Decal transferring method and decal transferring device

A technology of transfer printing and formed products, applied in the direction of coating, etc., can solve the problem of shifting the position of the transferred pattern and achieve high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

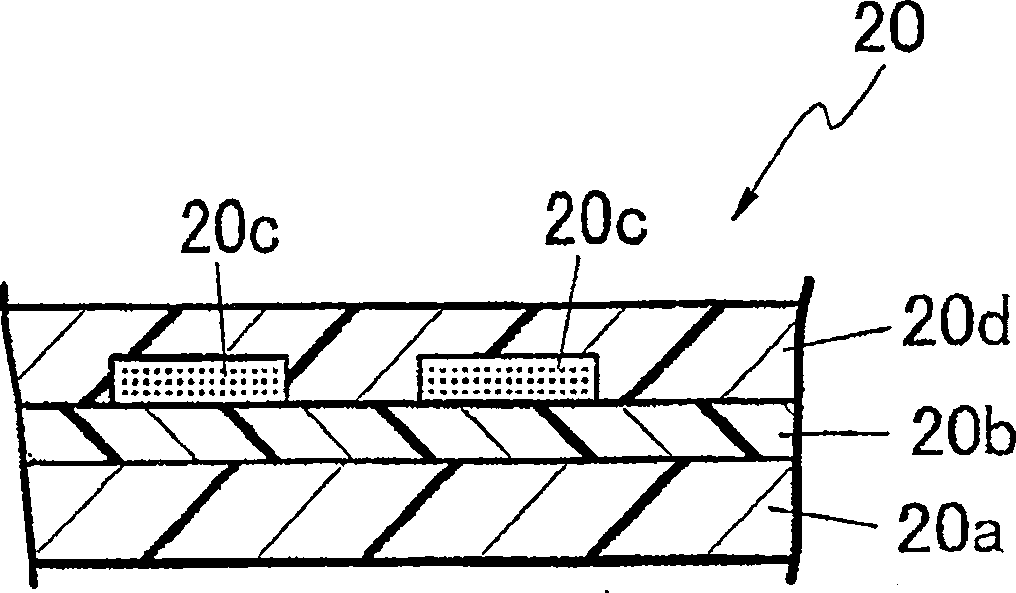

[0063] Before continuing the description of the present invention, in the drawings, the same reference numerals are assigned to the same parts.

