Patents

Literature

34results about How to "Correct position offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

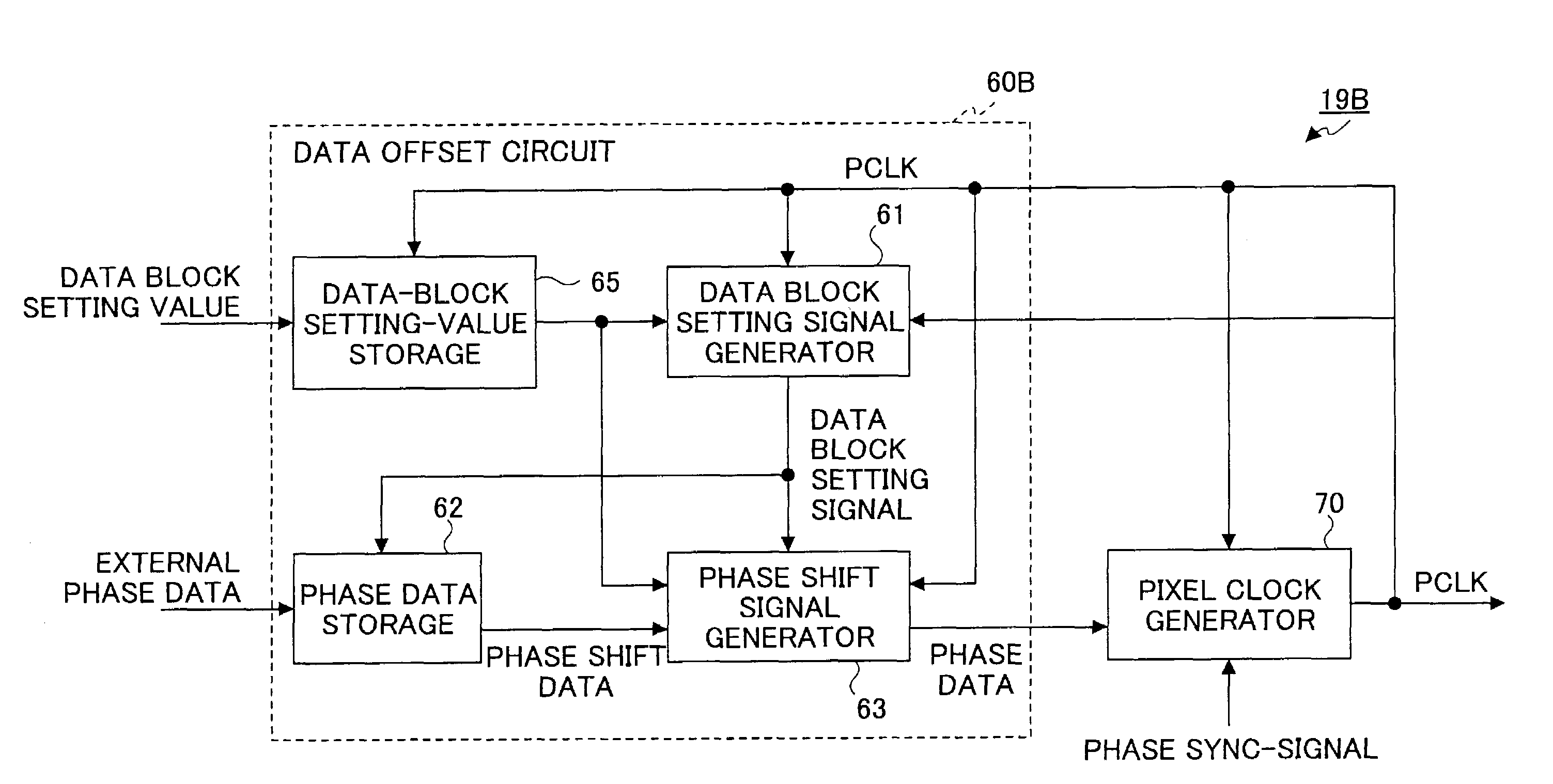

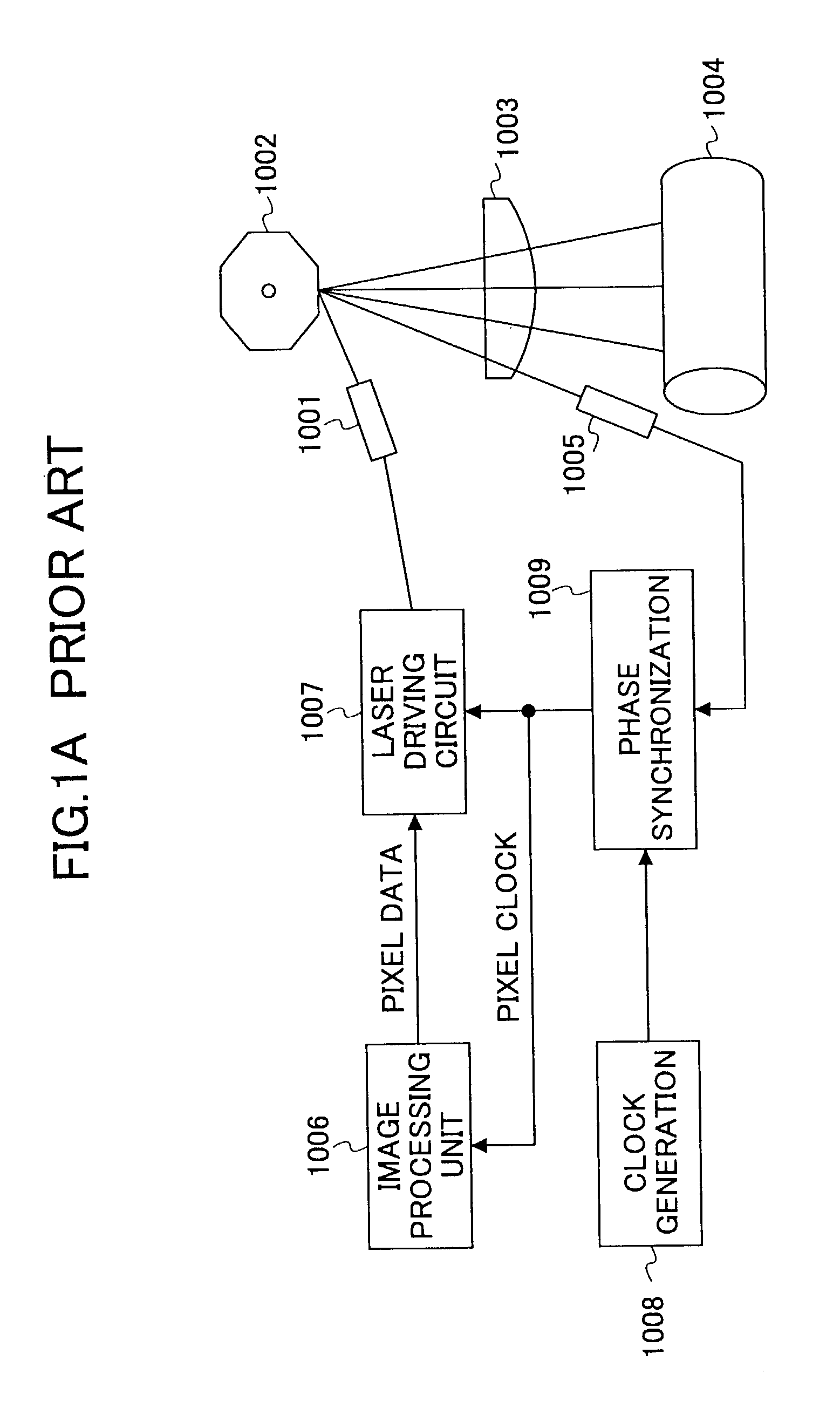

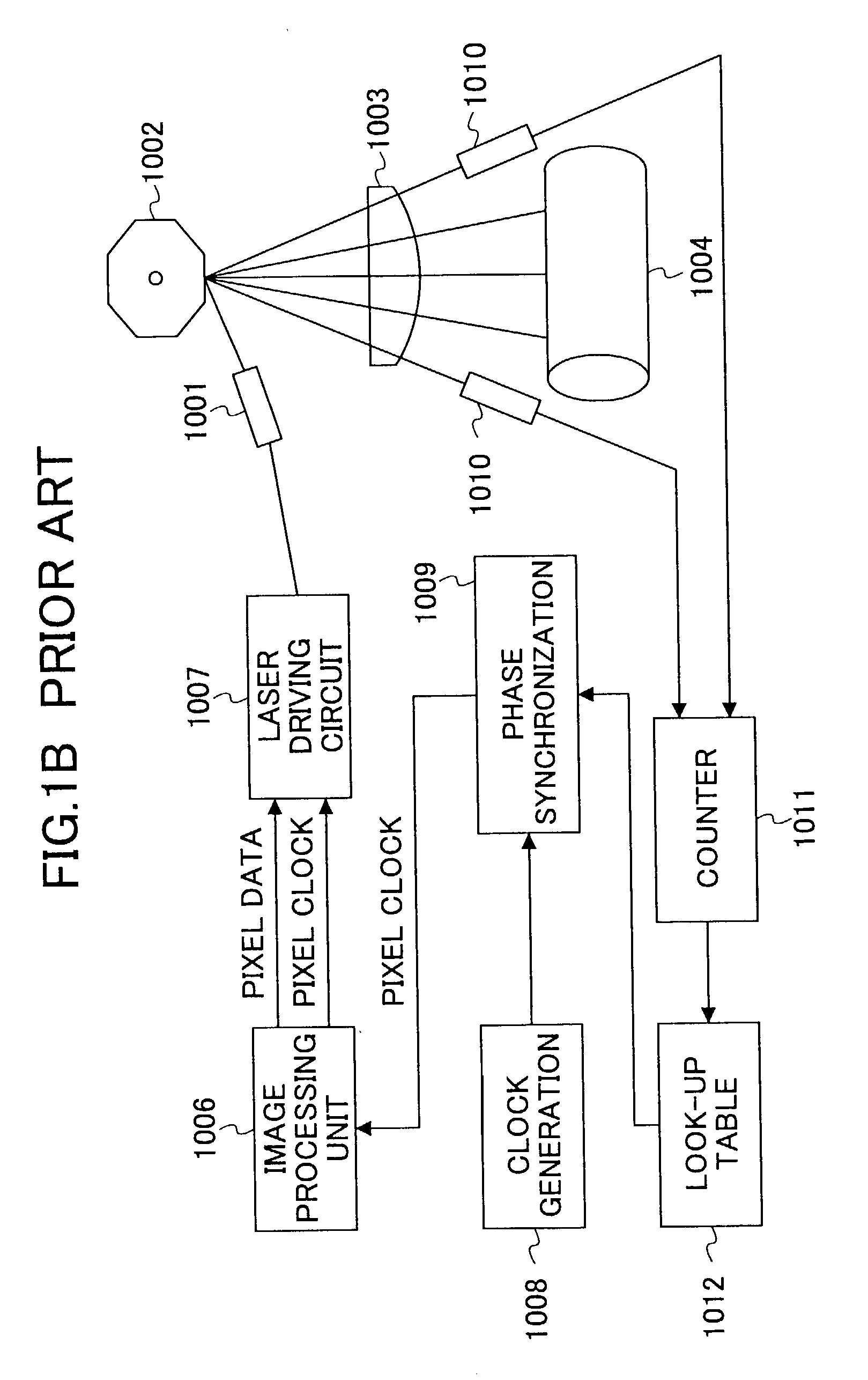

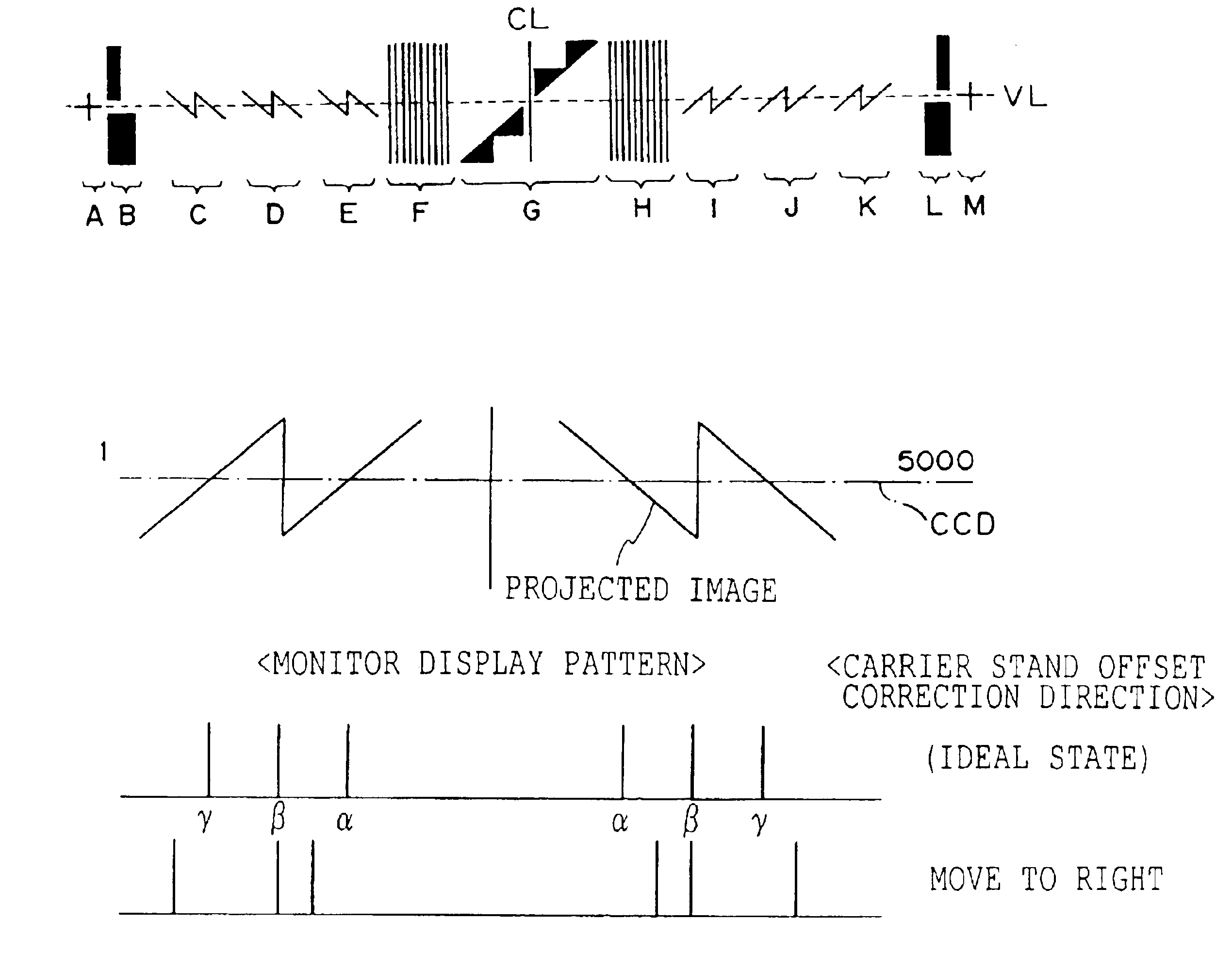

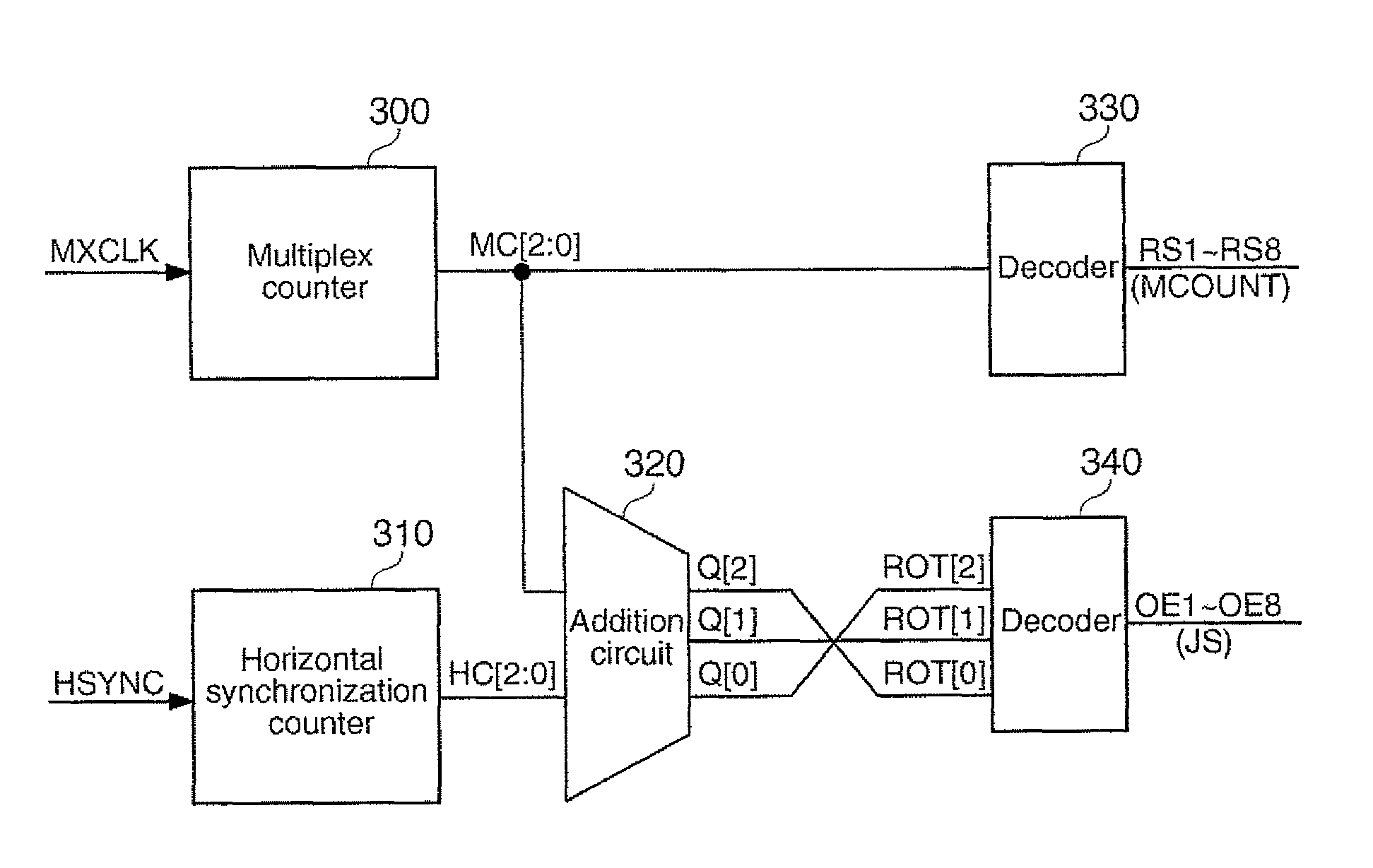

Pixel clock generating apparatus, optical writing apparatus using a pixel clock, imaging apparatus, and method for generating pixel clocks

InactiveUS7271824B2Reduce amountImprove accuracyDigitally marking record carriersInking apparatusPhase shiftedComputer science

A pixel clock generating apparatus includes a data offset circuit and a pixel generator. The data offset circuit defines multiple data blocks, each data block consisting of a predetermined number of successive clocks, and produces phase data for each data block. The phase data represents an amount and a direction of phase shift to be carried out for a certain clock in each data block. The pixel generator receives the phase data from the data offset circuit and generates a phase-shifted pixel clock a predetermined number of times in each data block based on the phase data.

