Laser machining apparatus and laser machining method

a laser machining and laser machining technology, applied in the direction of soldering apparatus, manufacturing tools,auxillary welding devices, etc., can solve the problems of inability to achieve the effect of improving work efficiency, no large installation area, and reducing machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

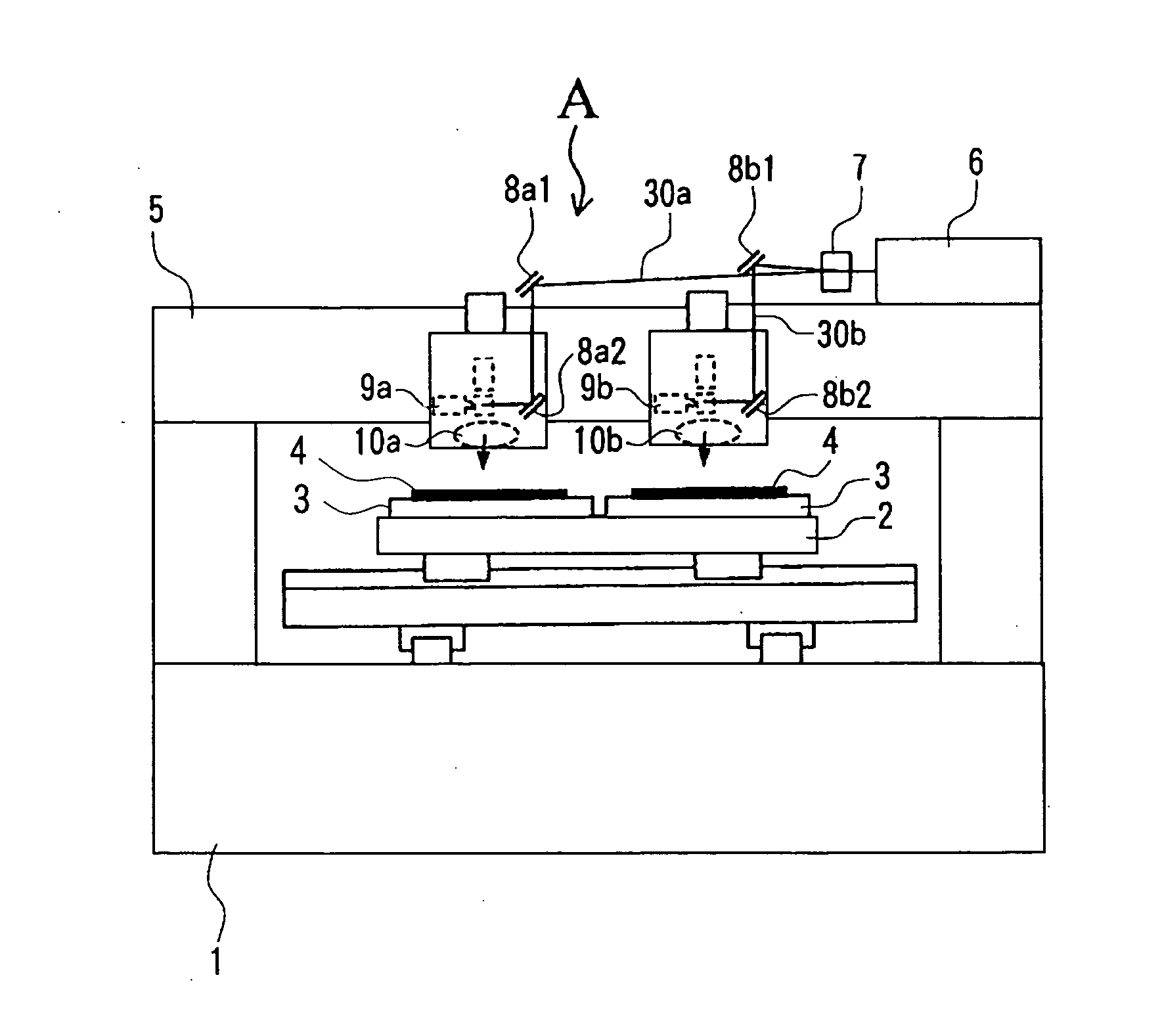

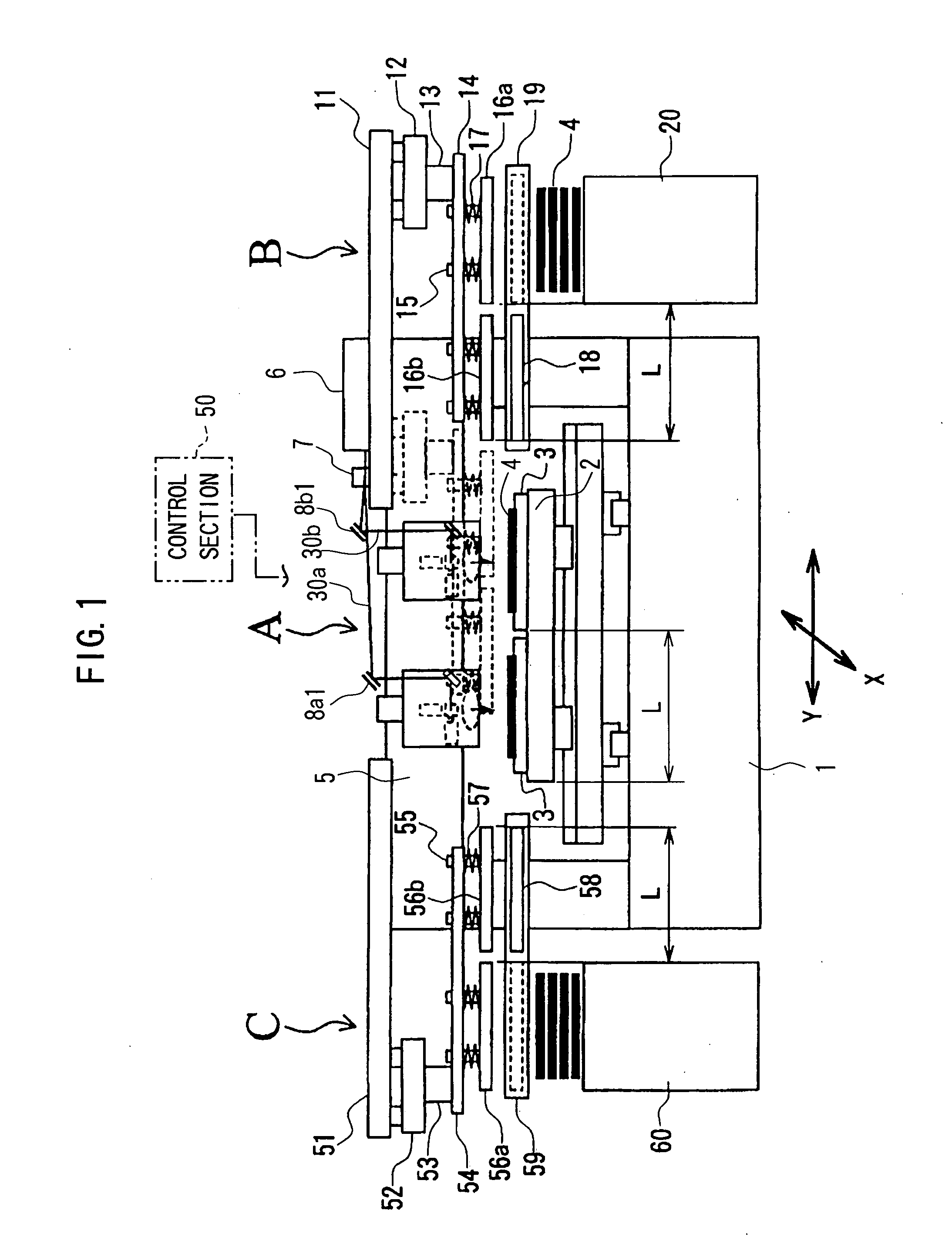

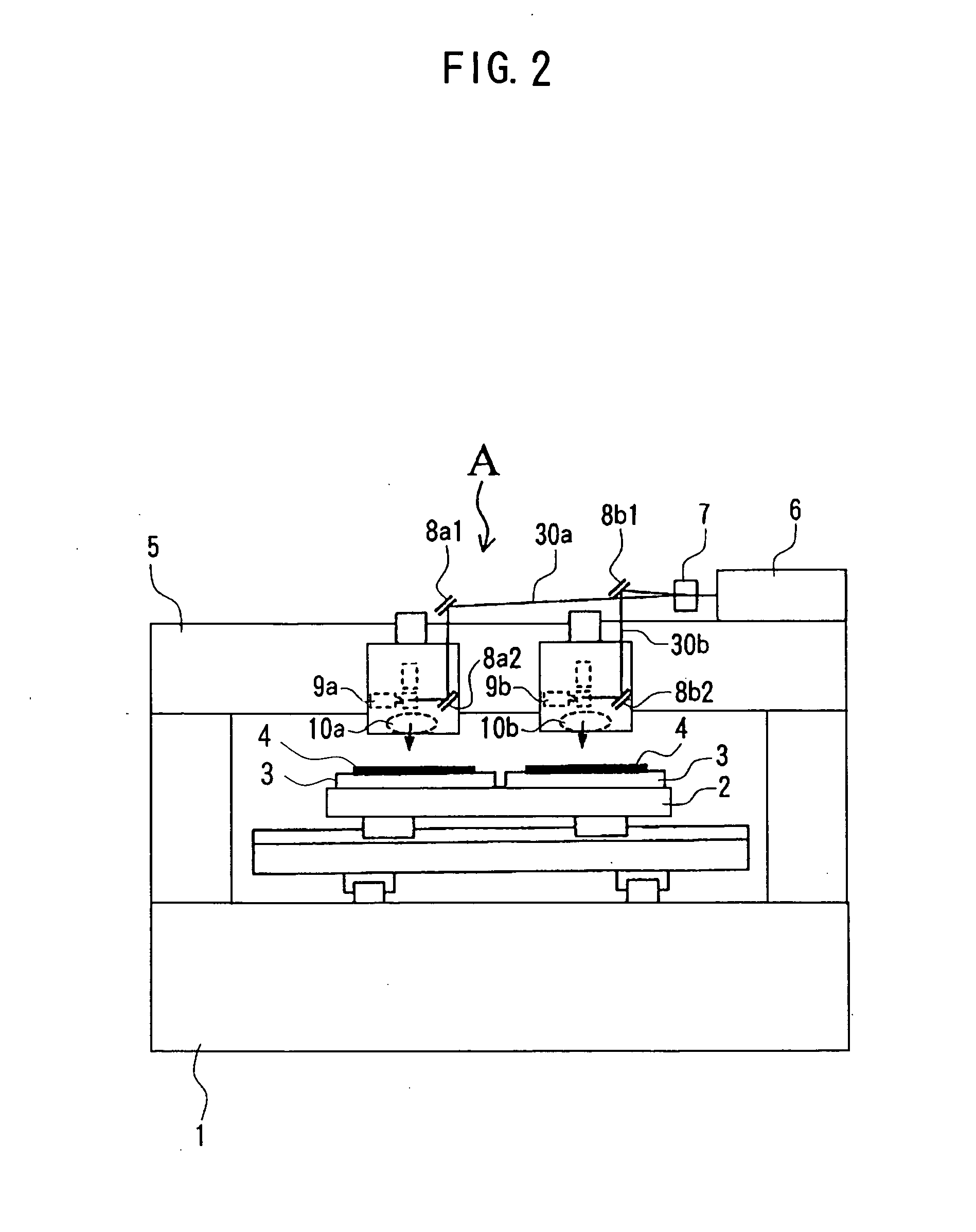

[0032]FIG. 1 is a front view showing the whole of a laser machining apparatus according to a first embodiment of the invention and FIG. 2 is a front view showing a body of the laser machining apparatus. As shown in FIG. 1, the inventive laser machining apparatus is composed of a body portion A thereof, a carrying-in unit B and a carrying-out unit C.

[0033] The structure of the body portion A will be explained at first with reference to FIGS. 1 and 2. An XY table 2 is disposed on a bed 1 of the body portion A. The XY table 2 is movable on the bed 1 horizontally in the X and Y directions. A plurality of (two in the figure) tables (work mounting sections) 3 is fixed on the XY table 