Base board transporting device, base board processing system and base board transporting method

A substrate processing system and substrate handling technology, applied in thin material processing, transportation and packaging, optics, etc., can solve the problems of high device cost, inability to detect position offset, time waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, embodiments of the present invention will be described based on the drawings.

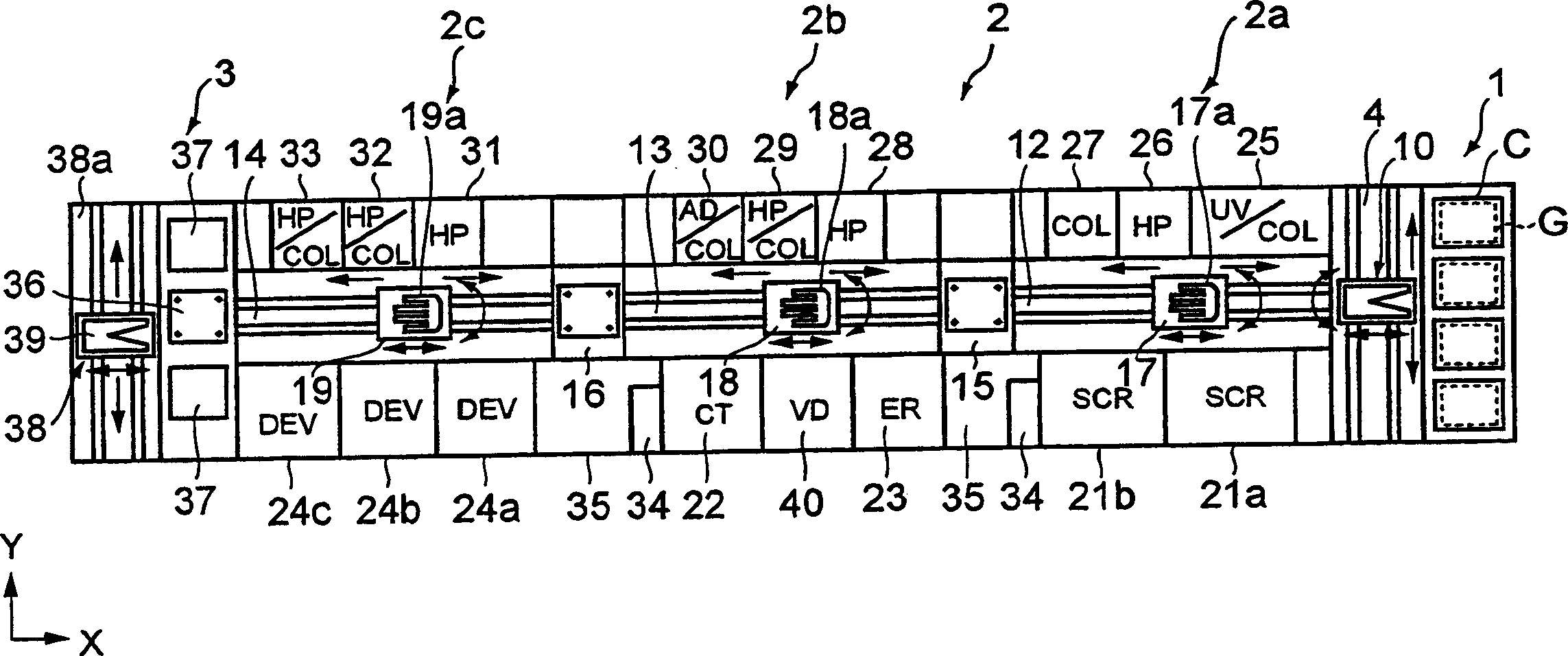

[0041] figure 1 It is a plan view showing the coating development processing system related to the first embodiment of the present invention. This coating and development processing system includes: a cassette table 1 on which a plurality of cassettes C for accommodating glass substrates G are placed; The processing section 2 of the unit; the interface section 3 for transferring the substrate G between the exposure device (not shown in the figure), and the cassette table 1 and the interface section 3 are respectively arranged at both ends of the processing section 2.

