Multiconnection plug connector and longitudinally laminated and laterally laminated socket connectors

A plug connector, socket connector technology, applied in the direction of two-part connection device, device to prevent wrong connection, connection, etc., can solve the problem of reducing the possibility of short-circuit failure, etc., to shorten the protruding size, prevent short-circuit failure, installation area reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

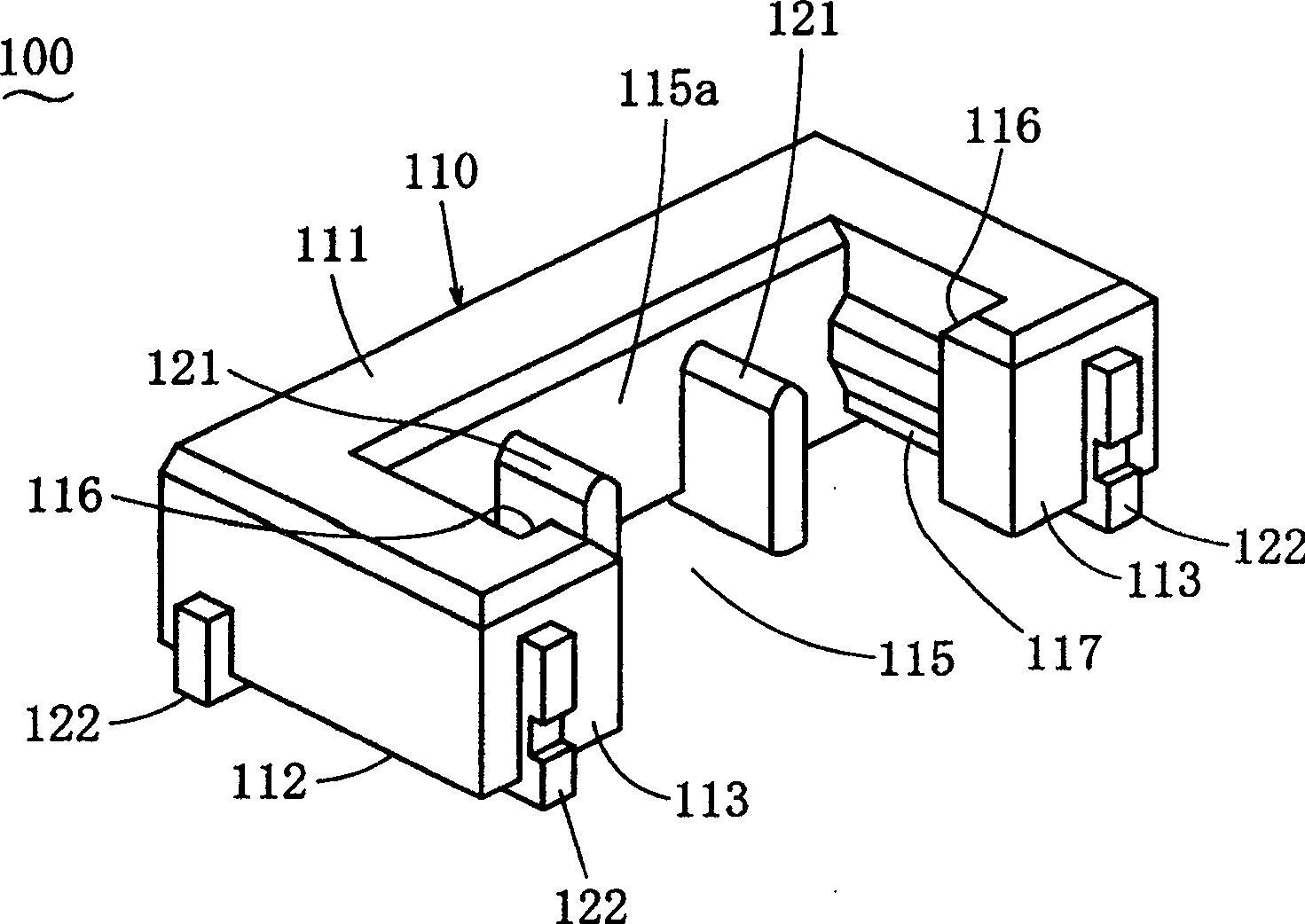

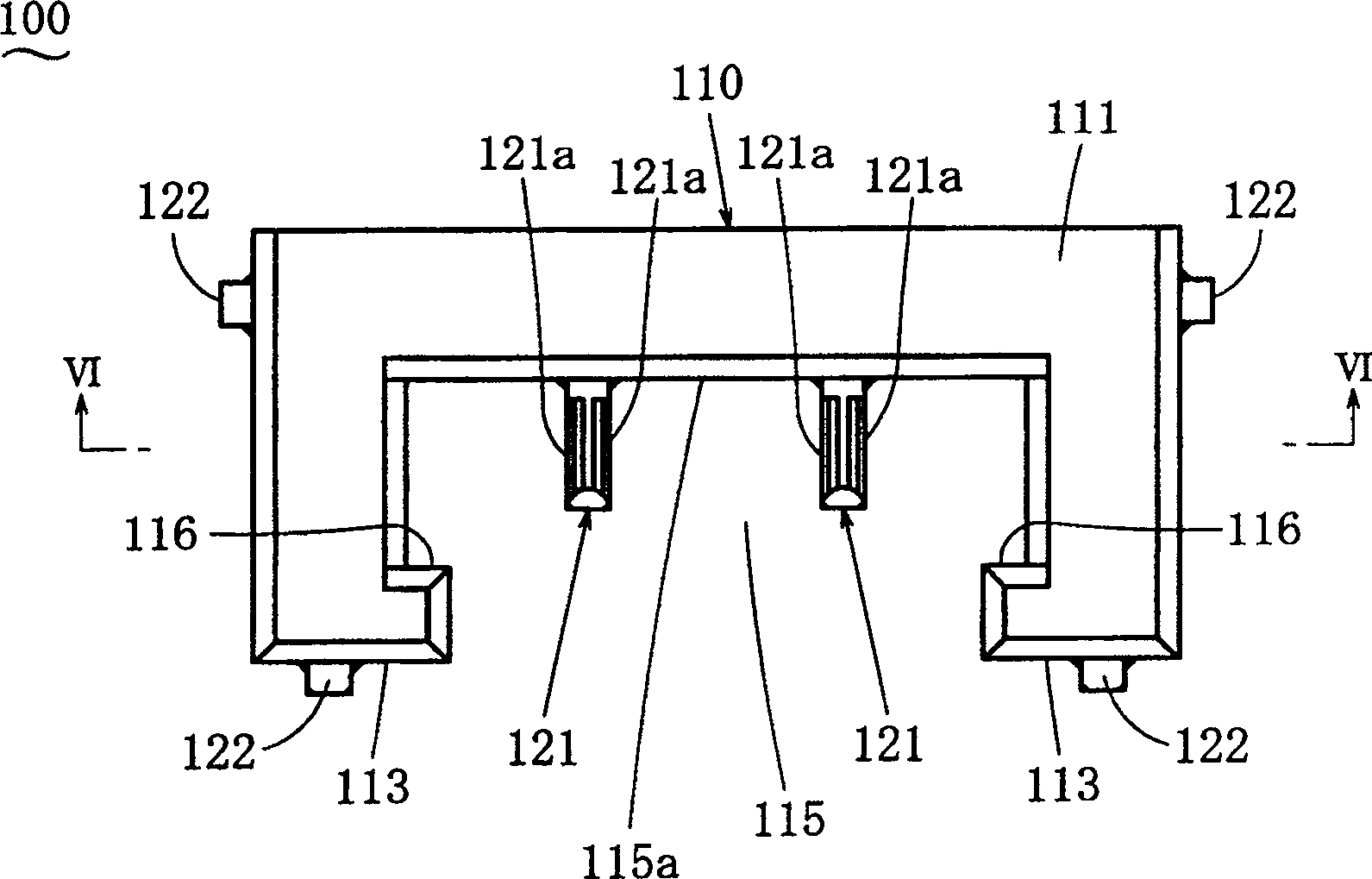

