Automatic positioning and cutting system for photographic identification

A cutting system and automatic positioning technology, applied in the direction of instruments, electrical digital data processing, digital control, etc., can solve the problems of not being able to automatically adjust and adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

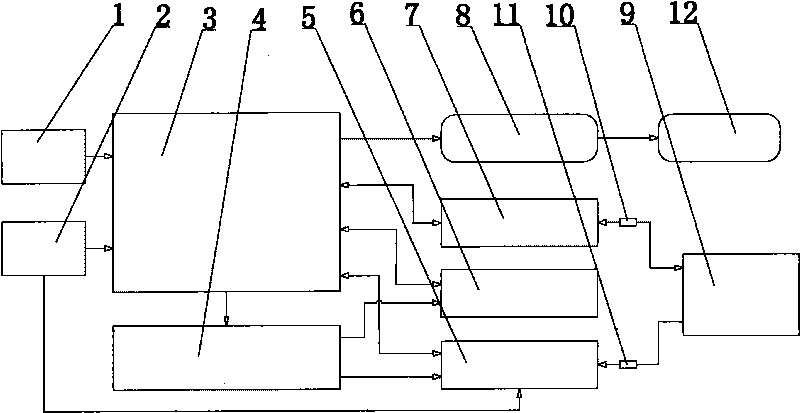

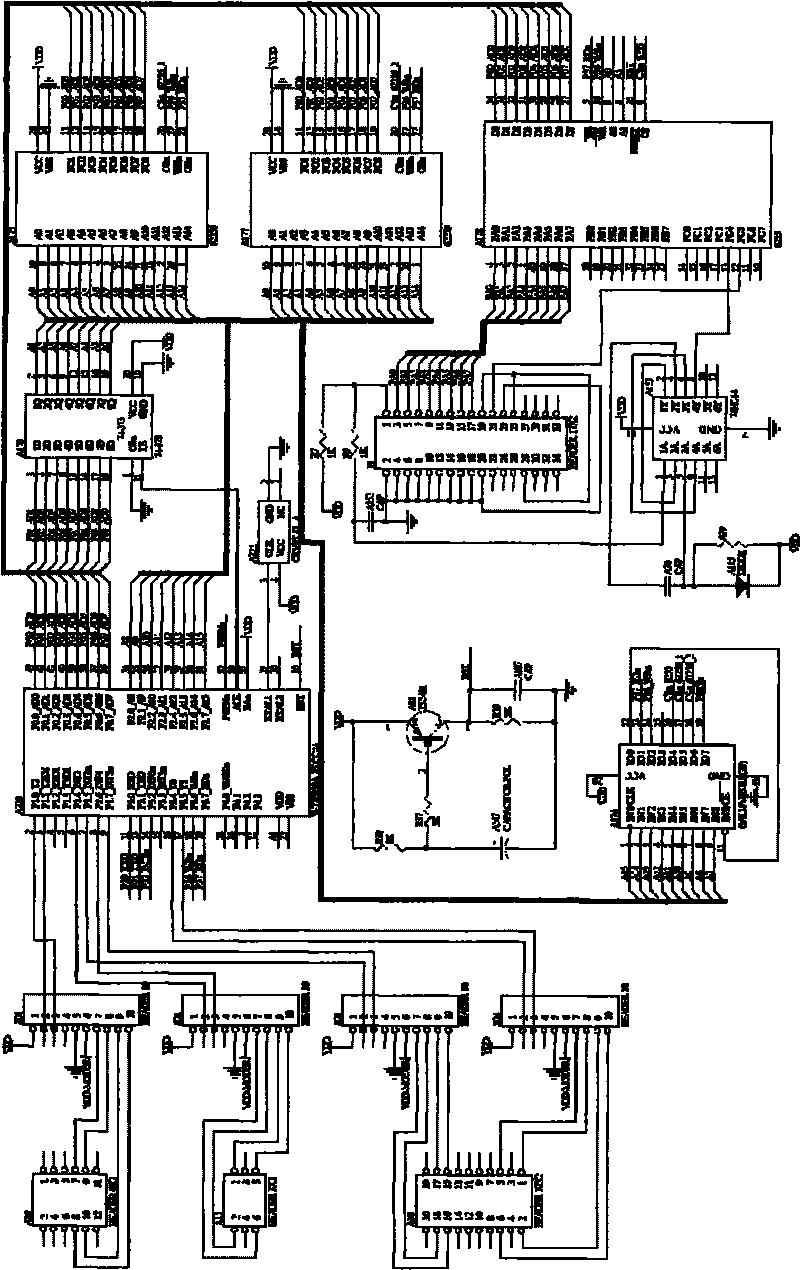

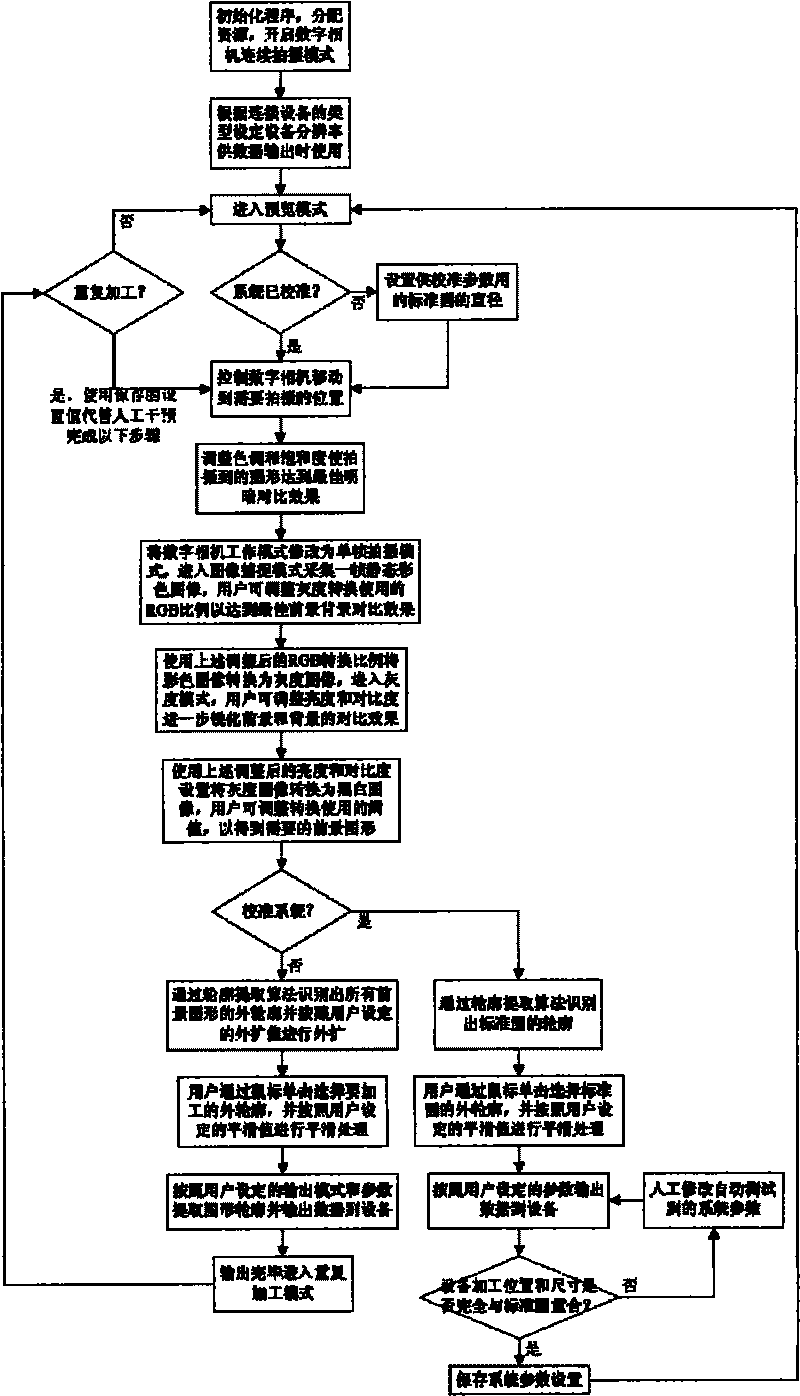

[0048] like figure 1 As shown, the camera recognition automatic positioning and cutting system described in the embodiment of the present invention mainly includes a main control MCU module 3 and a chip selection and logic module 4, and the main control MCU module 3 is input and connected to the crystal oscillator module 1 and the reset module 2. The output of the main control MCU module 3 is connected to the To / From drive module 8, and the output of the To / From drive module 8 is connected to the motor 12. The main control MCU module 3 can send the control signal of the motor 12 through the To / From drive module 8 to obtain the drive signal of the motor 12. , so as to control the motor 12; the input / output of the main control MCU module 3 is connected to the IO expansion module 5, the external SRAM module 6 and the serial port level conversion module 7, and the external SRAM module 6 can provide the required chips for the main control MCU module 3 External SRAM support; IO expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com