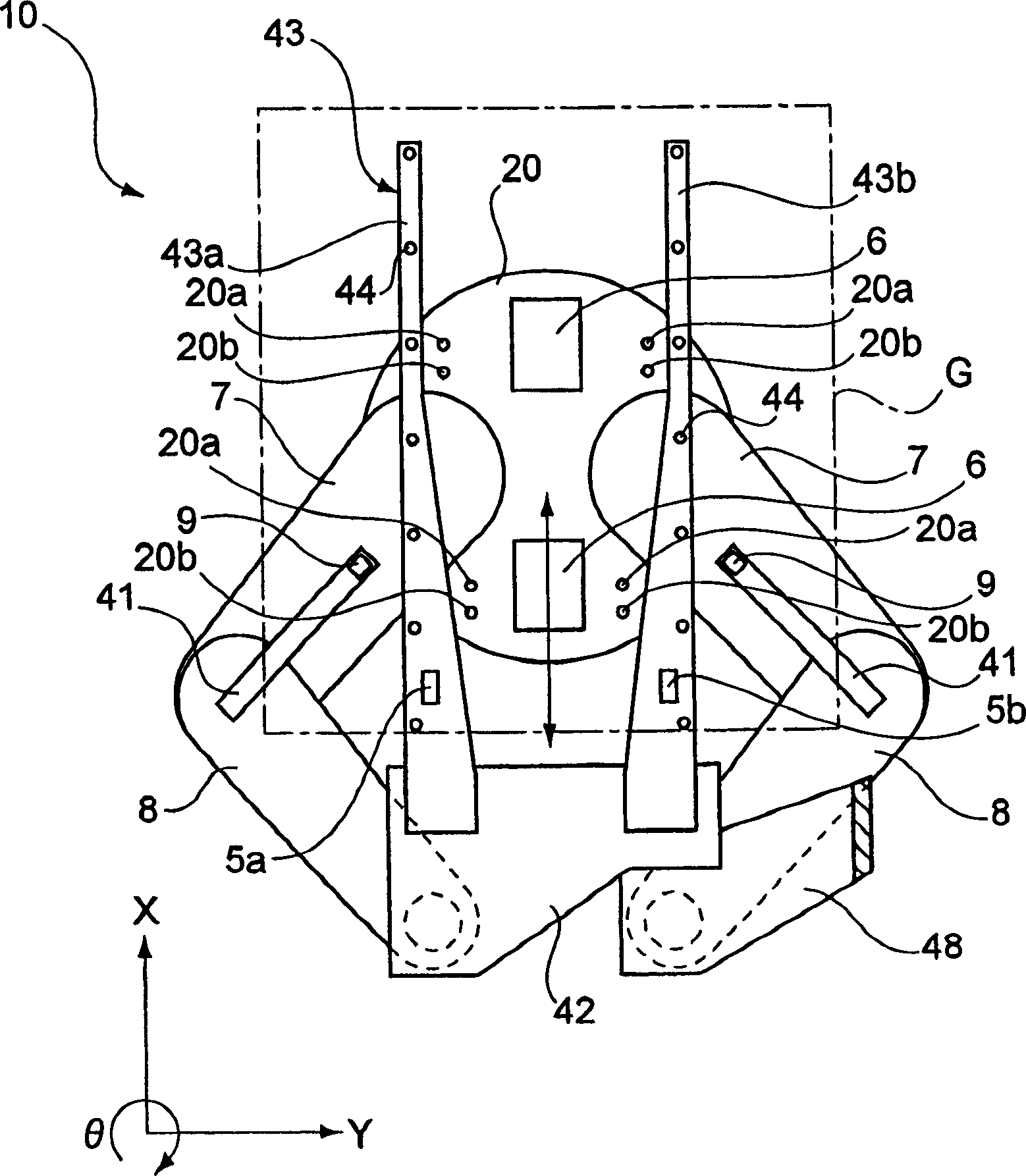

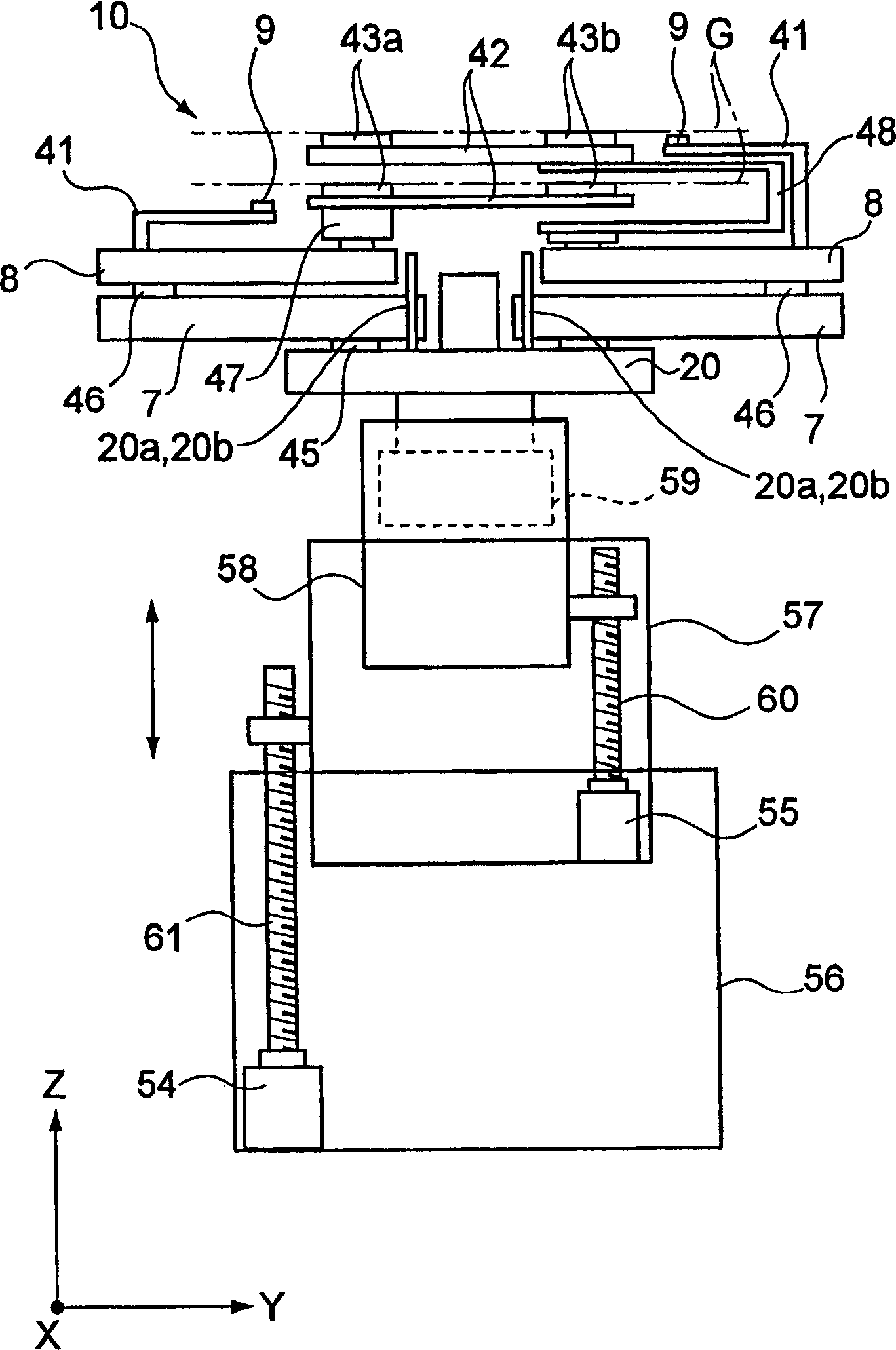

[0042] The cassette station 1 includes a transport device 10 having a articulated support arm related to the first embodiment of the present invention. The transport device 10 moves along the transport line 4 and transports the substrate G between the cassette C and the processing unit 2 . The transfer device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com