Small pump

A small pump and pump chamber technology, applied in the direction of pumps, pumps with flexible working elements, liquid variable capacity machines, etc., can solve problems such as the influence of pressurization time, function reduction, air leakage, etc. The function of high-efficiency valve, the effect of preventing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Below, according to Figure 1 to Figure 10 An embodiment of the present invention will be described.

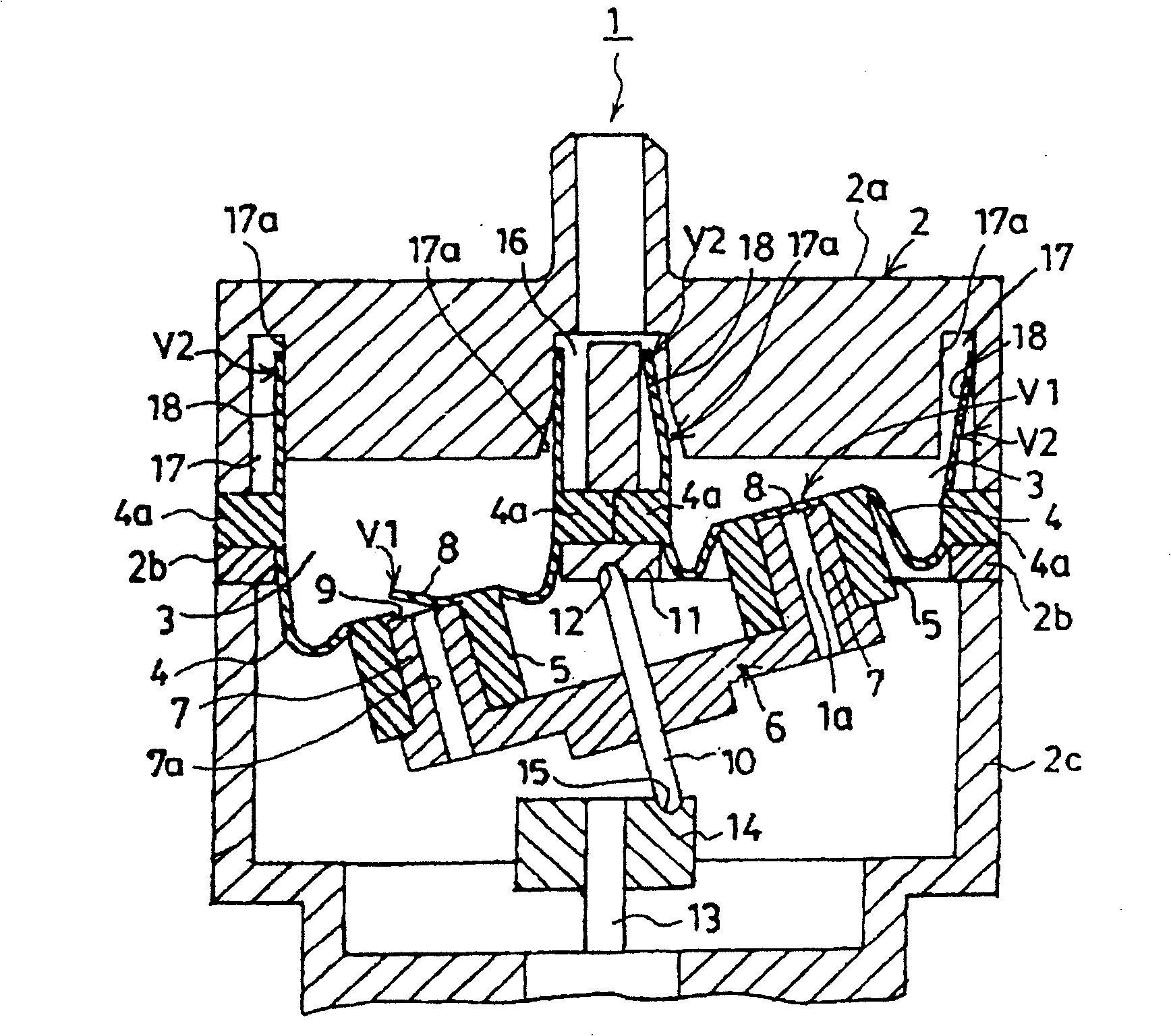

[0042] figure 1It is a vertical sectional view of a small pump. In this small pump 1, diaphragms 4, 4 forming pump chambers 3, 3 are provided in a rectangular housing 2 viewed from above. Hollow mounting bodies 5, 5 protrude downward, and oscillating bodies 6 for moving the lower surfaces of the diaphragms 4, 4 up and down are provided below the diaphragms 4, 4.