Owner:RICOH KK

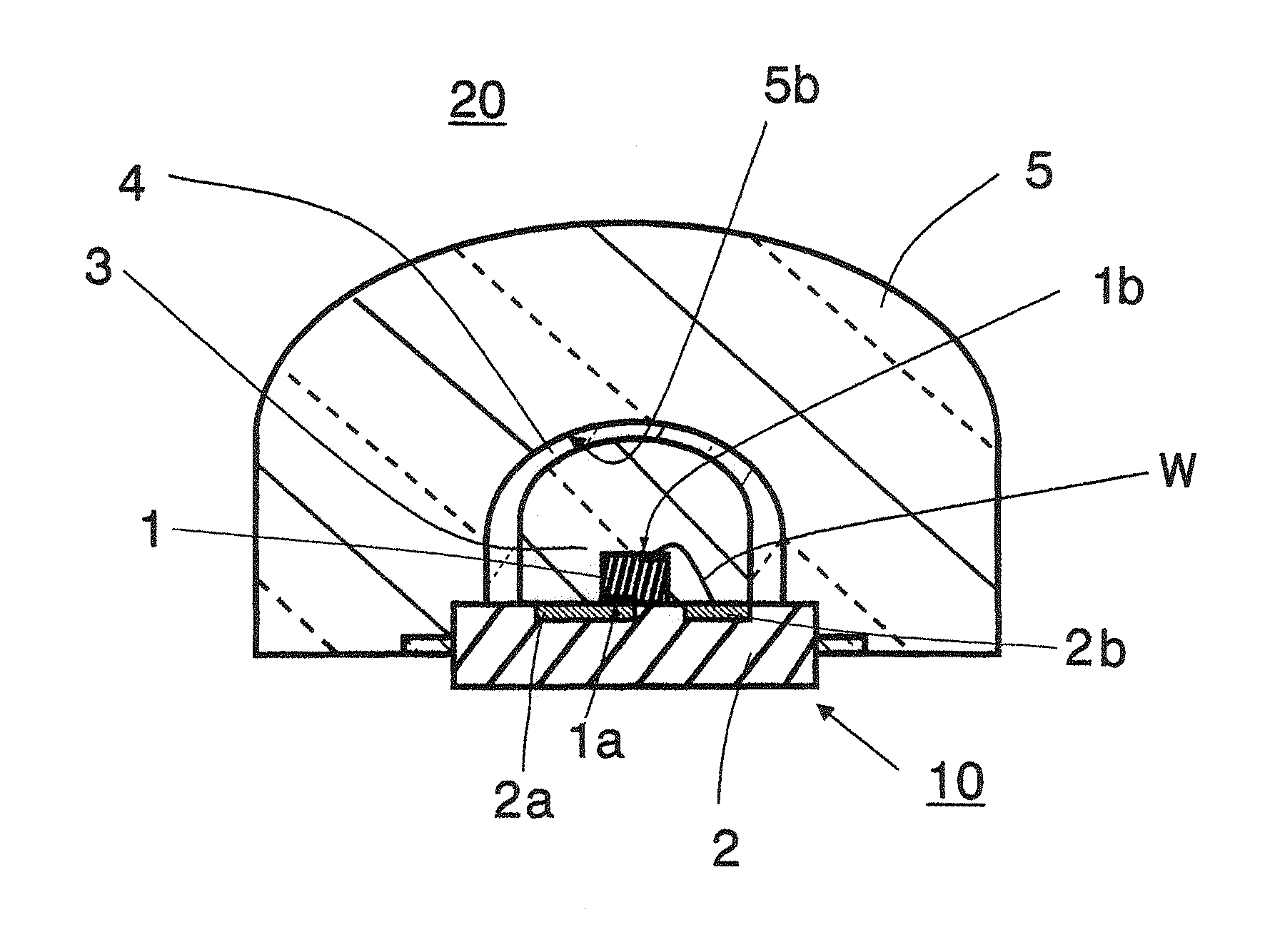

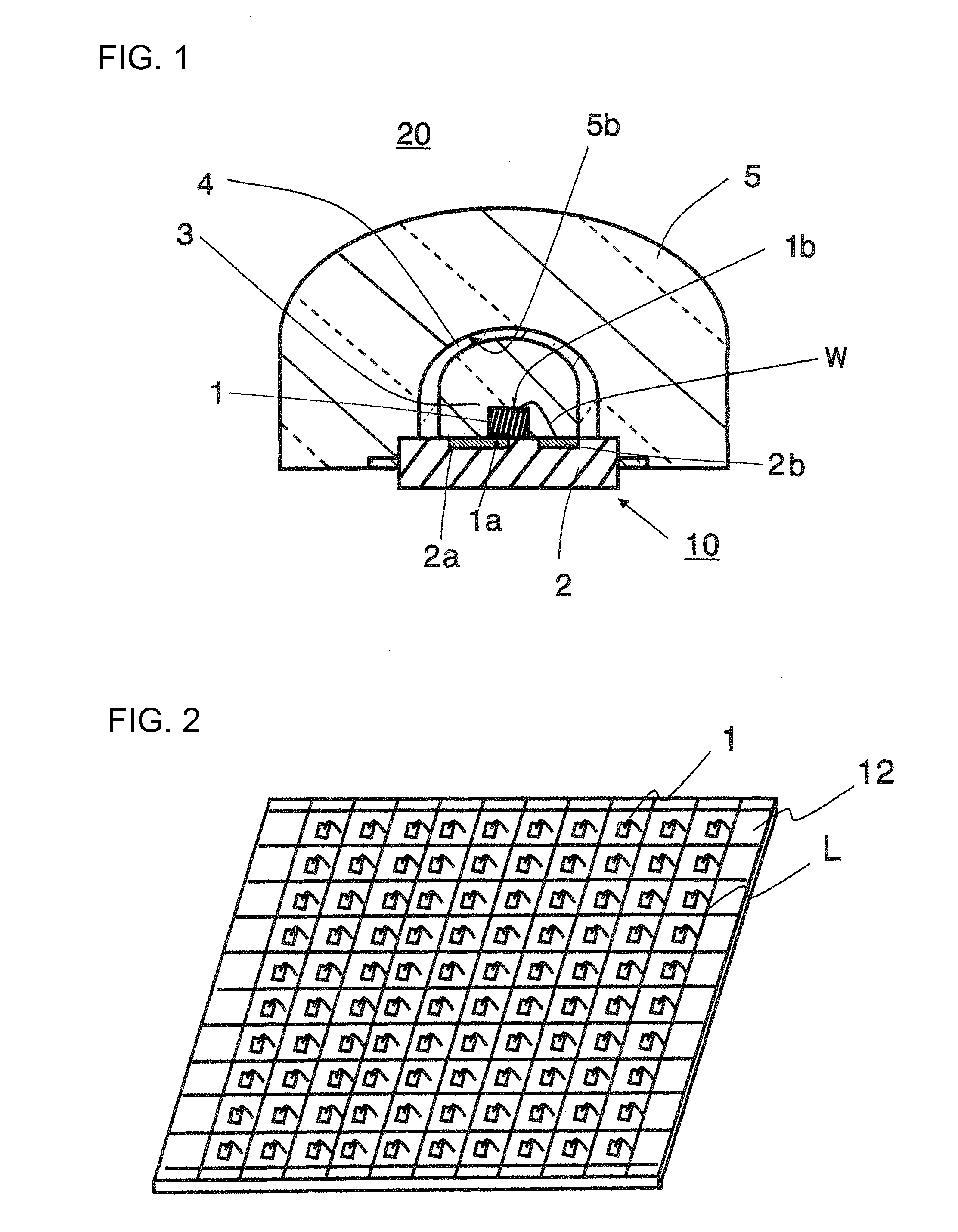

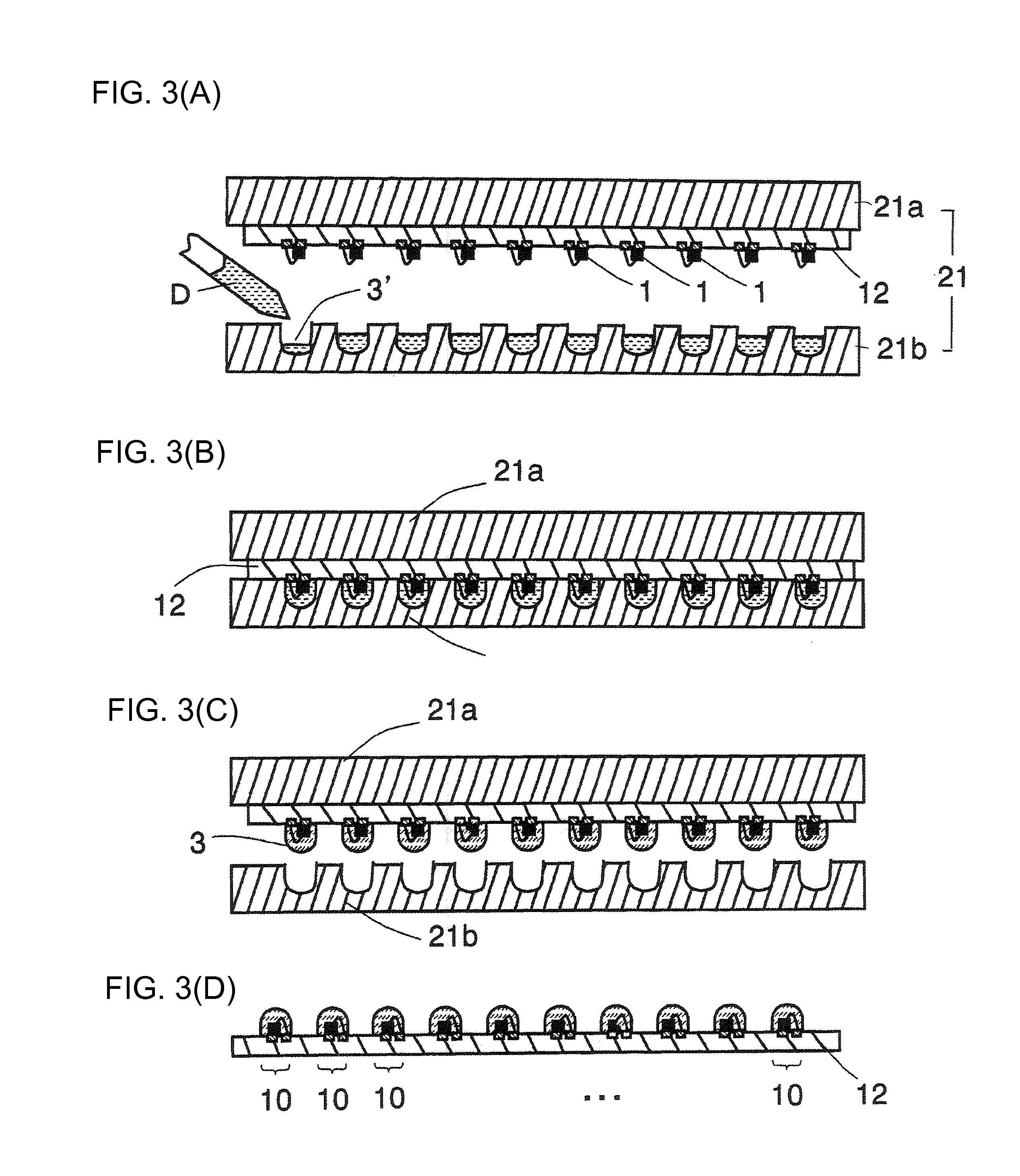

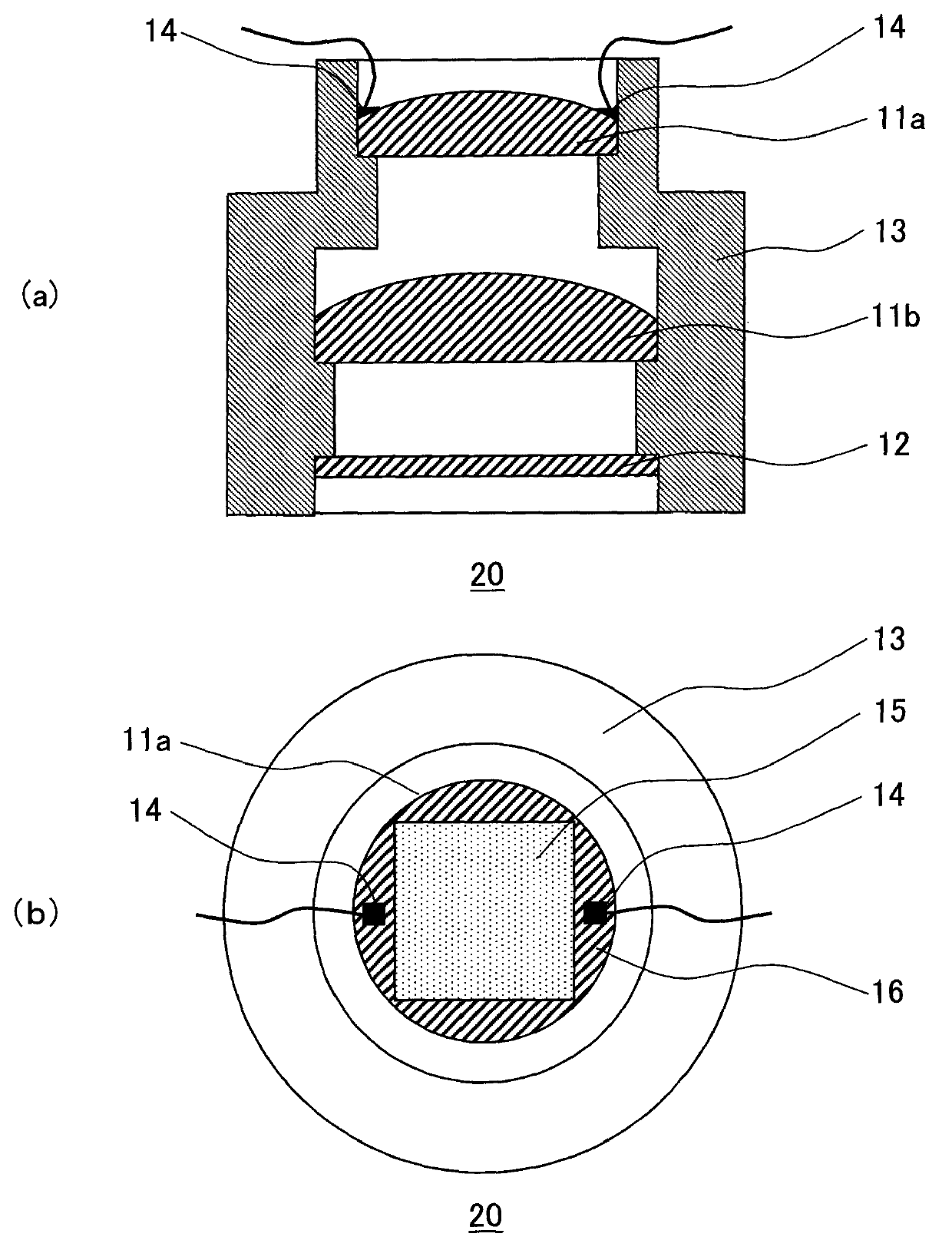

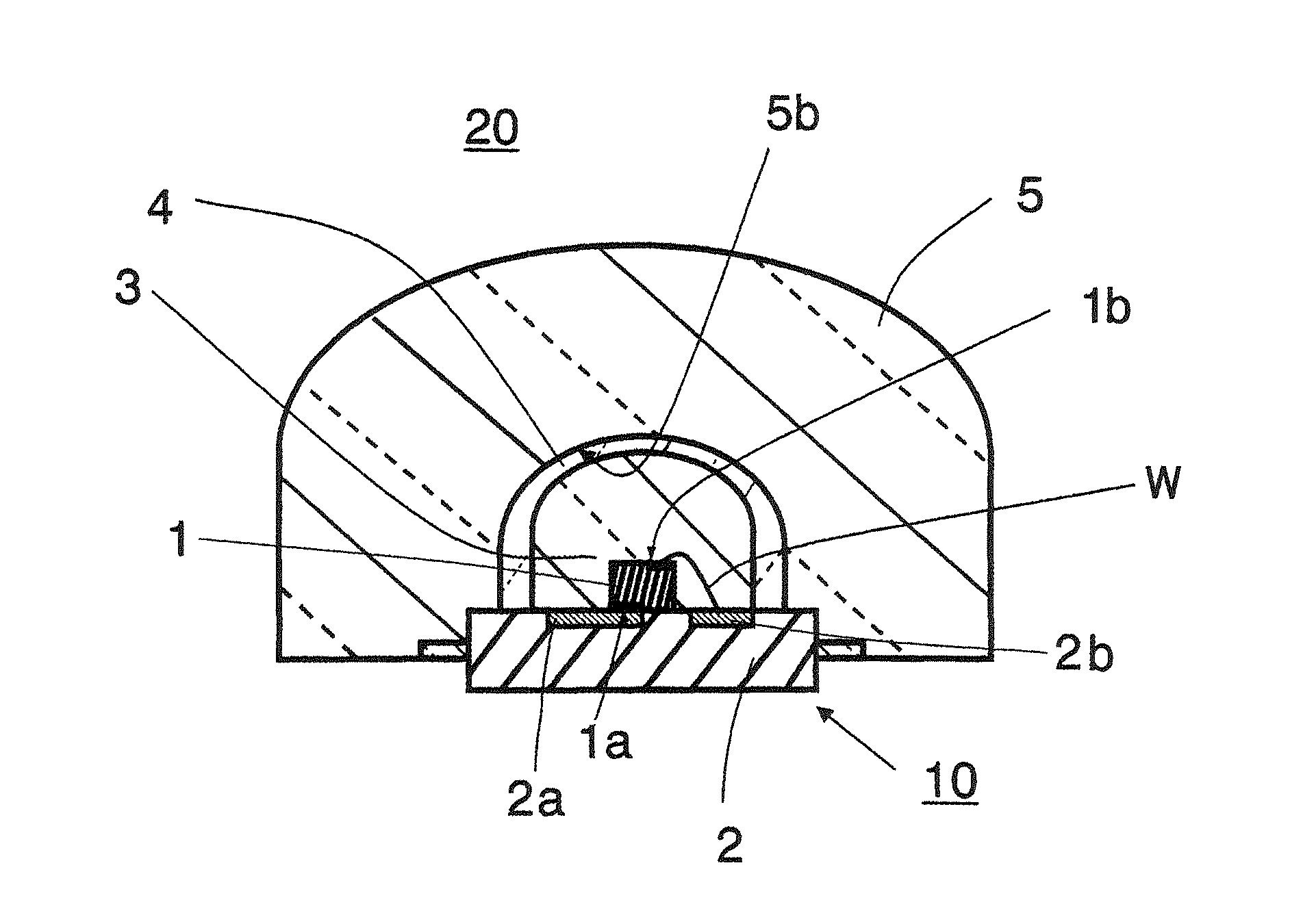

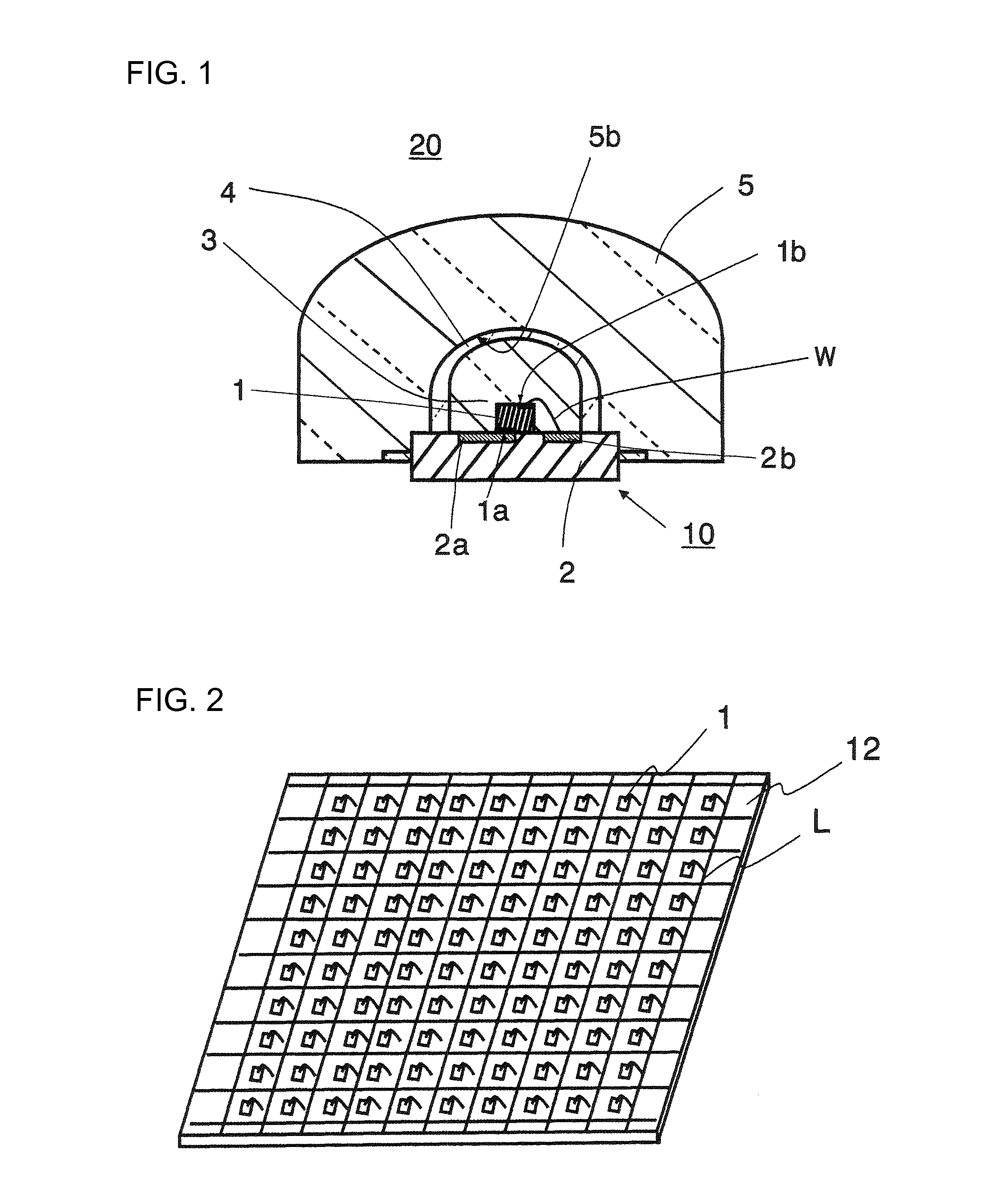

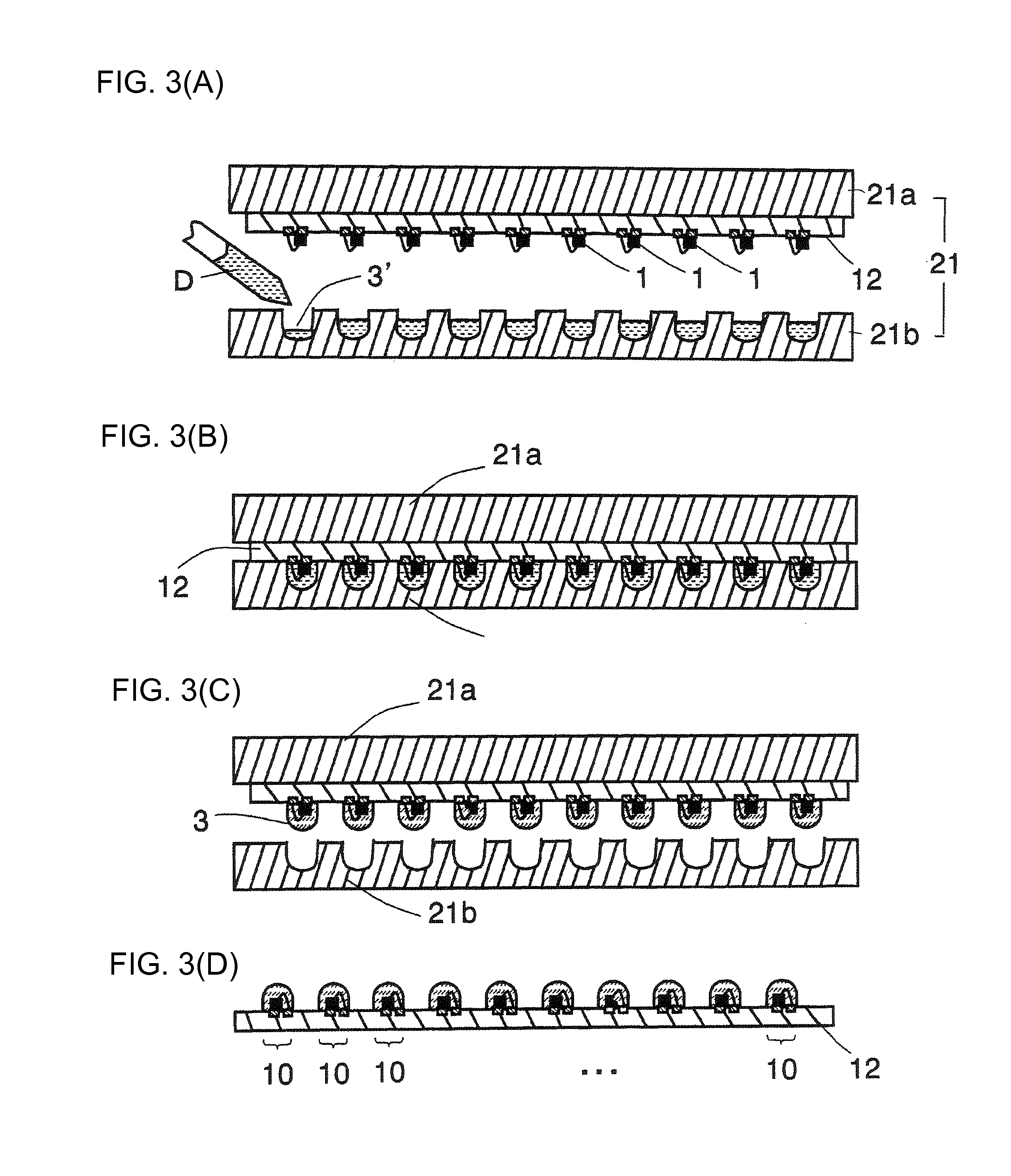

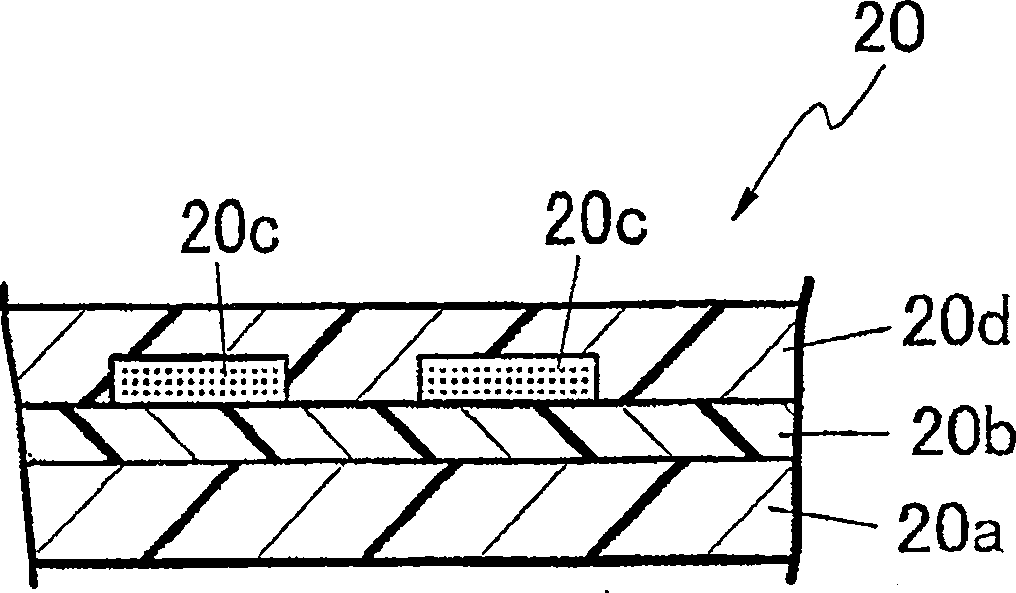

Lens-equipped optical semiconductor device and method for manufacturing the same

ActiveUS20140027807A1Improve accuracyCorrect offsetSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSemiconductor device

A lens-equipped optical semiconductor device including: an optical semiconductor device including at least one optical semiconductor element mounted on a substrate and a transparent resin encapsulating body that encapsulates the optical semiconductor element; a resin lens having a recessed portion for housing the transparent resin encapsulating body; and a transparent resin layer filled into a space among the substrate, the recessed portion, and the transparent resin encapsulating body, wherein the recessed portion has a capacity that is at least 1.1 times a total volume of the optical semiconductor element and the transparent resin encapsulating body.

Owner:ASAHI RUBBER

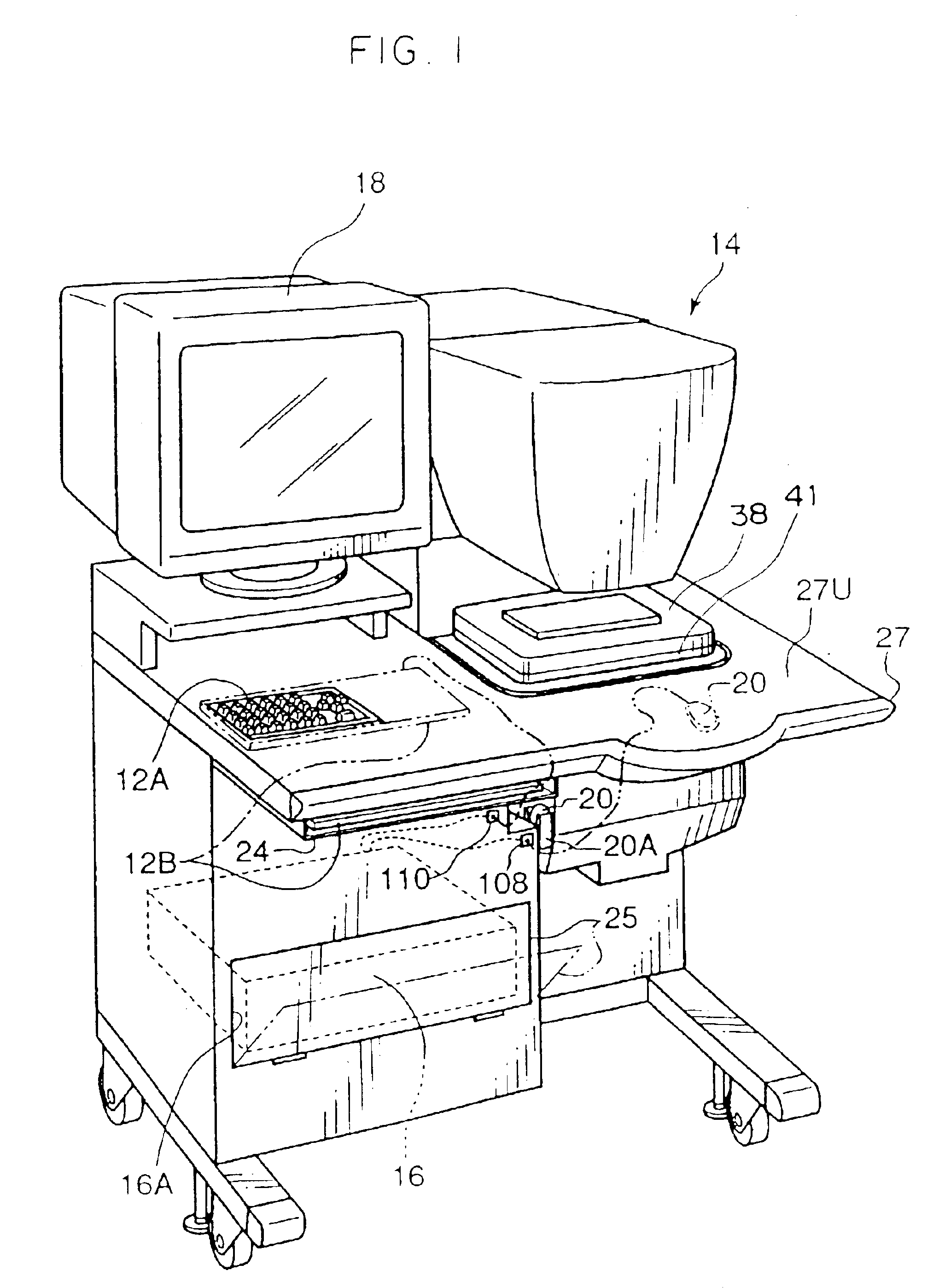

Image reading apparatus, default value adjusting method of image reading apparatus, and chart original

A chart original in which two or more patterns are disposed so as to be separated at predetermined intervals and are symmetric with respect to a second imaginary line which is orthogonal to a first imaginary line. Each of the patterns is formed from a first line segment, which is orthogonal to the first imaginary line, and two second line segments, which are disposed at opposite positions with respect to the first line segment so as to intersect the first line segment. Each of the patterns intersect the first imaginary line at three points.

Owner:FUJIFILM CORP

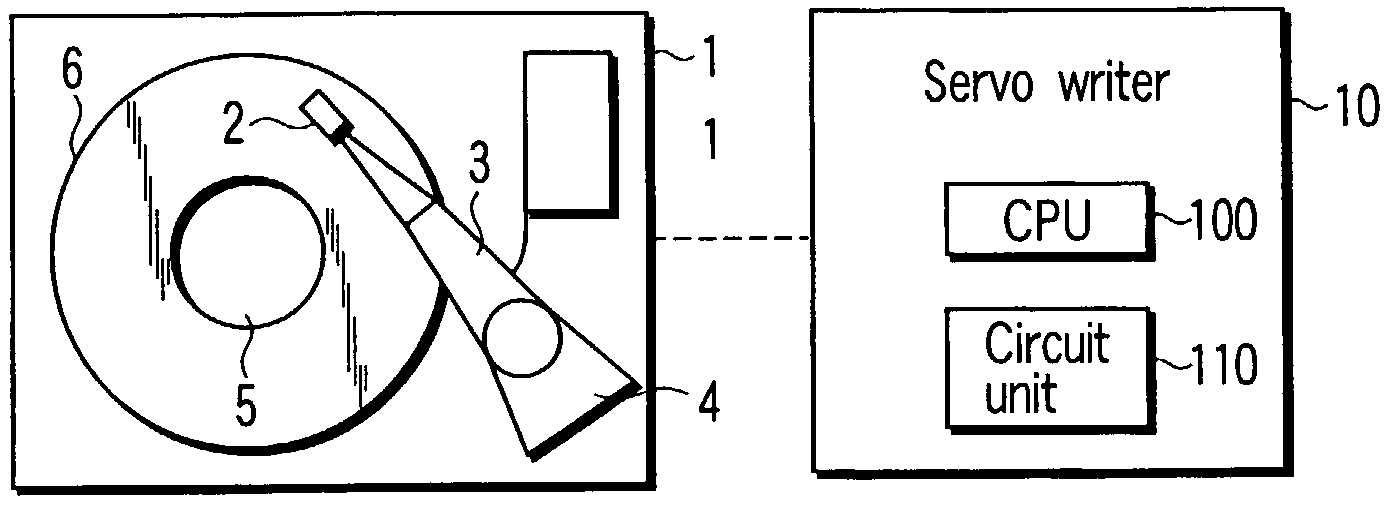

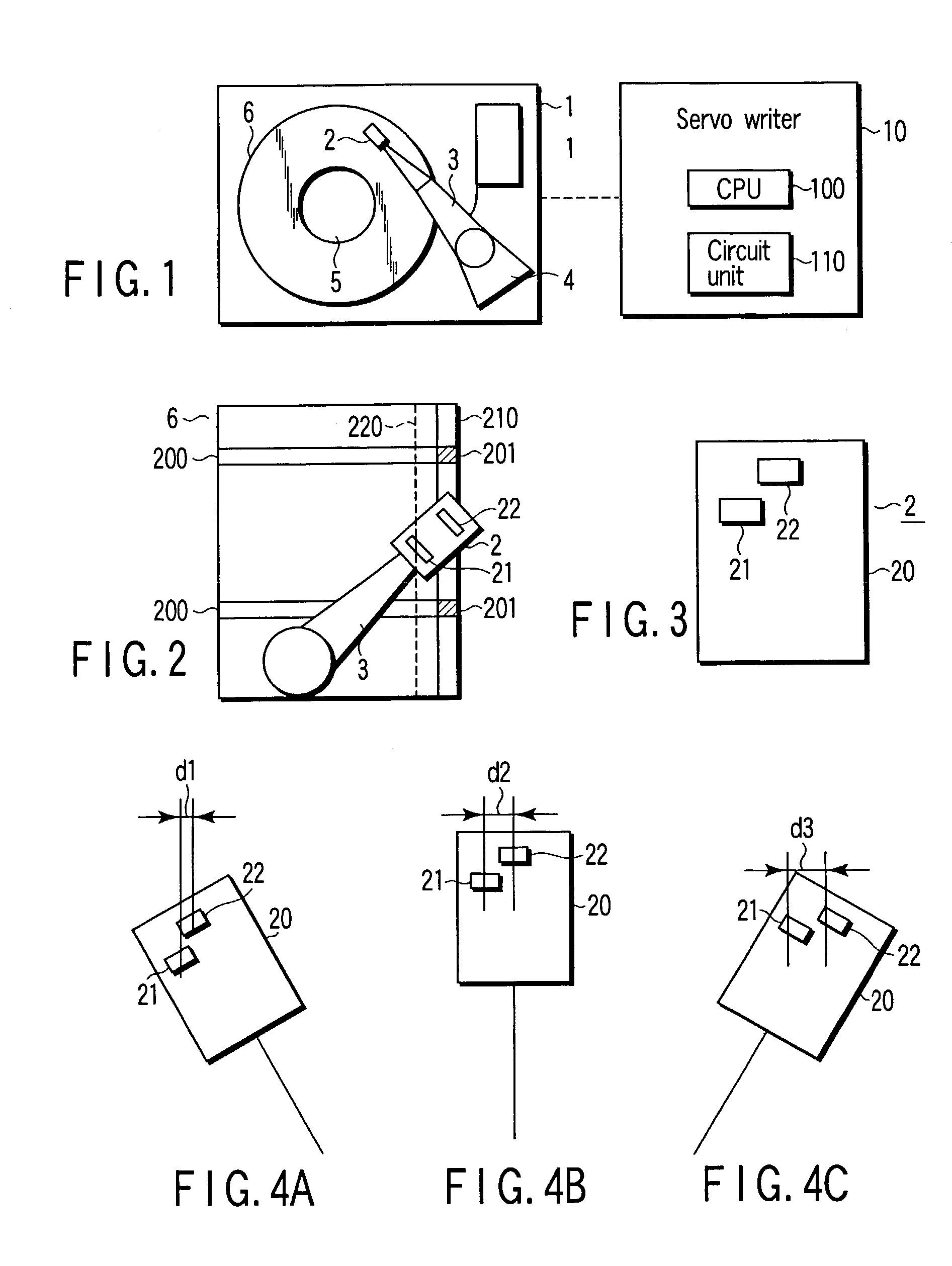

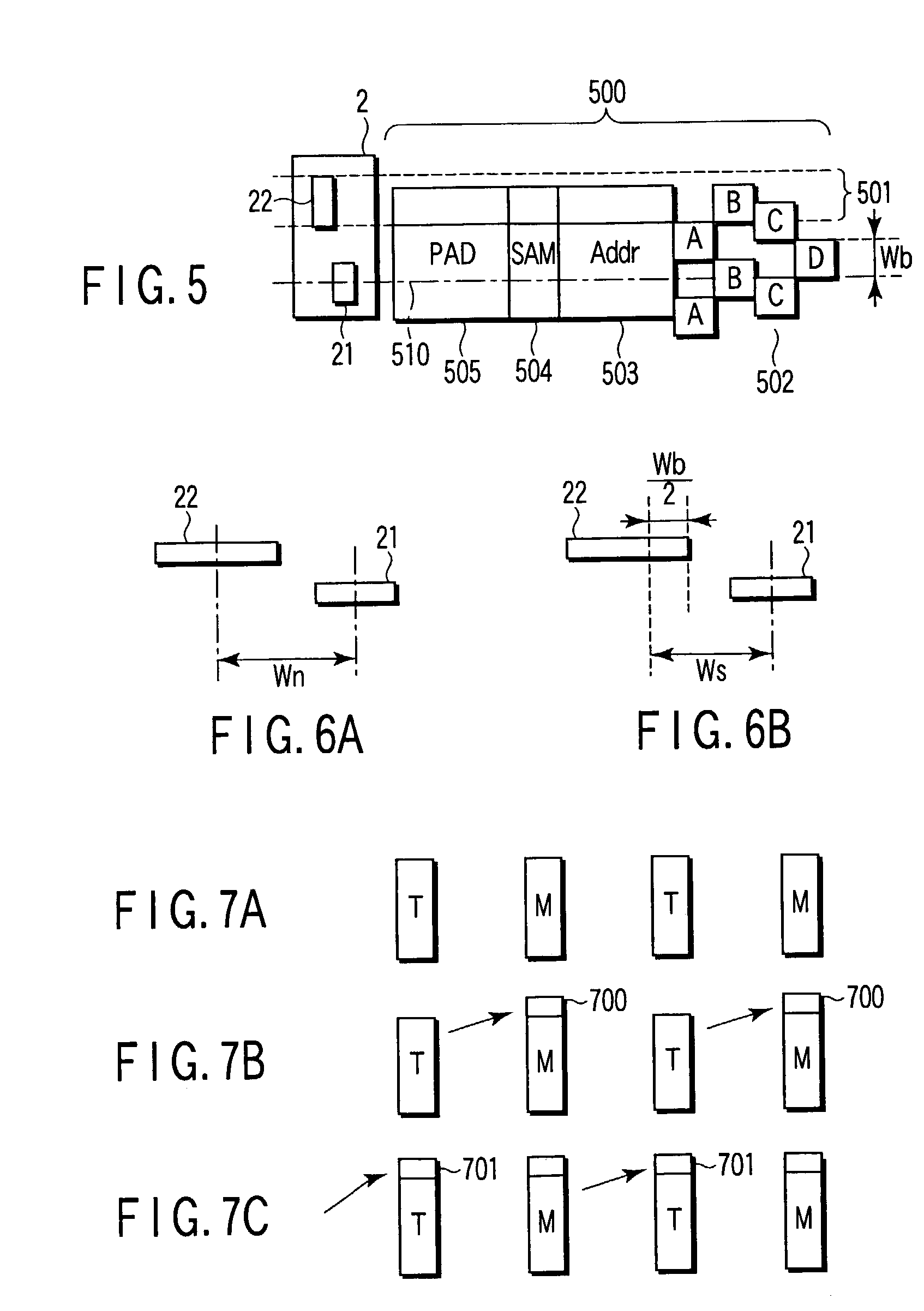

Method and apparatus for performing self-servo writing in a disk drive

InactiveUS7006322B2Correct position offsetTrack finding/aligningRecord information storageControl theory

Disclosed herein is a self-servo writing method that uses the head of a disk drive to write servo data on a disk-shaped medium. This method calculates an accurate position offset between the read-head element and write-head element incorporated in the head, by using the positioning servo data and measuring servo data that are recorded on the disk-shaped medium.