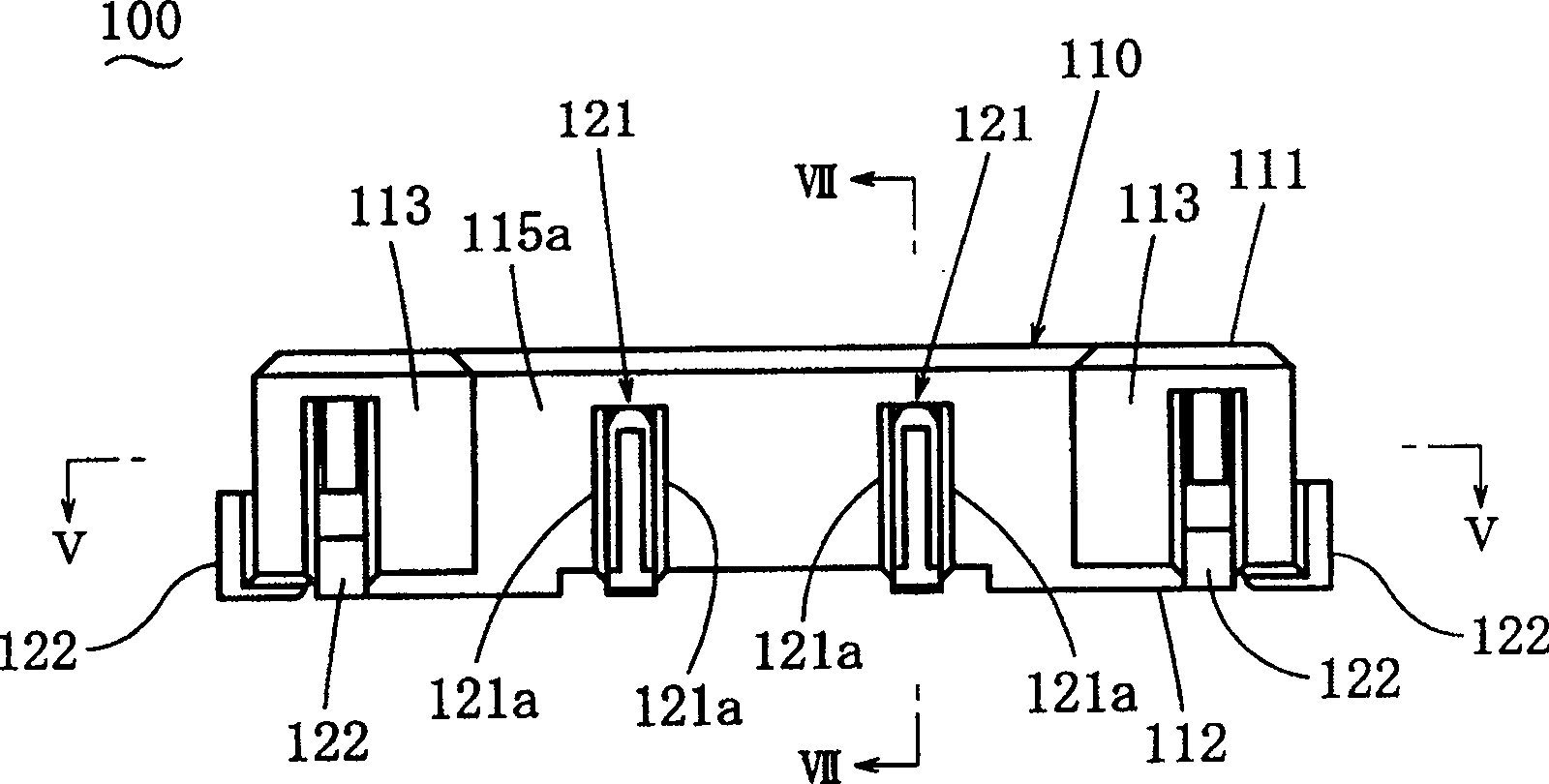

[0046] Hereinafter, examples of the present invention will be described. Figure 1 to Figure 7 A multi-connection type plug connector 100 according to an embodiment of the present invention is shown. It is assumed that the depth direction, the width direction, and the height direction are perpendicular to each other, and the description will be made using these direction settings. use figure 2 The case of this embodiment will be described, and the up and down directions in the figure represent the depth direction, the upper part in the figure represents the depth side in the depth direction, and the lower part represents the near side in the depth direction. In addition, the direction perpendicular to the paper surface in the figure is the height direction, and the left-right direction in the figure is the width direction. The multi-connection type plug connector 100 has: a plug housing 110 formed of an insulating material; and plug contacts 120 formed of a conductive mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com