[0043] In addition, the casing 2 is made into three sections: an upper casing 2a, a middle casing 2b and a lower casing 2c. In the diaphragms 4, 4, the flanges 4a, 4a... ... are sandwiched between the above-mentioned upper case 2a and the above-mentioned middle case 2b and held by the case 2 .

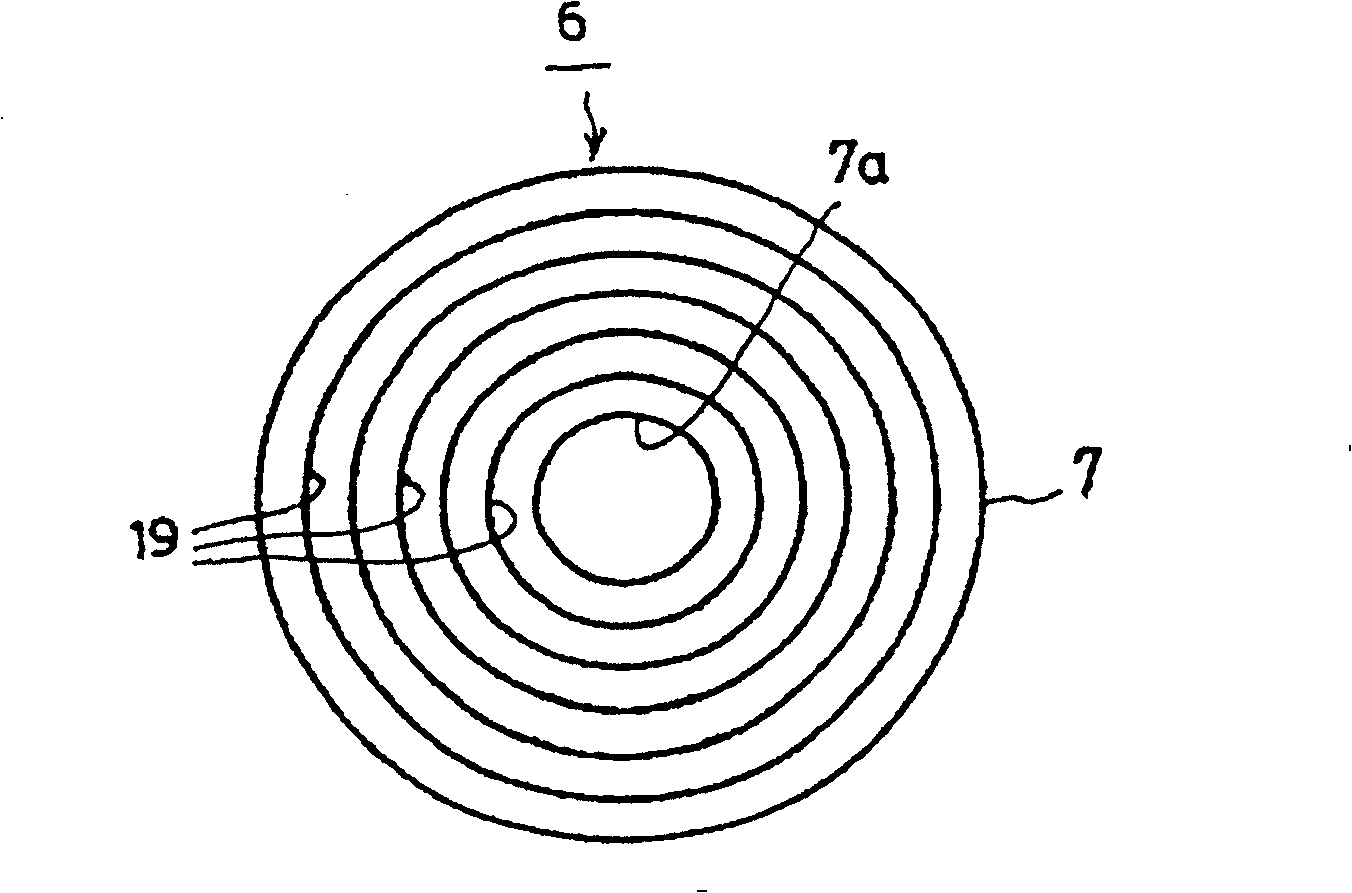