Owner:KK TOSHIBA

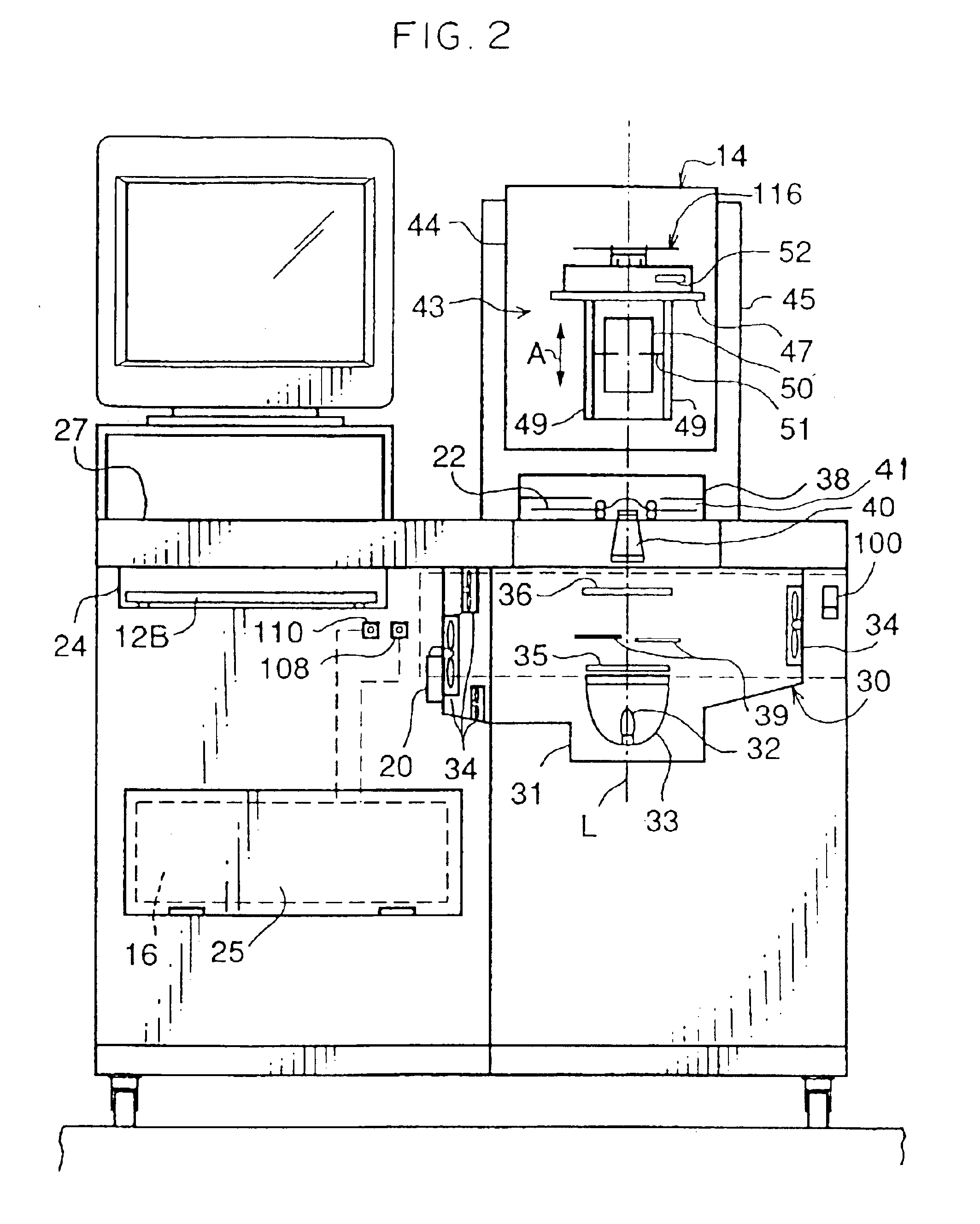

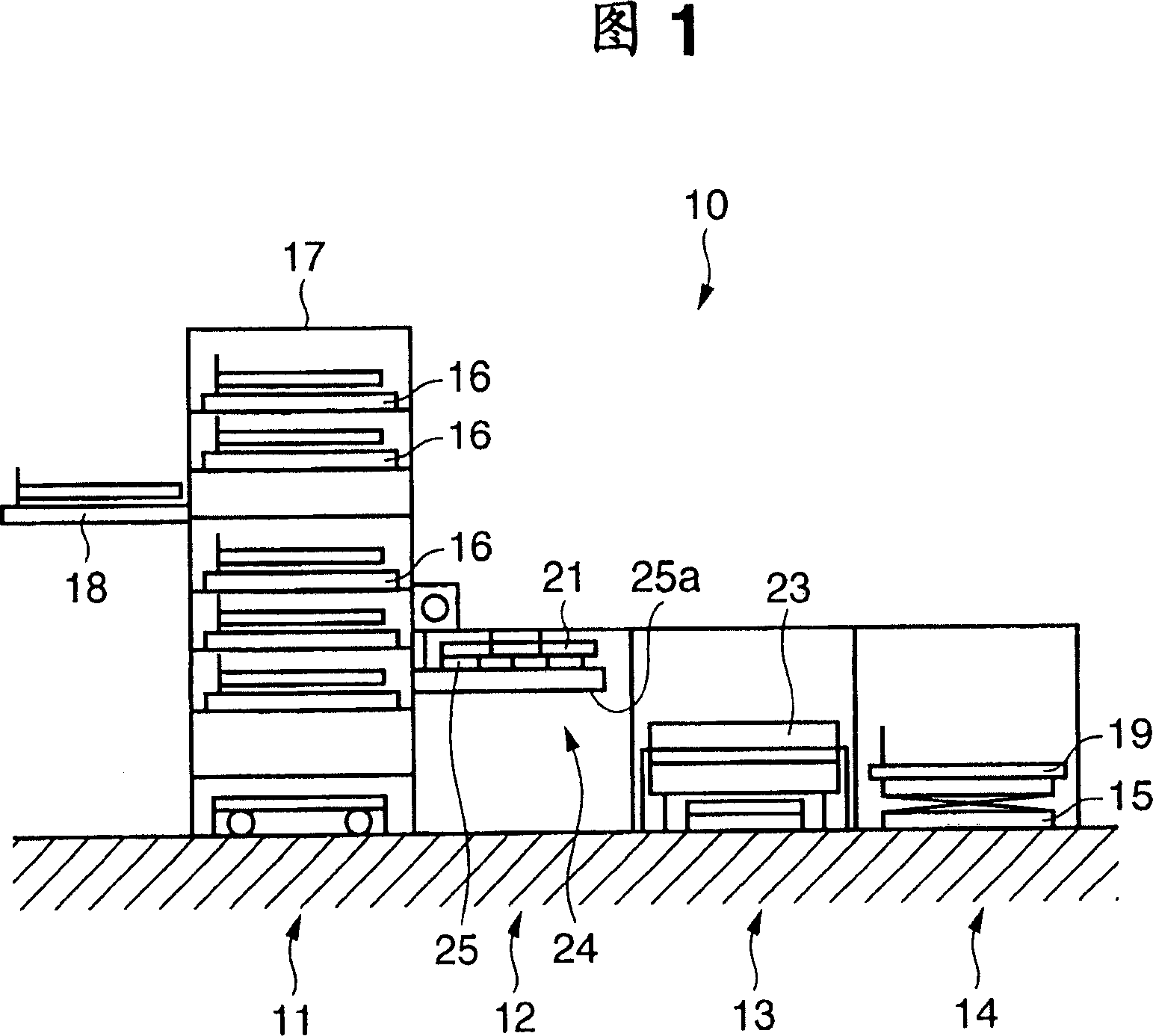

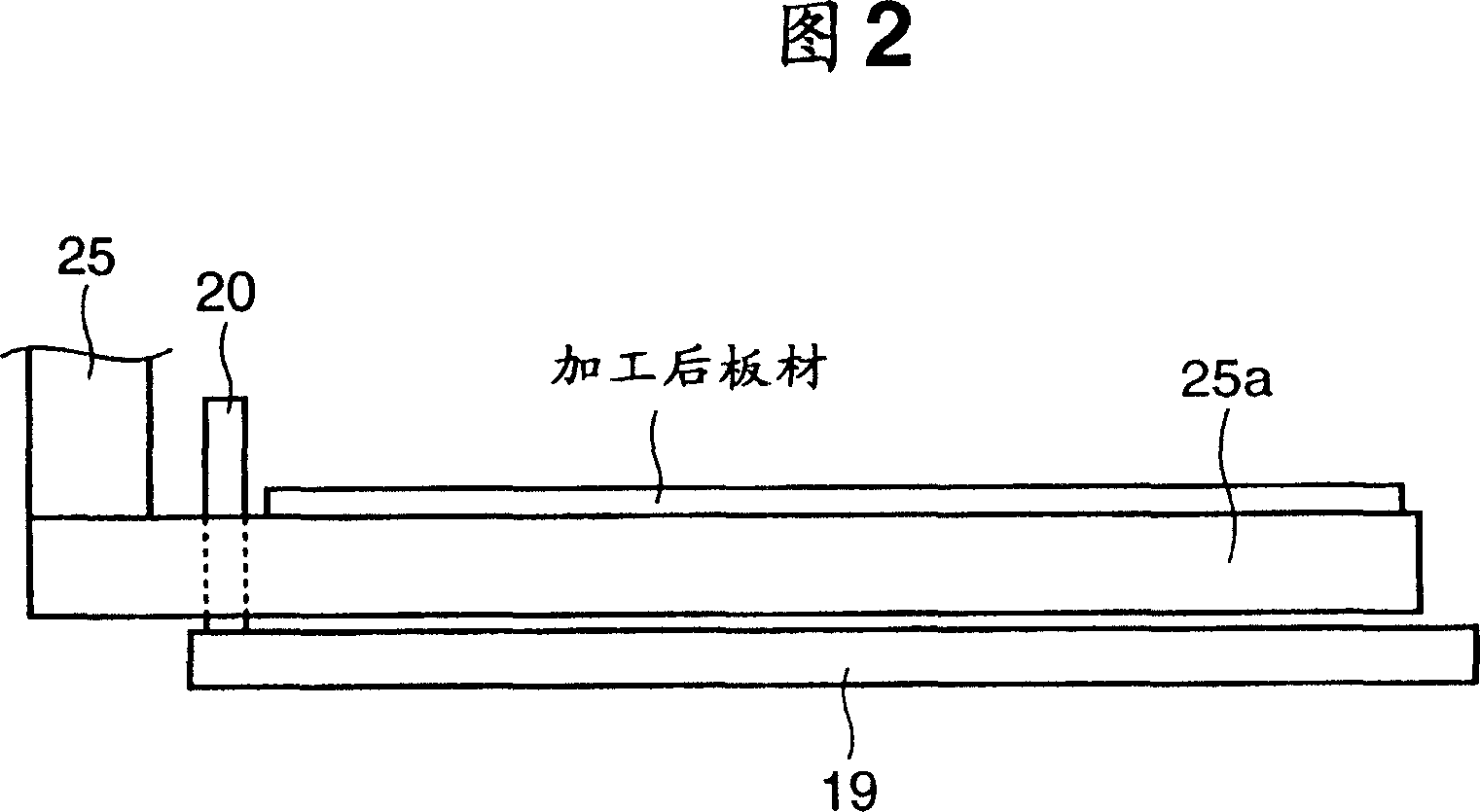

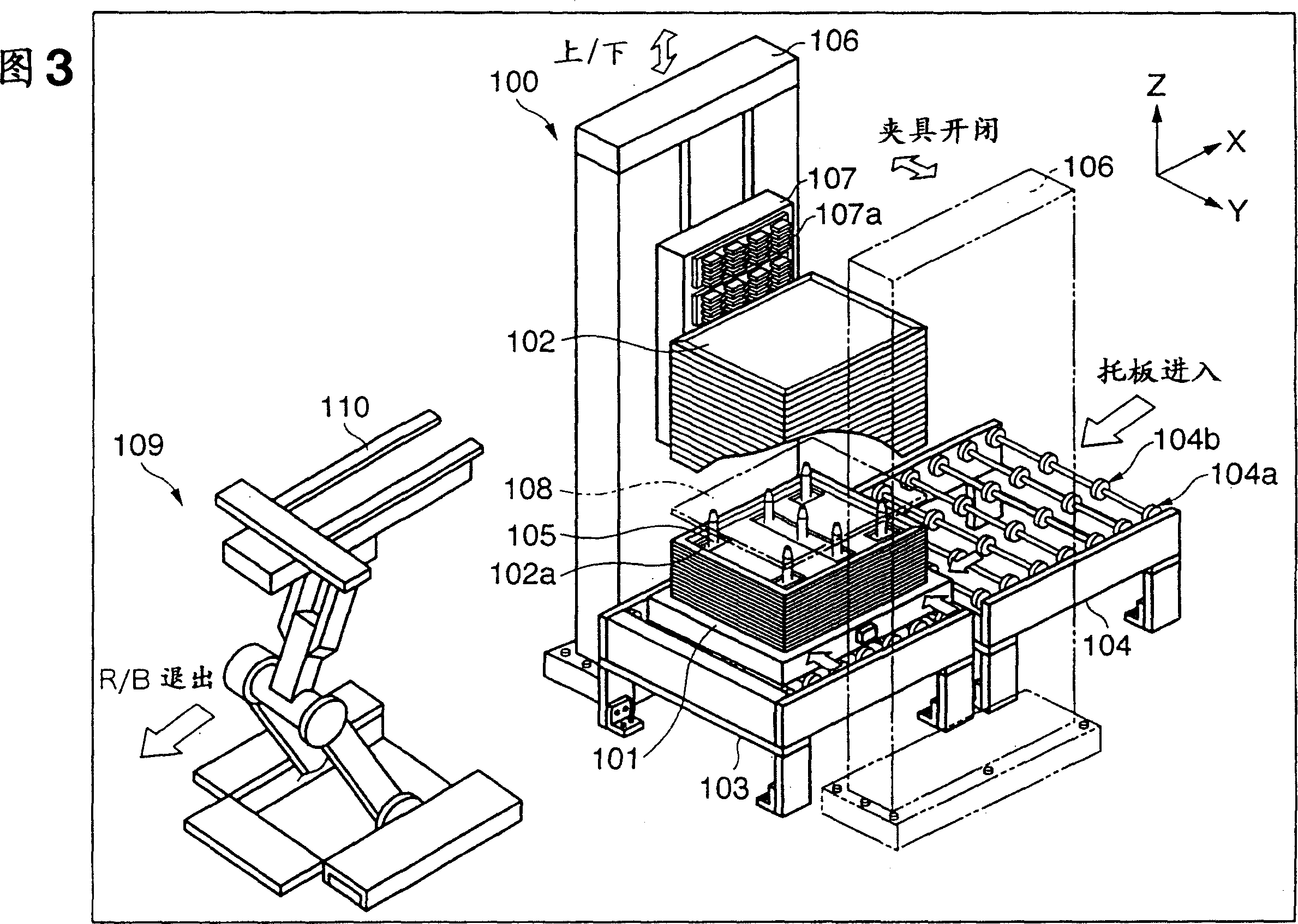

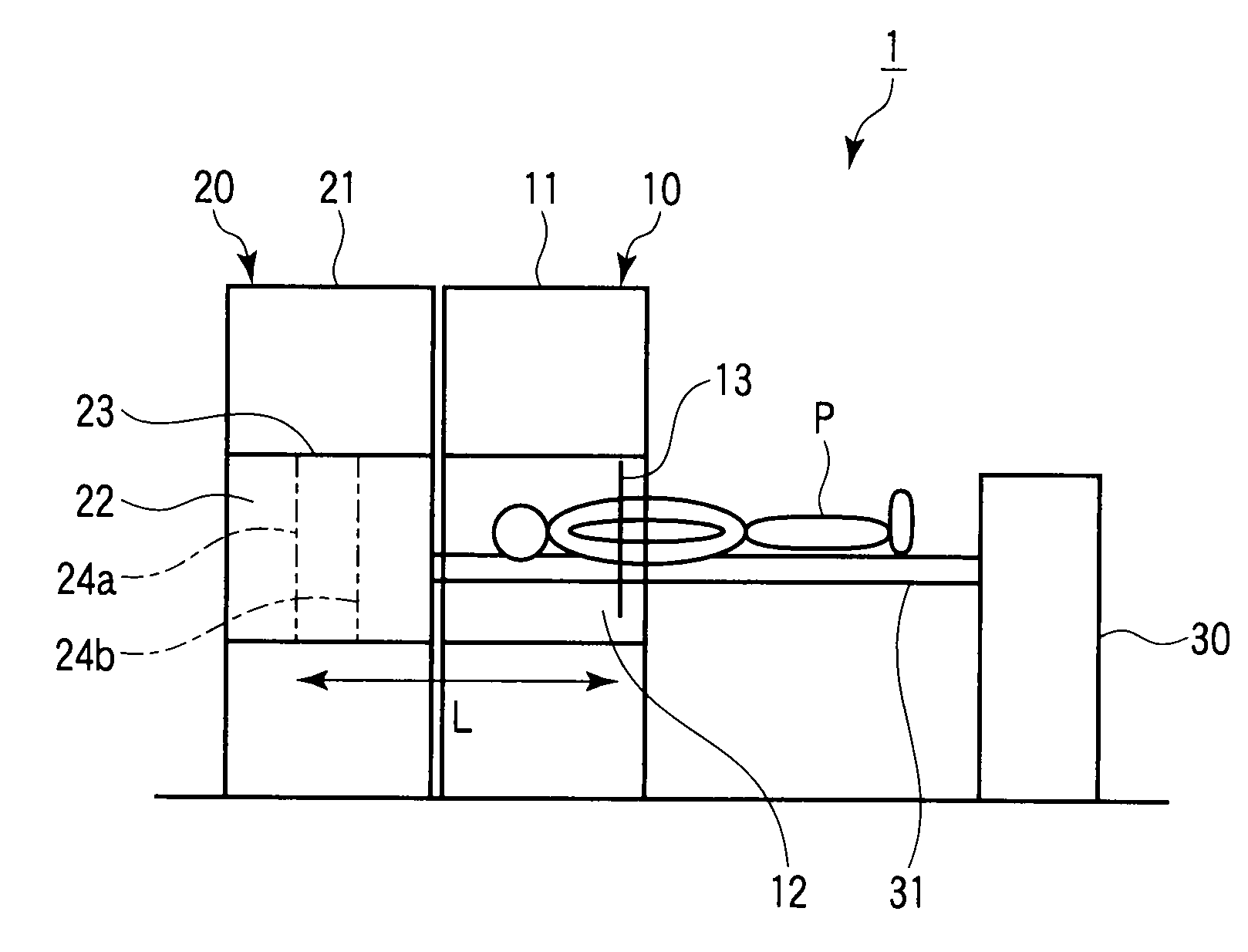

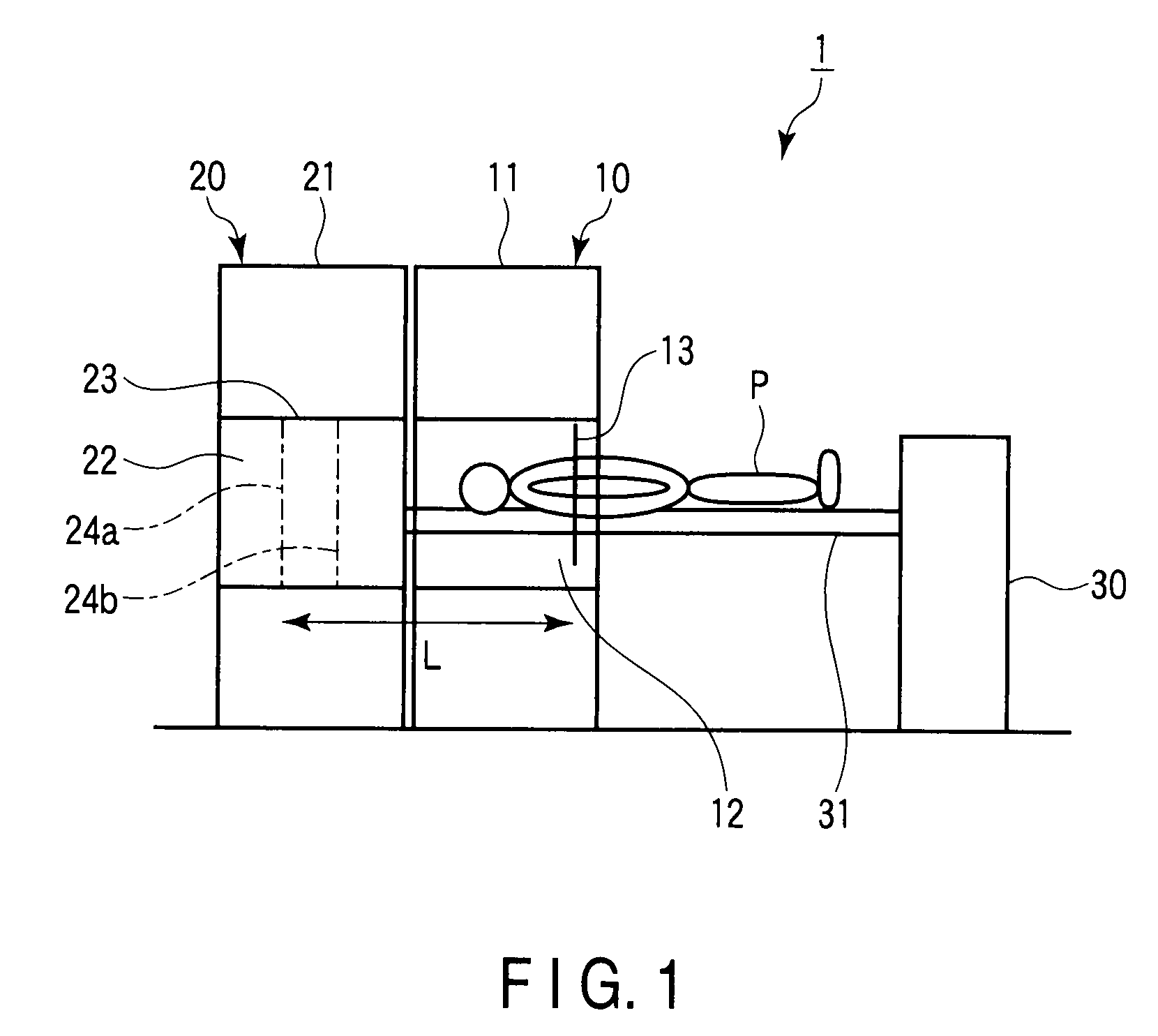

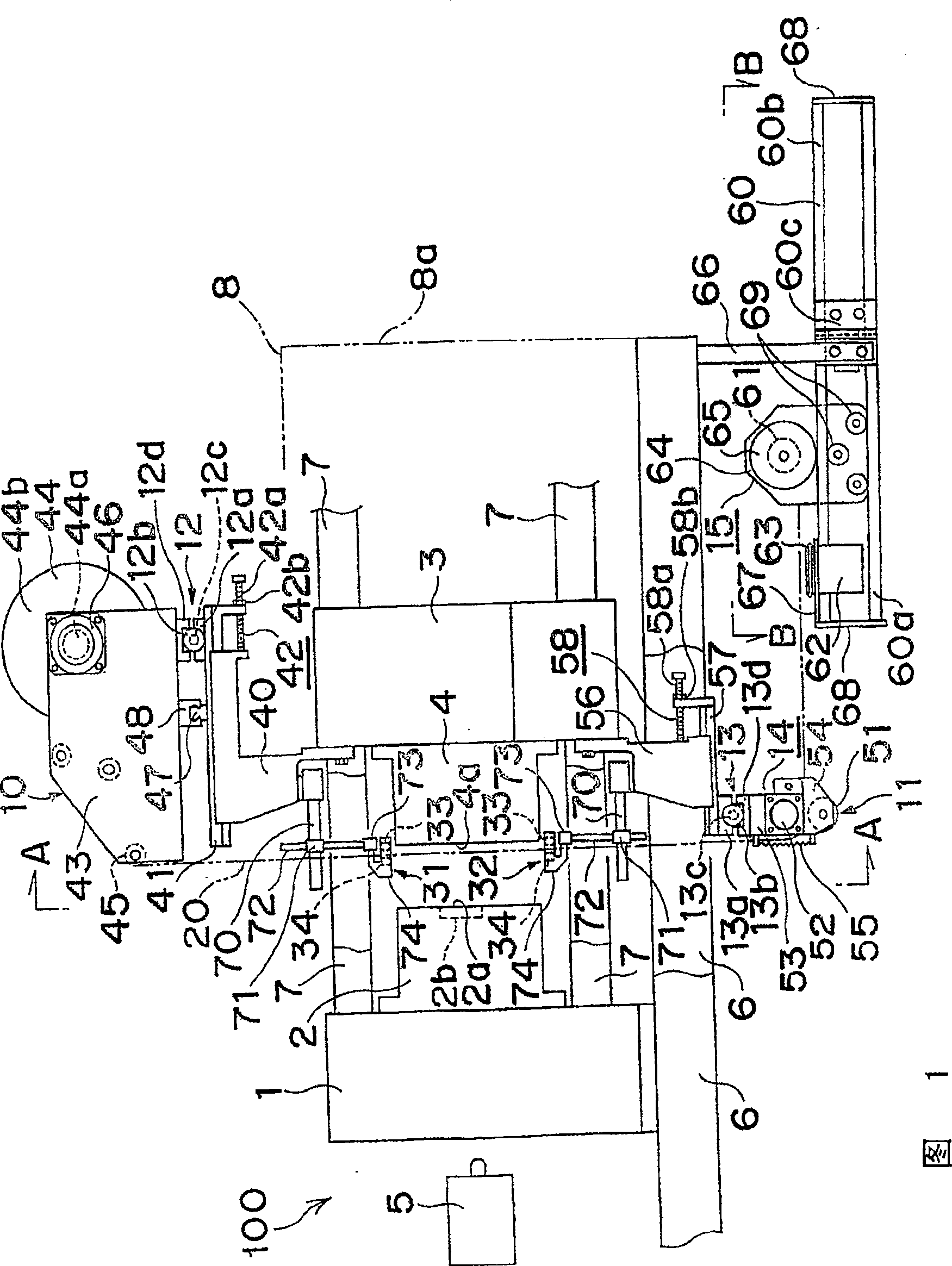

Base plate output-input device and base plate output-input method

InactiveCN1922087AEfficient loadingTake it out smoothlySemiconductor/solid-state device manufacturingCharge manipulationEngineeringPallet

A substrate carrying in / out device (100) and a substrate carrying in / out method for taking out a substrate from a tray or storing the substrate in the tray, the method comprising the steps of positioning a pallet (101) at a specified position on a conveyor (103), holding and lifting the untreated trays located on the upper stage of the treated tray among the multiple stages of trays (102) placed on the pallet by a tray chuck (107), and allowing lift pins (105) to pass lift pin pass holes (102a) formed in the pallet and the tray while the untreated trays are raised and a sufficient space is secured above the treated tray so that the operation of the lift pins can be controlled such that the tips of the lift pins can be separated a specified distance from the treated tray. Thus the substrate (108) can be carried in and out.

Owner:HIRATA & CO LTD

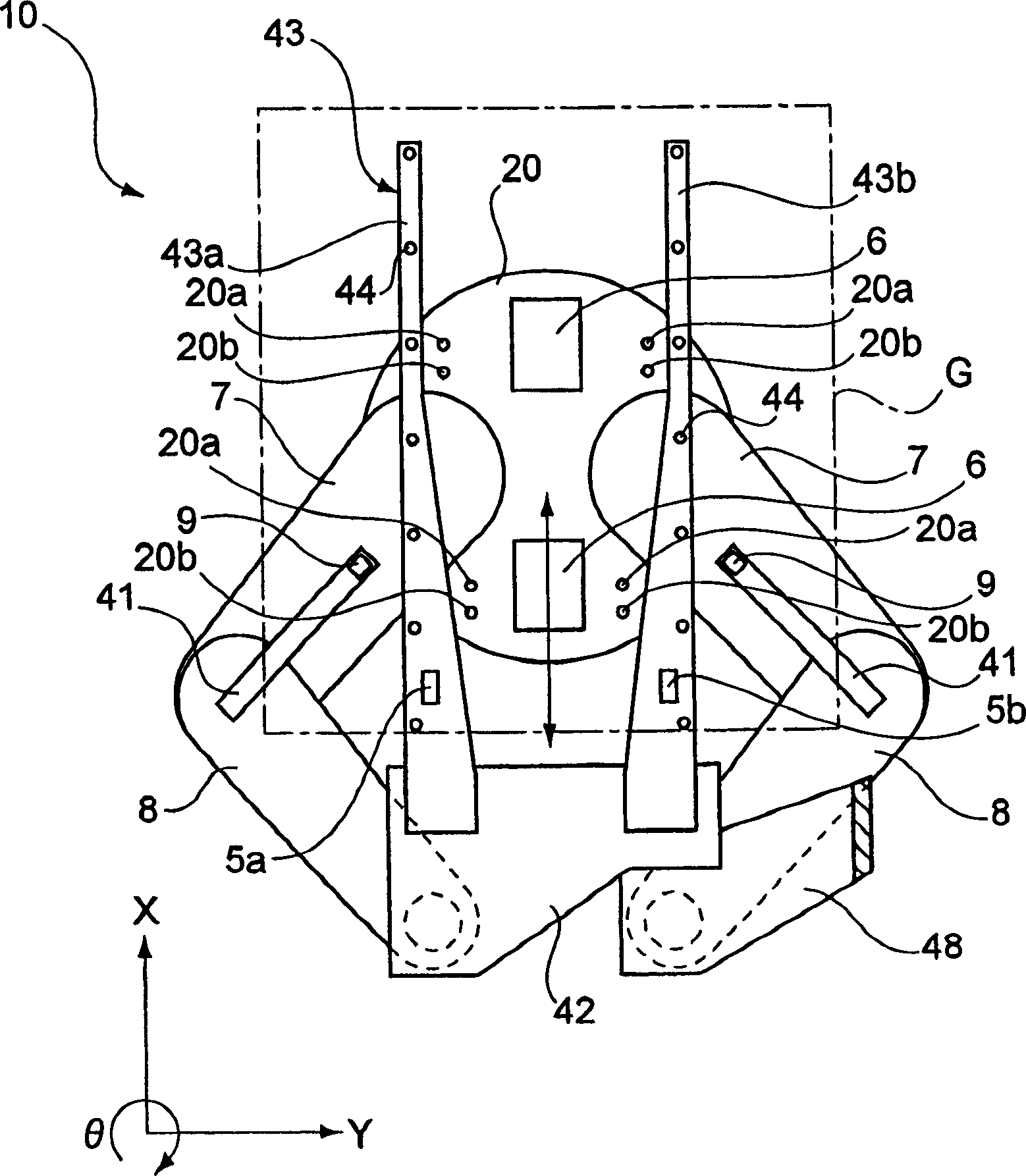

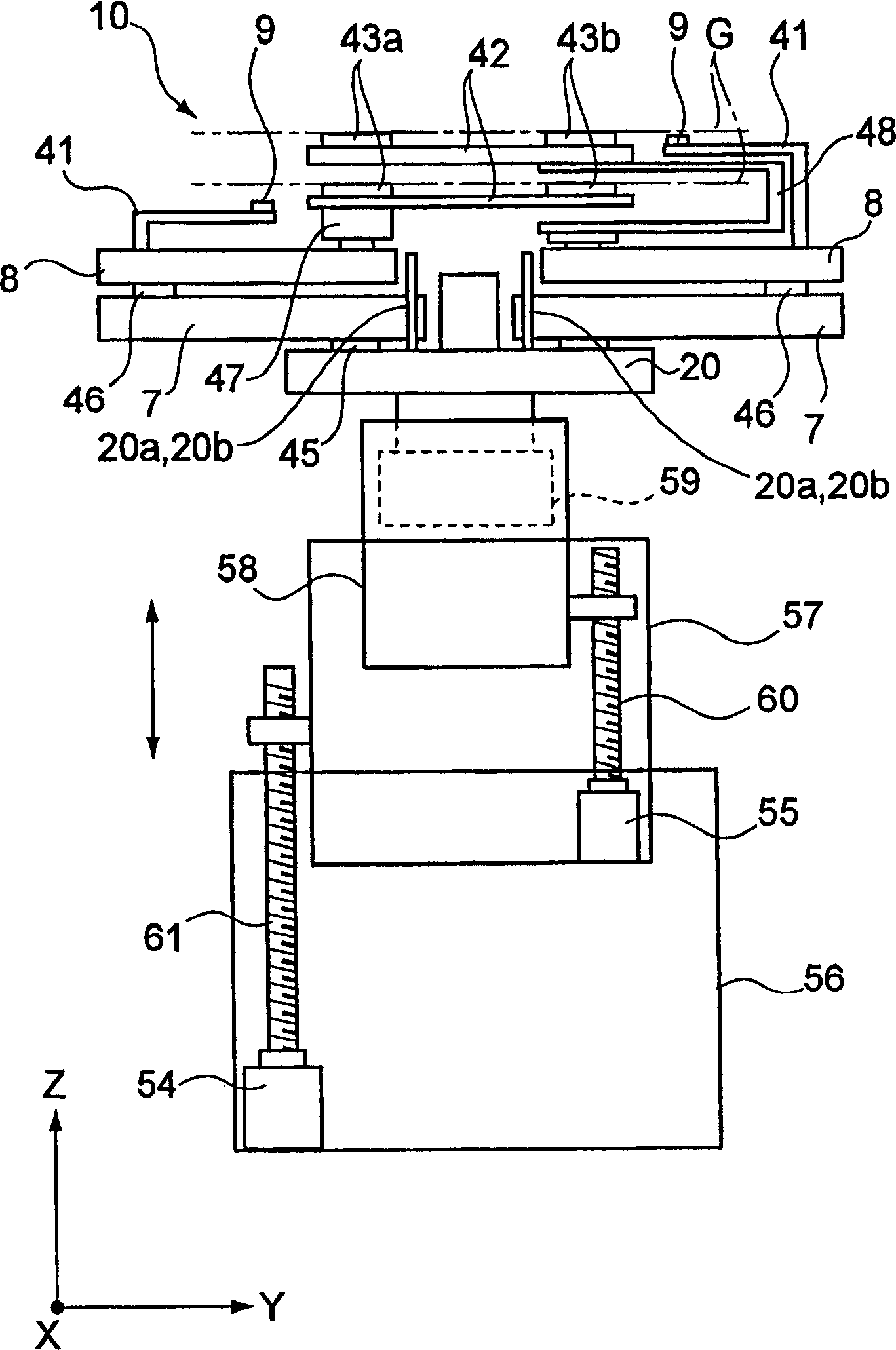

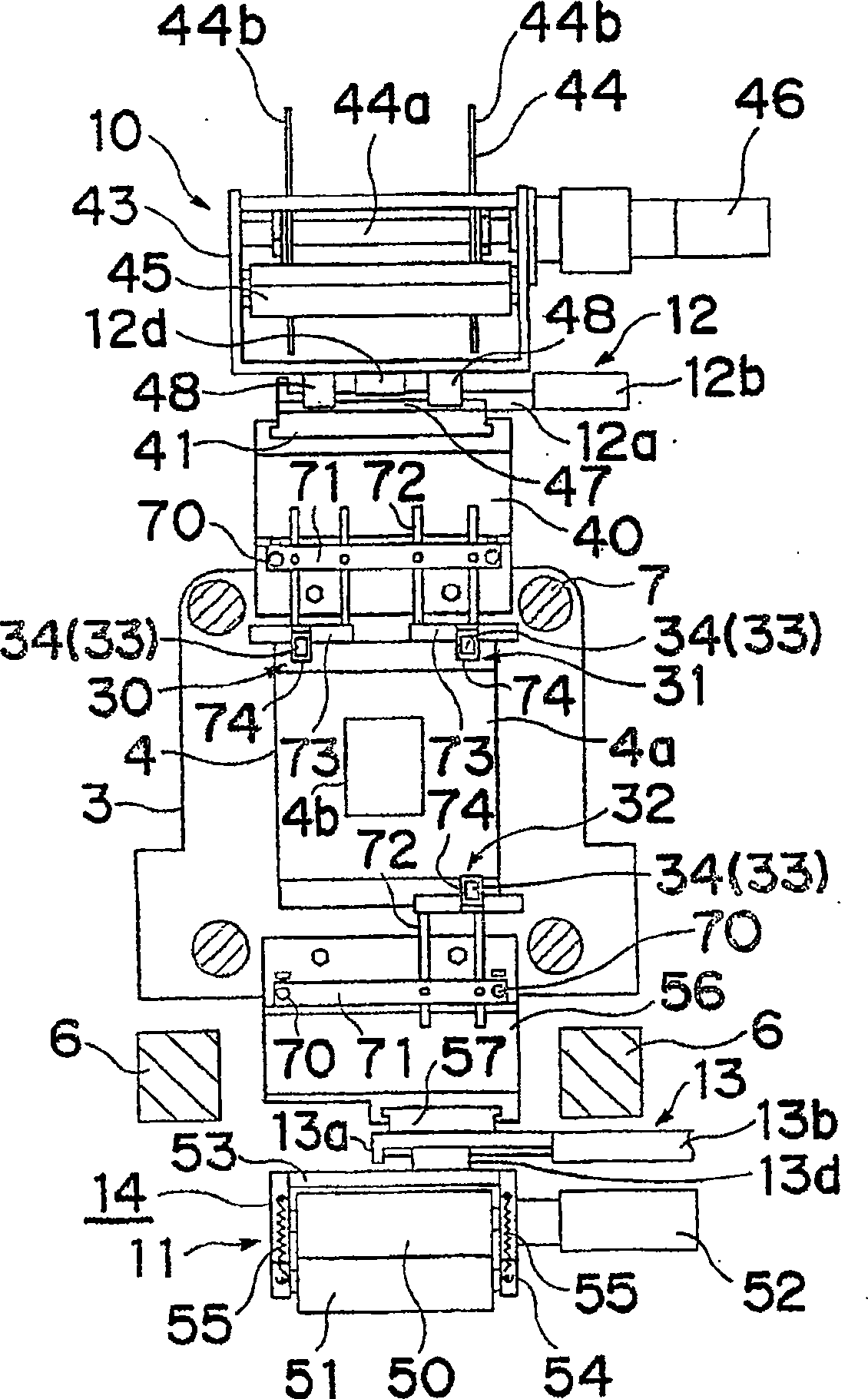

Base board transporting device, base board processing system and base board transporting method

InactiveCN1405839AAccurate detectionCorrect position offsetStatic indicating devicesSemiconductor/solid-state device manufacturingPulse numberPerpendicular direction

When a small pliers is pulled out to take substrate G from the cartridge C, the sensor 9 located at position P will draw a track T to move one side passing through one side(Ga) of substrate G. Thus, the position for having a perpendicular direction (Y direction) between the held substrate G and the moving forward / backward direction of small pliers 43 can be calculated from the timing of the subjected reflection light, which is obtained when the sensor 9 moves to pass through one side Ga, and the rotation pulse number of motor 6. Therefore, the shift can be detected by comparing with the timing when held at the normal position of small pliers 43.

Owner:TOKYO ELECTRON LTD

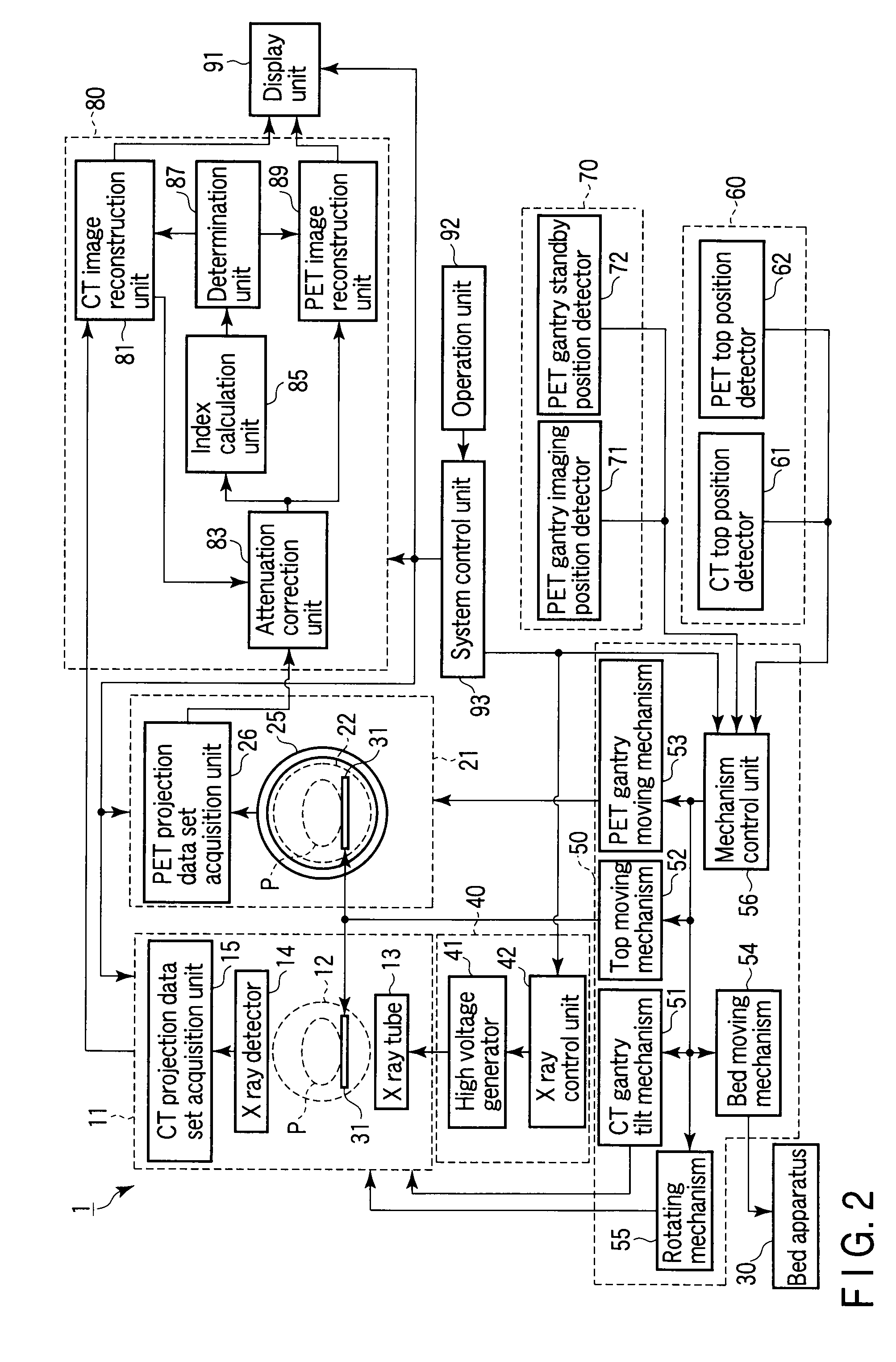

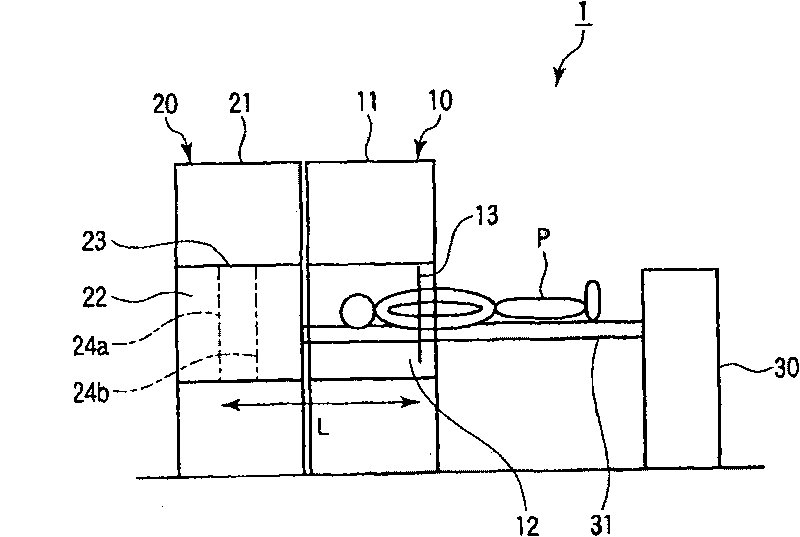

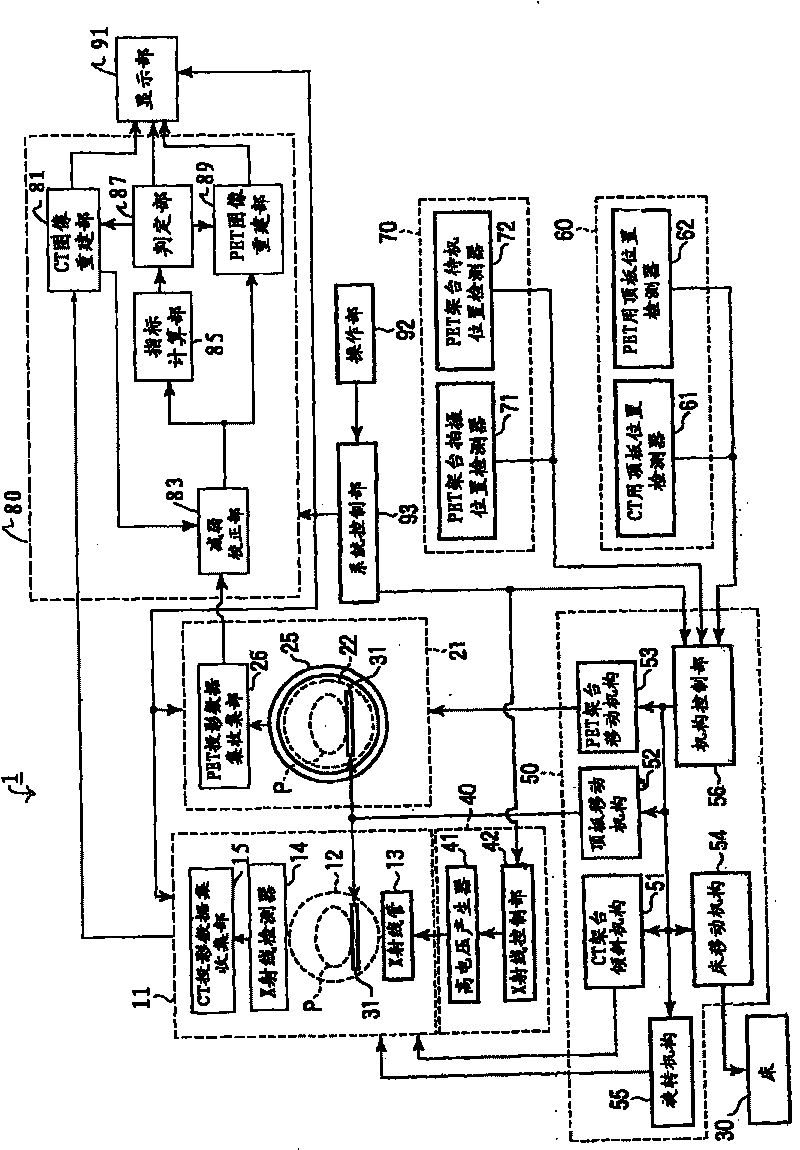

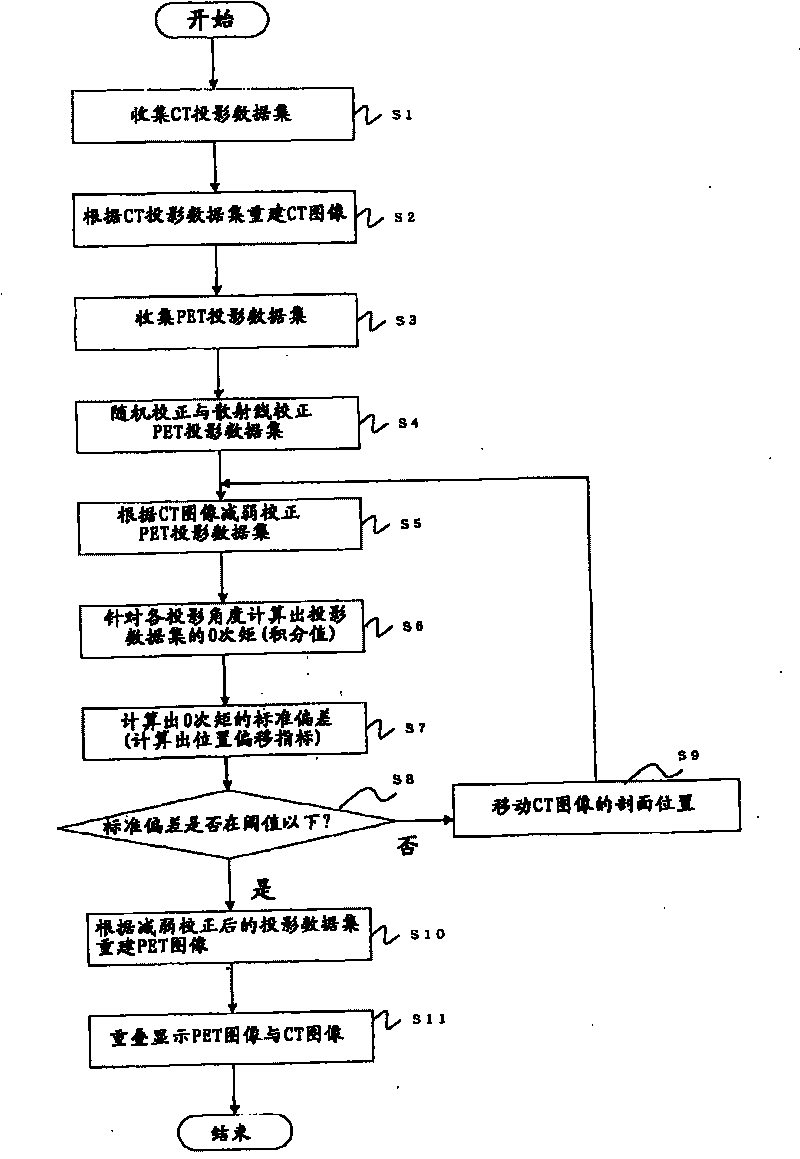

Image diagnosis apparatus and image diagnosis method

InactiveUS20100158336A1Correct position offsetReconstruction from projectionCharacter and pattern recognitionUltrasound attenuationImage diagnosis

A detector detects gamma-rays emitted from inside an imaging region. An acquisition unit acquires a plurality of first projection data sets associated with a plurality of projection angles via the detector. An attenuation-correction unit attenuation-correct the plurality of first projection data sets based on a first CT image associated with the imaging region to generate a plurality of second projection data sets associated with the plurality of projection angles. An index calculation unit calculates an index based on the plurality of second projection data sets. The index is corresponding to a degree of positional offset between the imaging region at the time of acquisition of a plurality of third projection data sets associated with the first CT image and the imaging region at the time of acquisition of the plurality of first projection data sets.