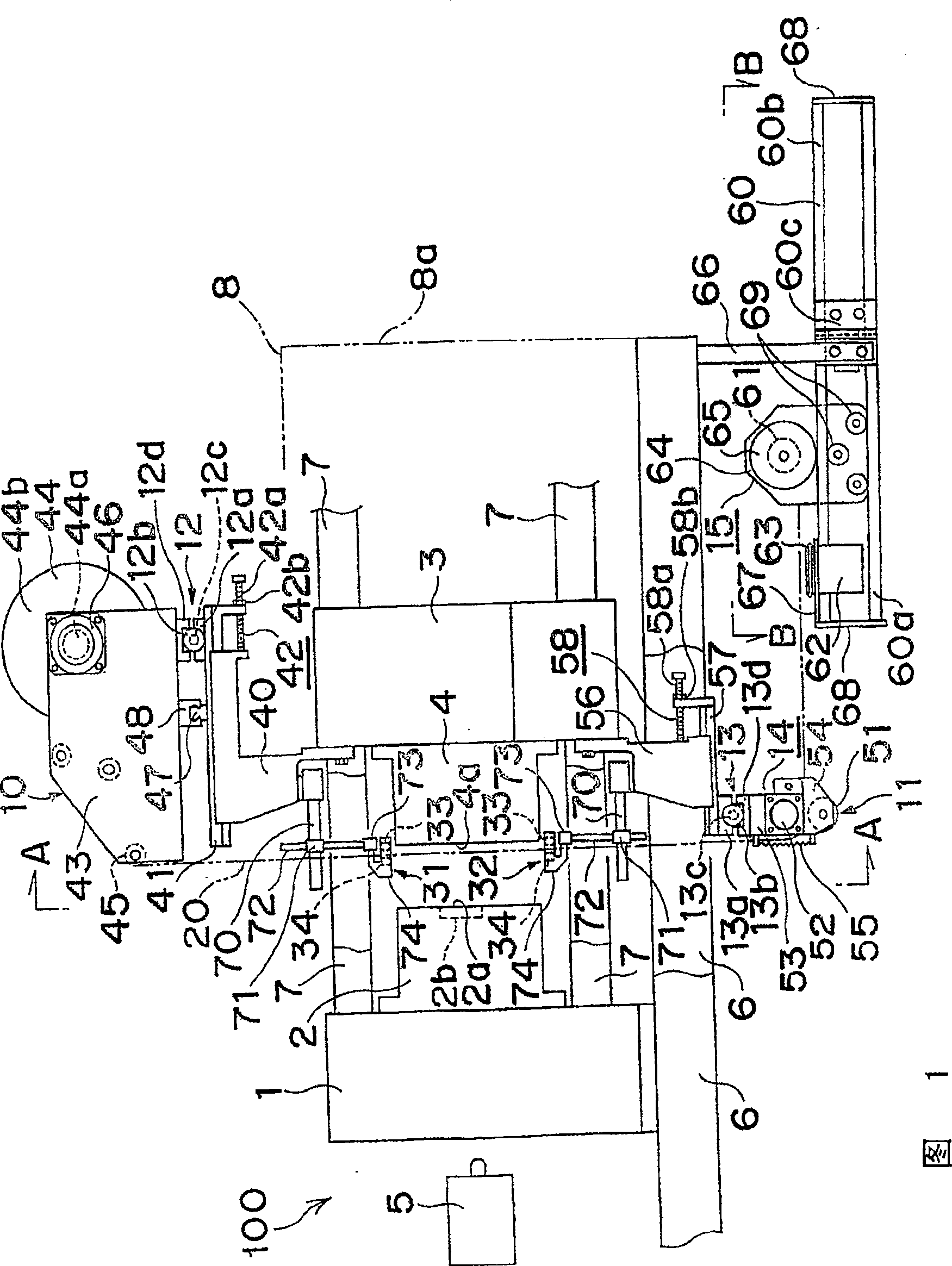

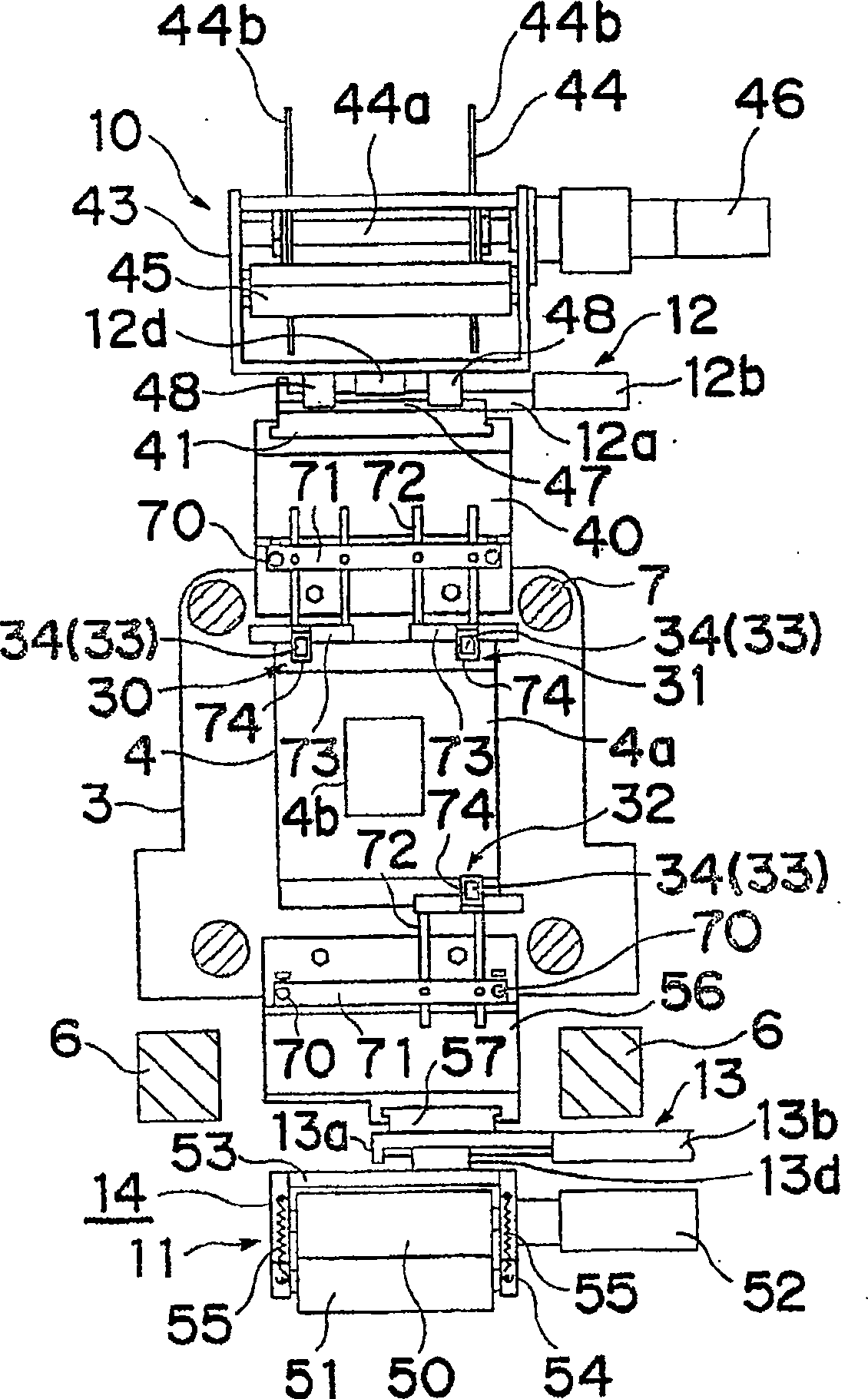

[0064] Figure 1 and figure 2 As shown, the transfer molding device has an injection molding part 100, and the injection molding part 100 includes: a fixed mold 2 mounted on a fixed plate 1 and a movable mold 4 mounted on a movable plate 3, and injecting molten resin into Injection nozzle 5 in the cavity between the two moulds.

[0065] In this embodiment, the fixed disk 1 is fixed on the platform 6 , and the movable disk 3 is moved by being guided by four tie rods 7 fixed on the fixed disk 1 , and can be separated from and contacted with the fixed disk 1 .

[0066] By moving the movable platen 3, the parting surface 4a of the movable mold 4 is brought into pressure contact with the parting surface 2a of the fixed mold 2, thereby becoming a forming part of the mold (the forming part 2b of the fixed mold 2 and the movable mold 4). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com