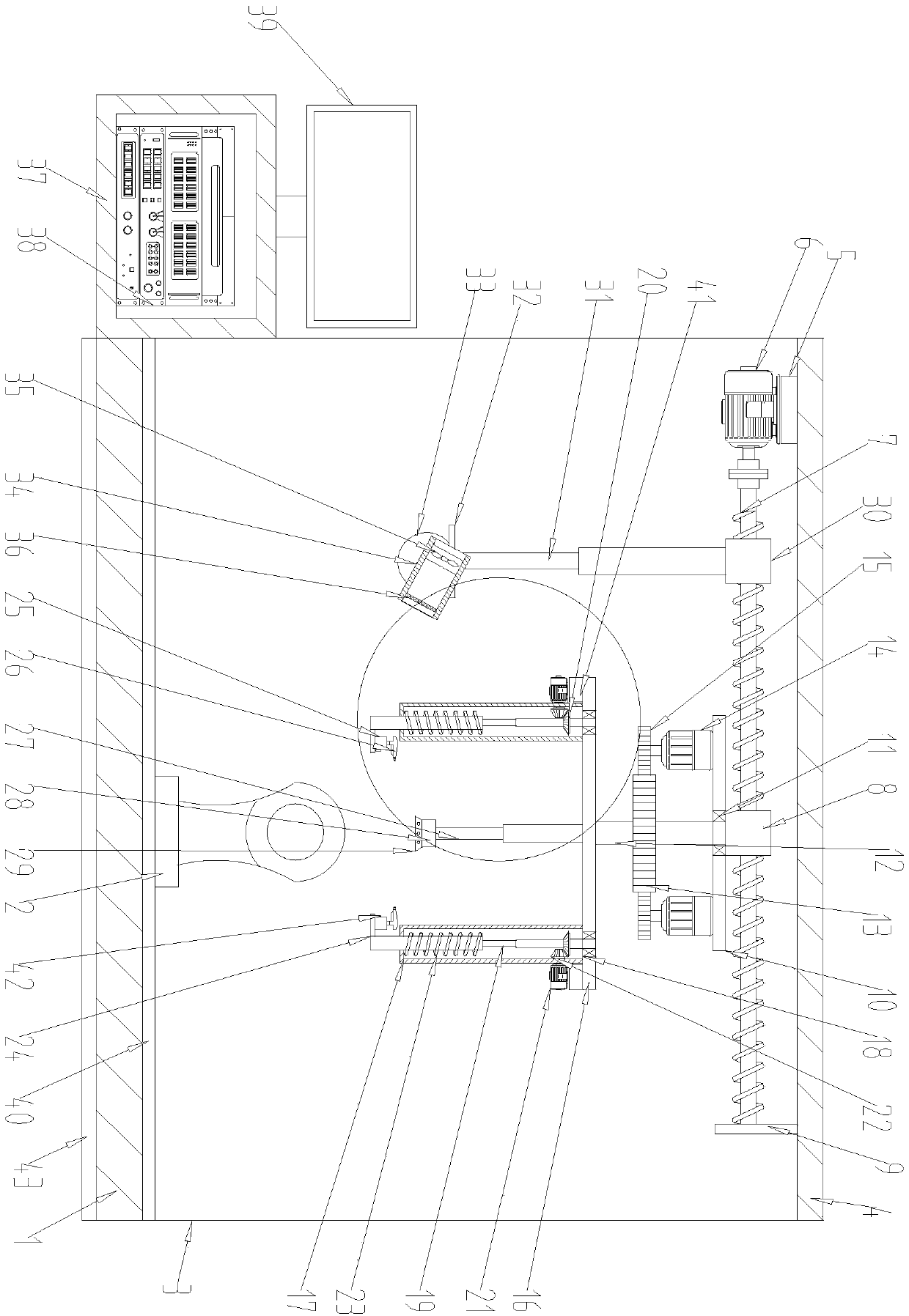

Coating device for building artworks, having automatic adjusting function

A work of art, automatic adjustment technology, applied to the surface coating liquid device, spray device, coating, etc., can solve the problems of uneven spraying, low efficiency, poor effect, etc., to improve work efficiency, facilitate replacement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