Owner:KK TOSHIBA +1

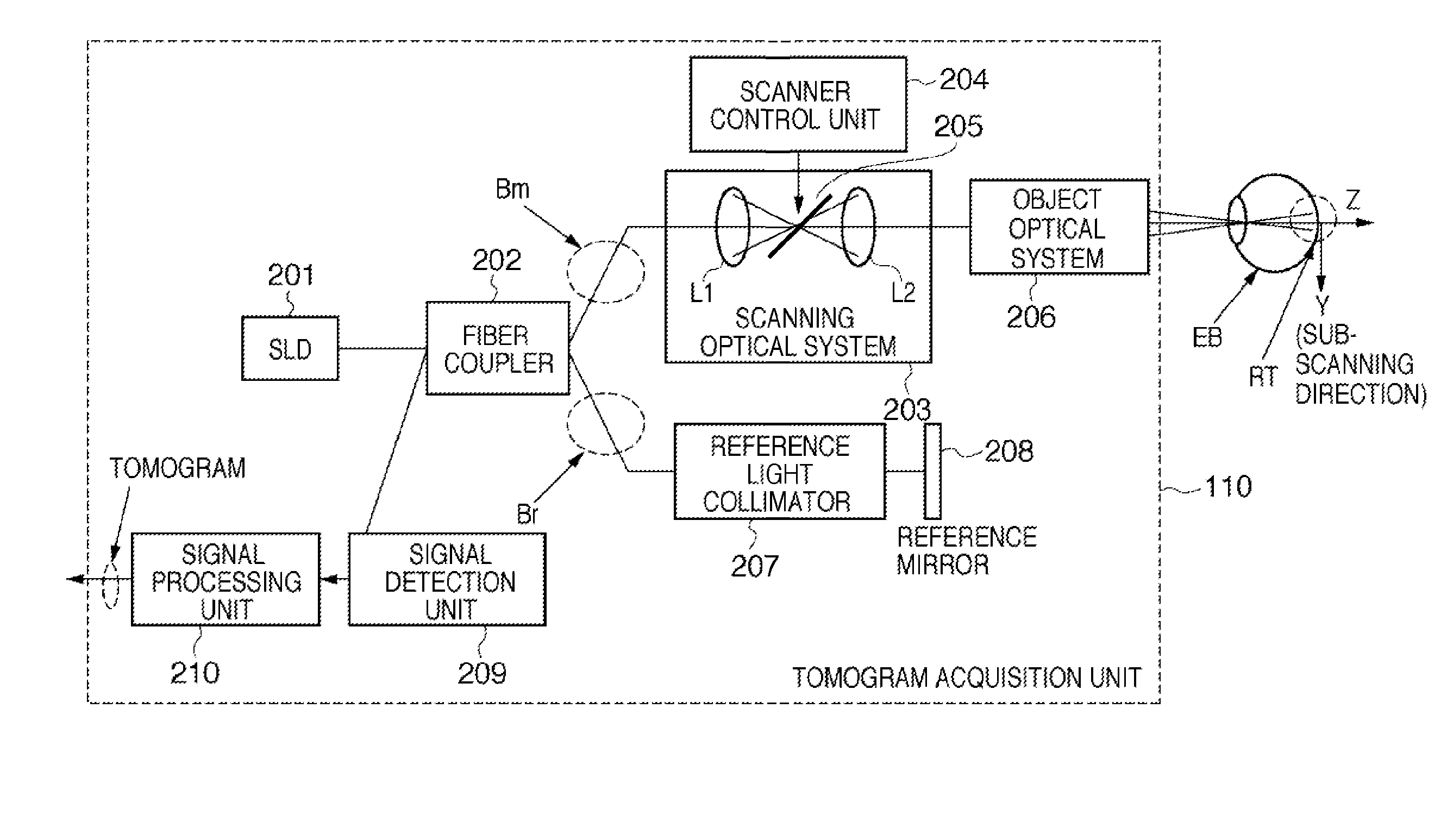

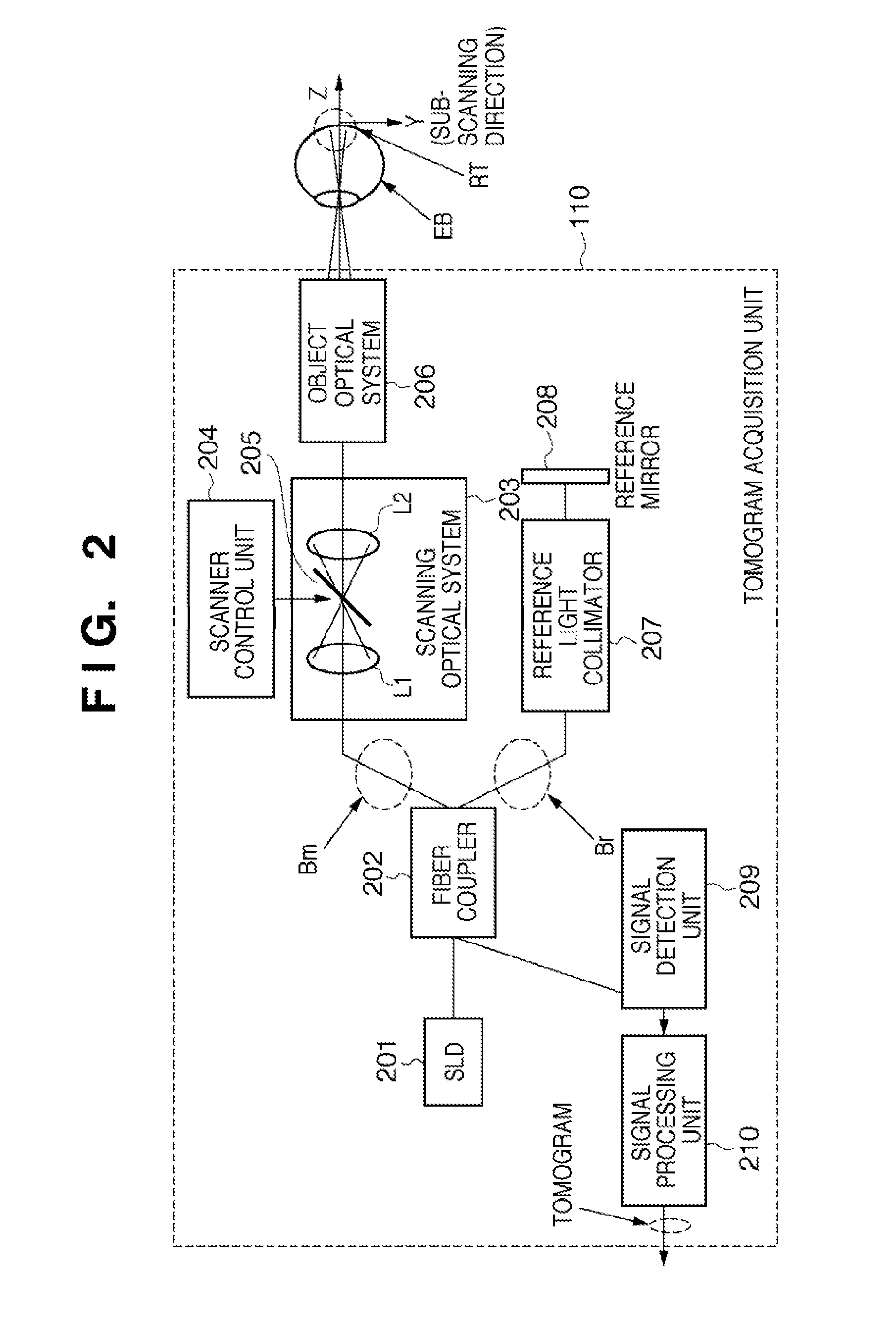

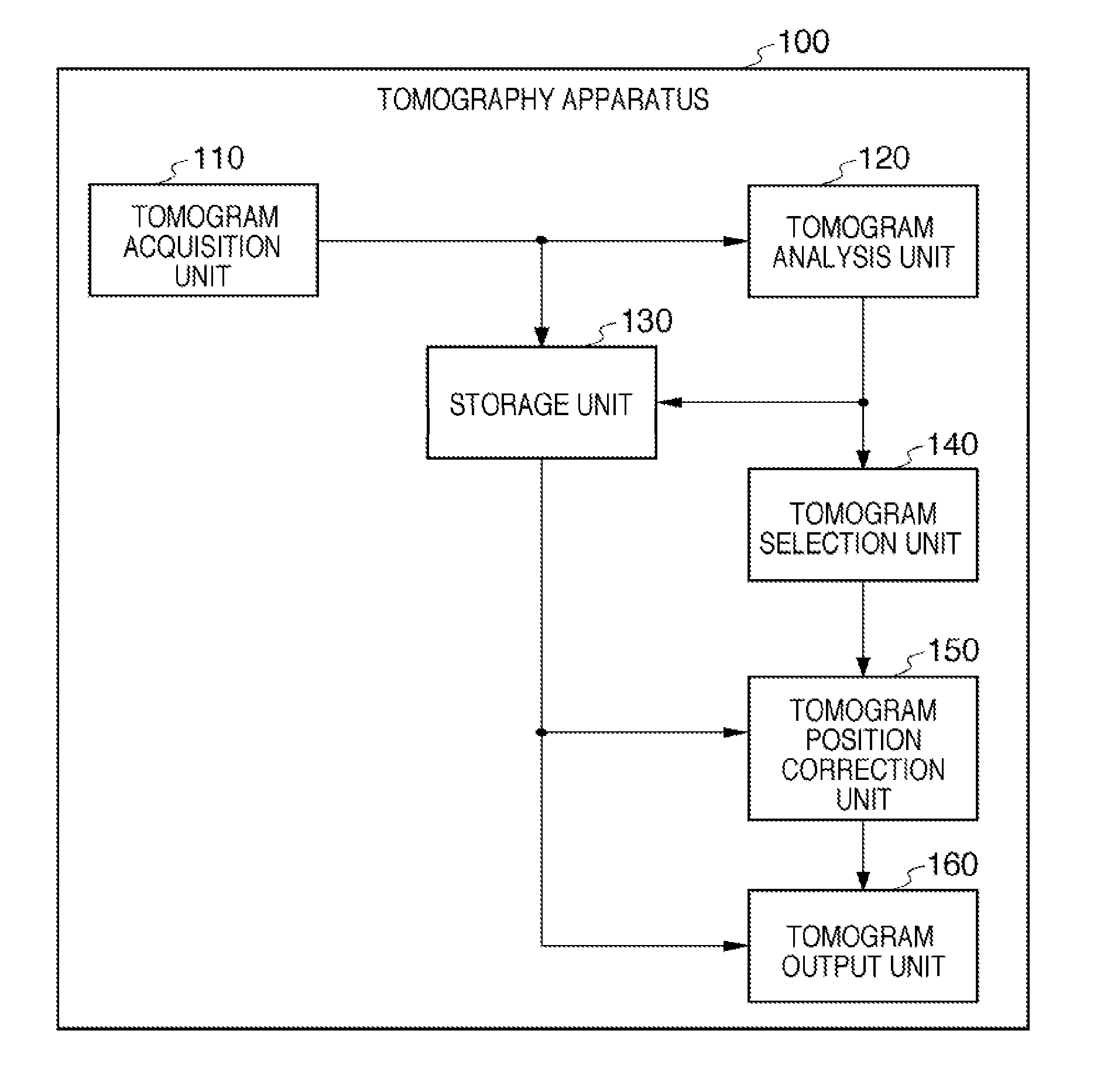

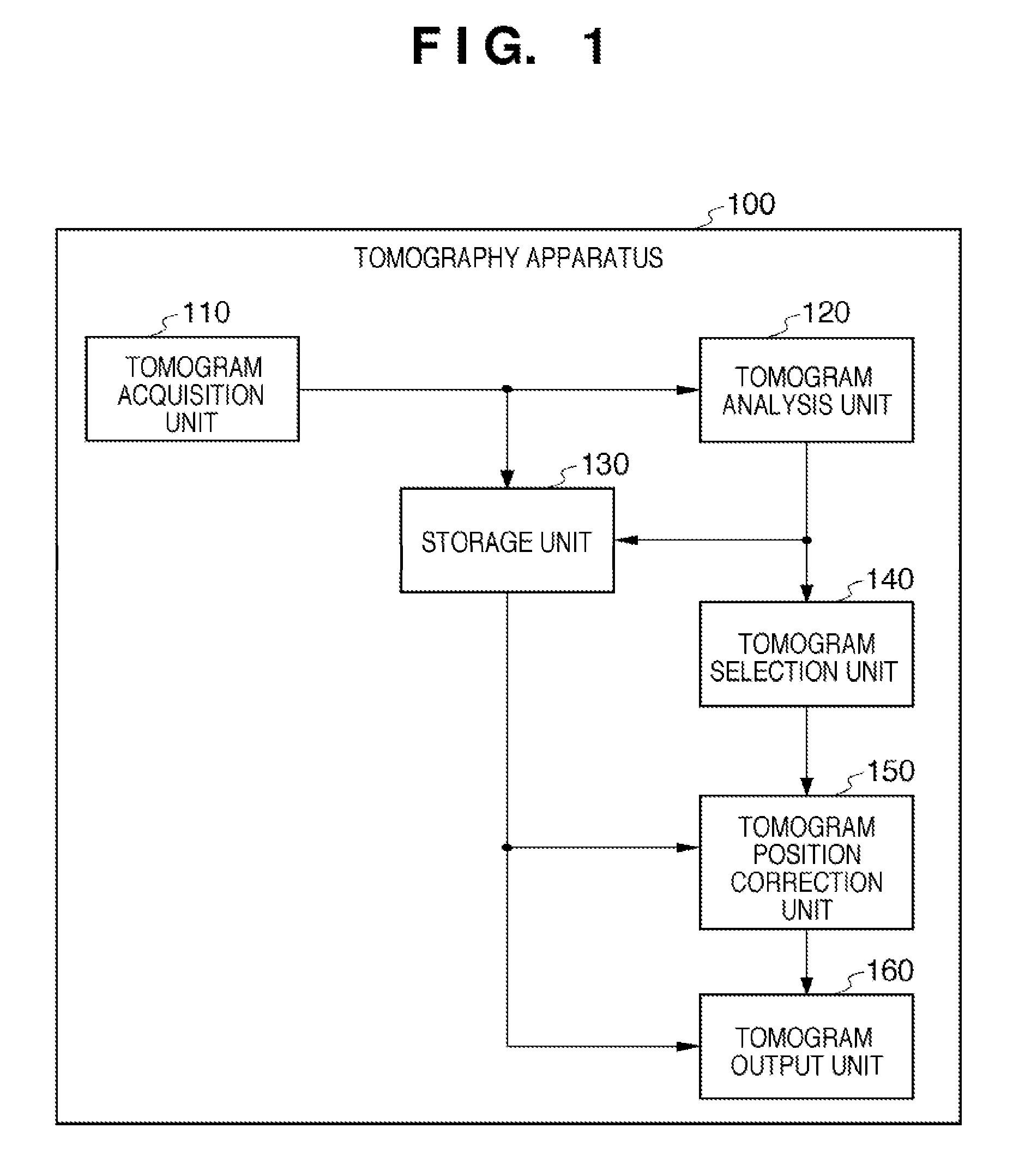

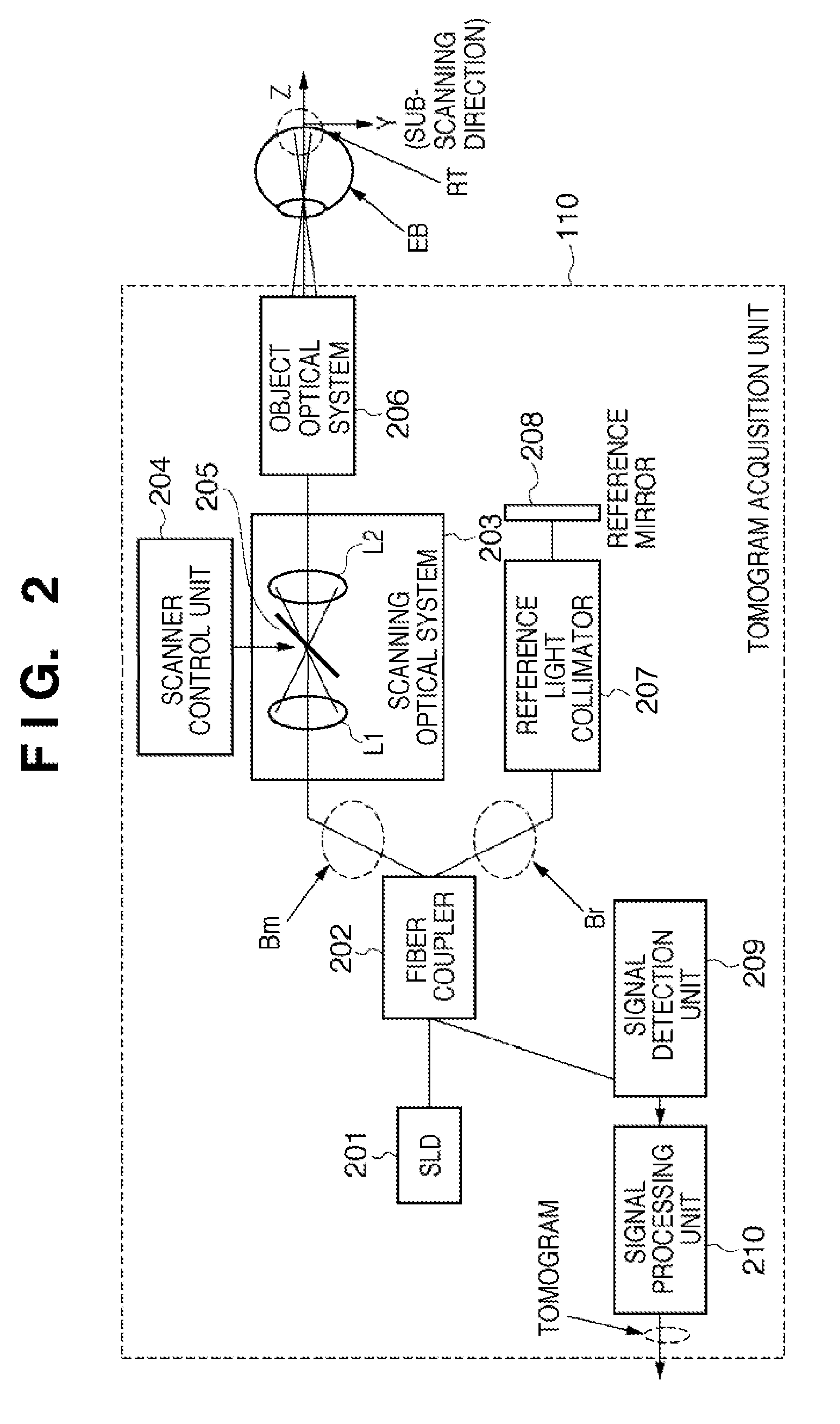

Tomography apparatus and tomogram correction processing method

InactiveUS20120075640A1Accurate positional offset correctionCorrect position offsetUsing optical meansEye diagnosticsTomographyTomographic image

This invention realizes accurate positional offset correction between a plurality of tomograms captured by using a tomography apparatus. The invention is a tomography apparatus which corrects the positional offsets between a plurality of two-dimensional tomograms constituting a three-dimensional tomogram. This apparatus includes a tomogram analysis unit (120) which extracts feature amounts representing the tissue of a measurement target, a tomogram selection unit (140) which selects a standard two-dimensional tomogram from the plurality of two-dimensional tomograms based on the feature amounts, and a tomogram position correction unit (150) which calculates the positional offset amount between the nth two-dimensional tomogram adjacent to the standard two-dimensional tomogram and the (n−1)th two-dimensional tomogram.

Owner:CANON KK

Image diagnosis apparatus and image diagnosis method

ActiveCN101756698AHigh precision position offsetCorrect position offsetReconstruction from projectionComputerised tomographsUltrasound attenuationData set

A detector detects gamma-rays emitted from inside an imaging region. An acquisition unit acquires a plurality of first projection data sets associated with a plurality of projection angles via the detector. An attenuation-correction unit attenuation-correct the plurality of first projection data sets based on a first CT image associated with the imaging region to generate a plurality of second projection data sets associated with the plurality of projection angles. An index calculation unit calculates an index based on the plurality of second projection data sets. The index is corresponding to a degree of positional offset between the imaging region at the time of acquisition of a plurality of third projection data sets associated with the first CT image and the imaging region at the time of acquisition of the plurality of first projection data sets.

