Base plate output-input device and base plate output-input method

A technology of output, input, and substrate, which is applied in the field of substrate input and output devices, and can solve problems such as lack of settings, inability to manufacture uniform products, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

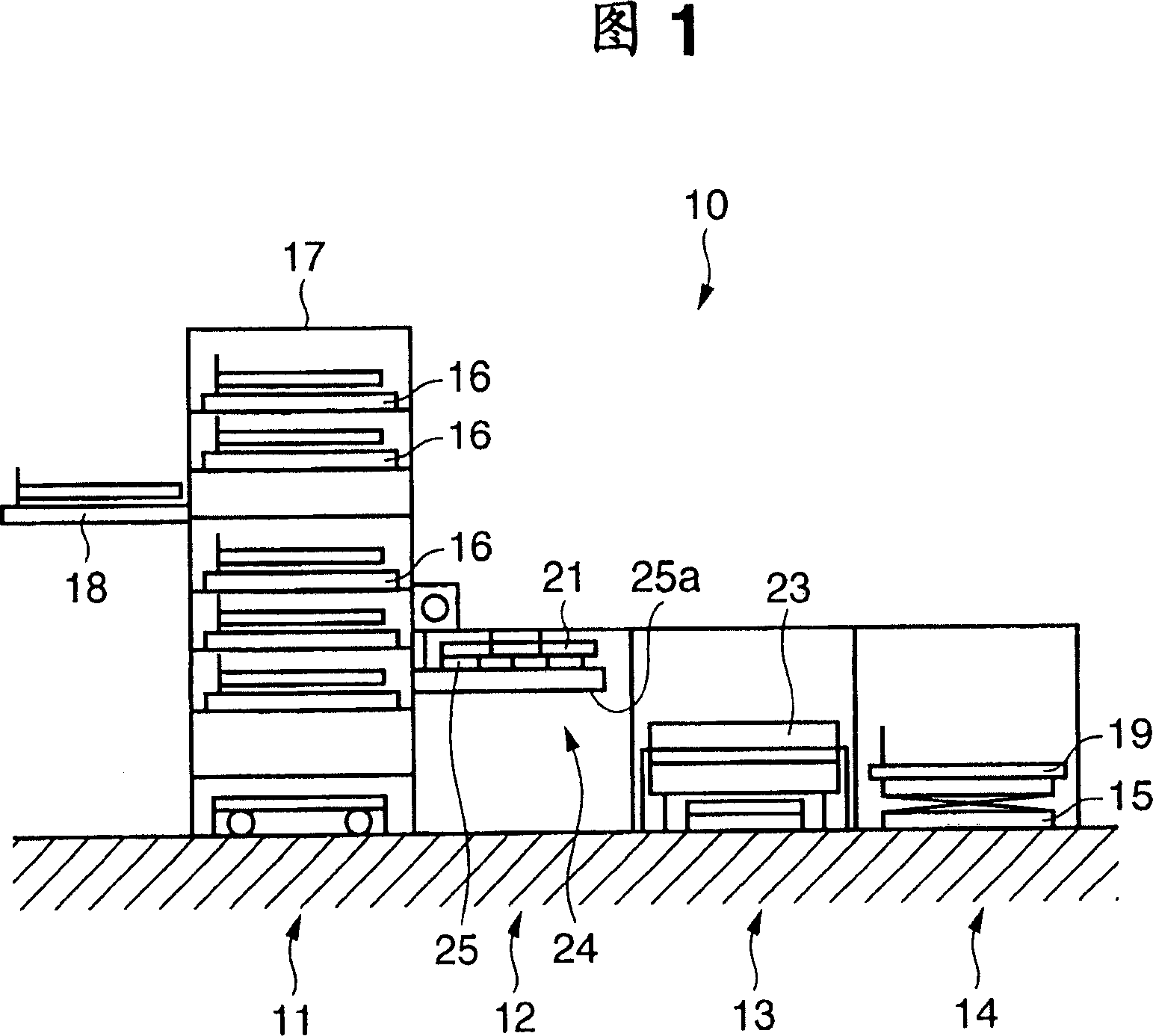

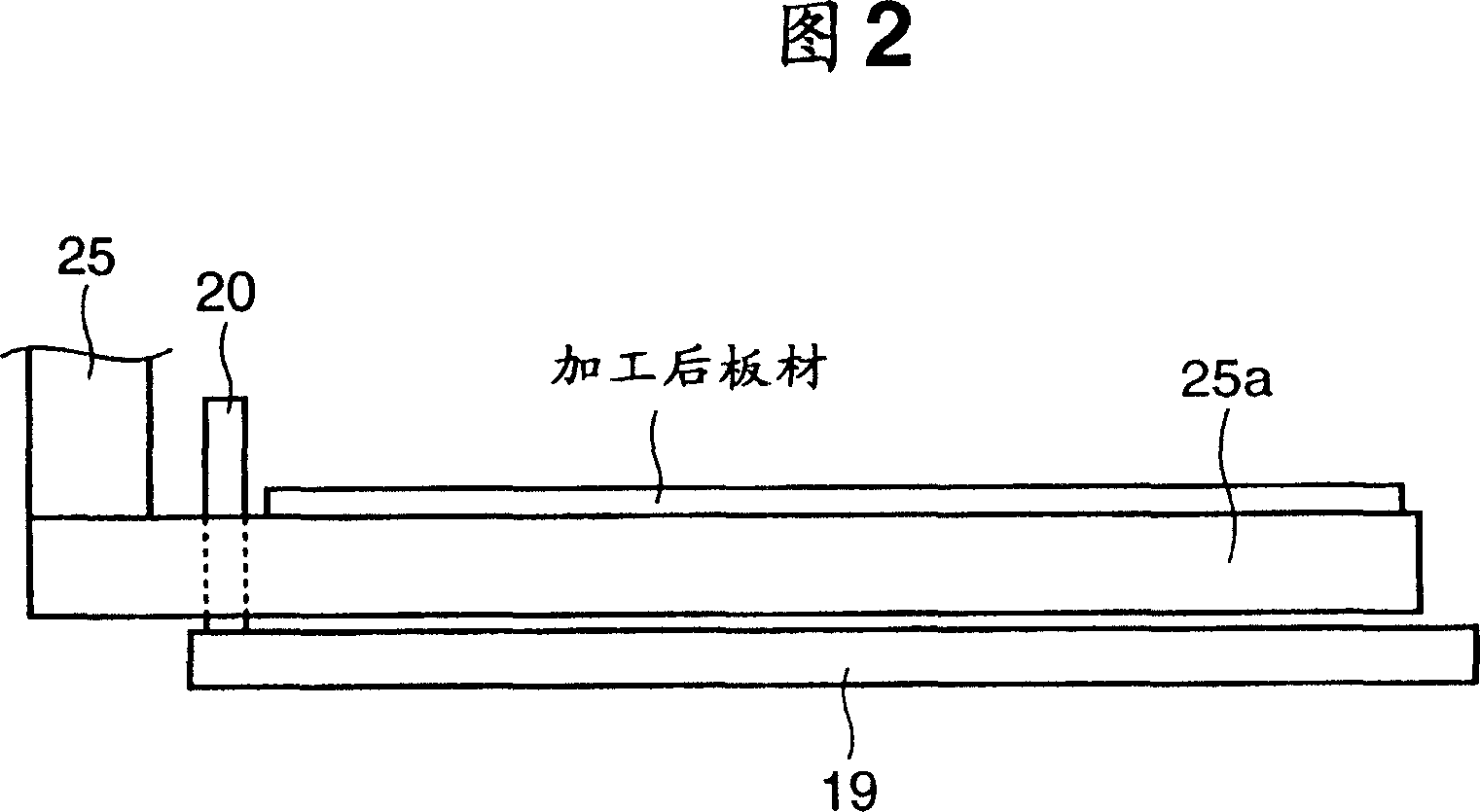

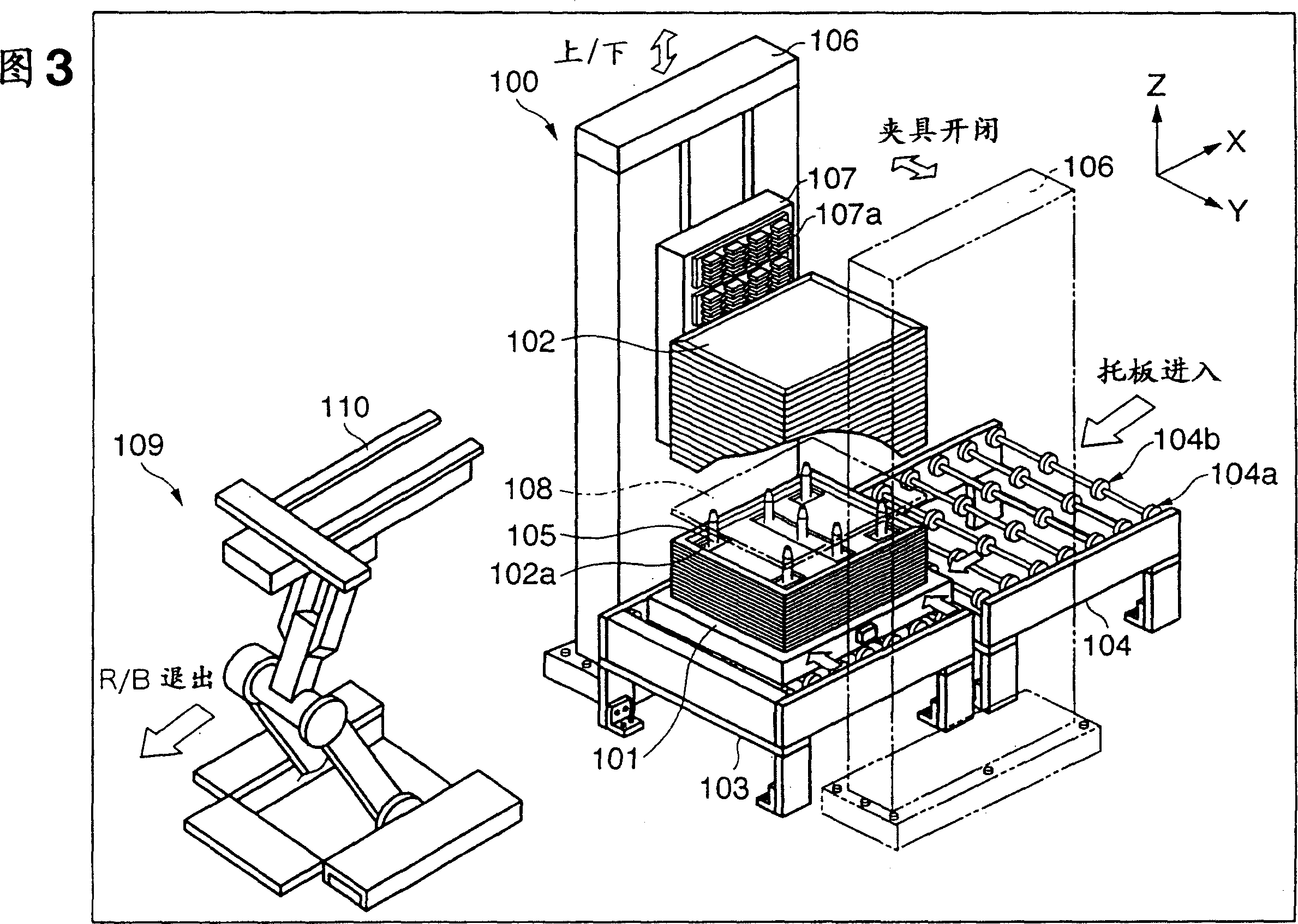

[0034] Hereinafter, an embodiment of a board input / output device to which the present invention is applied will be described with reference to the drawings.

[0035]FIG. 3 is an external view showing the entire board output / input device 100 of the present invention. The substrate input / output device 100 has a function of sequentially taking out the glass substrates 108 from the trays 102 stacked on the pallet 101, and then loading the processed substrates on the trays again. In addition, when substrates are loaded in all trays, the glass substrates 108 are taken out in order from the lowest tray. In addition, for example, when all trays in the lower layer of a tray of a certain layer are empty, the glass substrate 108 may be taken out from the tray or loaded into the tray with that layer as the processing target. When the glass substrate 108 is mounted on the trays of all layers, the glass substrates are taken out sequentially from below, and when the glass substrates are loaded i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com