Lightweight steel component

A technology of light steel components and processing methods, which is applied in building construction, covering/lining, construction, etc., can solve the problems of high cost, roughness, and the scope of application cannot meet the market demand, and achieve low cost and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

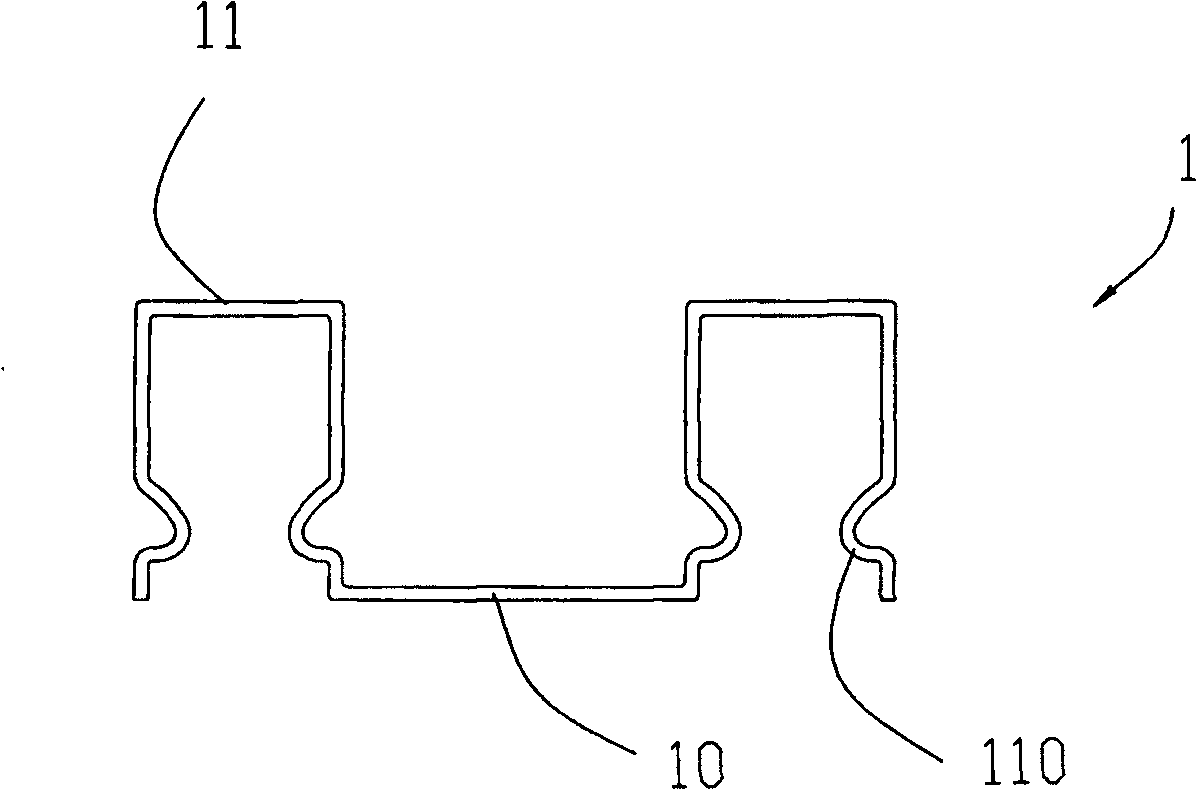

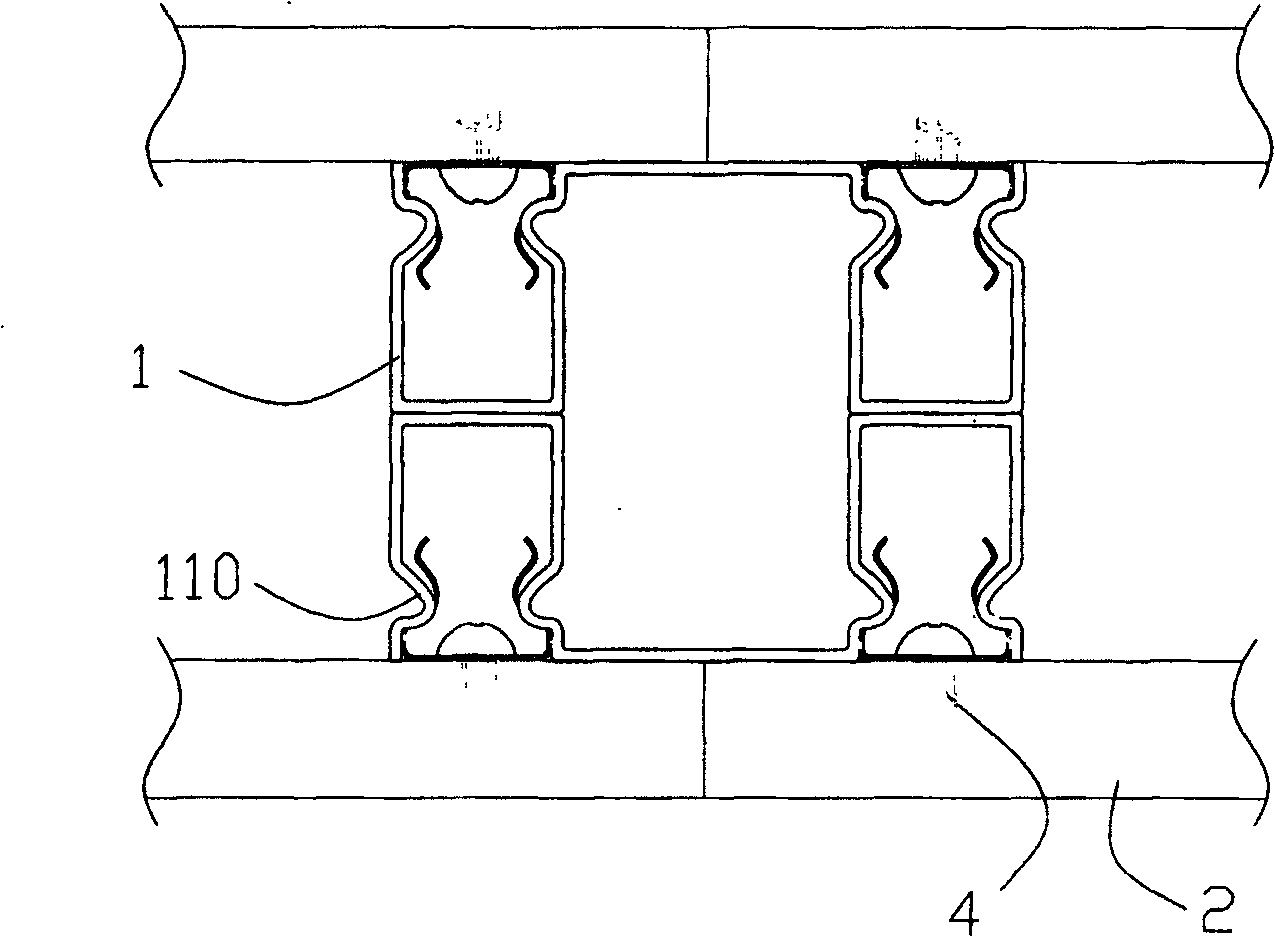

[0025] Please refer to figure 1 As shown, the light steel member 1 of the present invention can be used to connect two panels, including a main body 10 and two matching parts 11 bent and extended from the main body 10 to both sides. The matching parts 11 are opposite to each other near the main body 10 Two mounting parts 110 are recessed inwardly, and the two matching parts 11 are arranged opposite to each other, and are generally n-shaped. The material of the light steel member 1 is galvanized steel sheet, which is relatively low in cost and durable compared with the prior art. Because of its complex shape and section, it can be used in combination with accessories to produce high-grade and exquisite High-quality decorative products, there will be no phenomenon that the two panels are not firmly connected, and the decorative effect will not b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com