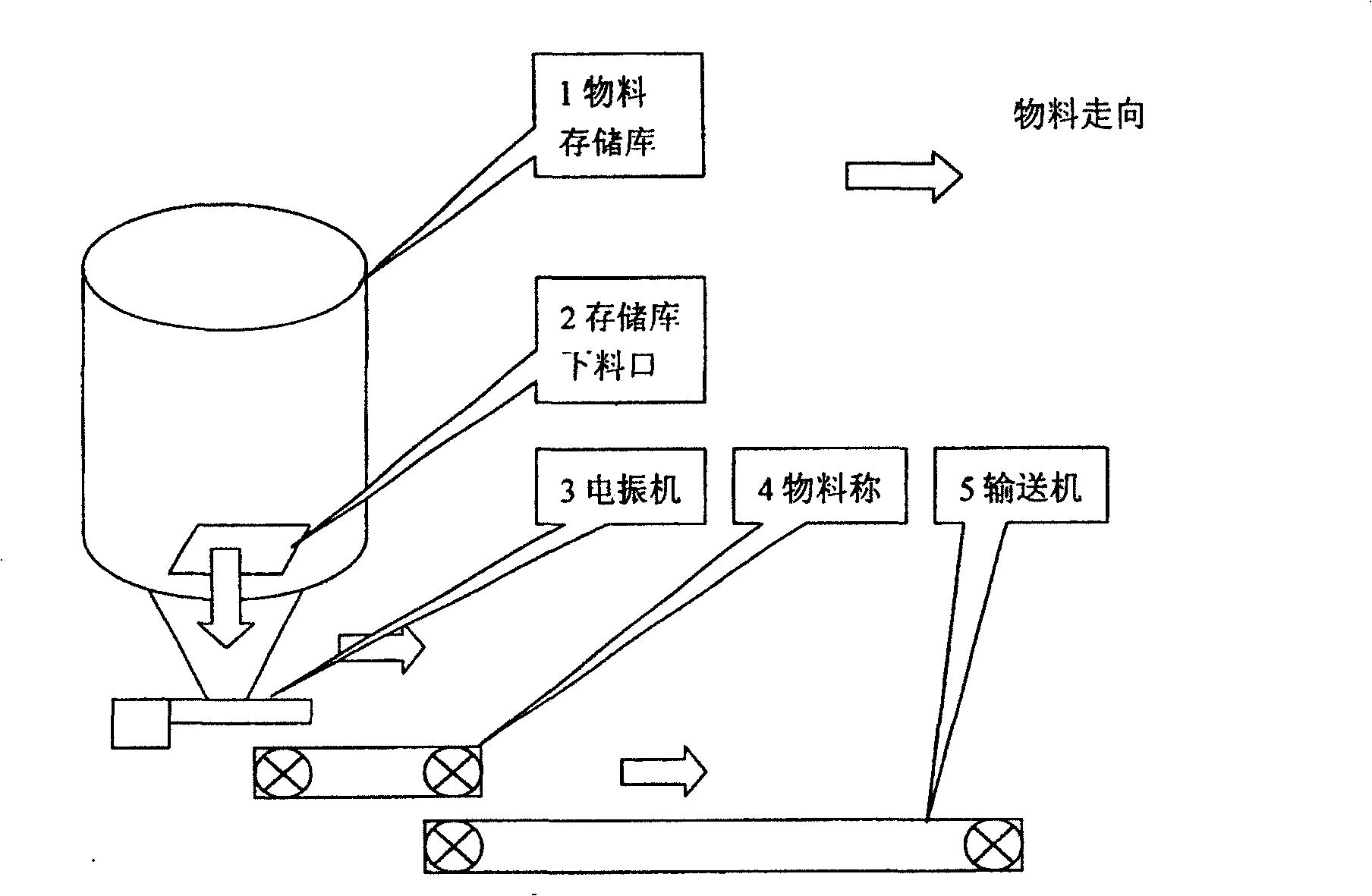

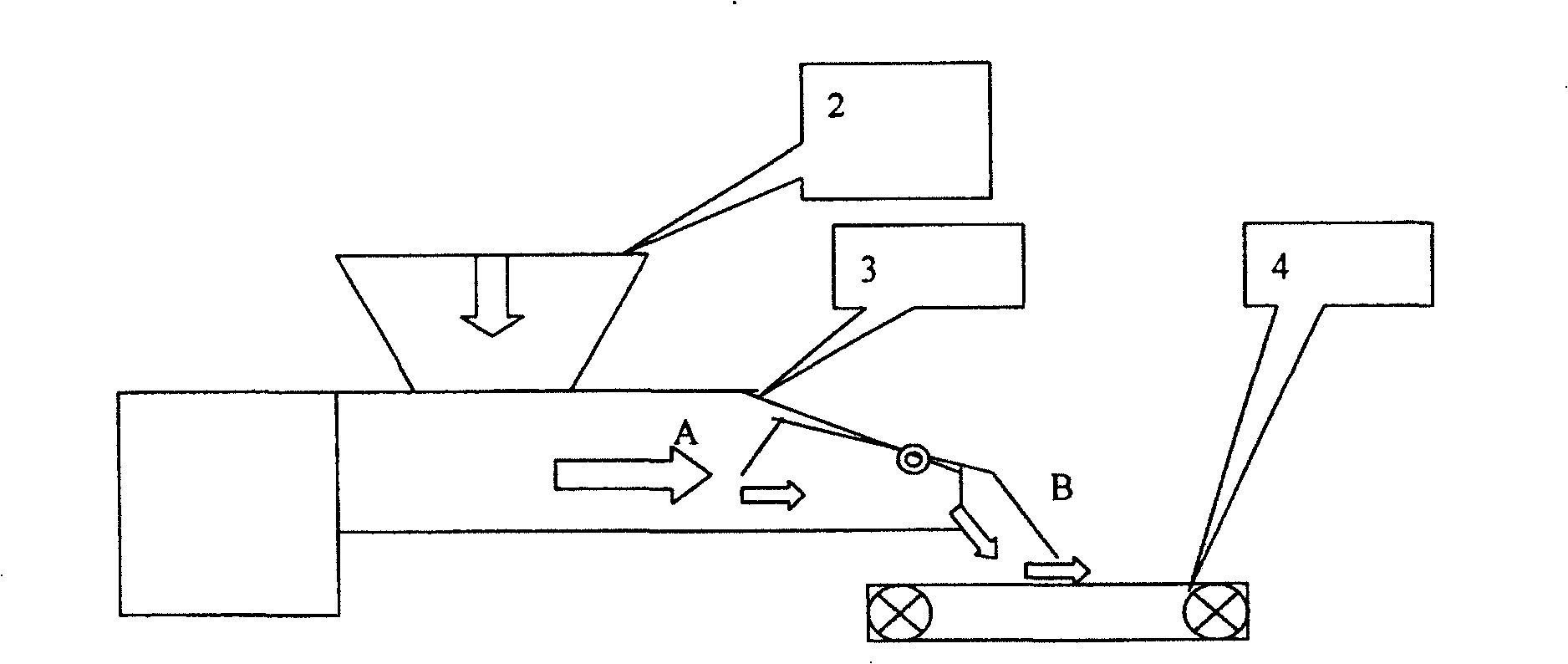

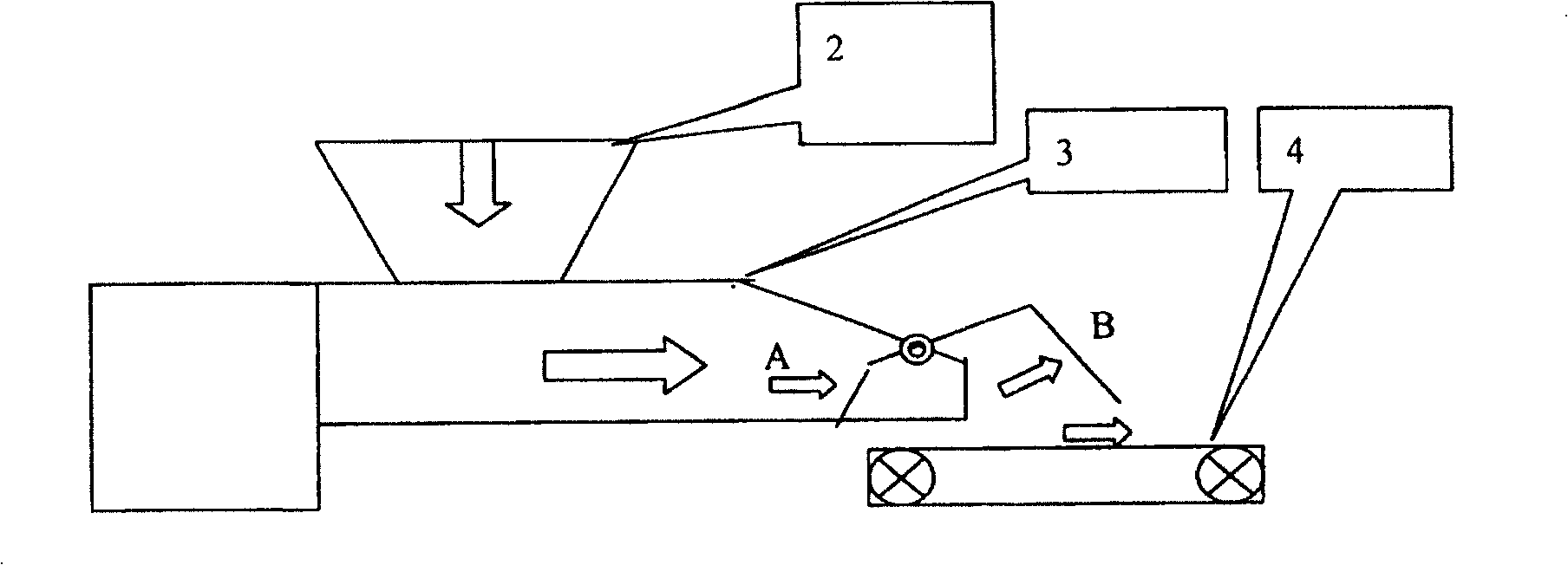

[0014] Control attached Figure 1-4 , the anti-shock material method at the bottom of the warehouse is to install the anti-shock material device at the bottom of the warehouse on the feeding end of the electric vibrator 3, and through a connecting rod 6, the connecting rod can be rotated, and two baffle plates A and B are installed on both sides of the connecting rod. The stopper is on the feeding end of the electric vibration machine, the B stopper is on the material weighing scale 4, and the B baffle is heavier than the A baffle. In the normal state, there is a gap between the A and B baffles, the electric vibration machine 3 and the material weighing scale. When feeding, the powdery material passes through the gap, and is evenly sprinkled on the material weighing scale 4 through the feeding end of the electric vibration machine 3 ;When the material is flushed, a large amount of material gushes out and acts on the B baffle, so that the B baffle is lifted upwards. Due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com