Electric vacuum cleaner head and electric vacuum cleaner using same

A technology for vacuum cleaners and vacuum cleaners, which is applied in the direction of vacuum cleaners, suction nozzles, applications, etc., which can solve problems such as inability to insert and difficult operation, and achieve the effect of improving the binding force and excellent assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A first embodiment of the present invention will be described below with reference to FIGS. 1 to 6. FIG.

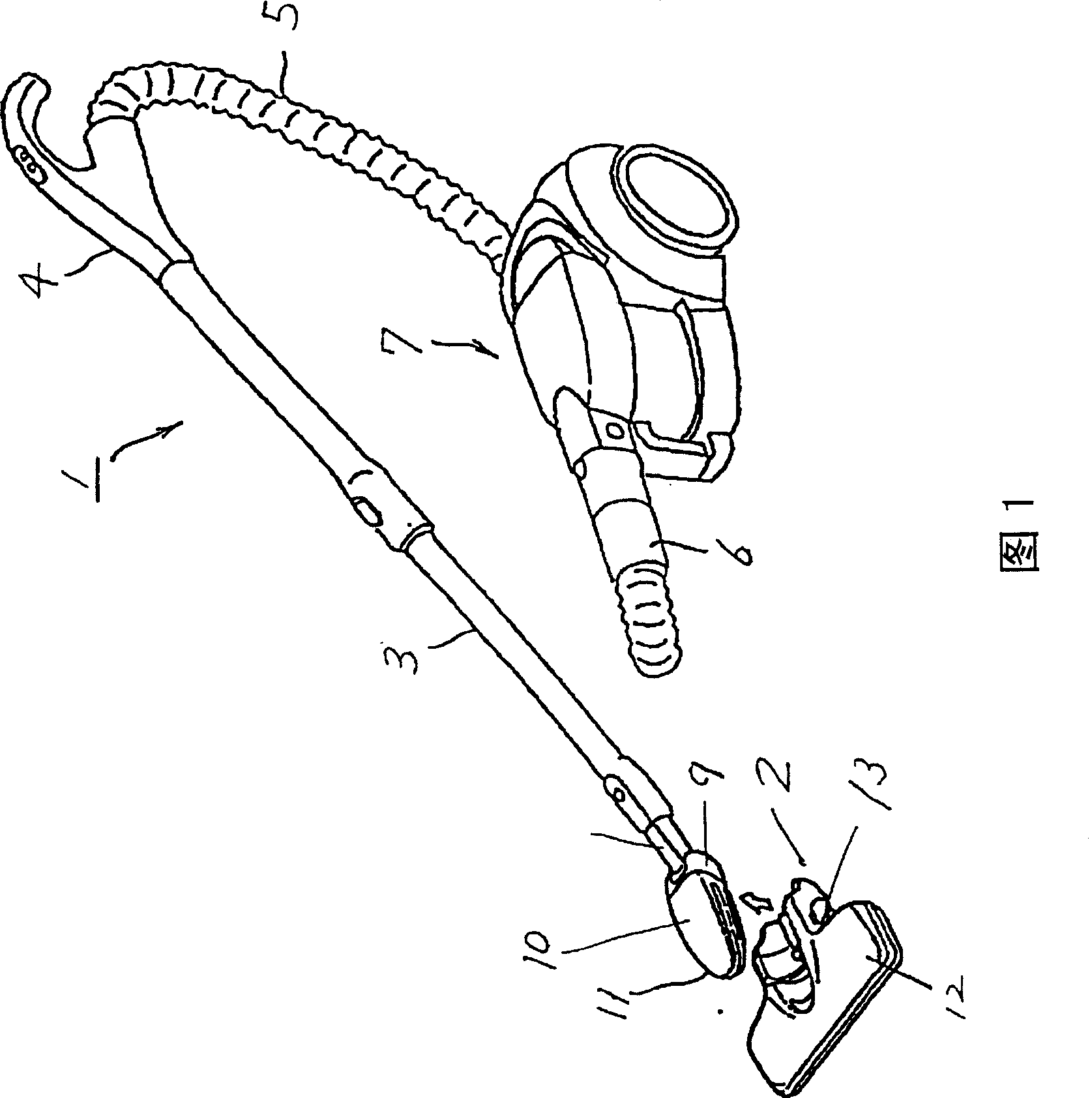

[0025] As shown in Figure 1, the electric vacuum cleaner 1 has: an extension tube 3 with a dust suction head assembly 2 detachably arranged on the front end; an armrest handle 4 connected with the other end of the extension tube 3; , the hose 5 that is connected to the hose connector 6 at the other end. The hose connector 6 is connected to the main body 7 of the vacuum cleaner.