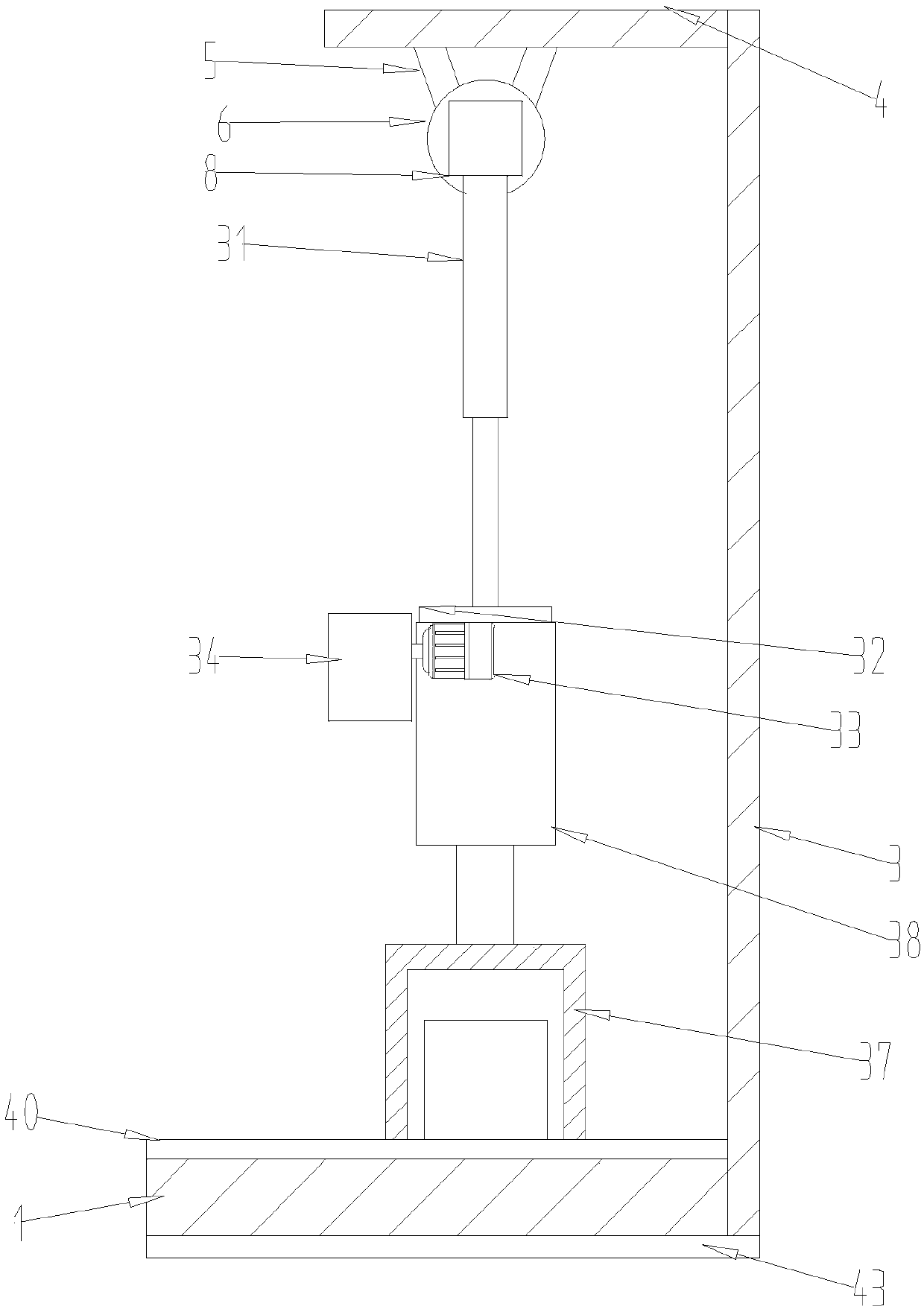

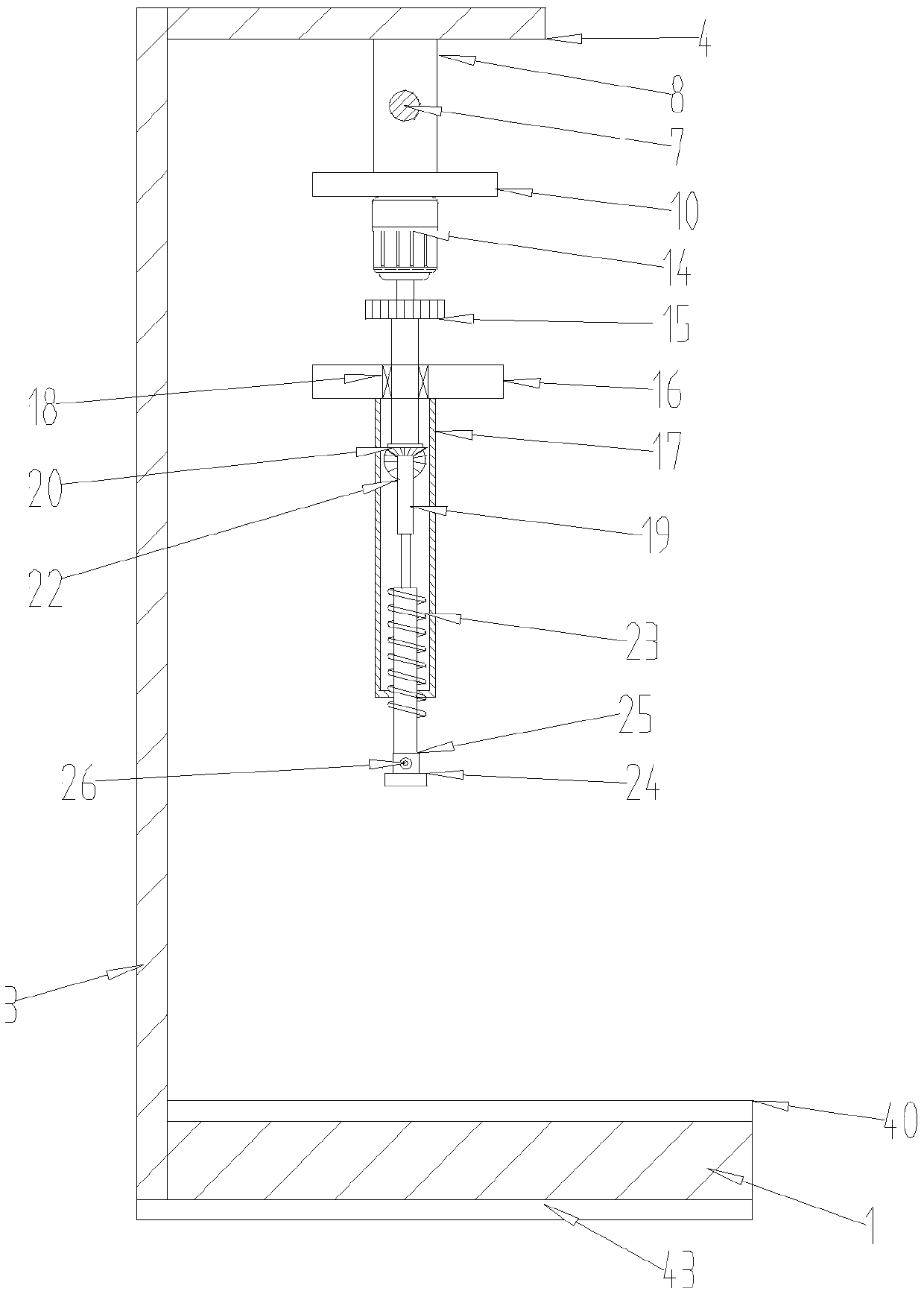

Method used

Image

Examples

Embodiment

[0043] Example: According to the attached Figure 1-6 It can be seen that when the power is turned on and the motor driver 38 receives the signal, the driving end of the third servo motor 21 starts to rotate the main gear 22, and the bevel gear 20 meshing with the main gear 22 is driven to rotate by the main gear 22, and is connected to the bevel gear 20. The telescopic rod 19 fixedly connected with the axis is also driven to rotate, and the rotating rod 23 arranged at one end of the telescopic rod 19 is also driven to rotate. Since the housing 17 is fixedly connected to the lower wall of the first fixing plate 16 and is provided with threads, when When the telescopic rod 19 drives the rotary rod 23 to rotate, the rotary rod 23 extends through the threaded connection with the inner wall surface of the housing 17 and moves downward. The electric spray gun 26 placed on the rotary rod 23 also moves downward. When the gun 26 descends to the work of art 2, the lifting spraying opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com