Owner:TOSHIBA MEDICAL SYST CORP

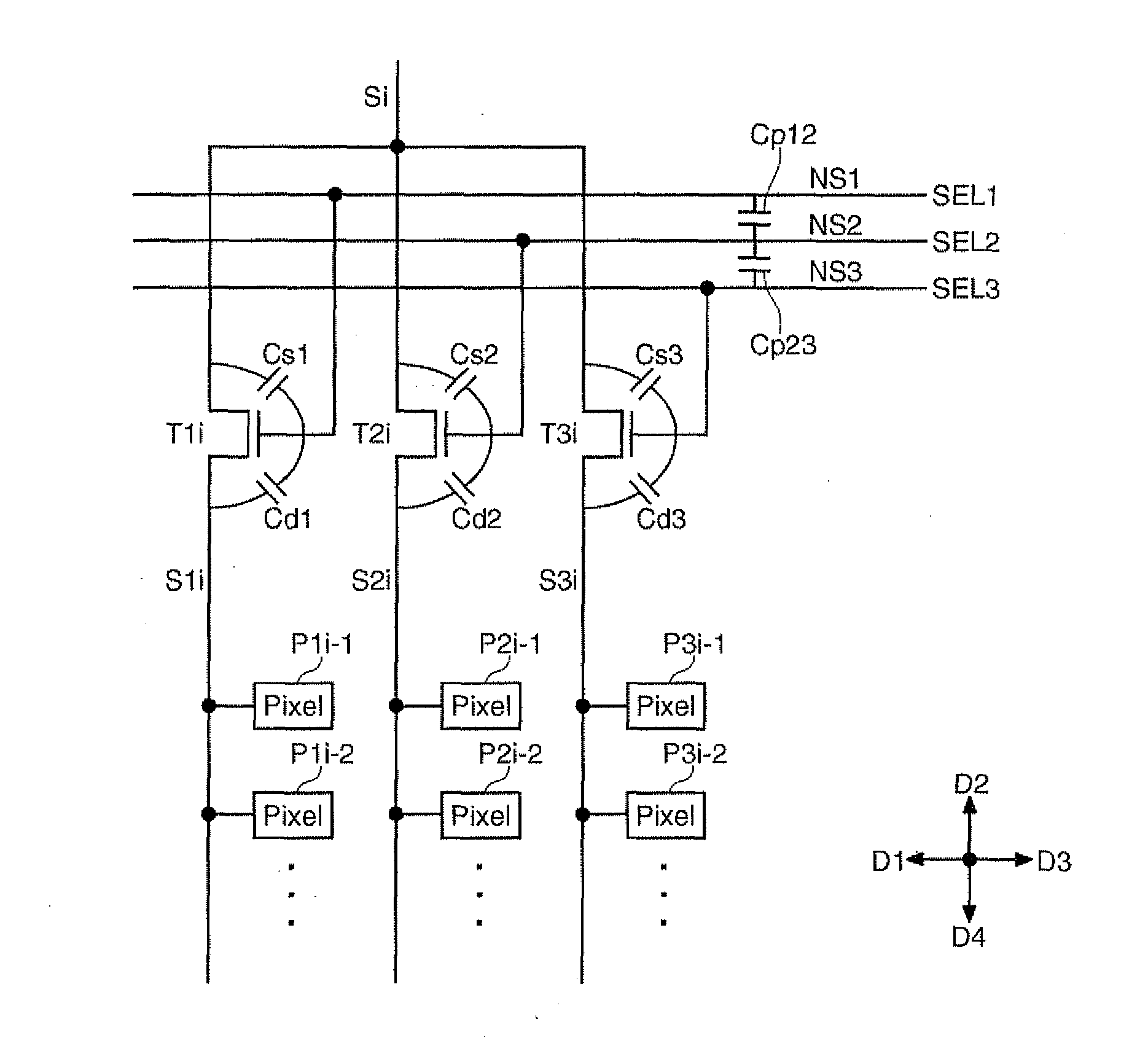

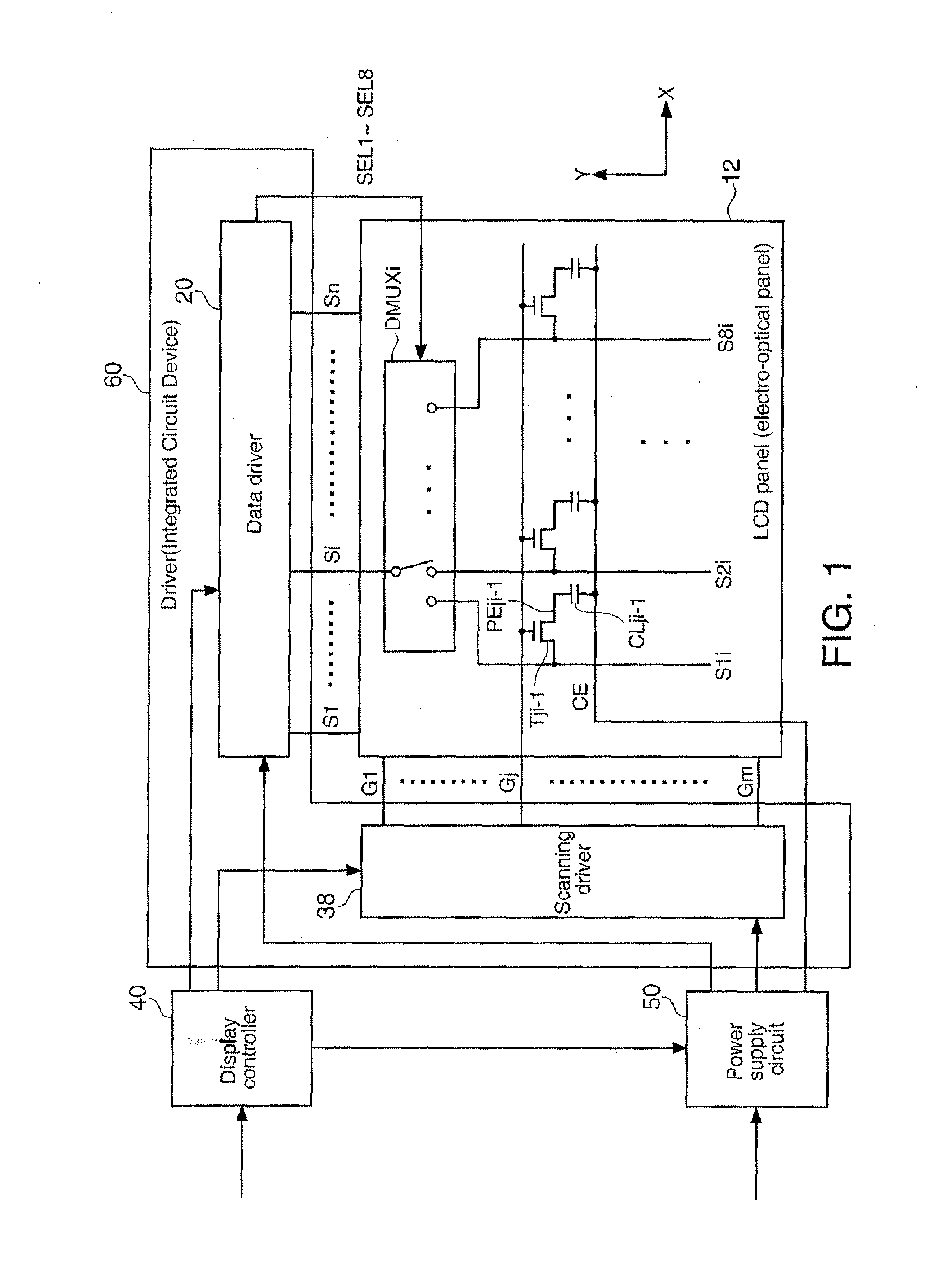

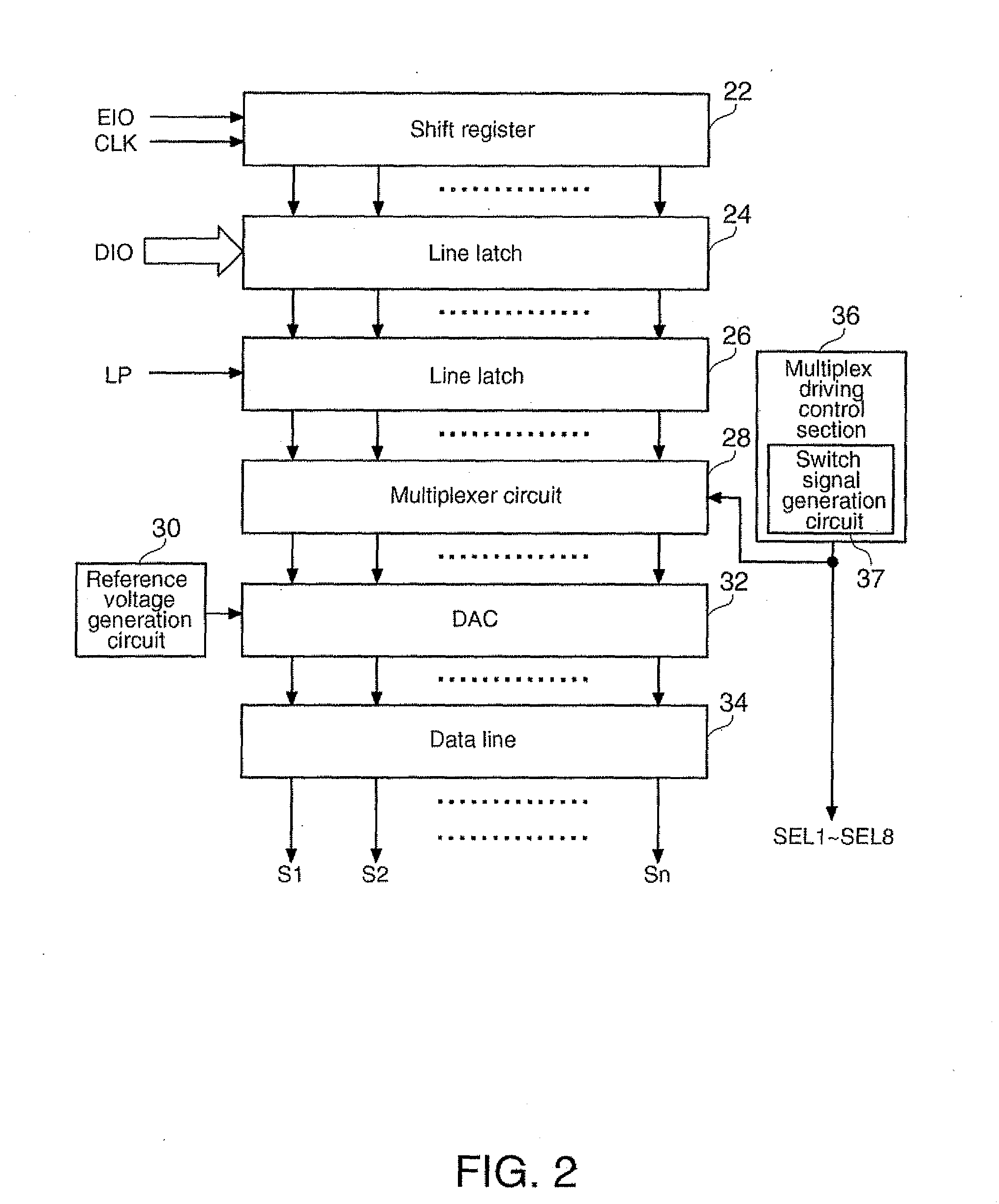

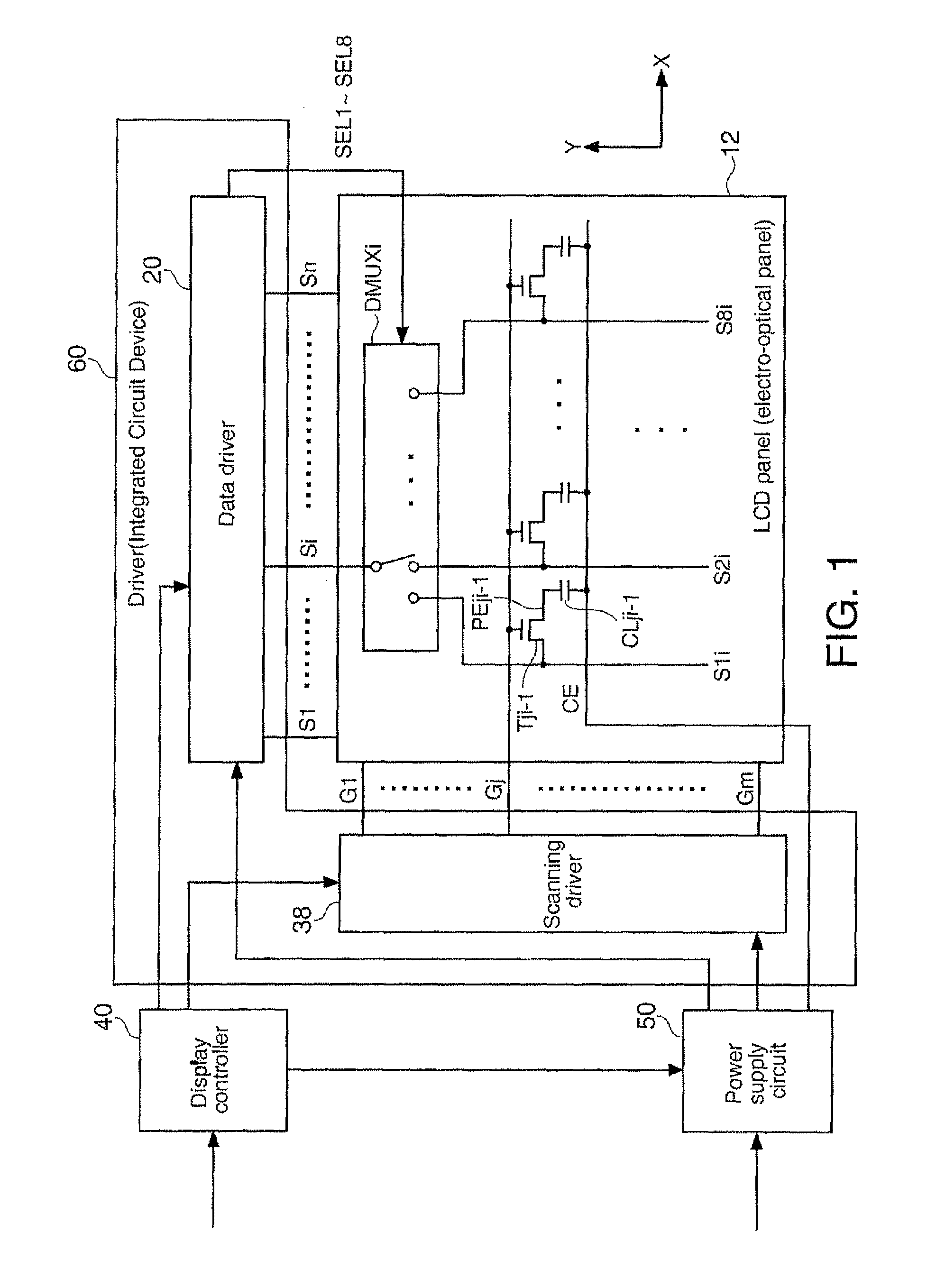

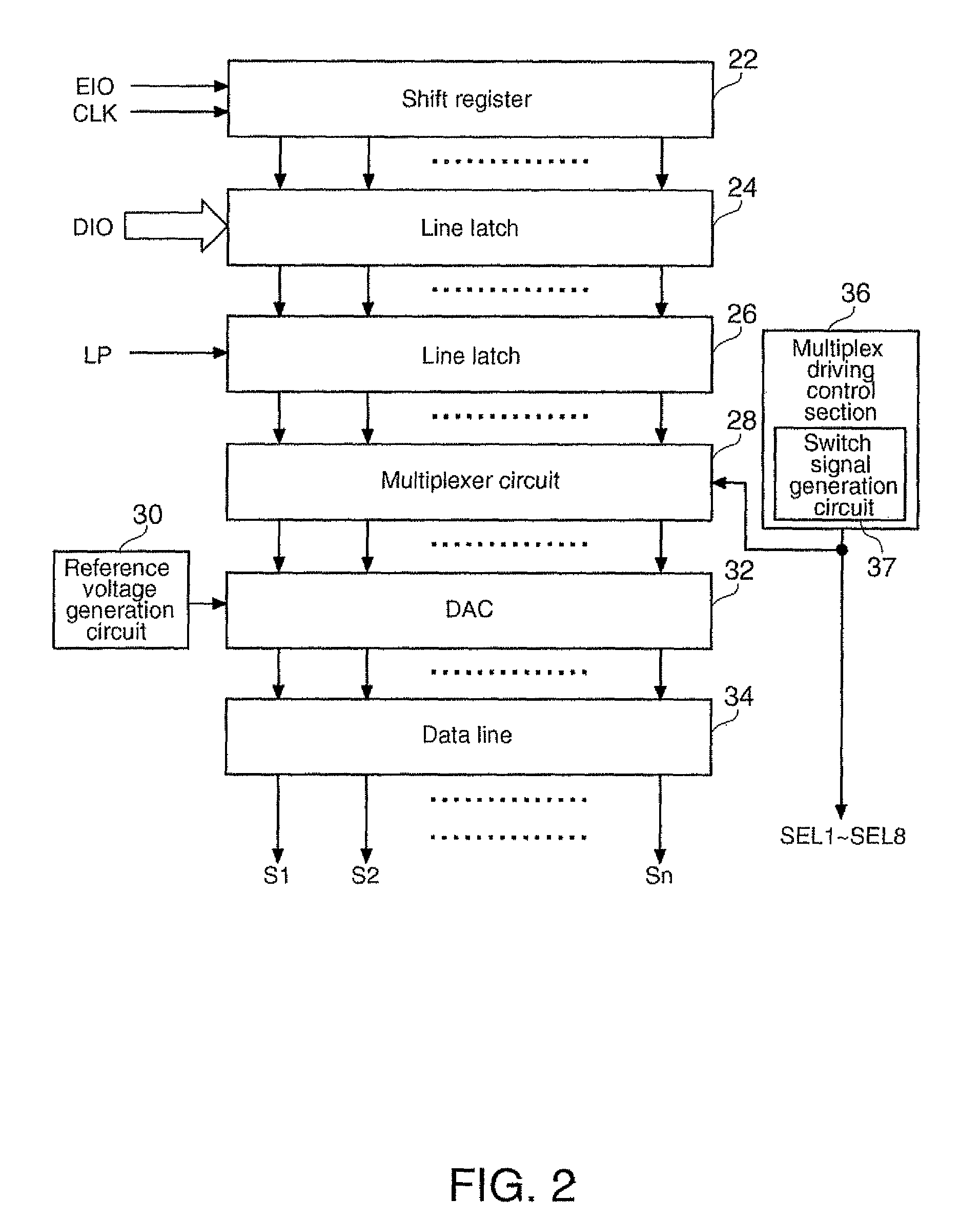

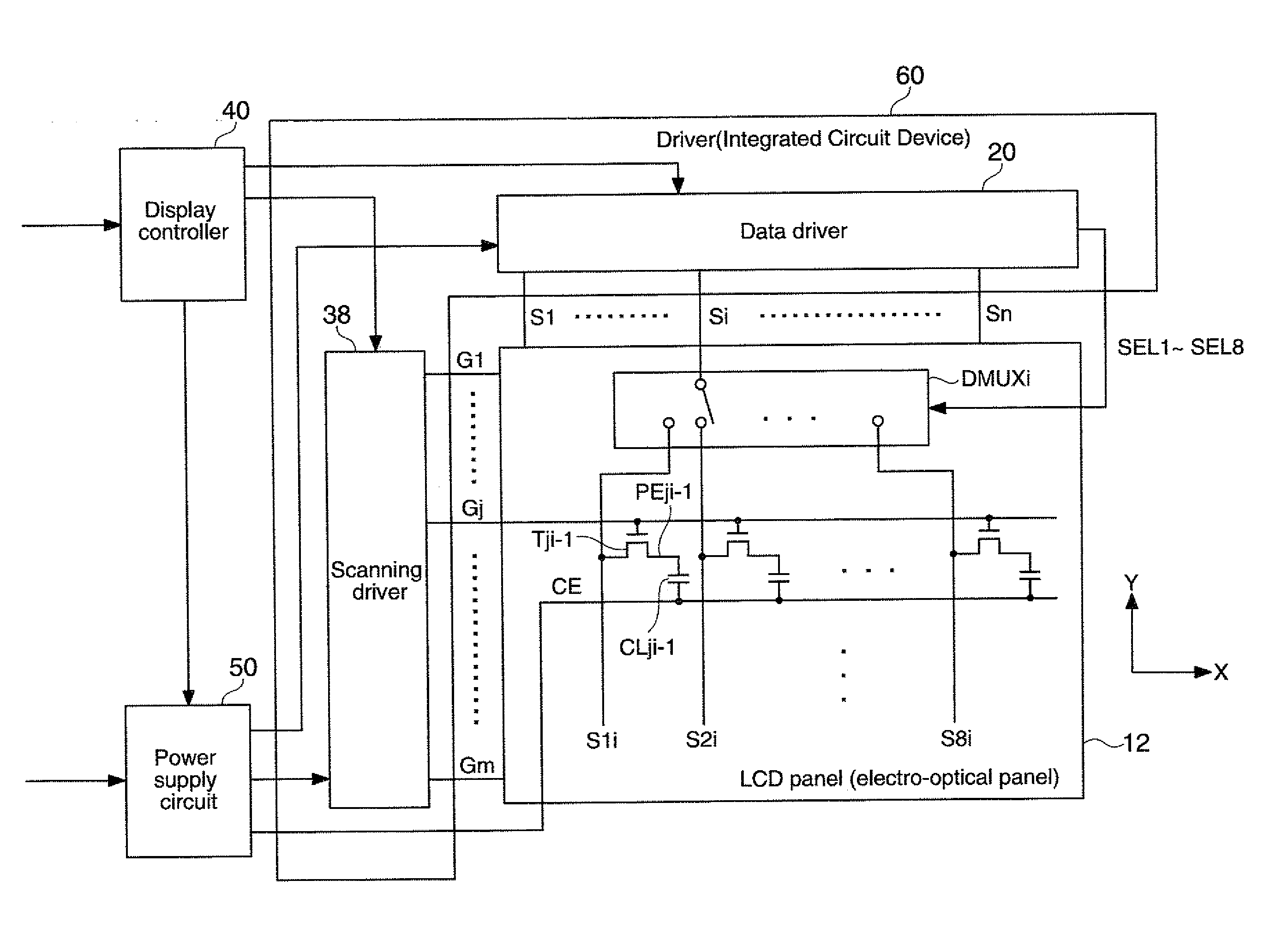

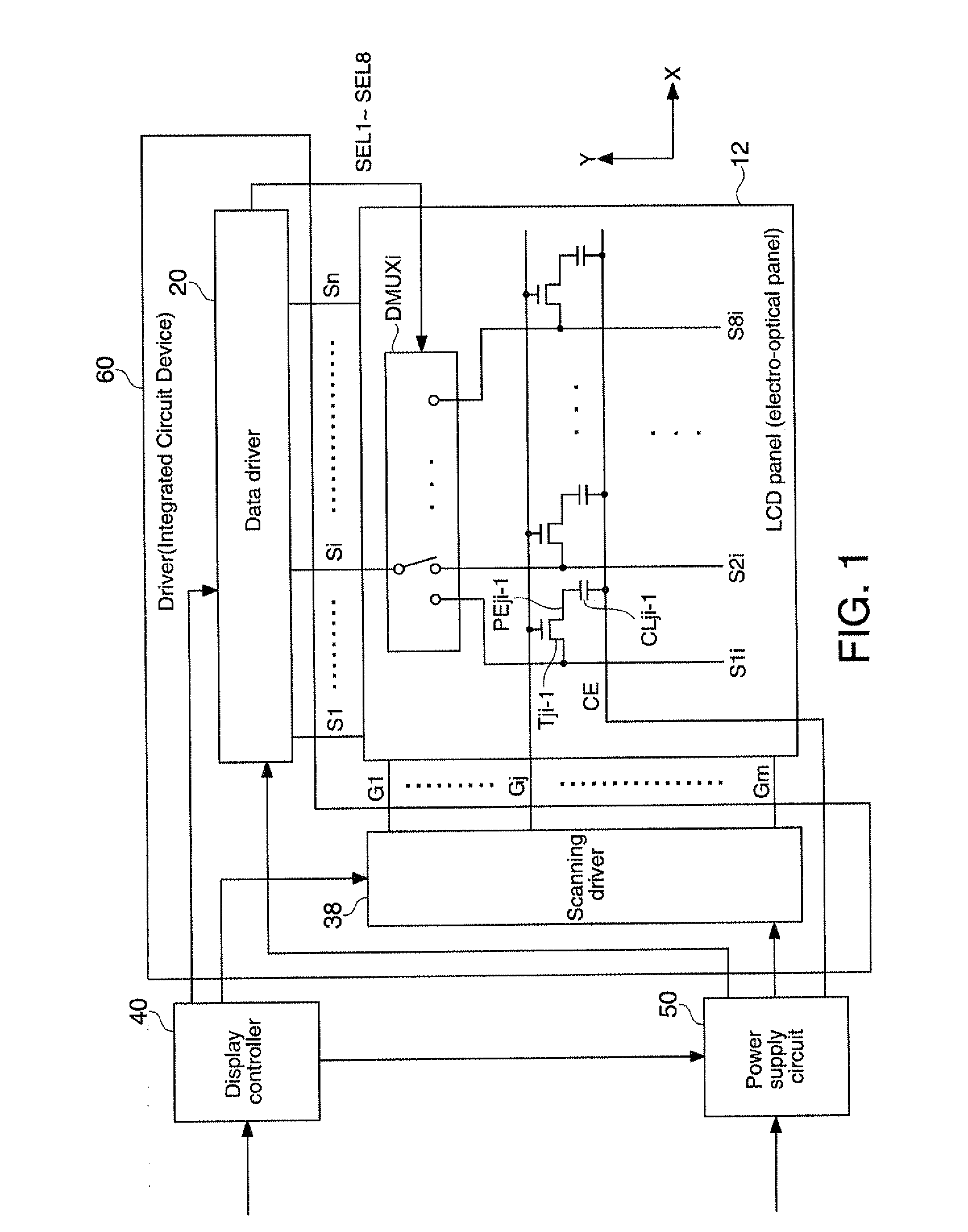

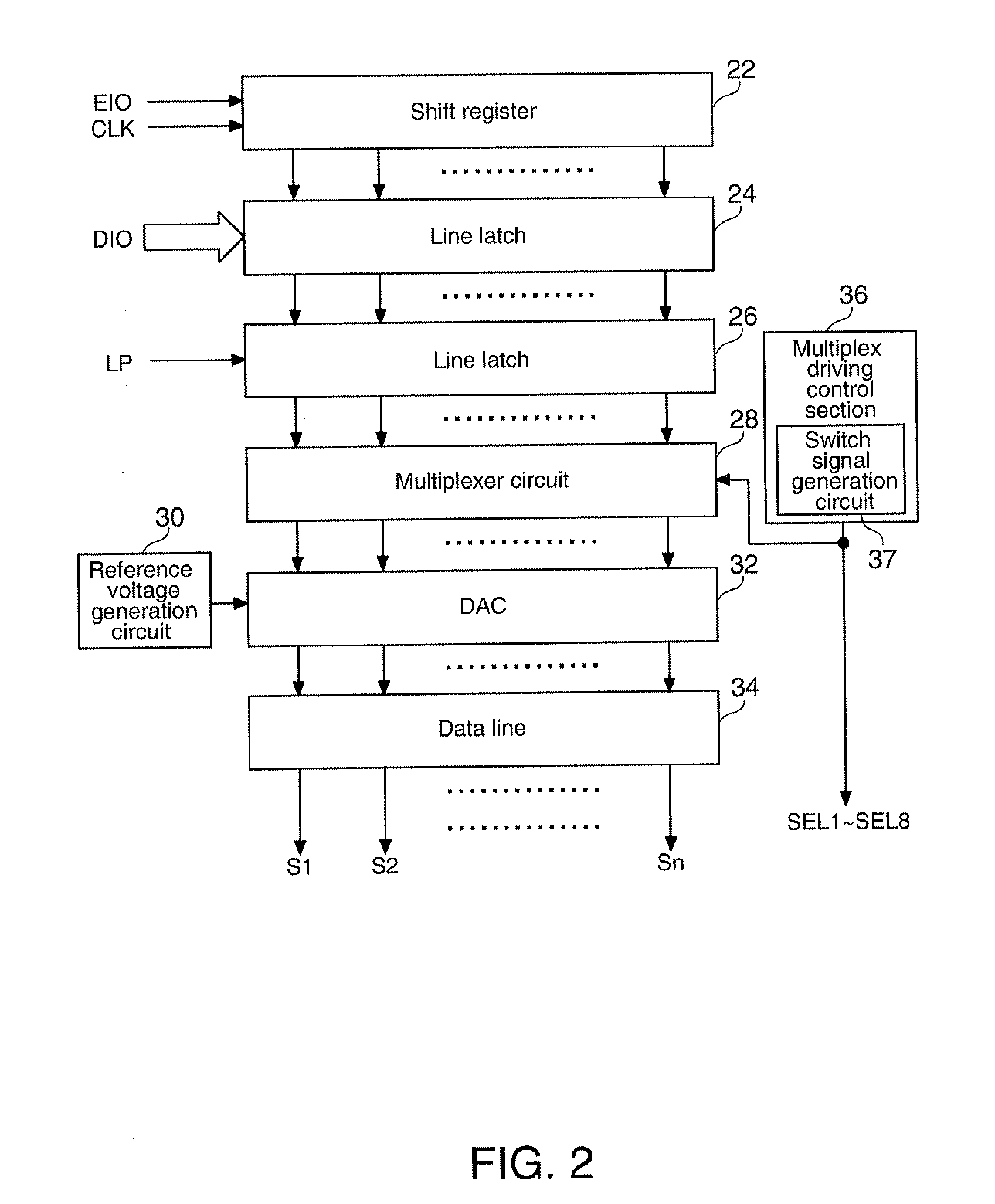

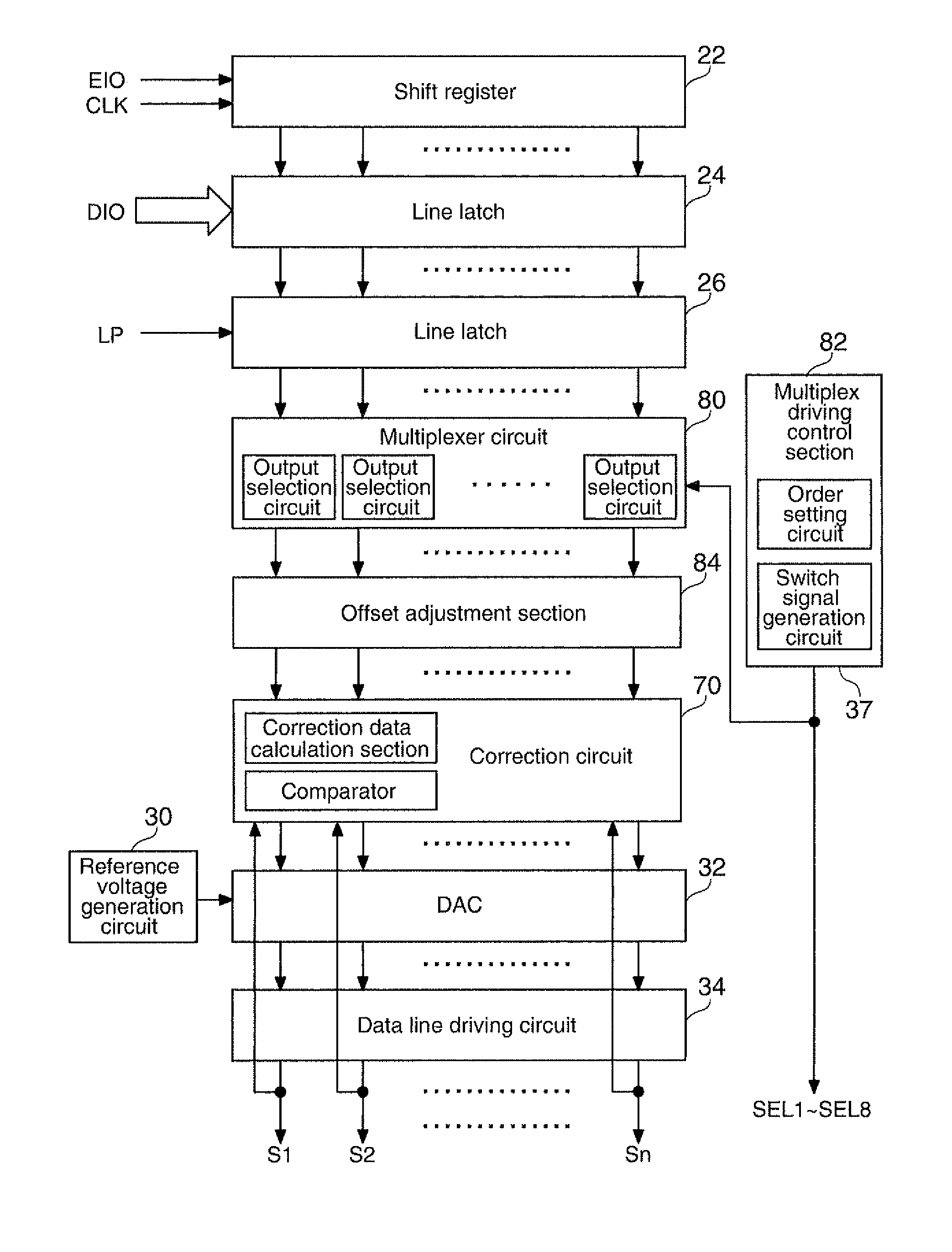

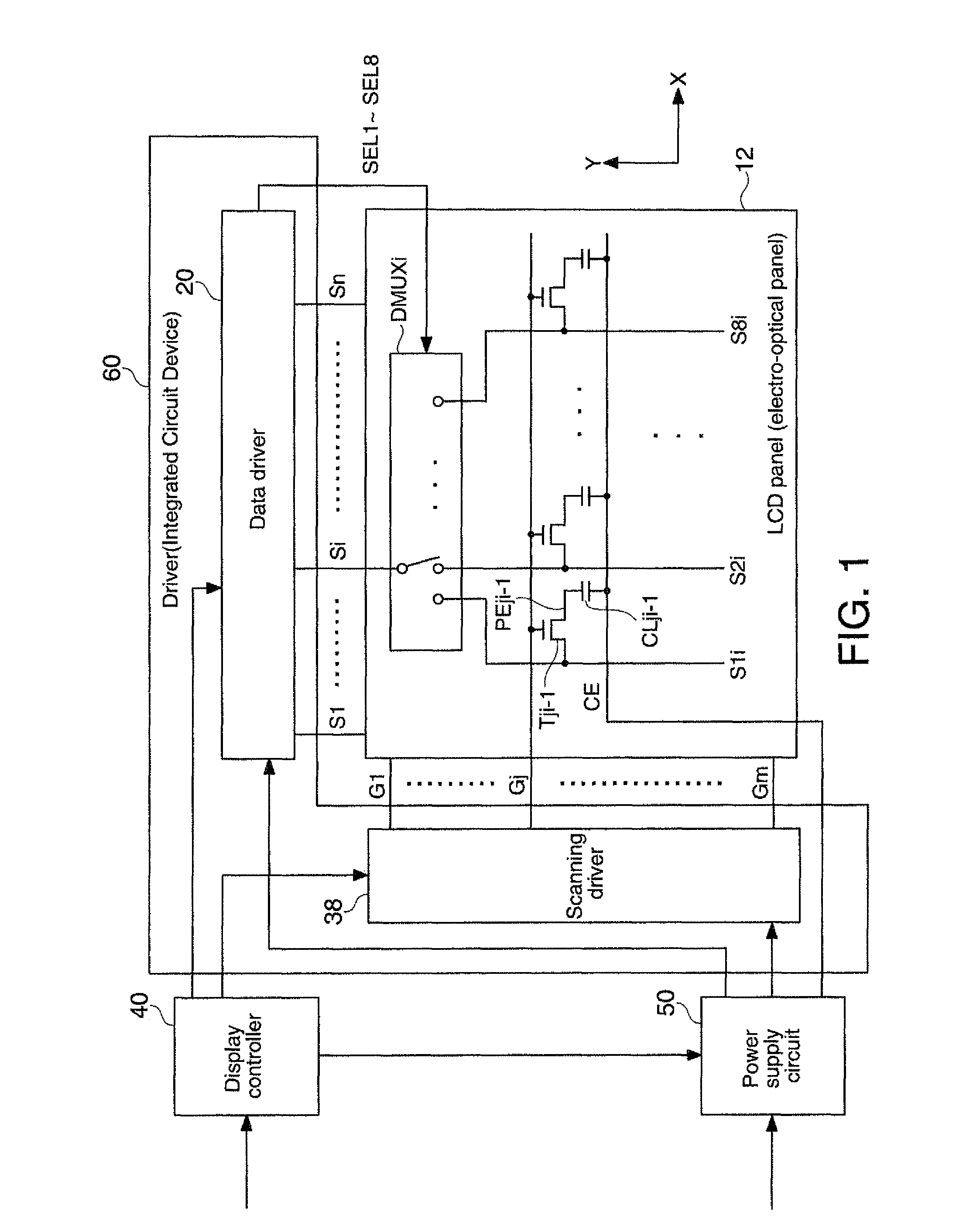

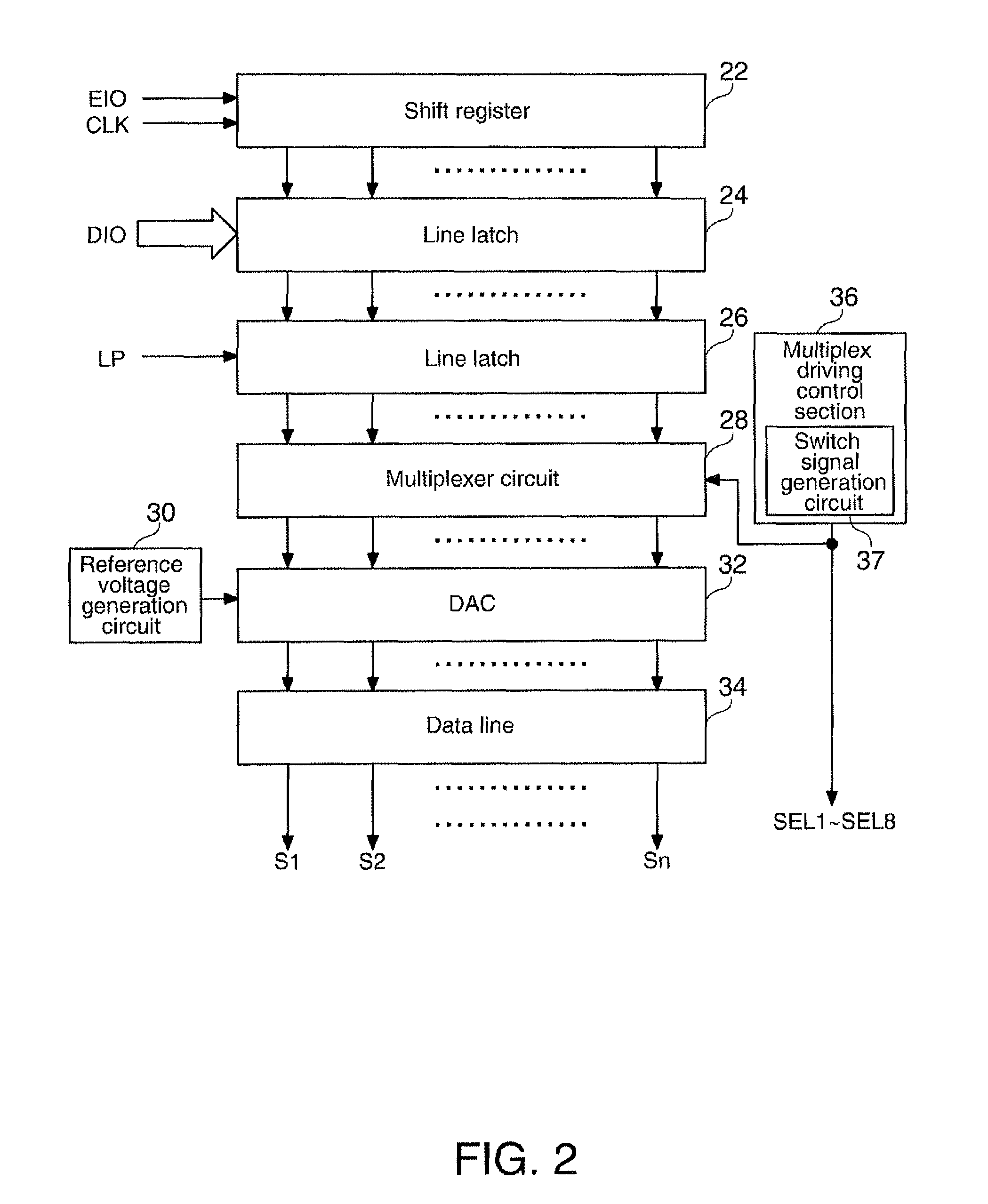

Integrated circuit device, electro optical device and electronic apparatus

ActiveUS20100194718A1Avoid irregularitiesVariation in output voltageCathode-ray tube indicatorsInput/output processes for data processingMultiplexingOrder form

An integrated circuit device includes: a data line driving circuit provided for each of a plurality of data signal supply lines that supplies a multiplexed data signal to a corresponding data signal supply line; an order offset register that stores a first order offset setting value; an order setting circuit that sets the order of driving the first pixel; and an order offset addition circuit corresponding to the data line driving circuit. When the data line driving circuit drives the q-th (q is a natural number less than p) pixel in the r-th (r is a natural number less than p) place in the order, the order offset addition circuit processes addition of an order offset correction value based on the r-th order offset setting value among the first order offset setting value.