2 separately by a distance L in the Y-axis direction. A plurality of holes connected to a hollow section inside is formed on the surface of the table 3. The hollow sections are connected to a vacuum source not shown so that the table 3 can adsorb / release the workpiece 4.

[0034] A gate-type column 5 is fixed ...

second embodiment

[0073] By the way, there is a case when workpieces are stacked by interleaving a soft sheet, e.g., a sheet of paper, resin or the like (hereinafter referred to as an ‘interleaf’) between the workpieces in order to prevent scratch of the surface of the workpiece. A laser machining apparatus suitable for such a case will be explained below. FIG. 3 is a front view showing the whole structure of the laser machining apparatus according to a second embodiment of the invention, wherein he same reference characters denote the same or corresponding parts with those in FIGS. 1 and 2 and an explanation thereof will be omitted here.

[0074] In FIG. 3, a rail 62 is disposed at the position in the vertical direction between the rail 19 and the supplying stocker 20. An interleaf receiving table (interleaf mounting table) 61 is disposed on the rail 62 so as to be movable horizontally in the Y-direction. Similarly to the work receiving table 18, the standby position of the interleaf receiving table 6...

third embodiment

[0119]FIG. 4 is a plan view showing a structure of a laser machining apparatus according to a third embodiment of the invention and FIG. 5 is a view in the direction of an arrow K in FIG. 4, wherein the same or corresponding parts with those in FIGS. 1 and 2 will be denoted by the same reference numerals and an explanation thereof will be omitted here. It is noted that a front view of the apparatus of the present embodiment is substantially the same with that shown in FIG. 1.

[0120] An interleaf carrying-out unit (interleaf removing and carrying-out unit) D is disposed behind the carrying-in unit (supply-side transfer unit) B in FIG. 1 and an interleaf carrying-in unit (interleaving unit) E is disposed behind the carrying-out unit (discharge-side transfer unit) C in FIG. 1, respectively (see FIG. 4). Here, the interleaf carrying-out unit D is a unit for retaining an interleaf 4s on a workpiece 4 placed on the supplying stocker 20 and for placing it on an interleaf discharging table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com