Linear temperature-sensing fire detector capable of raising response speed and alarming method thereof

A fire detector and response speed technology, applied in the direction of electrical fire alarms, instruments, thermometers, etc., can solve the problems of prolonged time, inability to meet the requirements of fire response time, slow response speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

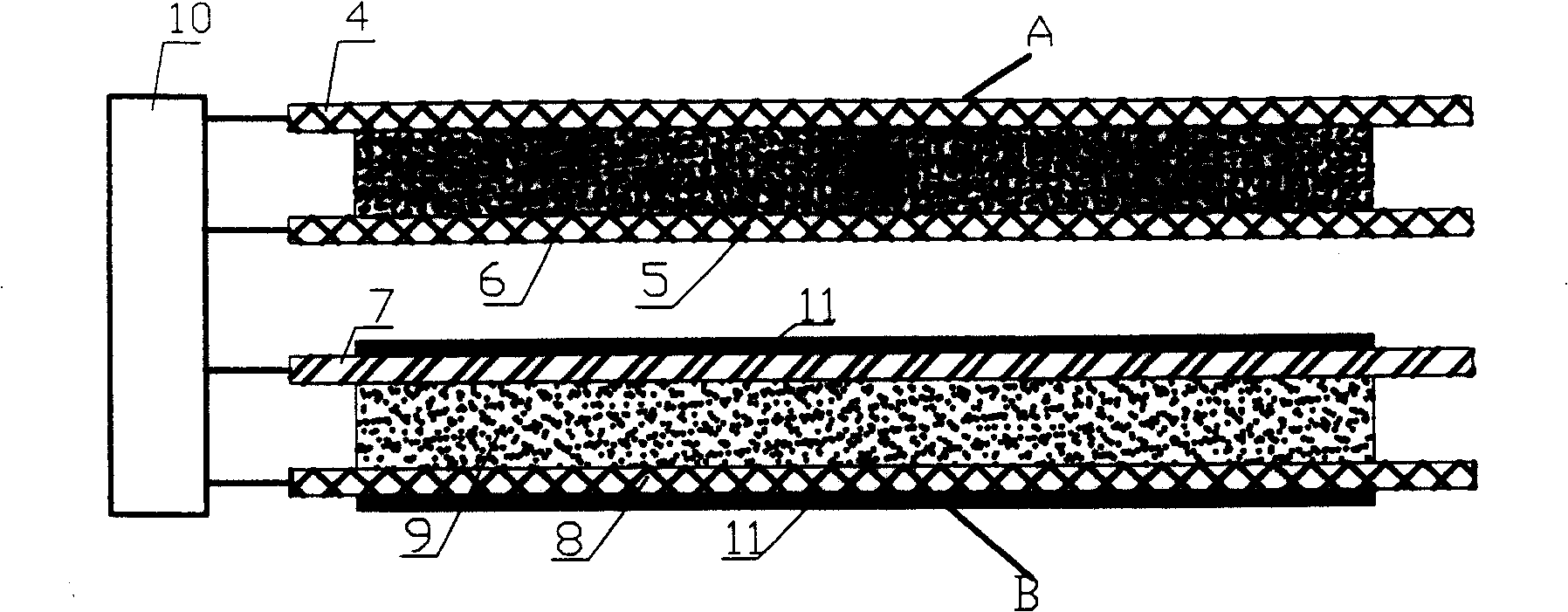

[0015] like figure 1 As shown, the linear temperature-sensing fire detector provided by the present invention that can improve the response speed includes two linear temperature-sensing elements A and B arranged in parallel and a conversion box 10 connected to one end of the linear temperature-sensing elements A and B at the same time; Among them, the linear temperature sensing element A is composed of two parallel detection conductors 4, 5 and the NTC characteristic barrier layer 6 arranged in parallel between the detection conductors 4, 5; the linear temperature sensing element B is composed of two parallel detection conductors The conductors 7 and 8 are composed of a layer of molten salt material 9 arranged in parallel between the detection conductors 7 and 8 and an outer sheath 11 covering the detection conductors 7 and 8 and the layer of molten salt material 9 . The parallel arrangement between the two detection conductors 4, 5 or 7, 8 includes methods such as parallel, w...

Embodiment 2

[0018] This embodiment is an improvement on the basis of Embodiment 1: one of the two detection conductors 4 and 5 of the above-mentioned linear temperature sensing element A is made of a thermocouple wire, so as to form a structure with the other detection conductor. A wire-type temperature sensing element A with thermocouple characteristics, at this time, the conversion box 10 will send out a fire alarm signal according to the change rate of the voltage (potential) value of the wire-type temperature sensing element A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com