Owner:SEIKO EPSON CORP

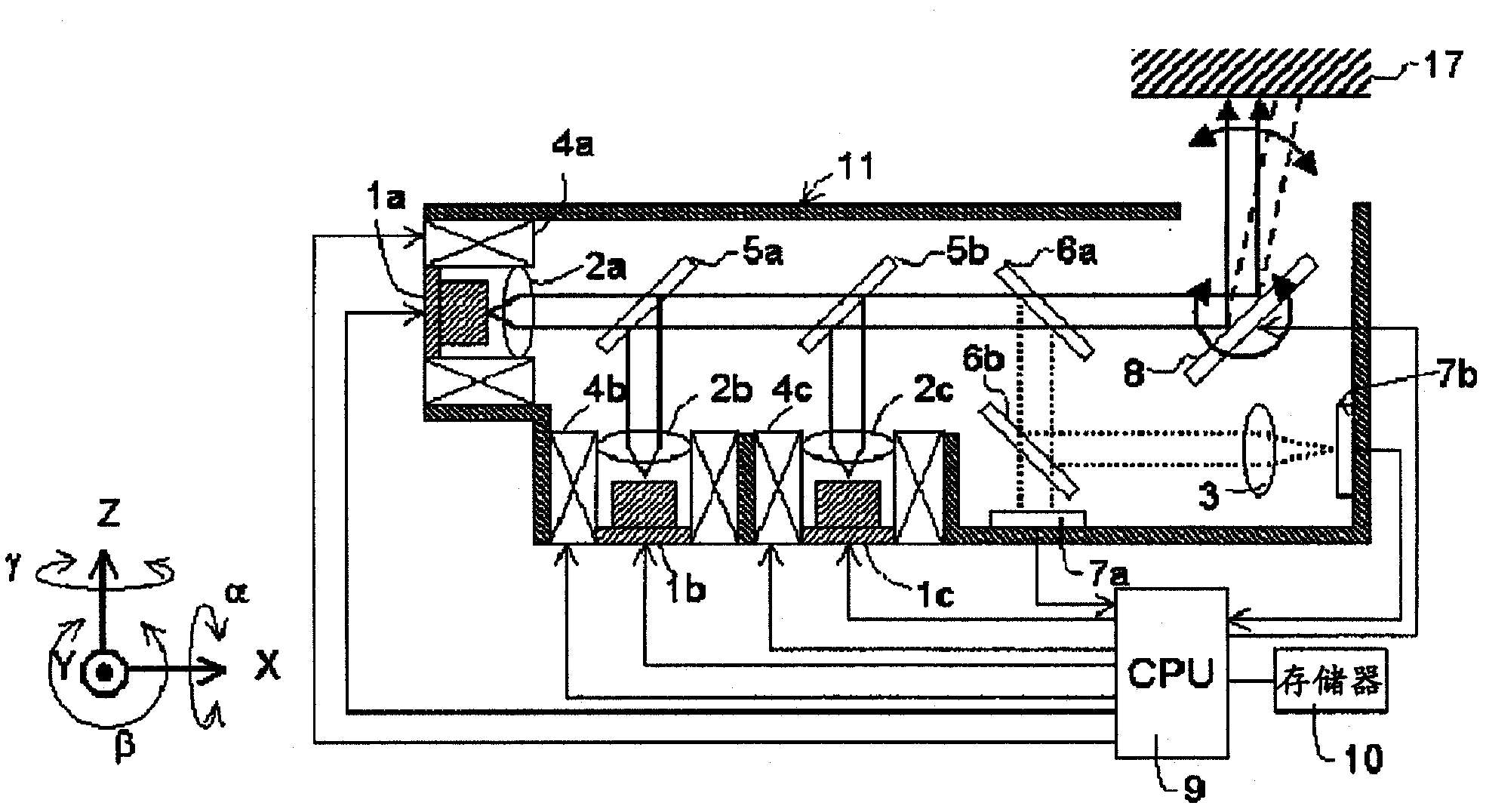

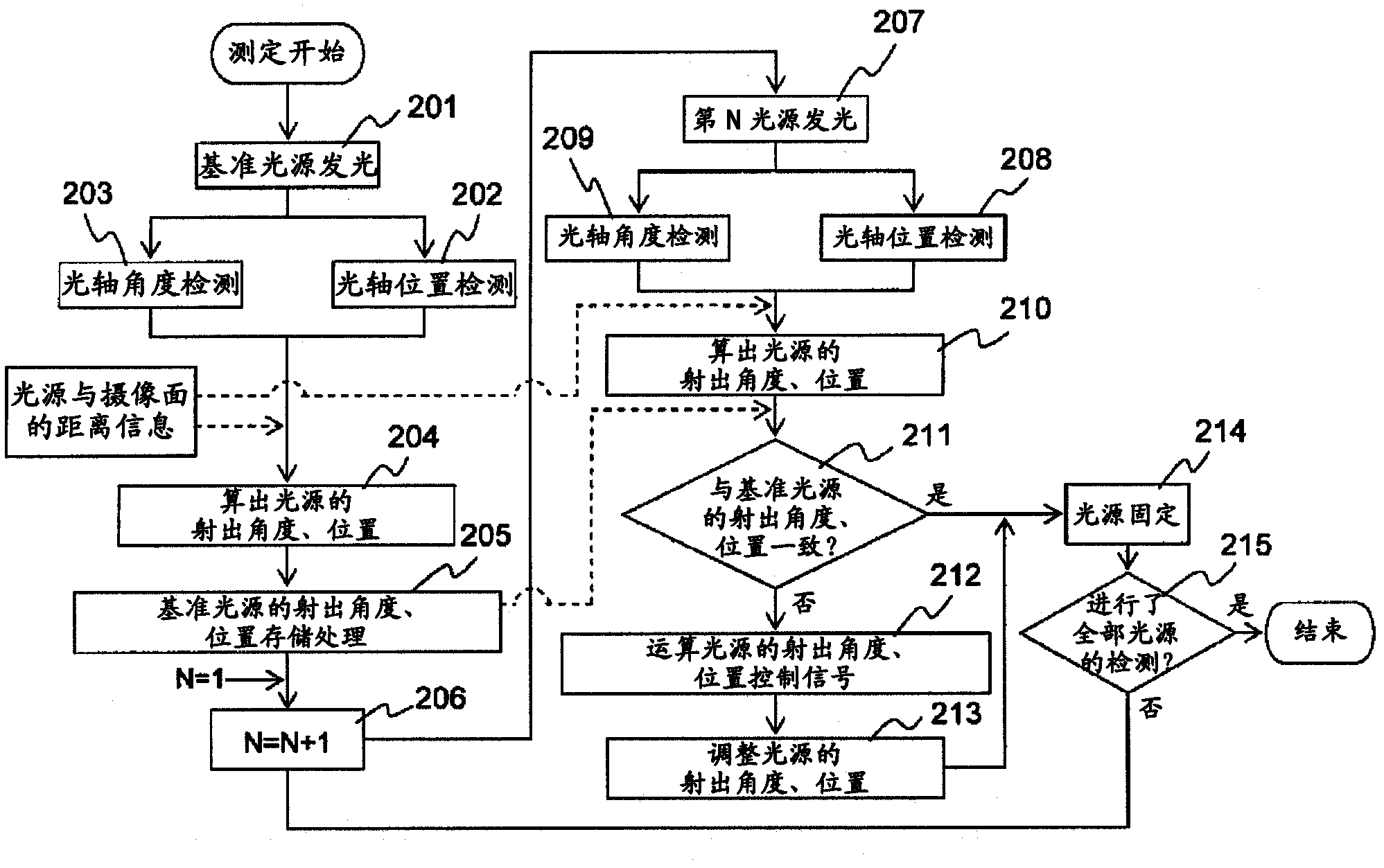

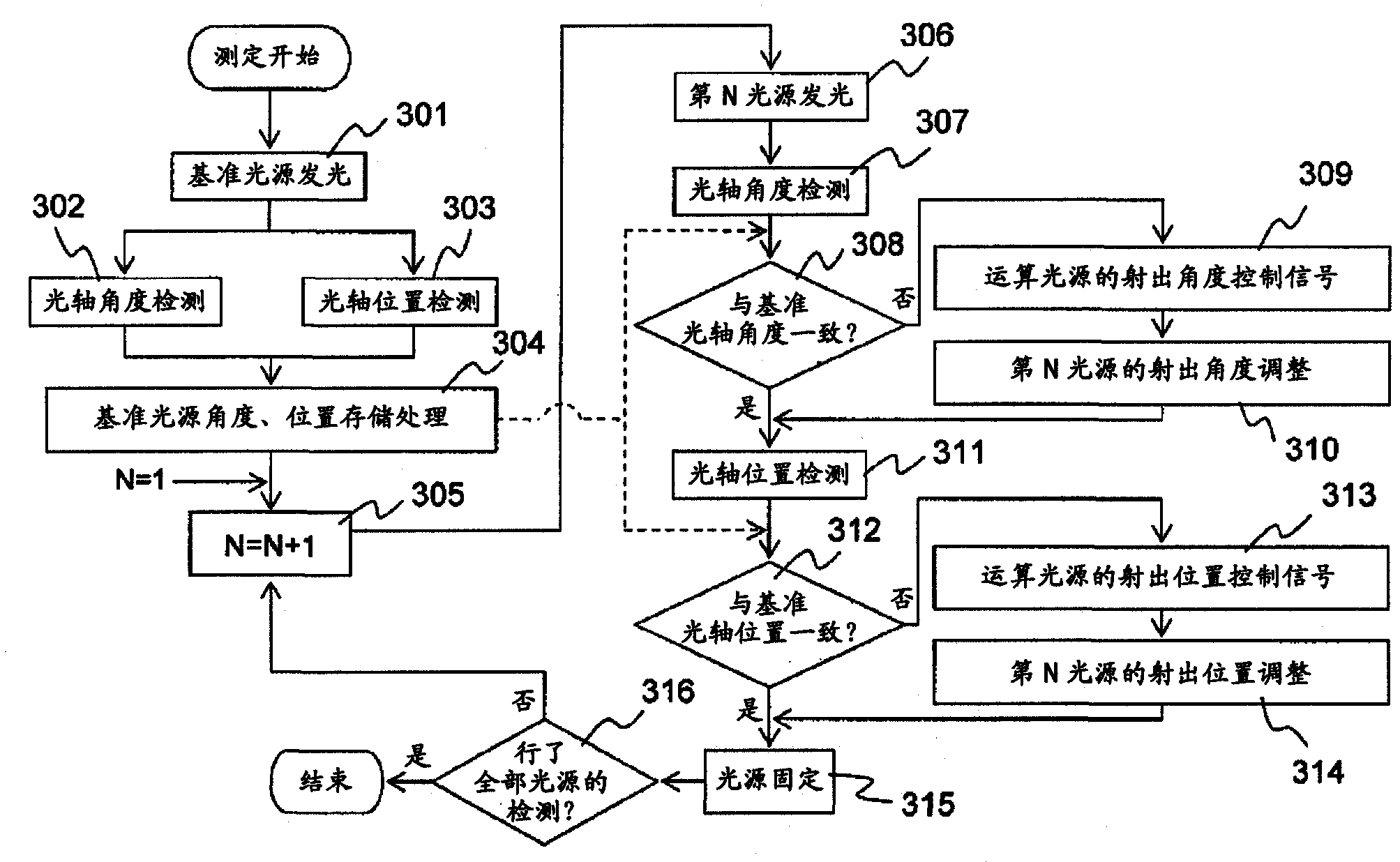

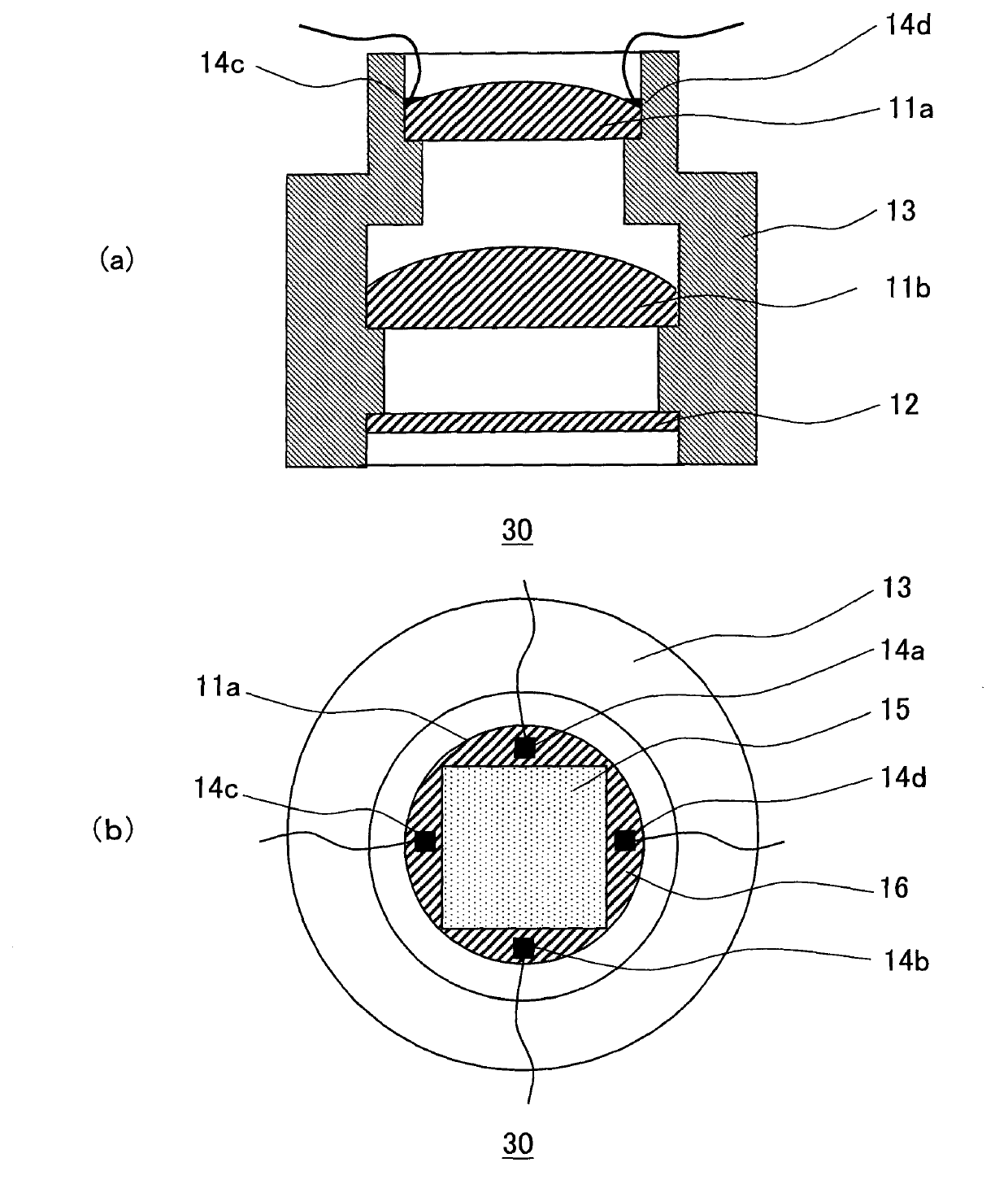

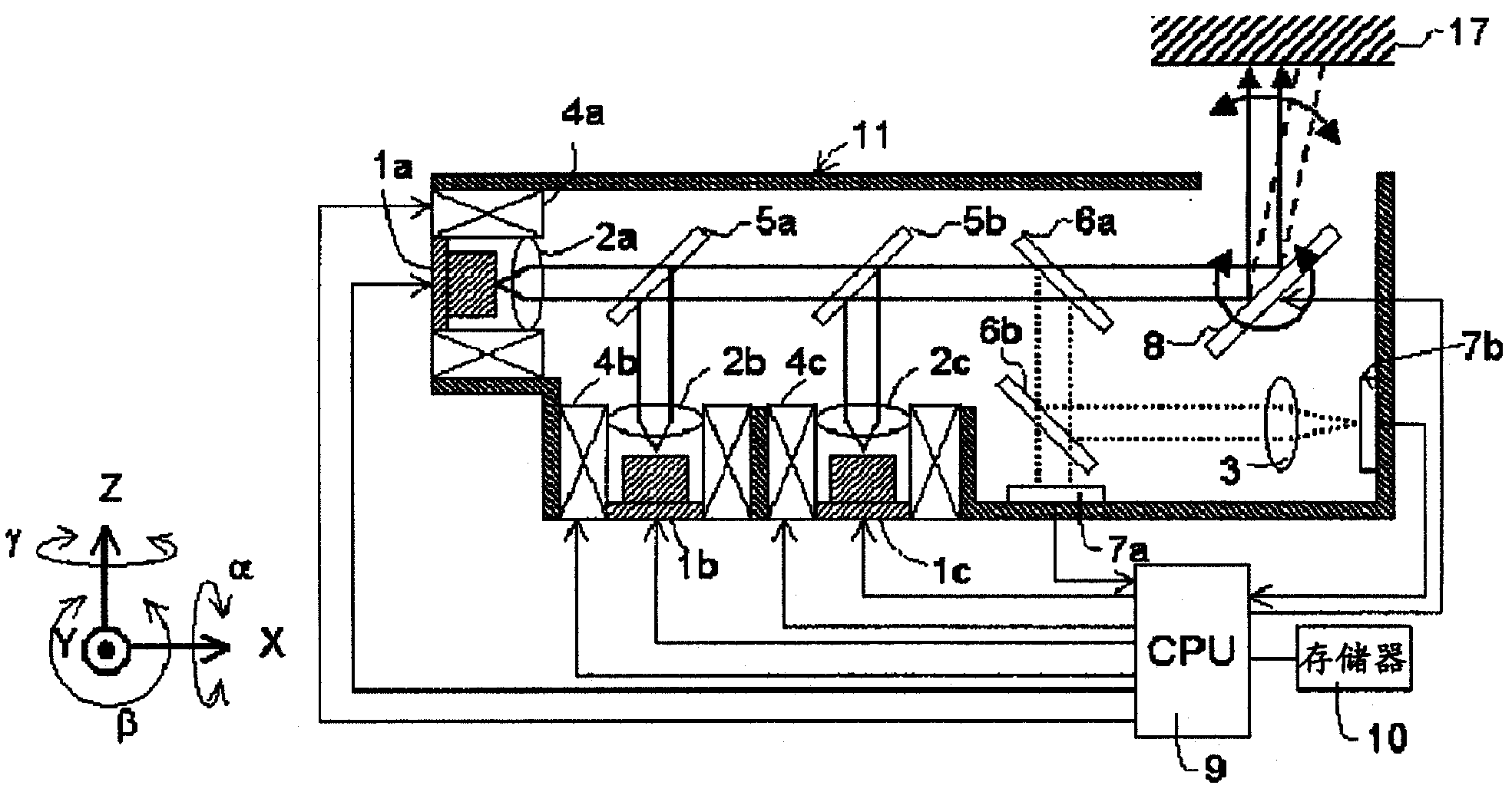

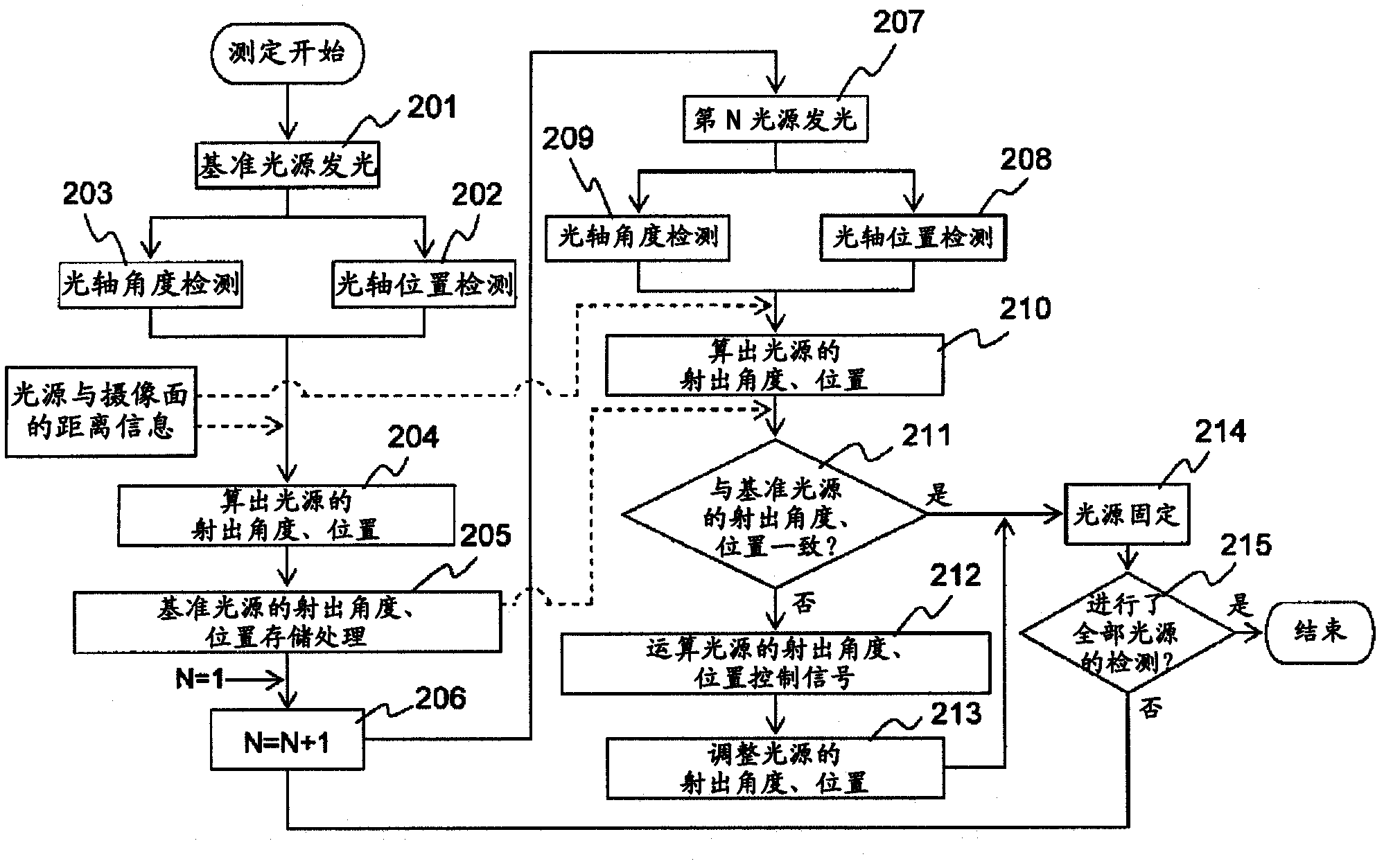

Optical axis adjusting apparatus, optical axis adjusting method, and projection type display apparatus

InactiveCN102326114AGood projected imageCompact structureTelevision system detailsProjectorsProjection imageOptical axis

Provided is a projection type display apparatus in which an inclination and a positional deviation of optical axes among a plurality of light sources can be easily corrected to obtain a high quality projection image. The green, blue and red laser beams emitted from light sources (1a, 1b, 1c) are converted to parallel beams by condenser lenses (2a, 2b, 2c), and the positions and angles of the optical axes of the beams of the three colors are evaluated by a position detection image pickup means (7a) and an angle detection image pickup means (7b), respectively. The positions and angles of the light sources are adjusted by respective actuators (4a, 4b, 4c) so that the positions and angles of the optical axes are identical. Consequently, the laser beams emitted from the light sources (1a, 1b, 1c) can be combined with high accuracy to thereby realize a high definition projection type display apparatus.

Owner:HITACHI LTD

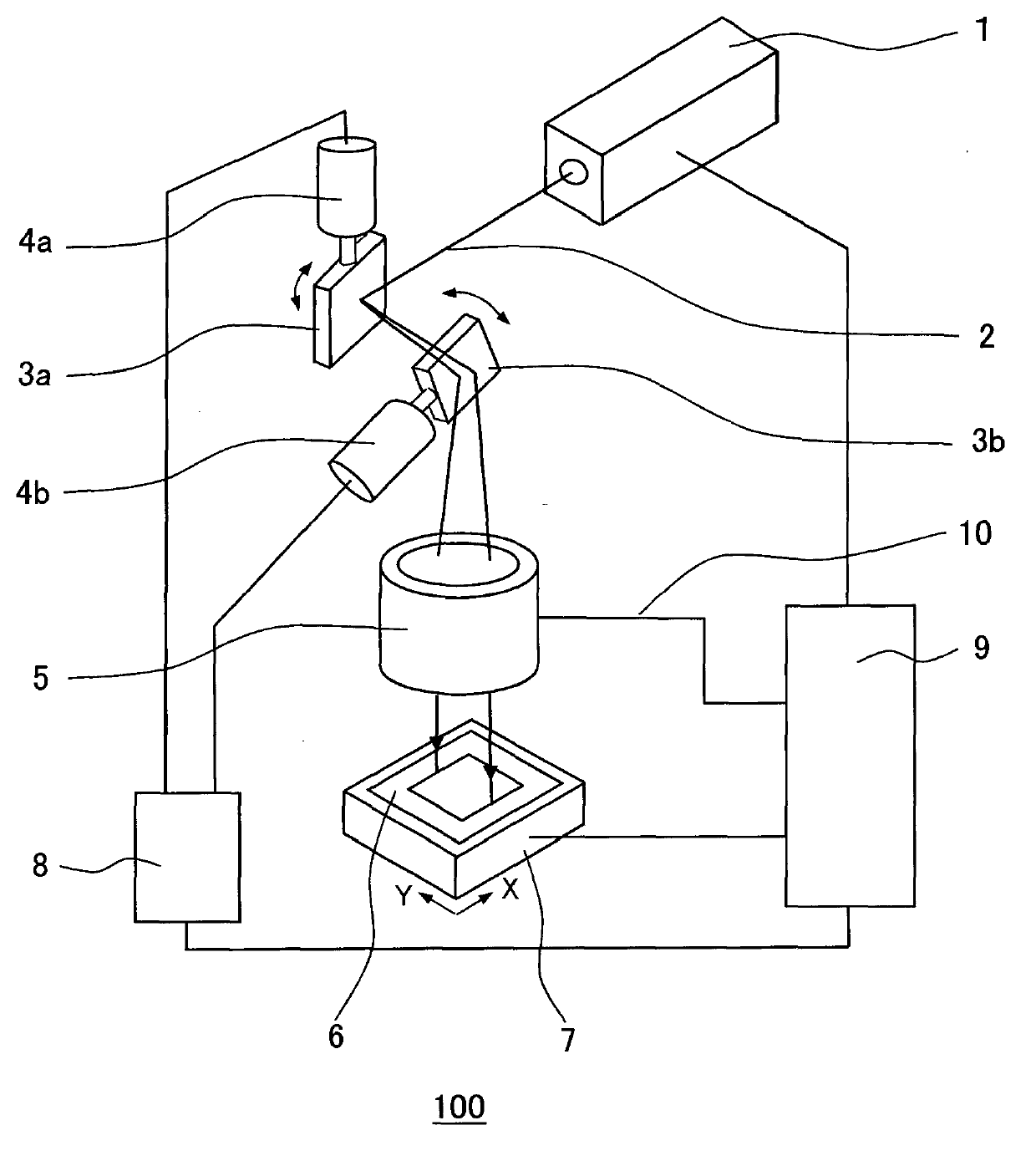

Lens unit and laser processing device

ActiveCN103128439ACorrect position offsetThermometer detailsWelding/cutting auxillary devicesLaser processingOptoelectronics

The invention provides a lens unit and a laser processing device. In the laser processing device (100), the lens unit (20) capable of measuring temperature change of optical lenses (11a, 11b) resulted from instant absorption of high-energy laser beams (2) by using temperature detectors (14) is used in a f[theta] lens. A plurality of temperature detectors (14) are disposed in non-irradiation part of the laser beams of the optical lenses (11a, 11b). A control device (9) corrects converged spot positions of the laser beams (2) according to temperature signals measured by the temperature detectors (14) to perform control.

Owner:MITSUBISHI ELECTRIC CORP

Integrated circuit device, electro optical device and electronic apparatus

ActiveUS8400439B2Avoid irregularitiesVariation in output voltageCathode-ray tube indicatorsInput/output processes for data processingMultiplexingData signal

An integrated circuit device includes: a data line driving circuit provided for each of a plurality of data signal supply lines that supplies a multiplexed data signal to a corresponding data signal supply line; an order offset register that stores a first order offset setting value; an order setting circuit that sets the order of driving the first pixel; and an order offset addition circuit corresponding to the data line driving circuit. When the data line driving circuit drives the q-th (q is a natural number less than p) pixel in the r-th (r is a natural number less than p) place in the order, the order offset addition circuit processes addition of an order offset correction value based on the r-th order offset setting value among the first order offset setting value.

Owner:SEIKO EPSON CORP

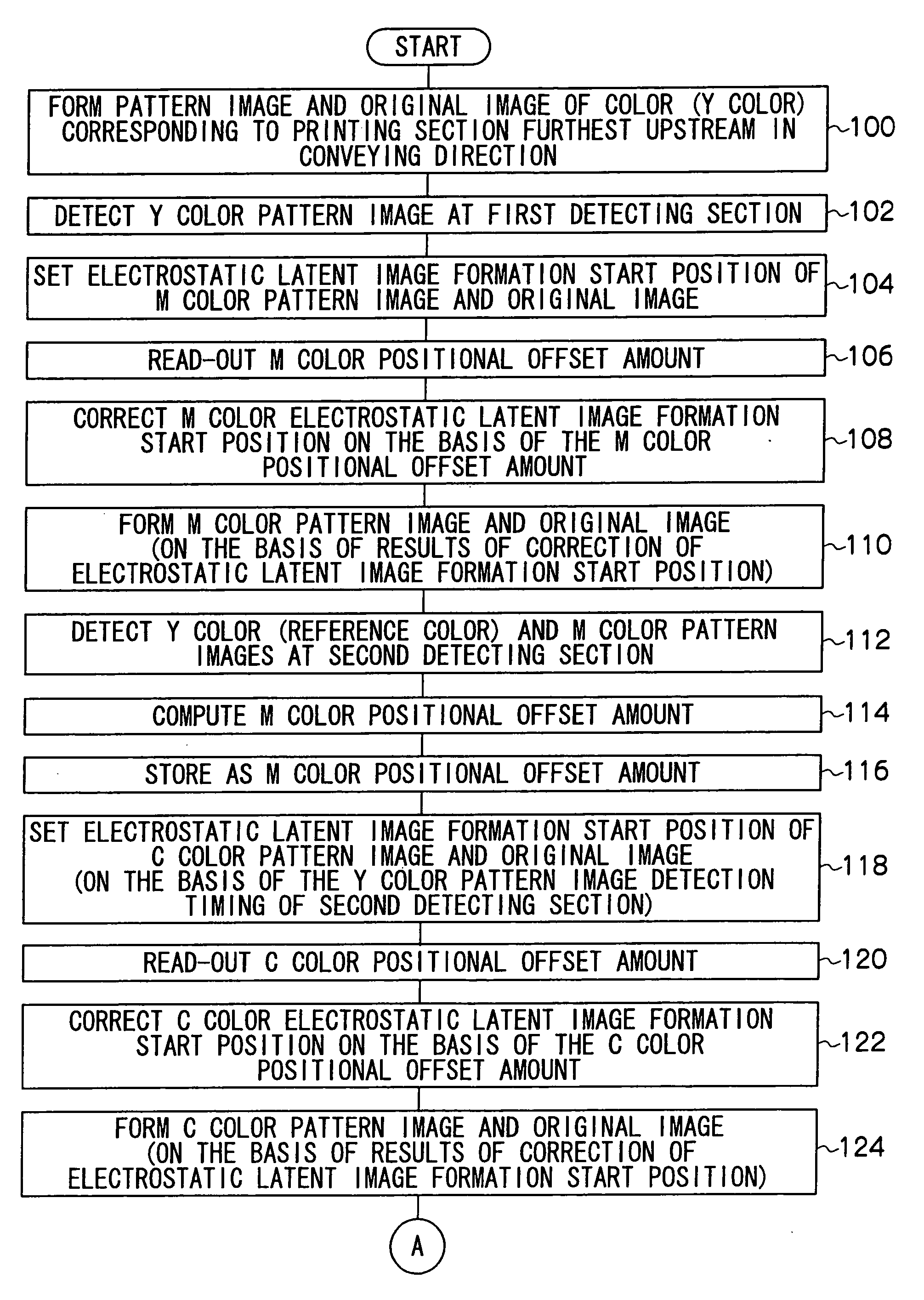

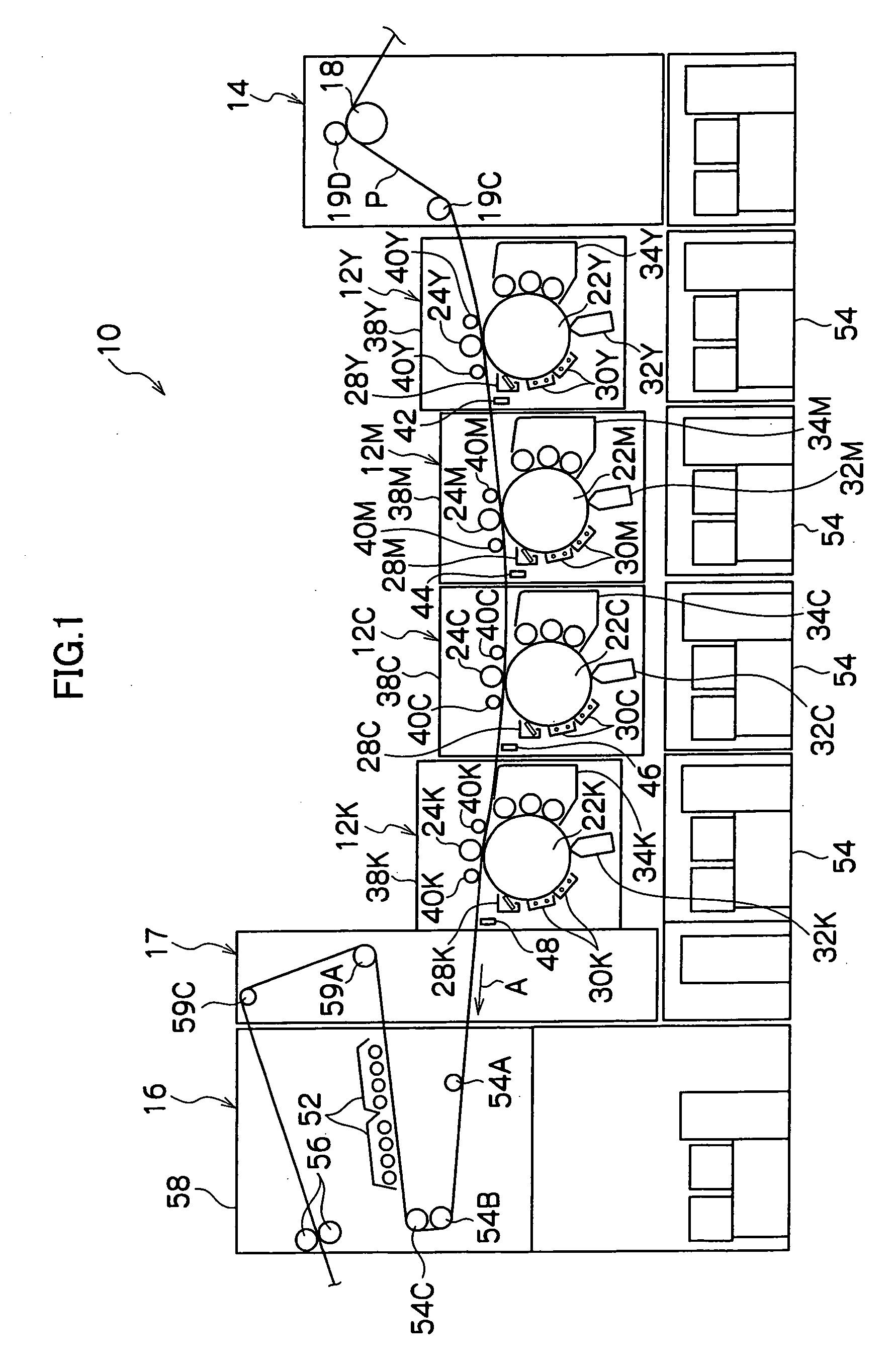

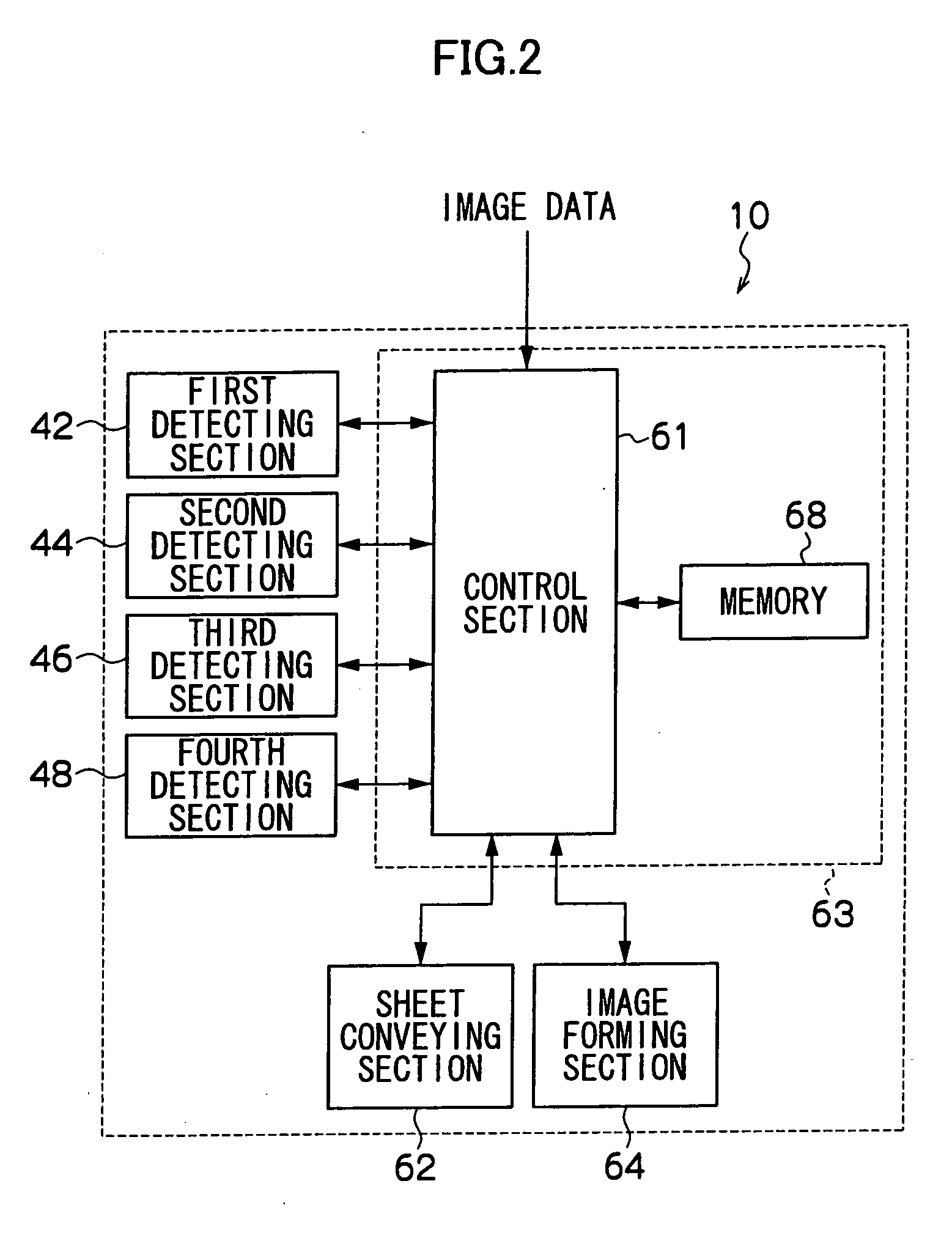

Image forming device

InactiveUS20060088344A1Accurate imagingImprove accuracyElectrographic process apparatusLatent imageImage formation

Electrostatic latent images of a pattern image and an original image are formed on each of a plurality of image carriers. Each image carrier is provided with a developing unit and a transfer unit, and images of a reference color and colors other than the reference color are formed on a continuous sheet of paper. Detectors that detect the pattern images on the continuous sheet are disposed at conveying direction downstream sides of image carriers, and positional offset amounts of the pattern images of the colors other than the reference color are computed. On the basis of a detection of the pattern image of the reference color, a start position of electrostatic latent image formation at each image carrier is determined. Further, the start position is corrected on the basis of a positional offset amount computed at a time of transferring a preceding pattern image.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Integrated circuit device, electro optical device and electronic apparatus

ActiveUS20100194738A1Avoid irregularitiesAvoid normal displayCathode-ray tube indicatorsInput/output processes for data processingComputer scienceImaging data

An integrated circuit device having a data line driving circuit and a position offset addition circuit that connects position offsets based on position offset setting values, wherein, among first pixel to p-th pixel of a plurality of pixels, a position offset register stores a first position offset setting value corresponding to the first pixel and a p-th position offset setting value corresponding to the p-th pixel among the first pixel to the p-th pixel; among first image data to p-th image data respectively corresponding to the first pixel to the p-th pixel, the position offset addition circuit processes a position offset correction value based on the first position offset setting value to the first image data, and processes a position offset correction value based on the p-th position offset setting value to the p-th image data among the first image data to p-th image data, to correct the position offsets.

Owner:SEIKO EPSON CORP

Integer lifting technique for house

InactiveCN101109232AHouse rises steadilyCorrect position offsetBuilding repairsEngineeringStructural engineering

The invention discloses a process for integrally elevating the rooms of a low-course building. Wherein, the quantity, interval and locations of the lifting supports are determined depending upon the load pressure of the part to be elevated; an integral gird is formed by solidifying the truss on the surrounding wall along a reference line; holes are dug at certain interval under the integral gird, two lifting supports are arranged in each hole; the wall reserved under the integral gird is cut open by a cutter, meanwhile the lifting supports are elevated synchronously; after elevating to certain height, the lifting supports are removed in an alternative way in each hole, and the wall is re-built; the upper part of the building is matched with the lower part of the building; the wall is re-built at the location where the removed lifting supports are; expansion concrete is filled full and compact into the gaps between the upper and lower walls, now the elevation of the building is completed. The invention is featured by steady elevation of rooms, is capable for correcting the positional shift of upper and lower wall, and not liable to tilting, etc.

Owner:刘子波 +1

Lens-equipped optical semiconductor device and method for manufacturing the same

ActiveUS9018663B2Improve accuracyLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor device

A lens-equipped optical semiconductor device including: an optical semiconductor device including at least one optical semiconductor element mounted on a substrate and a transparent resin encapsulating body that encapsulates the optical semiconductor element; a resin lens having a recessed portion for housing the transparent resin encapsulating body; and a transparent resin layer filled into a space among the substrate, the recessed portion, and the transparent resin encapsulating body, wherein the recessed portion has a capacity that is at least 1.1 times a total volume of the optical semiconductor element and the transparent resin encapsulating body.

Owner:ASAHI RUBBER

Tomography apparatus and tomogram correction processing method

InactiveUS8970849B2Correct position offsetEye diagnosticsUsing optical meansTomographyTomographic image

This invention realizes accurate positional offset correction between a plurality of tomograms captured by using a tomography apparatus. The invention is a tomography apparatus which corrects the positional offsets between a plurality of two-dimensional tomograms constituting a three-dimensional tomogram. This apparatus includes a tomogram analysis unit (120) which extracts feature amounts representing the tissue of a measurement target, a tomogram selection unit (140) which selects a standard two-dimensional tomogram from the plurality of two-dimensional tomograms based on the feature amounts, and a tomogram position correction unit (150) which calculates the positional offset amount between the nth two-dimensional tomogram adjacent to the standard two-dimensional tomogram and the (n−1)th two-dimensional tomogram.

Owner:CANON KK

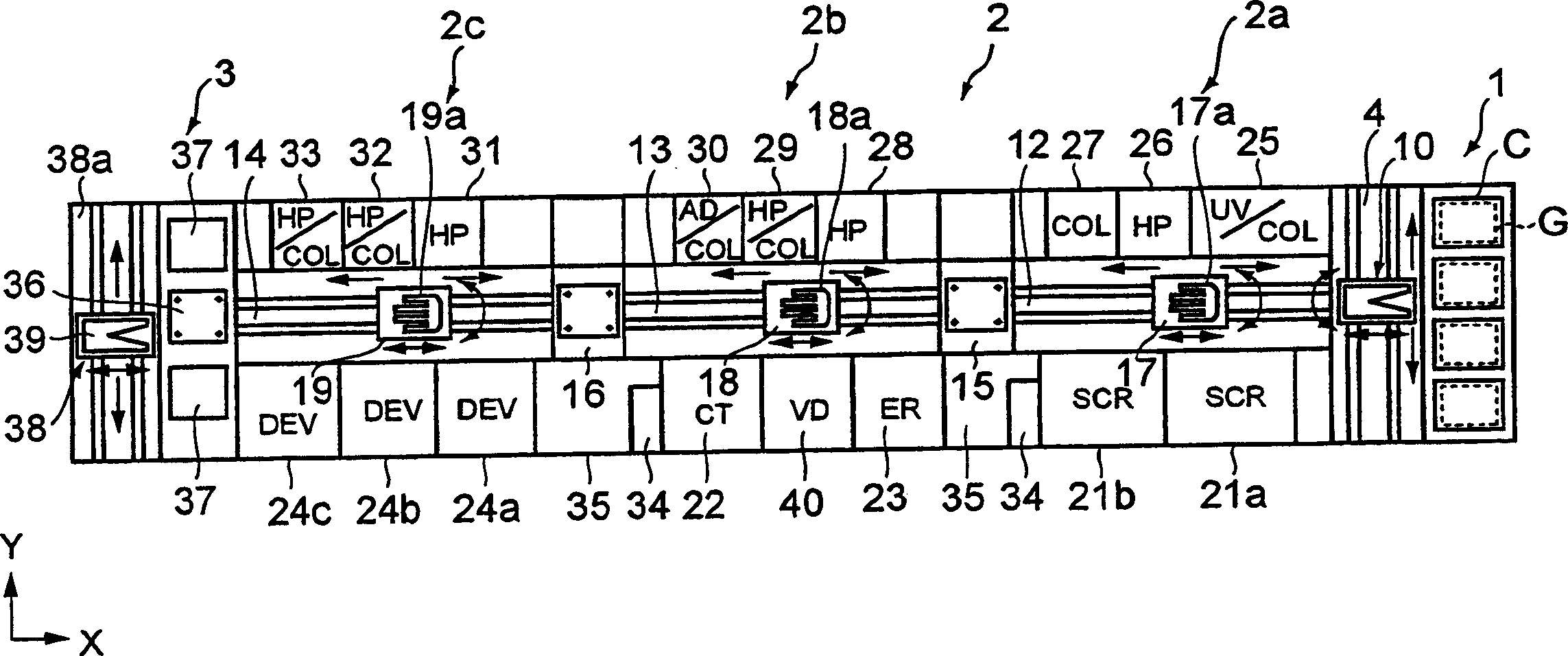

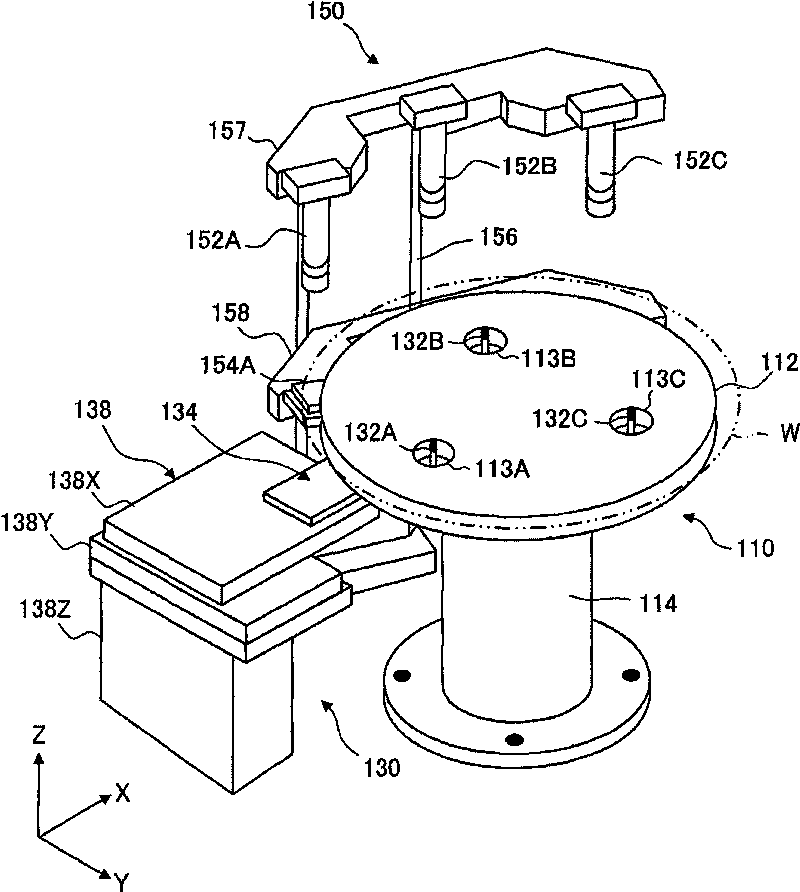

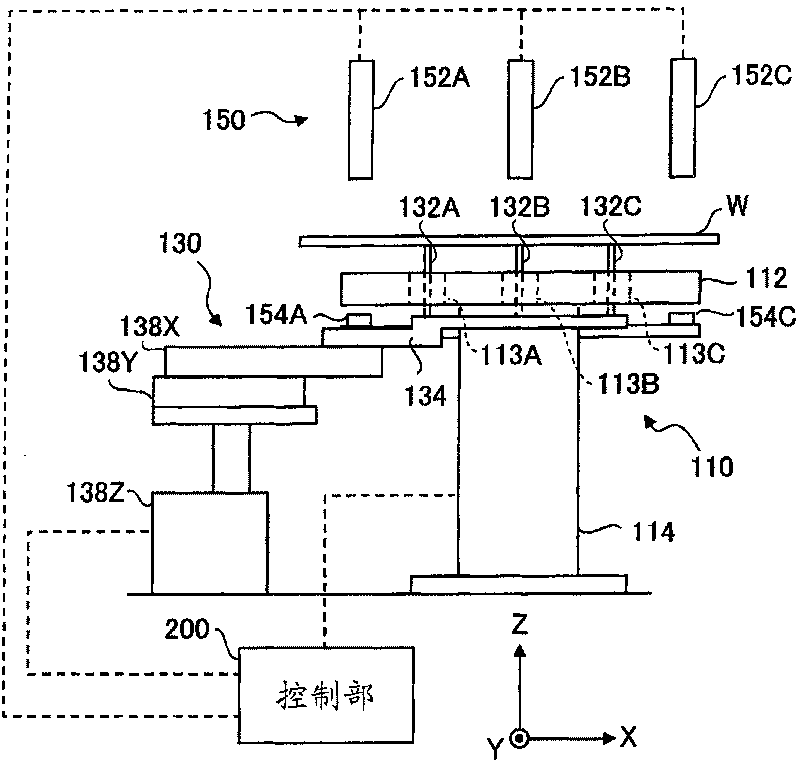

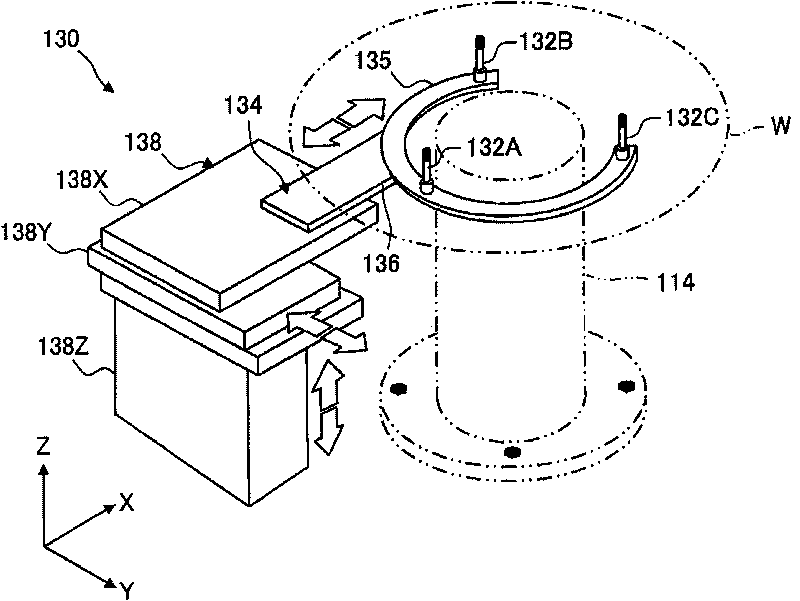

Substrate transfer device, substrate processing apparatus and substrate transfer method

InactiveCN101351878BCorrect position offsetQuick correction of position offsetSemiconductor/solid-state device manufacturingConveyor partsEngineeringMechanical engineering

A substrate transfer device capable of correcting the displacement of a substrate in a horizontal direction by itself without using a transfer arm. The device comprises support pins (132A to 132C) disposed around a support shaft (114) for a load stage (112), separated from the support shaft (114), and supporting a substrate such as a wafer (W) on its lower surface, a base (134) to which the support pins are fitted, a vertical driving means (Z-direction drive means (138Z)) for elevating and lowering the wafer (W) by vertically driving the support pins through the base, and a horizontal drive means (X-direction drive means (138X), Y-direction drive means (138Y)) for adjusting the position of the wafer in horizontal directions (X-, Y-directions) by horizontally driving the support pins through the base.