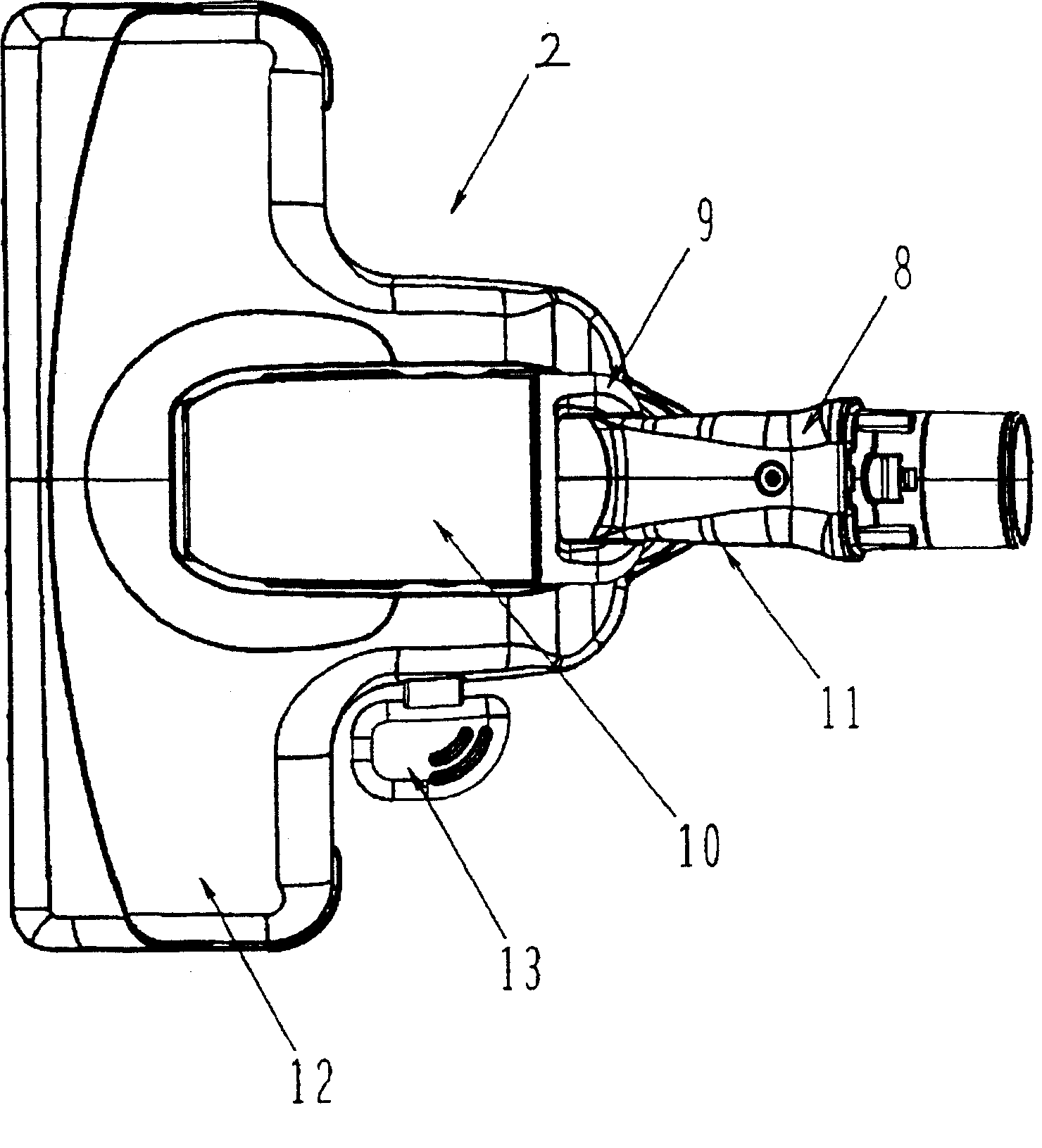

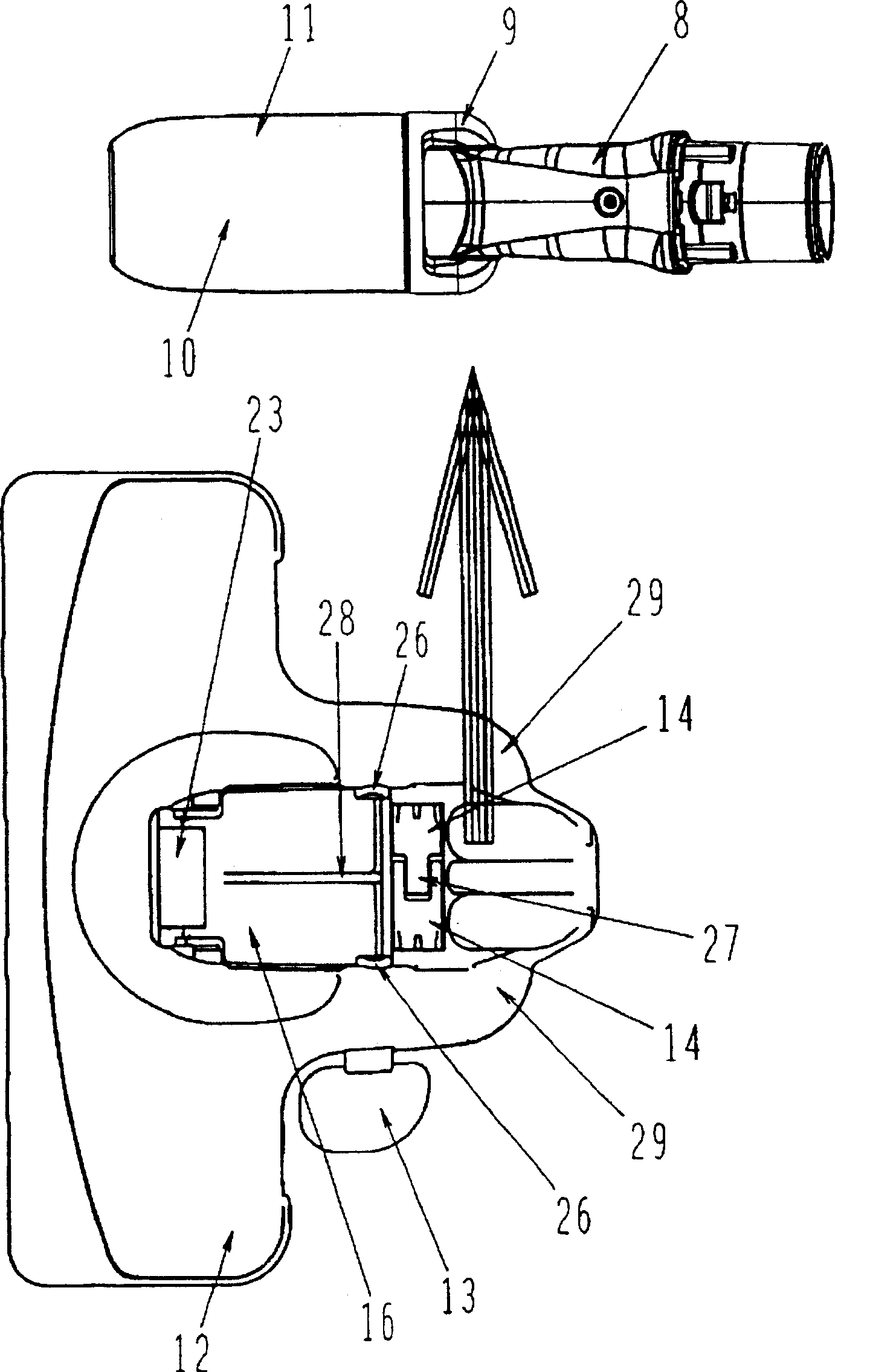

[0026] The cleaning head assembly 2 is composed of a small suction head 11 and a floor suction head 12 on which the small suction head 11 is detachably mounted. The small suction head 11 is provided with a connection pipe 8 connected to the extension pipe 3 in a detachable manner, and a suction head 10 connected to the connection pipe 8 through a connection member 9 .

[0027] Additionally, if figure 2 ~ As shown in Figure 6, a small suction head installation pit 16 roughly matching the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com