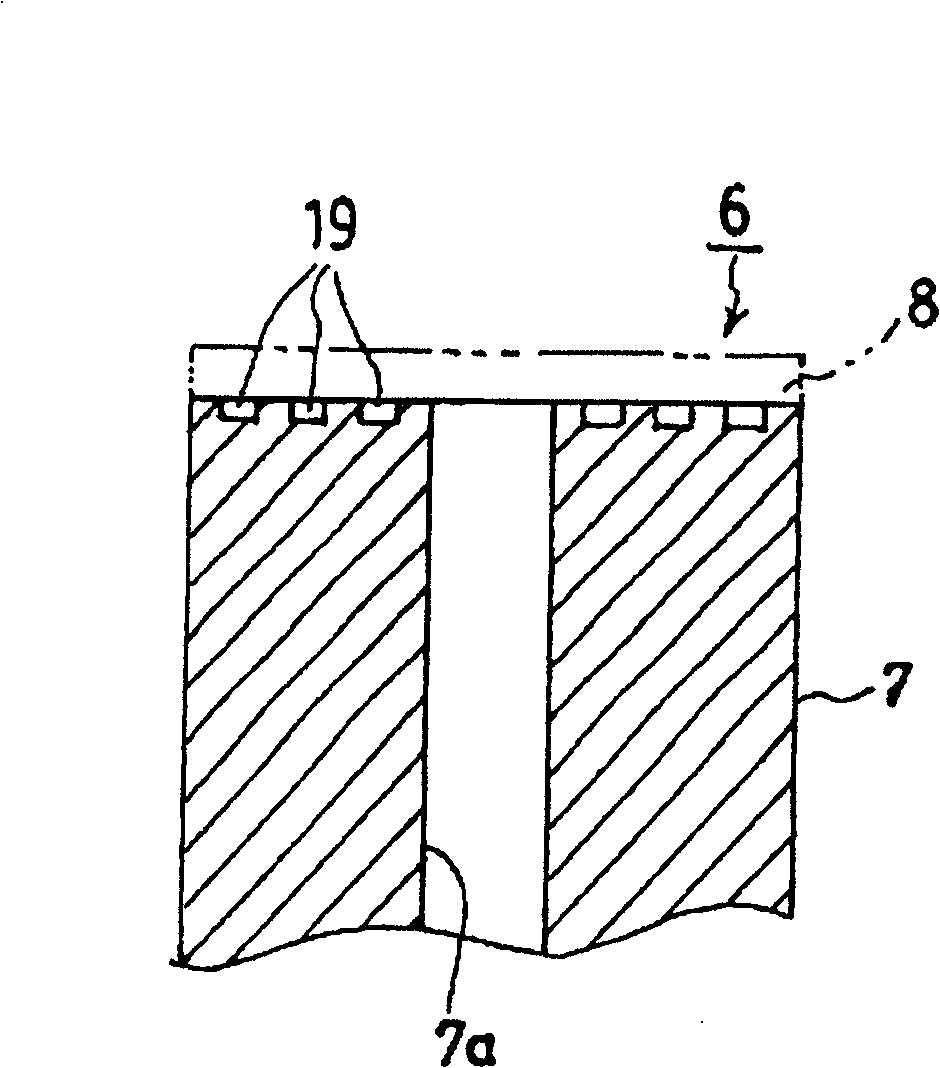

[0044] Furthermore, on the oscillating body 6, in the vicinity of the periphery of the oscillating body 6, and below the central parts of the respective diaphragms 4, 4, an upwardly protruding shaft body 7, 7 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com