Owner:TOKYO ELECTRON LTD

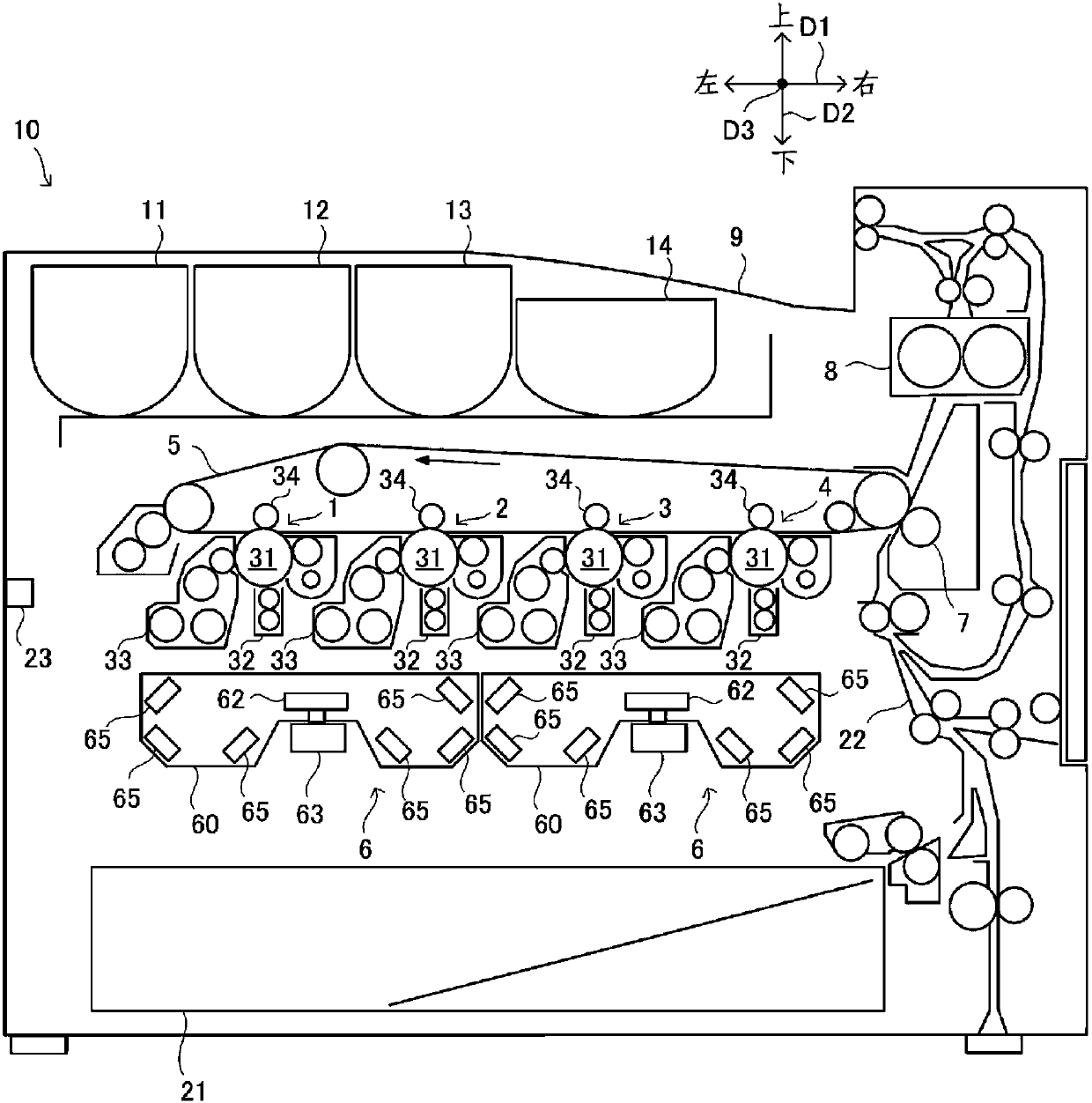

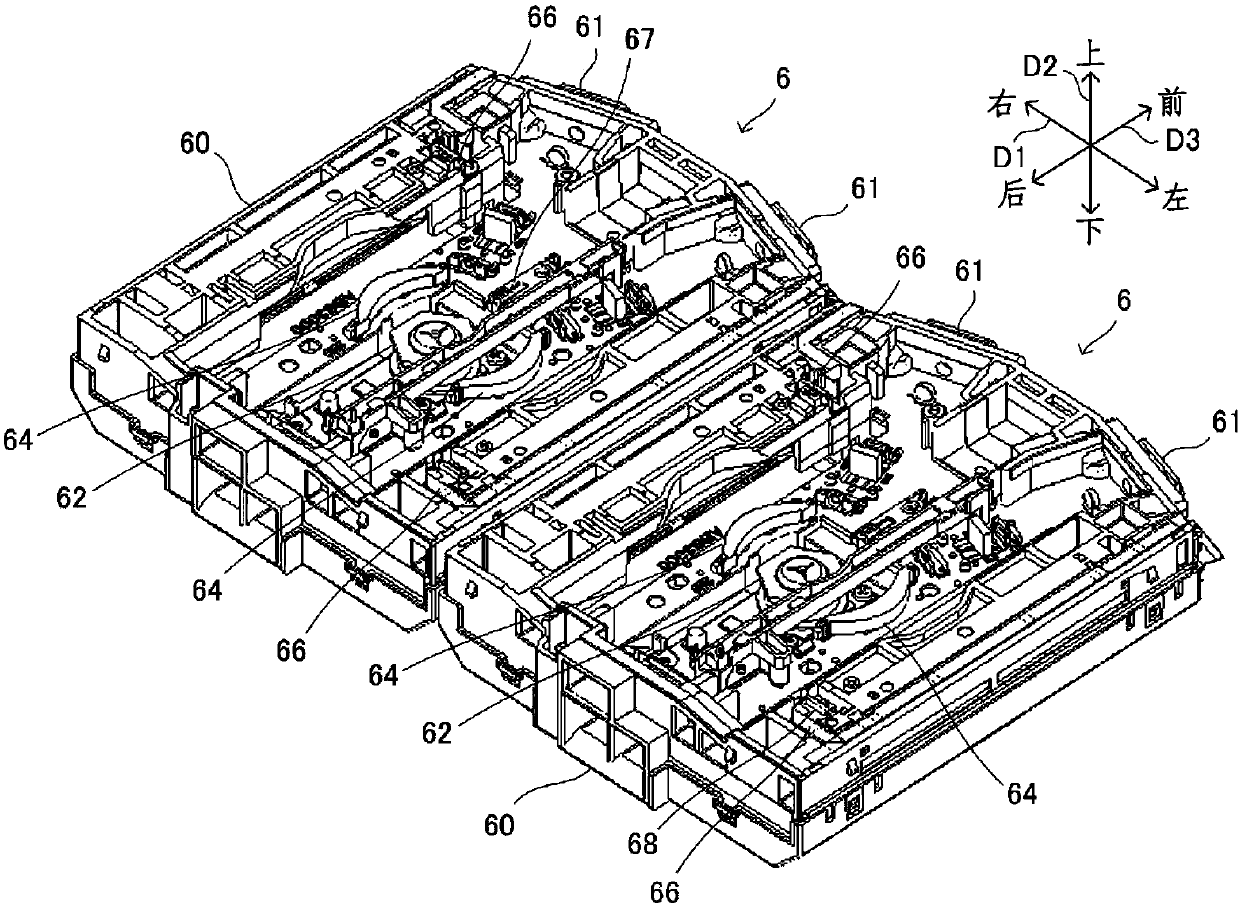

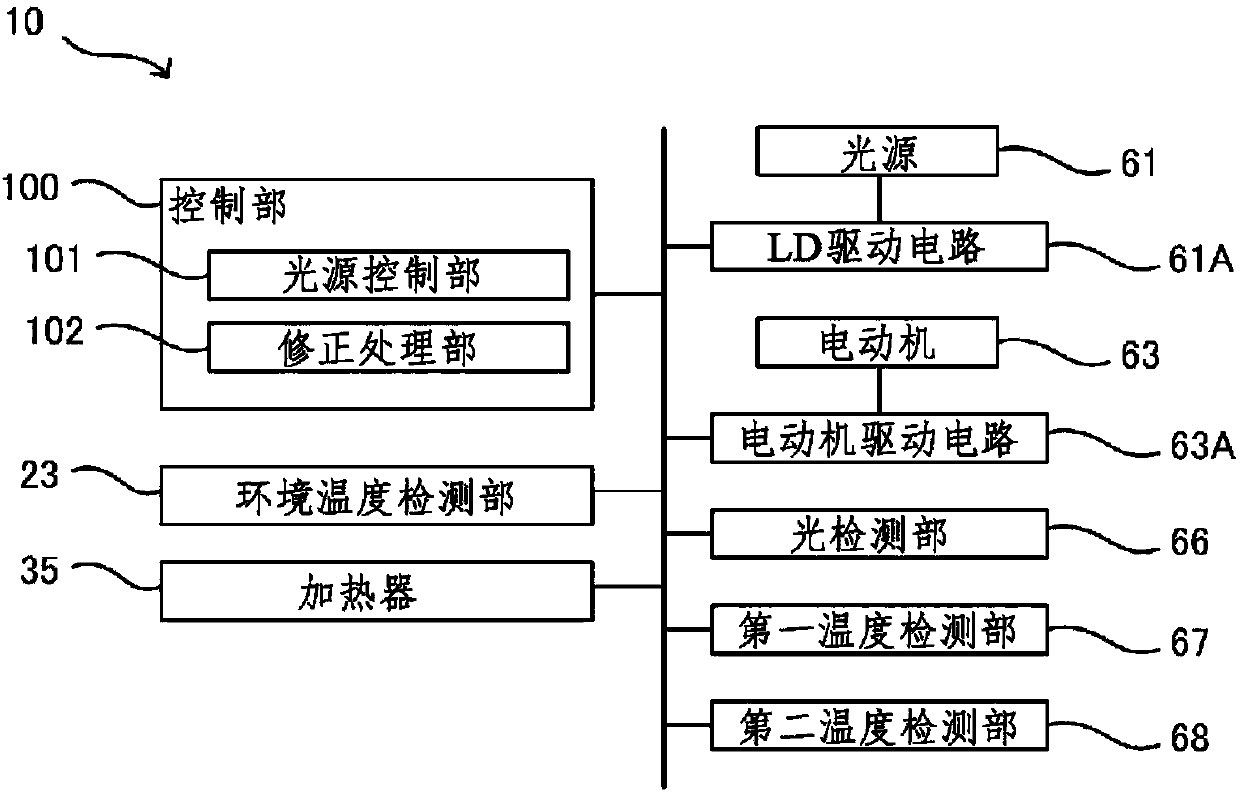

Image forming device

InactiveCN107921785ACorrect position offsetElectrographic process apparatusPrintingStart timeOptoelectronics

This image forming device (10) is provided with: a housing (60) having disposed therein a light source (61), a light scanning member (62), a light detection unit (66) that detects light that is incident at a predetermined position on the scanning path of the light from the light scanning member (62), and a scanning lens (64) that causes uniform scanning of the light scanned by the light scanning member (62) on an image carrier (31); temperature gradient detectors (67), (68) that detect the temperature gradient of the housing (60); a heating heater (35) that heats the image carrier (31) or a sheet; and a correction processing unit (102) that corrects emission start timing on the basis of a detected temperature detected by the temperature gradient detection units (67), (68), and a predetermined operation expression, and that changes the content of the operation expression according to the operating status of a heating heater (35) at the time an image forming process starts.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

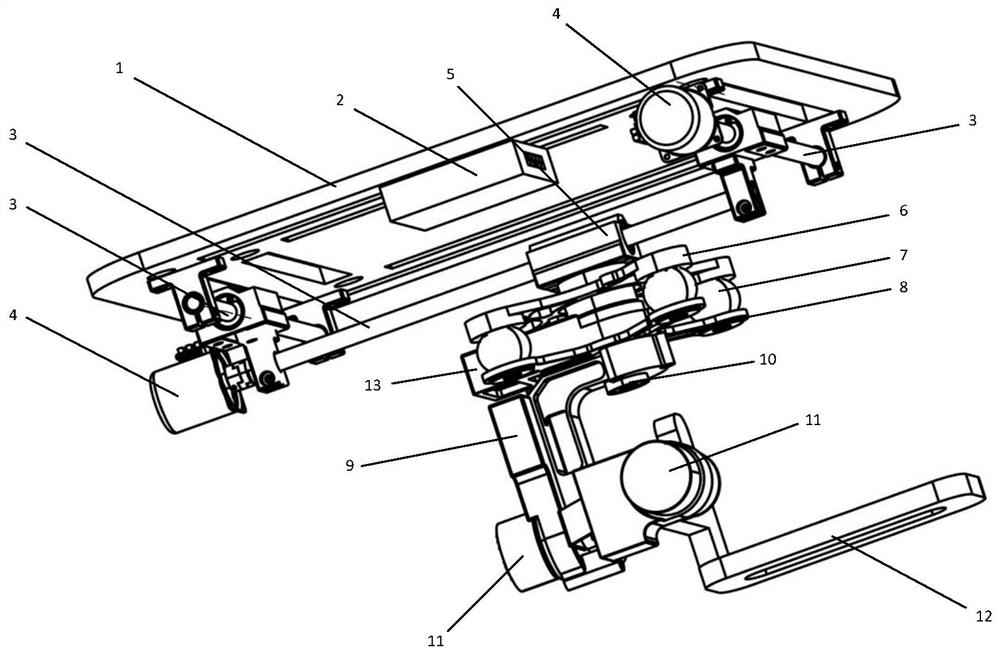

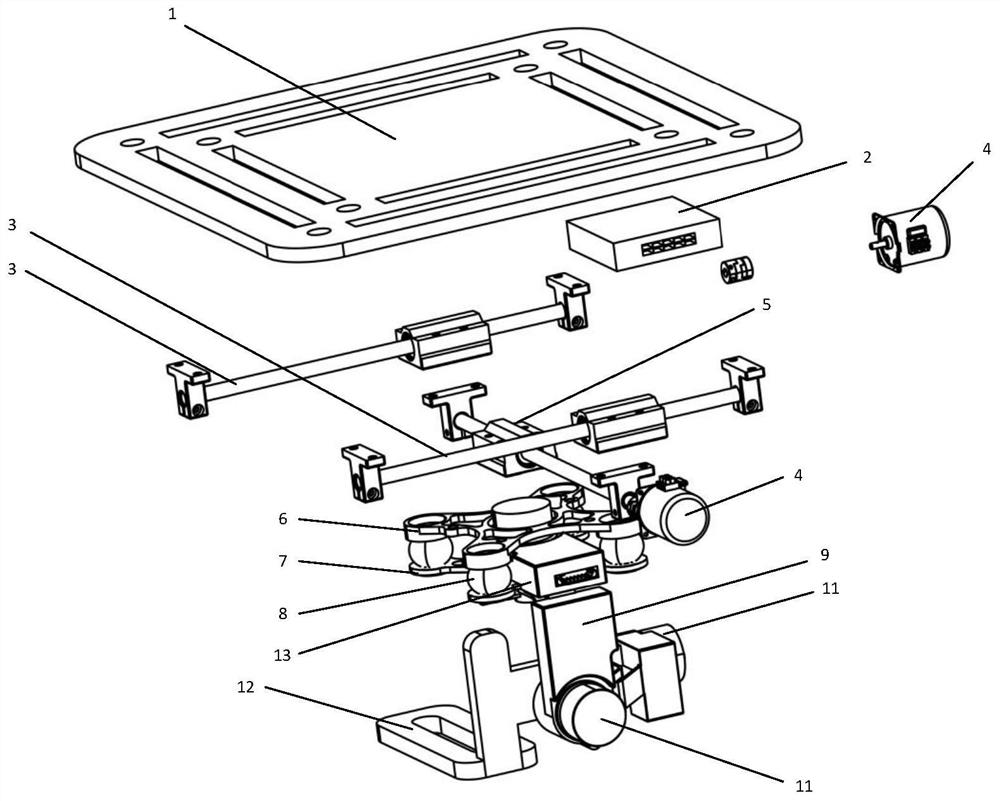

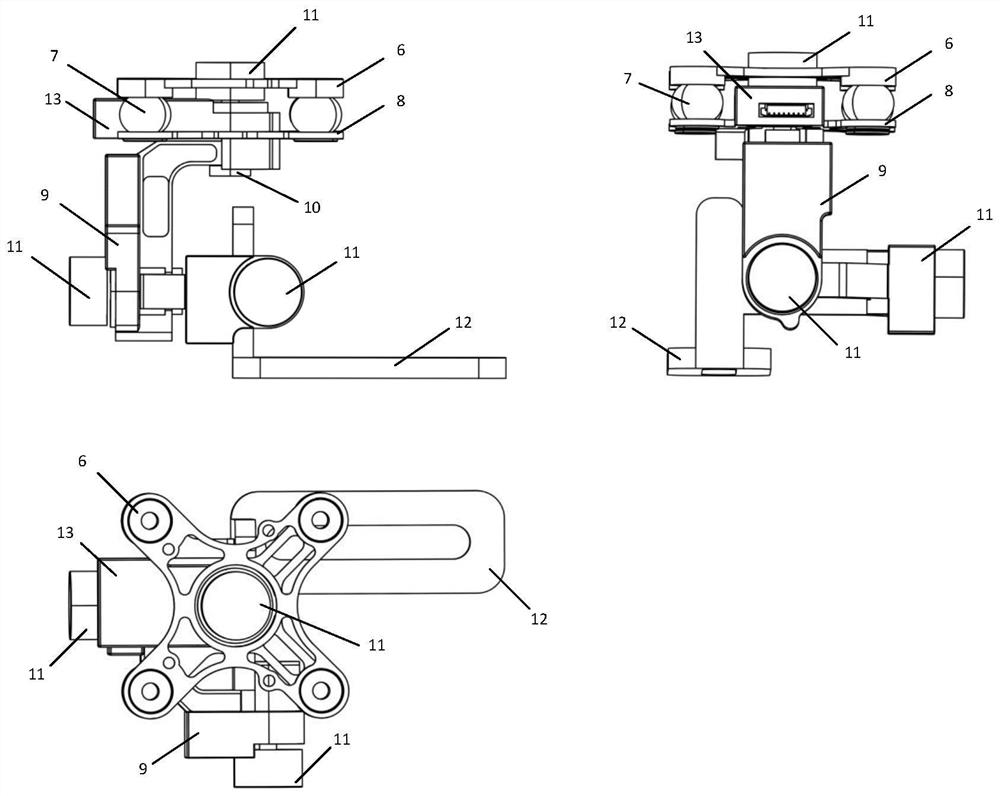

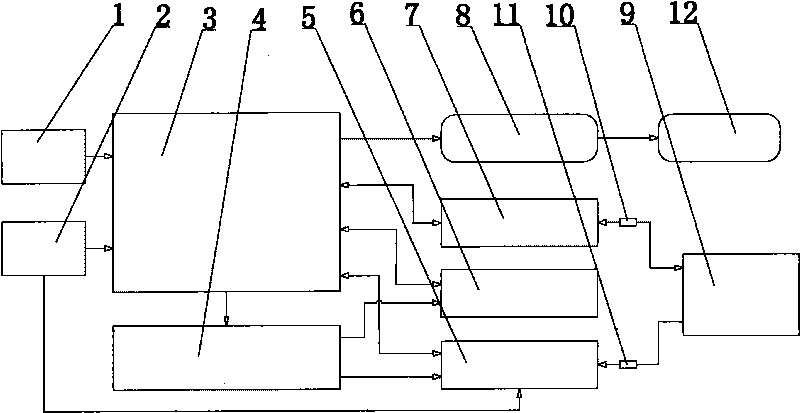

Modularized unmanned aerial vehicle anti-shake holder system based on LoRa

PendingCN113905077ACorrect position offsetReal-time control of angular offsetAircraft componentsMain station arrangementsCommunication unitAutomatic control

The invention discloses a modularized unmanned aerial vehicle anti-shake holder system based on LoRa. The modularized unmanned aerial vehicle anti-shake holder system comprises an anti-shake holder and a remote client, the anti-shake holder is fixed on a unmanned aerial vehicle, and realizes communication with the remote client through a LoRa communication unit; the remote client is used for selecting an operation mode of the anti-shake holder and remotely monitoring an acceleration parameter and a pose parameter of the holder at the same time; the anti-shake holder comprises an acrylic quick-release plate, a ball screw, a direct current motor, a circuit bin, a supporting block, an upper supporting frame, a lower supporting frame, a rubber ball, a connecting rod, a fixing shaft, an objective table and a brushless holder motor. The system adopts a modular design, has the characteristics of easy installation, remote control, reduction of unmanned aerial vehicle resource utilization and the like, and has a certain reference value in the field of unmanned aerial vehicle automatic control.

Owner:NANJING INST OF TECH

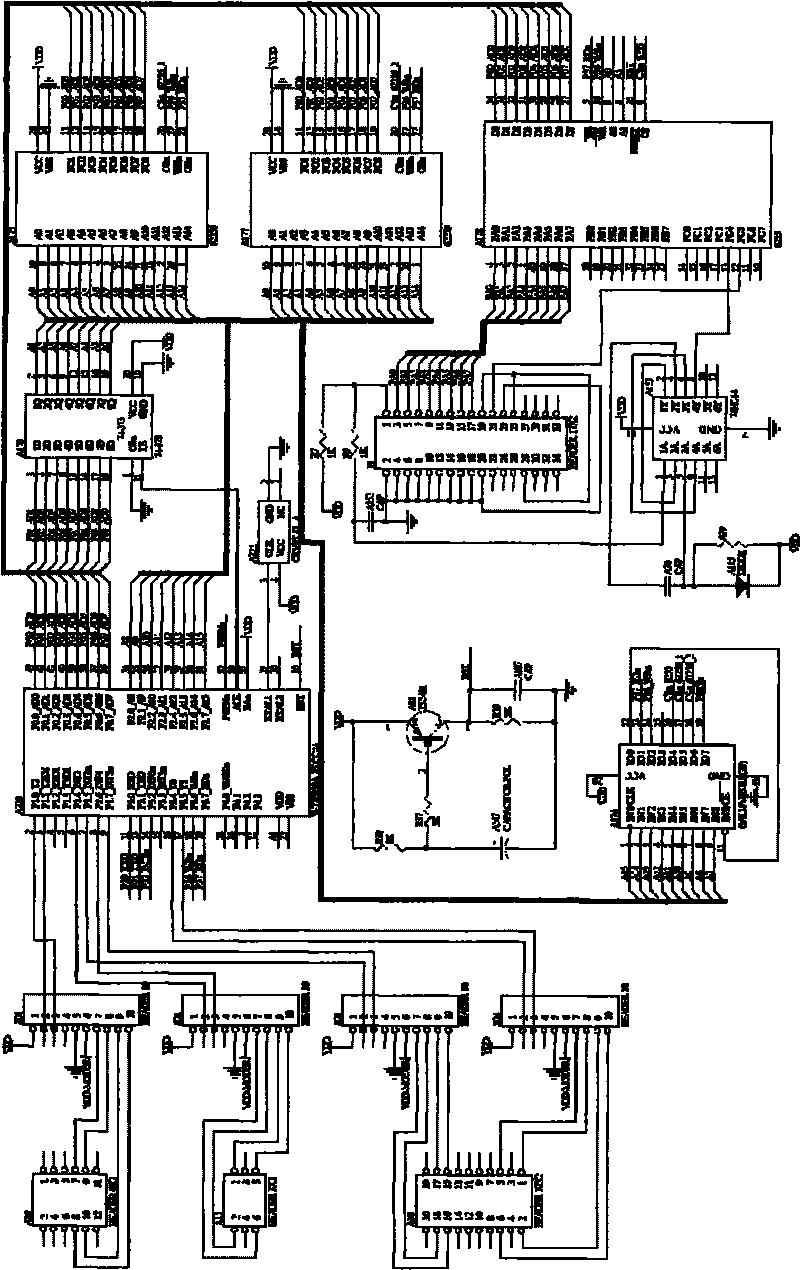

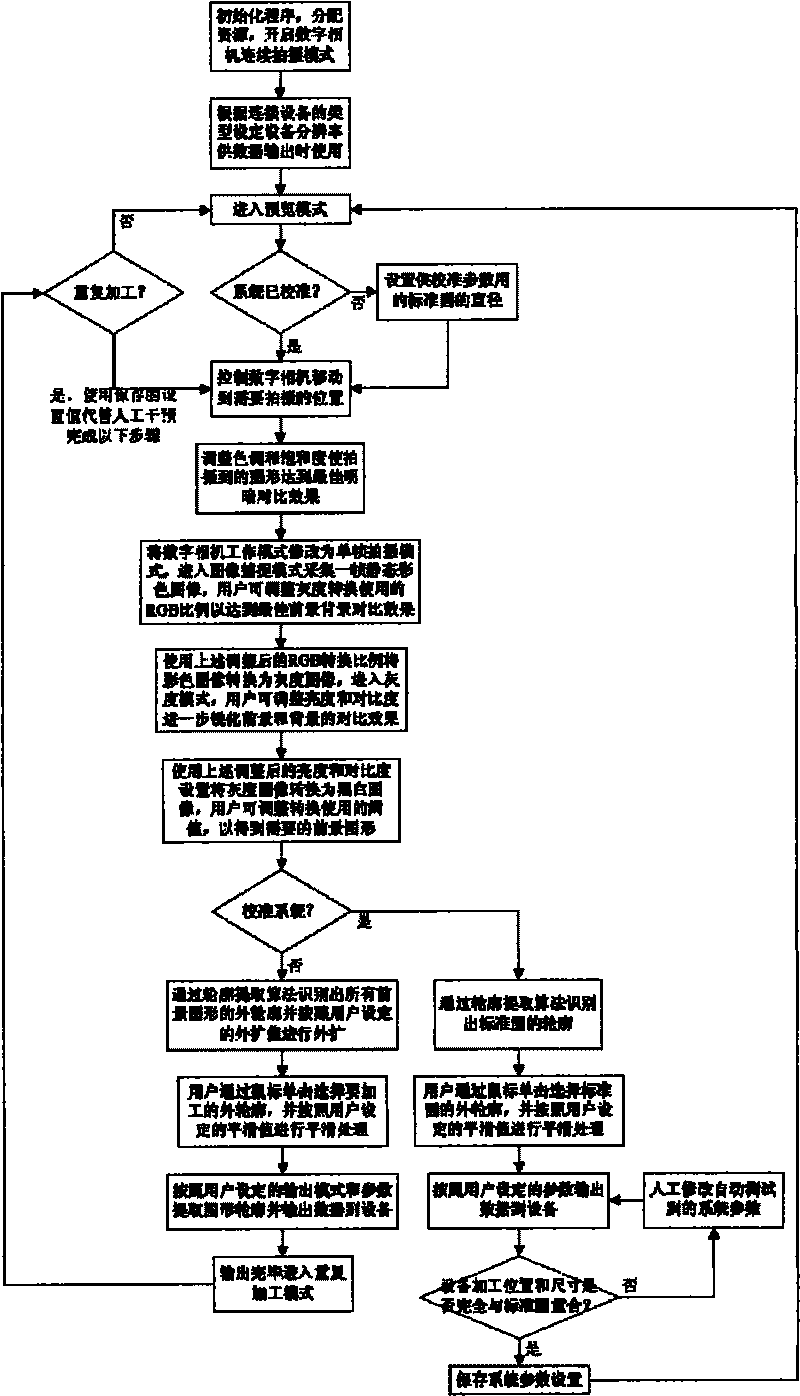

Automatic positioning and cutting system for photographic identification

ActiveCN101699358AWith automatic adjustment functionCorrect position offsetElectric digital data processingNumerical controlElectric machineryLogic module

The invention relates to an automatic positioning and cutting system for photographic identification, which comprises a main control MCU module and a chip selection logic module, wherein the main control MCU module is connected with a To / From driving module, and the To / From driving module is connected with a motor; the main control MCU module is connected with an IO extension module, an external SRAM module and a serial port level conversion module, the IO extension module is in input connection with a reset module, and the IO extension module is connected with a PC module; the serial port level conversion module is connected with the PC module; the main control MCU module is in output connection with the chip selection logic module, and the chip selection logic module is connected with the IO extension module and the external SRAM module respectively; and an automatic re-positioning module and a matching module are arranged in the PC module. The automatic positioning and cutting system has the beneficial effects that the automatic positioning and cutting system has the automatic adjustment function and can correct the position deviation, the angle deviation and the like, automatically generate a path and identify the deformation, the position derivation and the rotation of a work piece in a real time manner.

Owner:BEIJING KAITIAN TECH

Integrated circuit device, electro optical device and electronic apparatus

ActiveUS8605079B2Avoid irregularitiesAvoid normal displayCathode-ray tube indicatorsInput/output processes for data processingComputer scienceImaging data

An integrated circuit device having a data line driving circuit and a position offset addition circuit that connects position offsets based on position offset setting values, wherein, among first pixel to p-th pixel of a plurality of pixels, a position offset register stores a first position offset setting value corresponding to the first pixel and a p-th position offset setting value corresponding to the p-th pixel among the first pixel to the p-th pixel; among first image data to p-th image data respectively corresponding to the first pixel to the p-th pixel, the position offset addition circuit processes a position offset correction value based on the first position offset setting value to the first image data, and processes a position offset correction value based on the p-th position offset setting value to the p-th image data among the first image data to p-th image data, to correct the position offsets.

Owner:SEIKO EPSON CORP

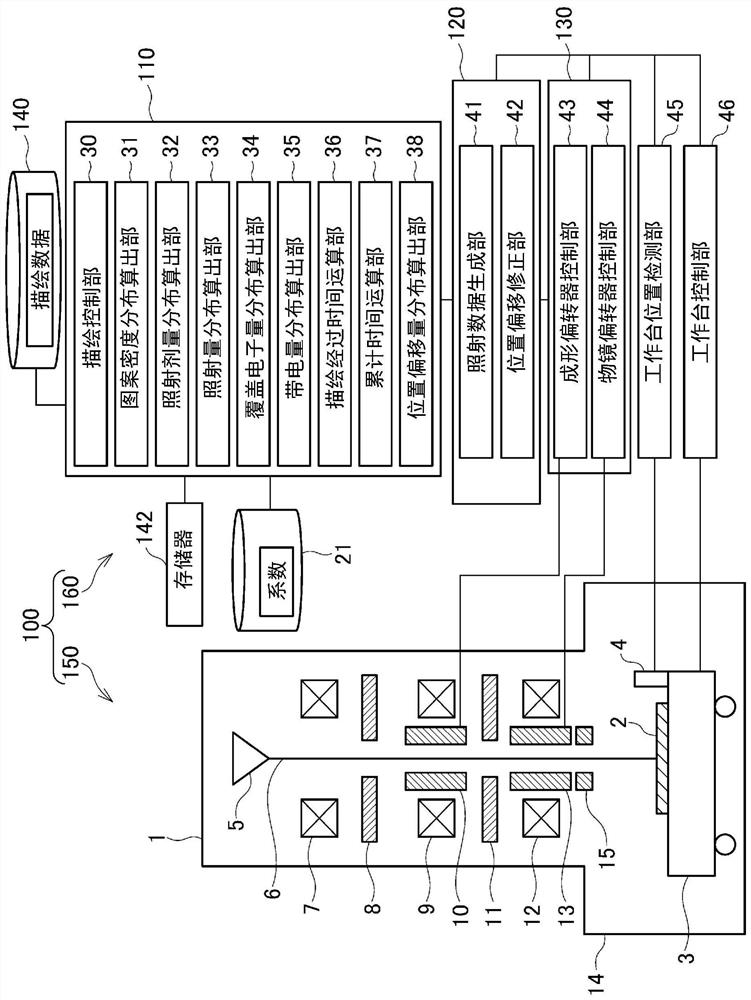

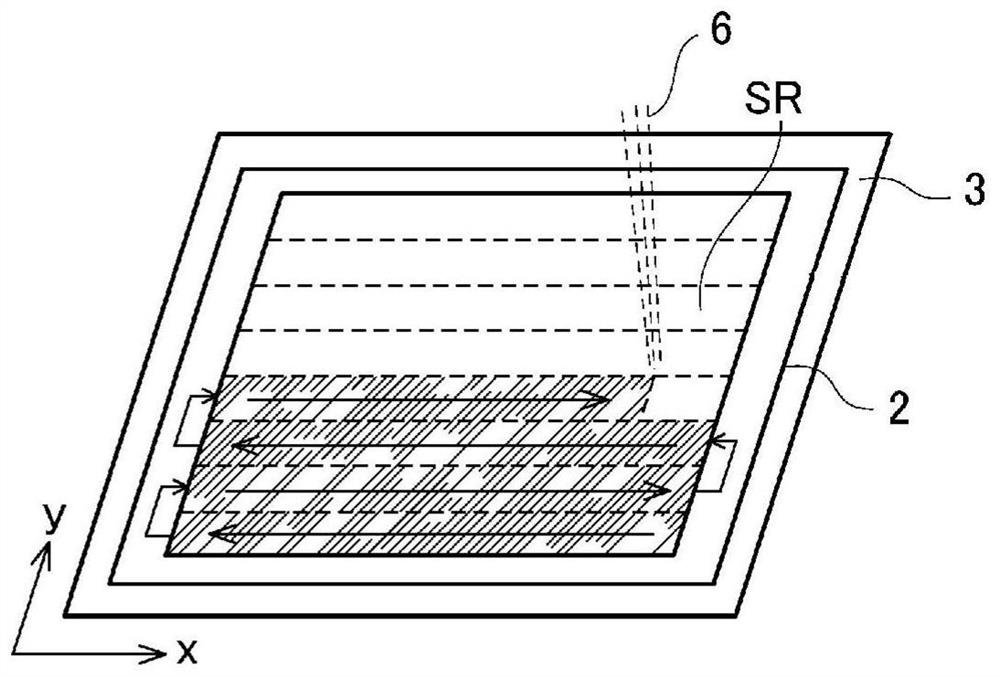

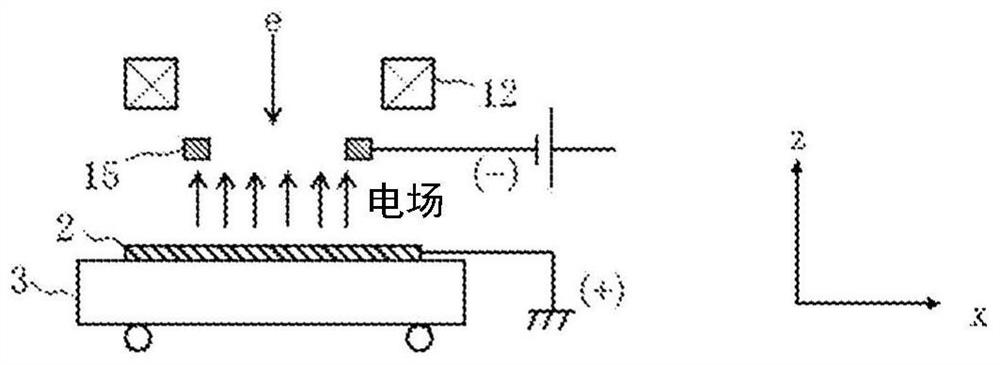

Charged particle beam drawing device, charged particle beam drawing method, and program

PendingCN112840437ACorrect position offsetElectric discharge tubesSemiconductor/solid-state device manufacturingParticle beamParticle physics

The purpose of the present invention is to correct, in a highly accurate manner, positional displacement due to a charging phenomenon. A charged particle beam drawing device (100), provided with: an irradiation amount distribution calculation unit (33) for calculating the irradiation amount distribution of a charged particle beam using a pattern density distribution and dose distribution; a fogging charged particle amount distribution calculation unit (34) for convolution-integrating each of the irradiation amount distribution and the respective distribution function for a plurality of fogging charged particles, and thereby calculating a plurality of fogging charged particle amount distributions; a charge amount distribution calculation unit (35) for calculating the charge amount distribution due to direct charging using the pattern density distribution, the dose distribution, and the irradiation amount distribution, and calculating the charge amount distribution due to a plurality of fogging charges using the plurality of fogging charged particle amount distributions; a positional displacement amount calculation unit (38) for calculating the positional displacement amount of the drawing position on the basis of the charge amount distribution due to direct charging and the charge amount distribution due to the plurality of fogging charges; a correction unit (42) for correcting the irradiation position using the positional displacement amount; and a drawing unit (150) for irradiating the corrected irradiation position with a charged particle beam.

Owner:NUFLARE TECH INC

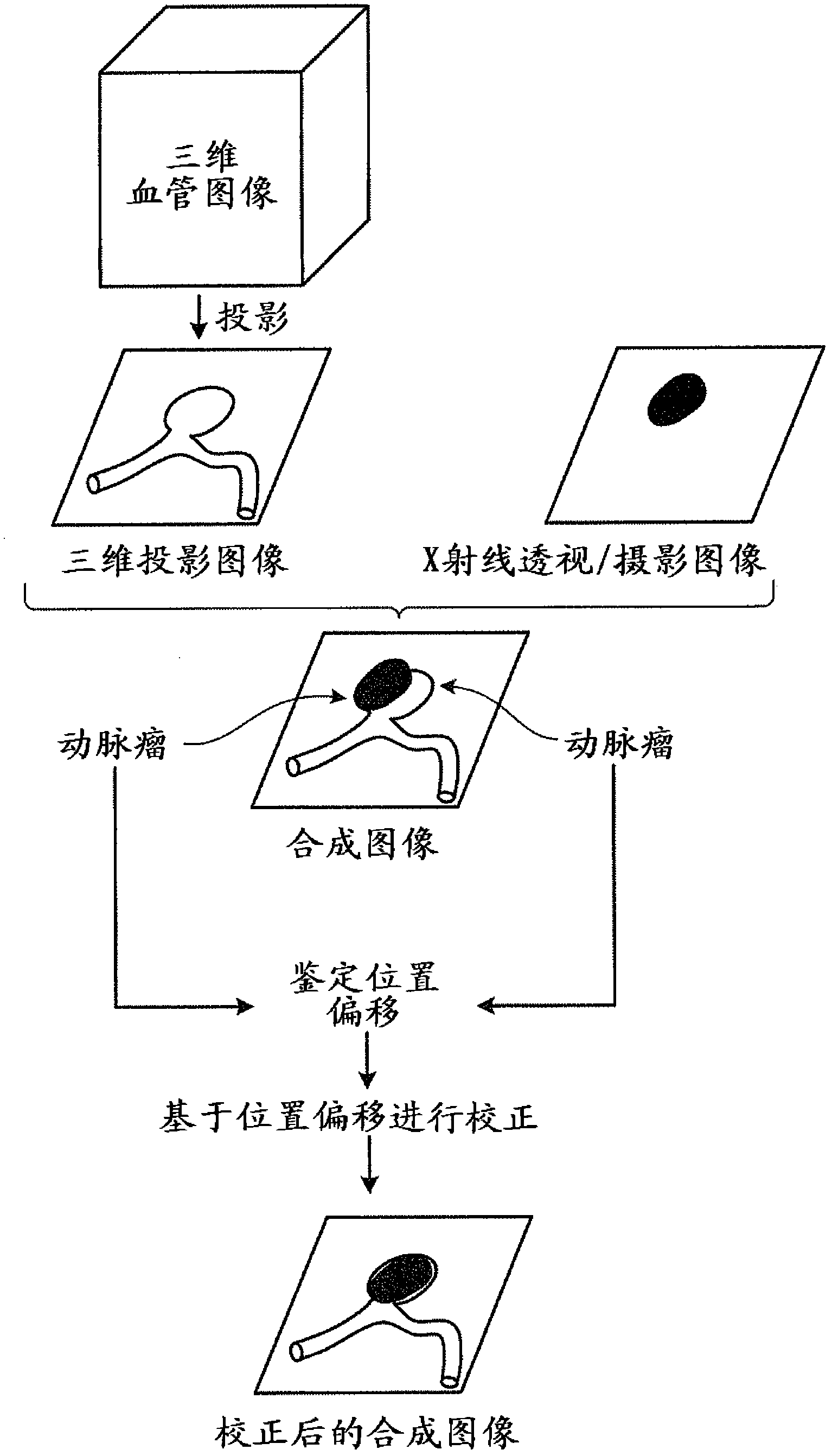

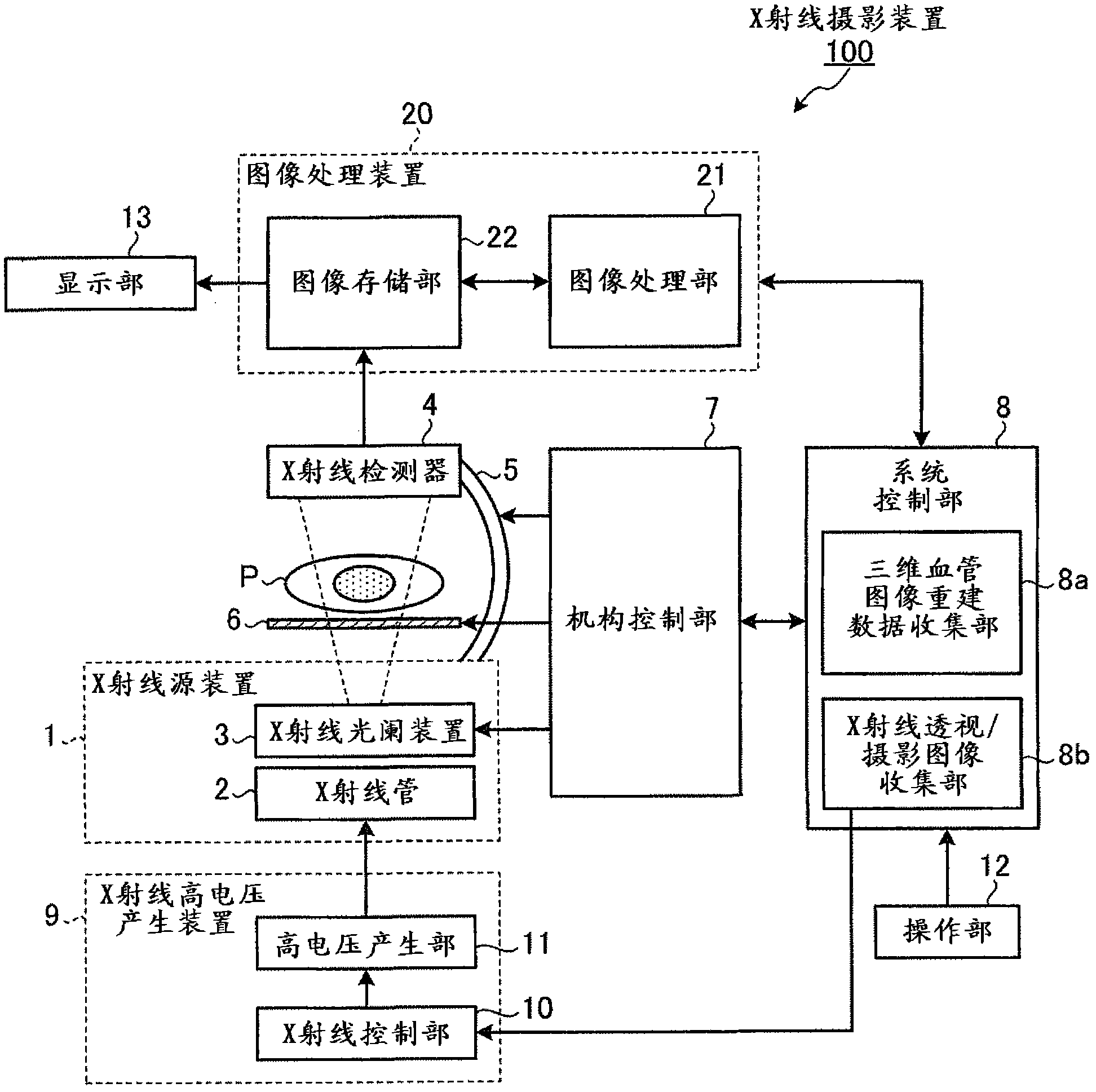

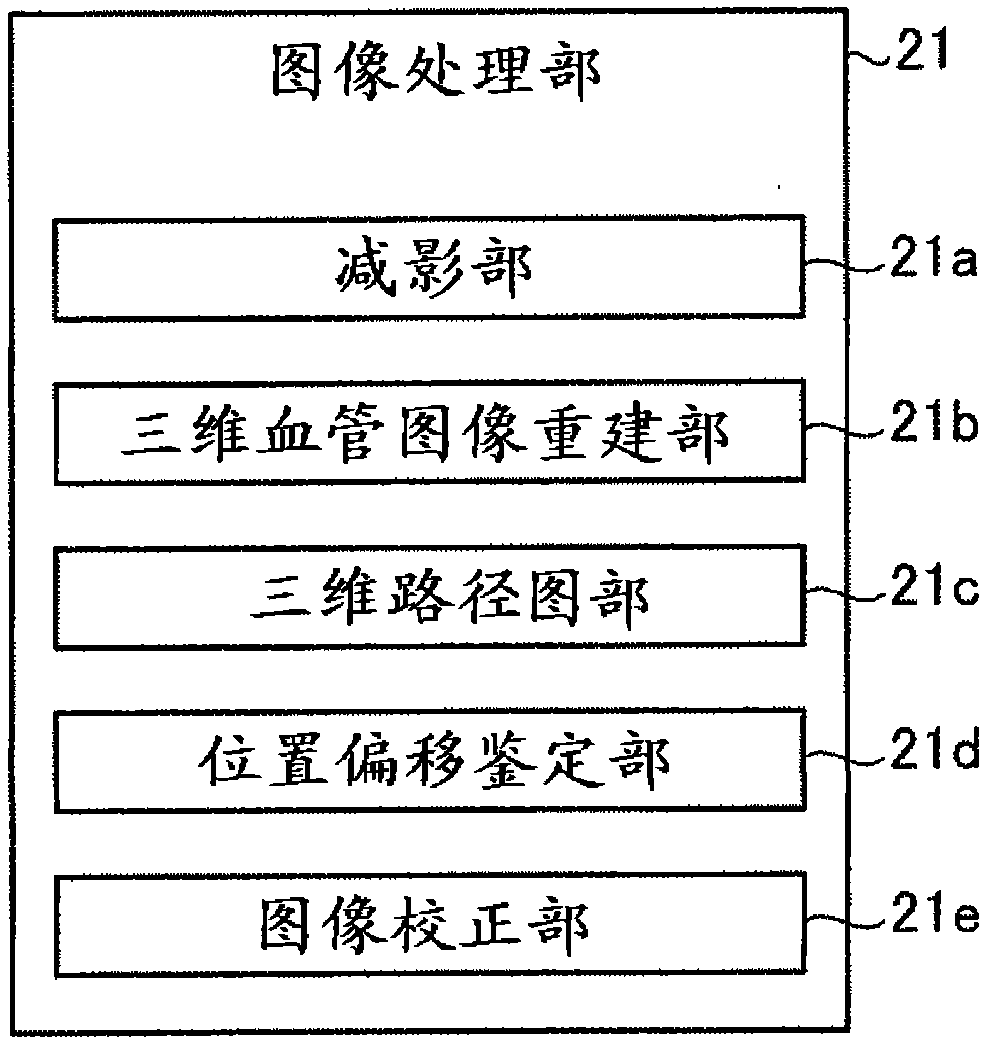

X-ray photography device

ActiveCN102048548BCorrect position offsetImage enhancementReconstruction from projectionSoft x rayProjection image

The present invention relates to an X-ray imaging apparatus in which a three-dimensional blood vessel image collecting unit collects three-dimensional blood vessel images. In addition, the X-ray image collection unit collects X-ray images. Then, the composite image generator generates a three-dimensional projection image projected based on the state of the X-ray imaging device based on the collected three-dimensional blood vessel image, and generates a composite image of the generated three-dimensional projection image and the X-ray image. Next, the positional displacement identification unit identifies a positional deviation between the aneurysm on the three-dimensional projection image and the aneurysm on the X-ray image. Then, the display control unit performs control to correct the composite image using the identified positional shift, and displays the corrected composite image on the display unit.

Owner:TOSHIBA MEDICAL SYST CORP

Optical axis adjusting apparatus, optical axis adjusting method, and projection type display apparatus

InactiveCN102326114BGood projected imageCompact structureTelevision system detailsProjectorsLocation detectionProjection image

A projection type display apparatus in which an inclination and a positional deviation of optical axes among a plurality of light sources can be easily corrected to obtain a high quality projection image. Green, blue and red laser beams emitted from light sources are converted into collimated beams by condenser lenses, and the positions and angles of the optical axes of the beams of the three colors are evaluated by position detection imaging device and angle detection imaging device, respectively. The positions and angles of the light sources are adjusted by respective actuators so that the positions and angles of the optical axes match each other. Consequently, the laser beams emitted from the light sources can be combined with high accuracy to thereby realize a high definition projection type display apparatus.

Owner:HITACHI LTD

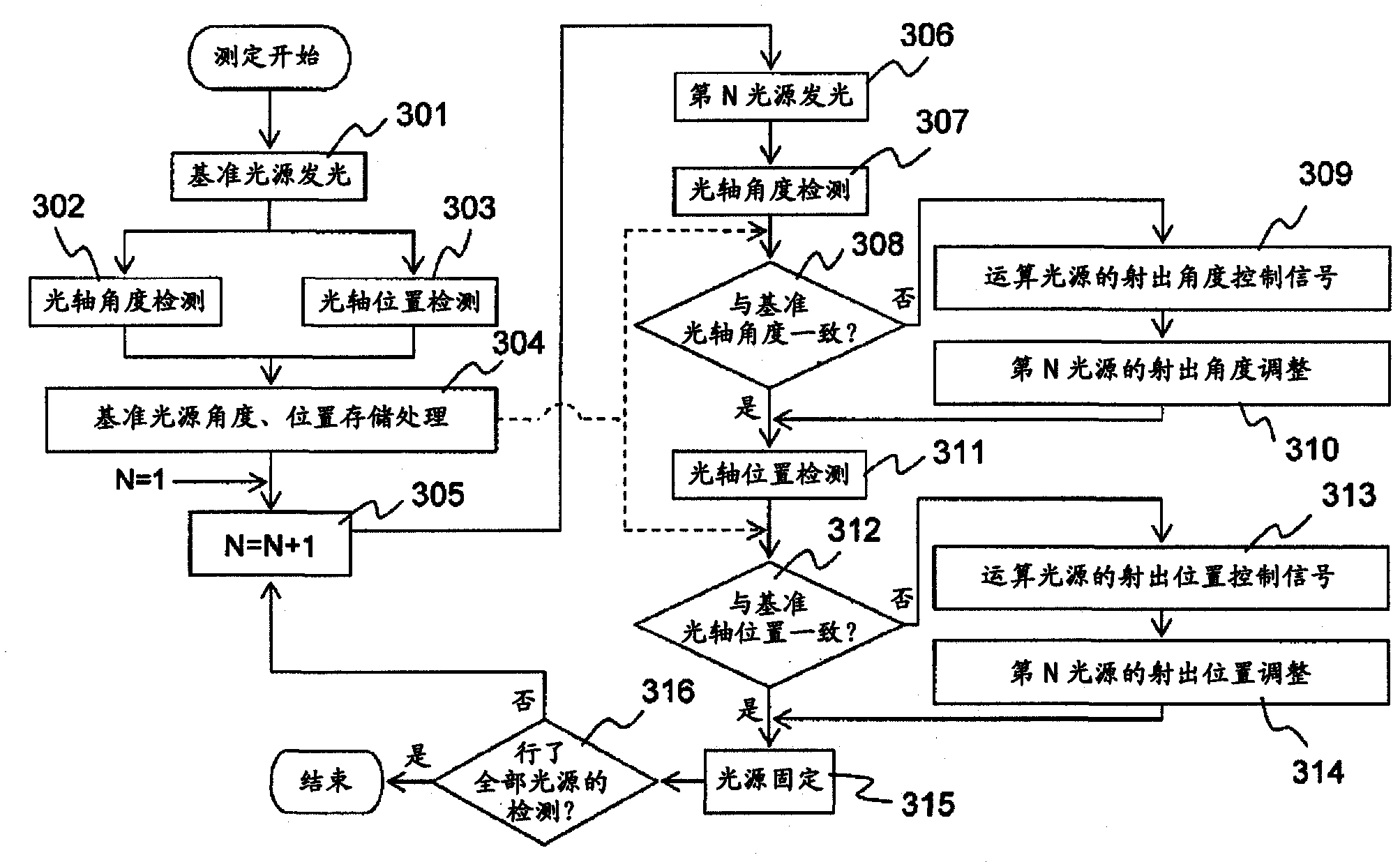

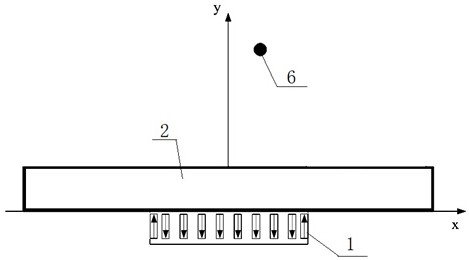

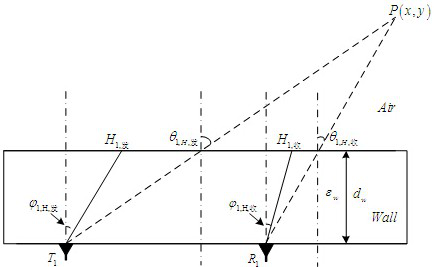

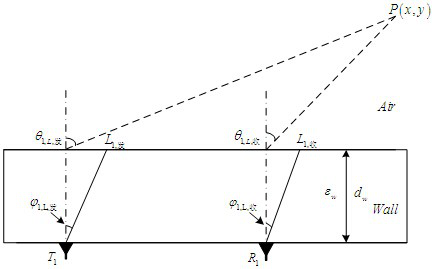

Fast wall compensation method for mimo through-wall radar imaging

ActiveCN108717188BOvercoming the problem of excessive computationCorrect position offsetRadio wave reradiation/reflectionPropagation delayTransceiver

The invention discloses a fast wall compensation method suitable for MIMO through-wall radar imaging, which comprises the following steps: setting the radar to establish a coordinate system, and specifying pixel points; the MIMO through-wall radar performs multi-transmit and multi-receive real-aperture face-on detection to obtain echoes Signal; find the upper end and lower end corresponding to the first pixel point to calculate the abscissa, calculate the propagation delay value of the first pixel point corresponding to all the transceiver channels, and finally get the propagation delay value of all the pixel points corresponding to all the transceiver channels; combined with the echo signal and propagation delay values according to backprojection imaging to form the final image. The present invention avoids the problem of excessive computational load caused by iteration and traversal in the traditional wall compensation method, and at the same time has the good characteristics of correcting the position deviation of the target image and having a large focused imaging area, and the finally obtained output image can be used for positioning , identifying and extracting targets, and has a good application prospect in MIMO through-wall radar imaging applications that require real-time processing.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

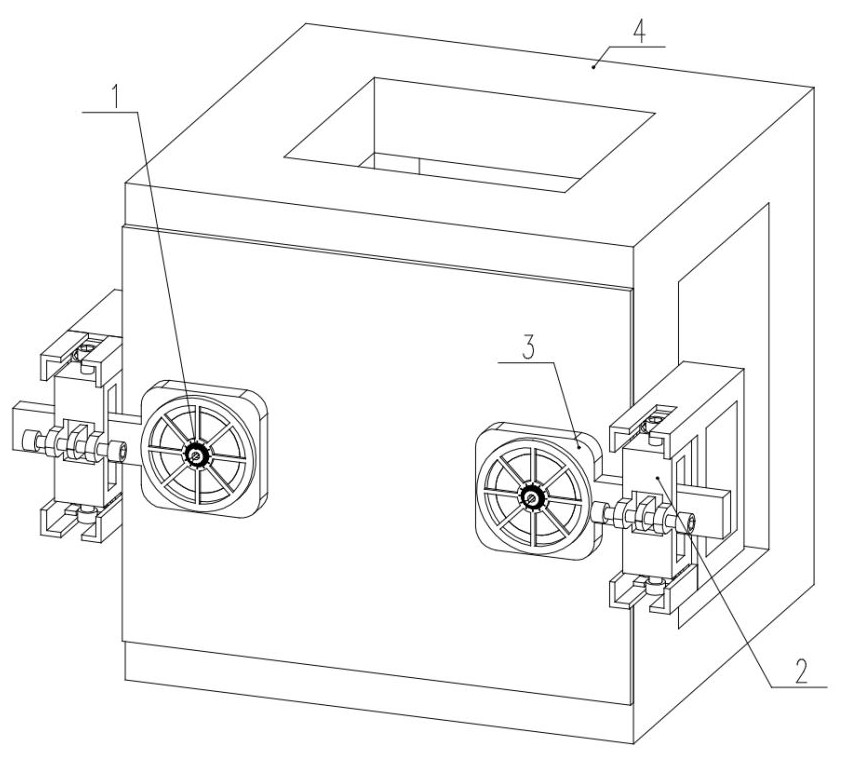

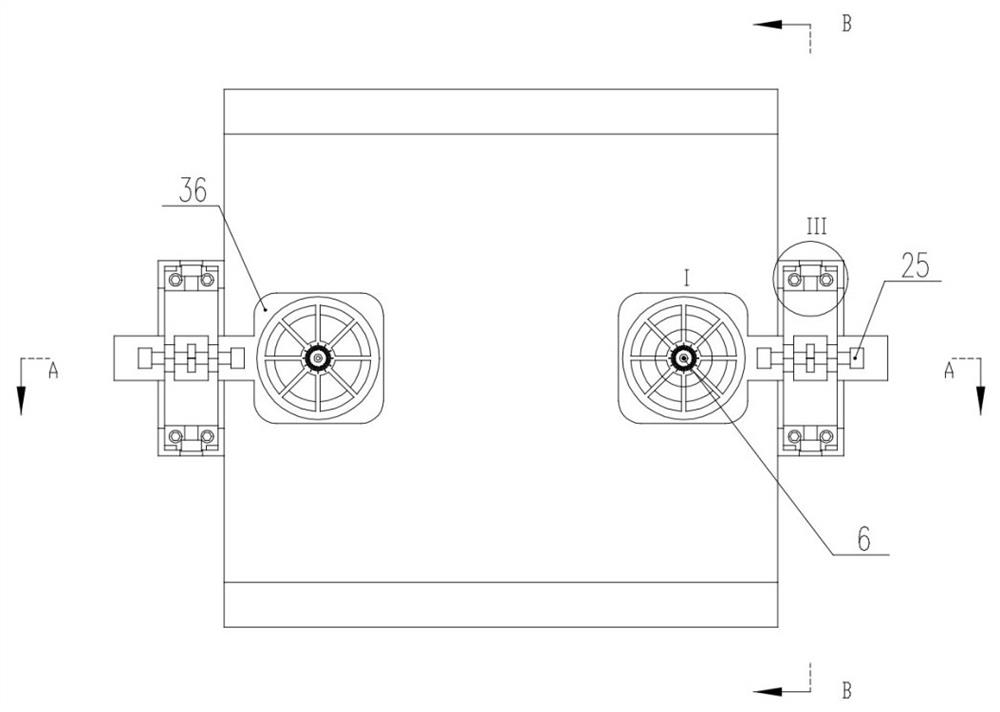

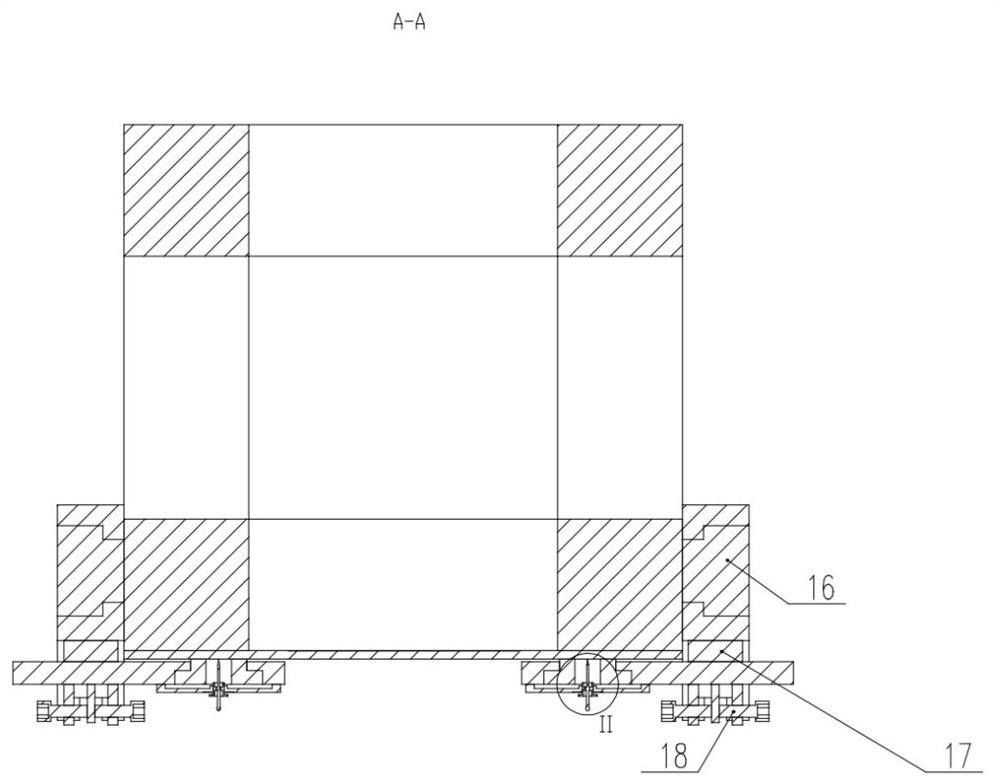

Clamping device for manual welding of vertical face of electric appliance cabinet and application method of clamping device

PendingCN113560797AEffective observationEasy to observeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention discloses a clamping device for manual welding of a vertical face of an electric appliance cabinet and an application method of the clamping device. The clamping device comprises a three-dimensional pointer type feedback warning device, a three-axis type two-way fine adjustment reset device, an adjustable ferromagnetic iron sheet adsorption device and a to-be-welded main body rack. The invention belongs to the technical field of welding clamping devices, and particularly relates to the clamping device for manual welding of the vertical face of the electric appliance cabinet and the application method of the clamping device. Through the three-dimensional pointer type feedback warning device, the amplitude and the direction of position deviation generated by the tip, making contact with an iron skin, of a pointer body are fed back, observation by operators is facilitated, and deviation correction measures can be conveniently taken in time when the deviation amplitude is too large; and an annular adjustable strong magnet drives the iron skin to translate, so that the position deviation of the iron skin caused by thermal stress in the welding process is corrected, the technical prejudice that the skin can only be clamped and fixed in the opposite direction is overcome, and the problem that the edge closing position of the side face of the rack cannot be clamped and positioned is effectively solved.

Owner:江苏楚亚电气科技有限公司

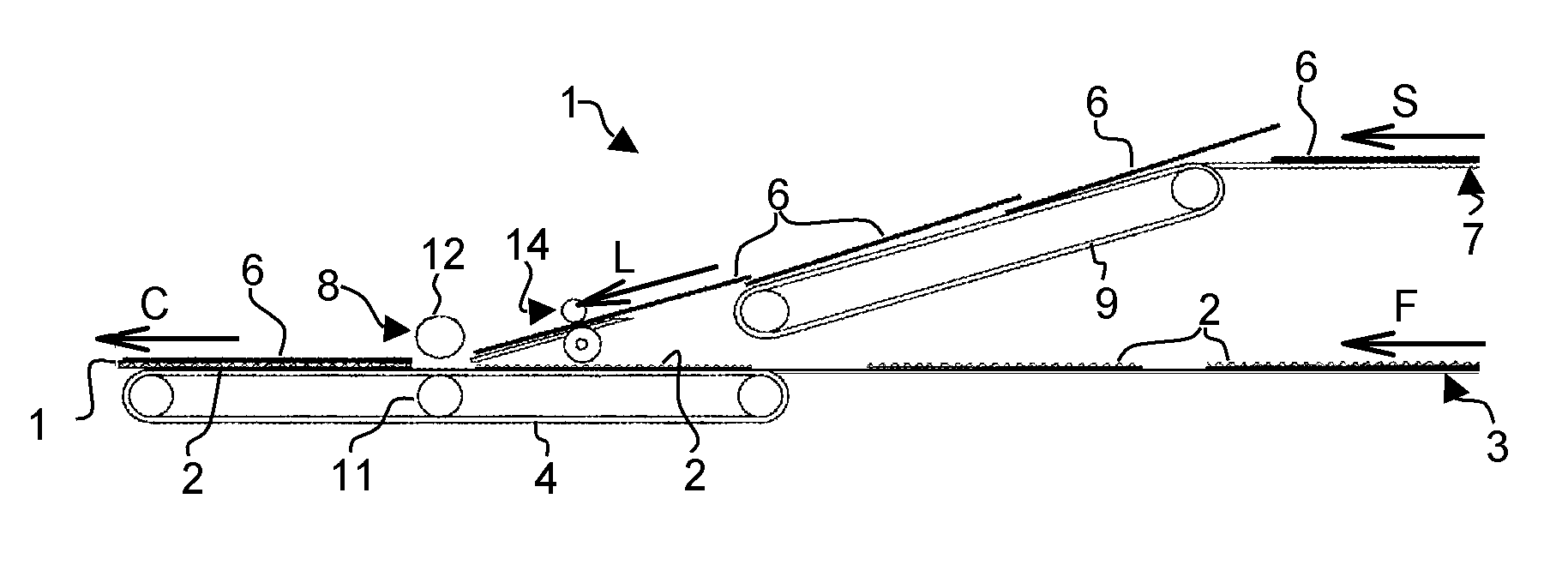

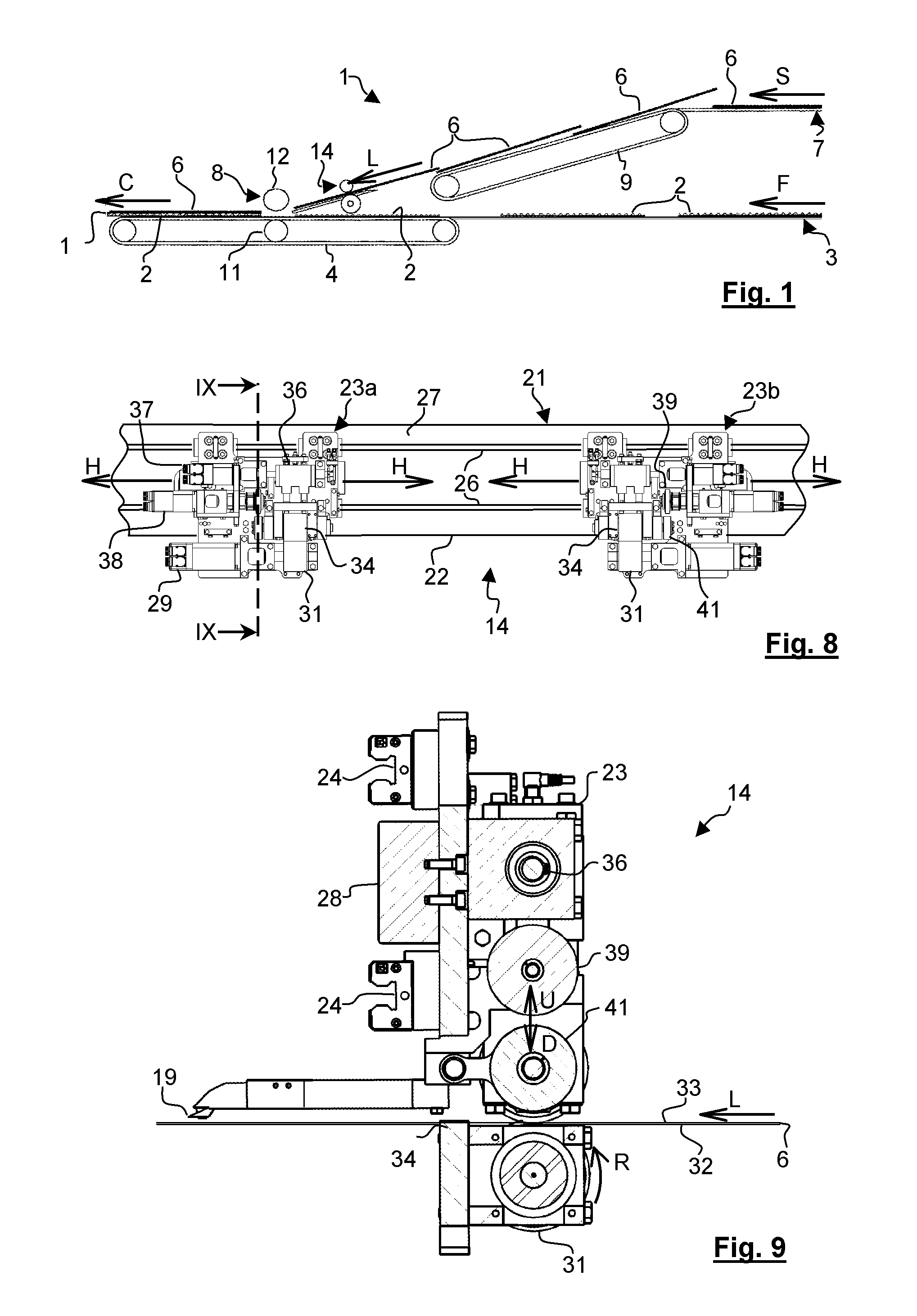

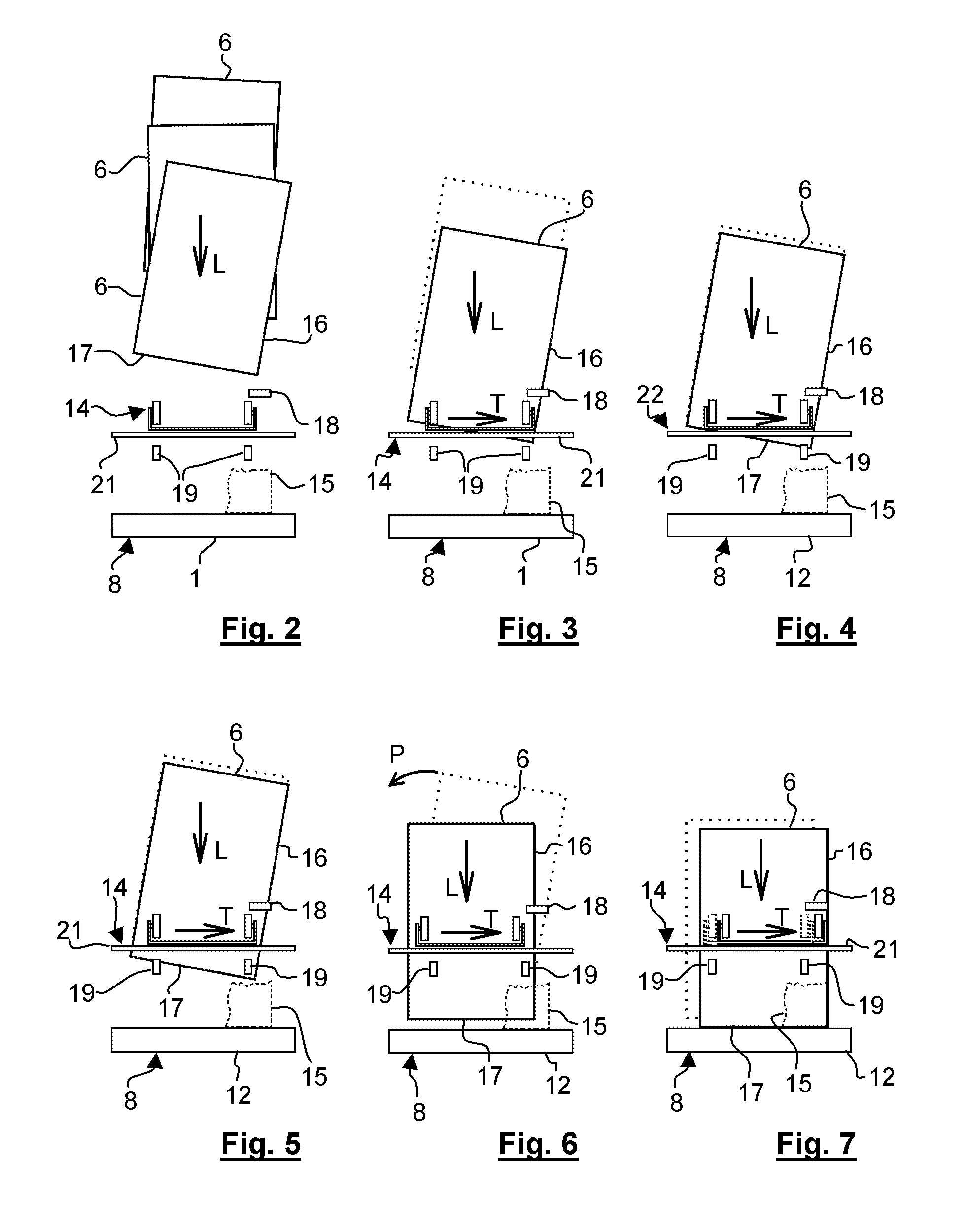

Method for manufacturing a multi-layer composite, arrangement for positioning a sheet-like element onto a backing in a laminating unit

ActiveUS9011617B2Increase speedCorrect position offsetLamination ancillary operationsControlling laminationEngineeringLateral movement

A method and an arrangement for manufacturing a multi-layer composite (13) by laminating a sheet-like element (6) onto a backing (2) in a laminating unit (1), having steps, in this order, of conveying the element (6) in a longitudinal direction, detecting a position of the element (6), correcting the position of the element (6) on the basis of the detected position and on the basis of a reference position (15), and bonding said element (6) onto the backing (2). The detection step comprises the phases of measuring the lateral position, an angle of pivoting, and a longitudinal position of the element (6), and the correction step includes phases of lateral movement (T), pivoting (P), and longitudinal movement (L) of the element (6), apparatus elements perform the steps.

Owner:ASITRADE

Decal transferring method and decal transferring device

Owner:YKK CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com