Filtering plate, vertical rotation gypsum dehydrator, working method and gypsum dehydrating system

A technology of vertical rotation and filter plate, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc. It can solve the problem of not being able to deal with the site constraints and water balance constraints of the desulfurization system at the same time, low operating failure rate, and low operating costs. advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

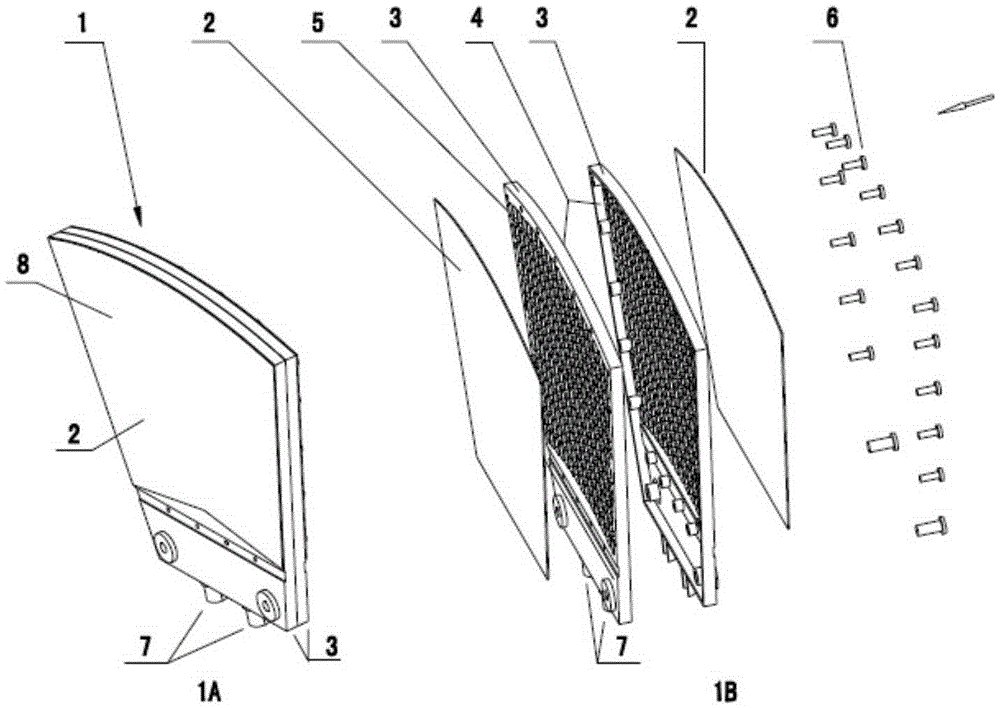

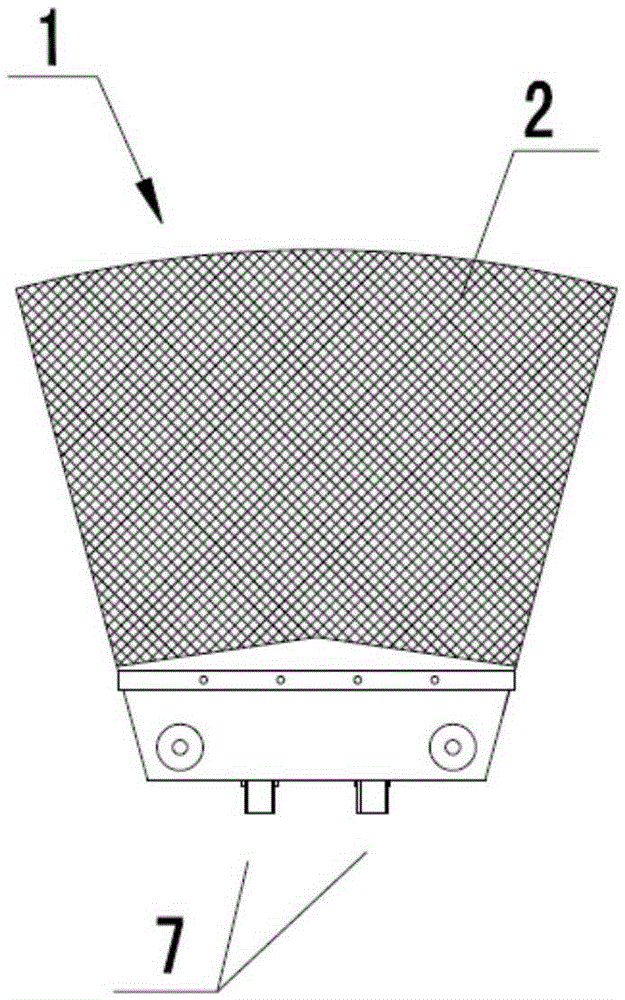

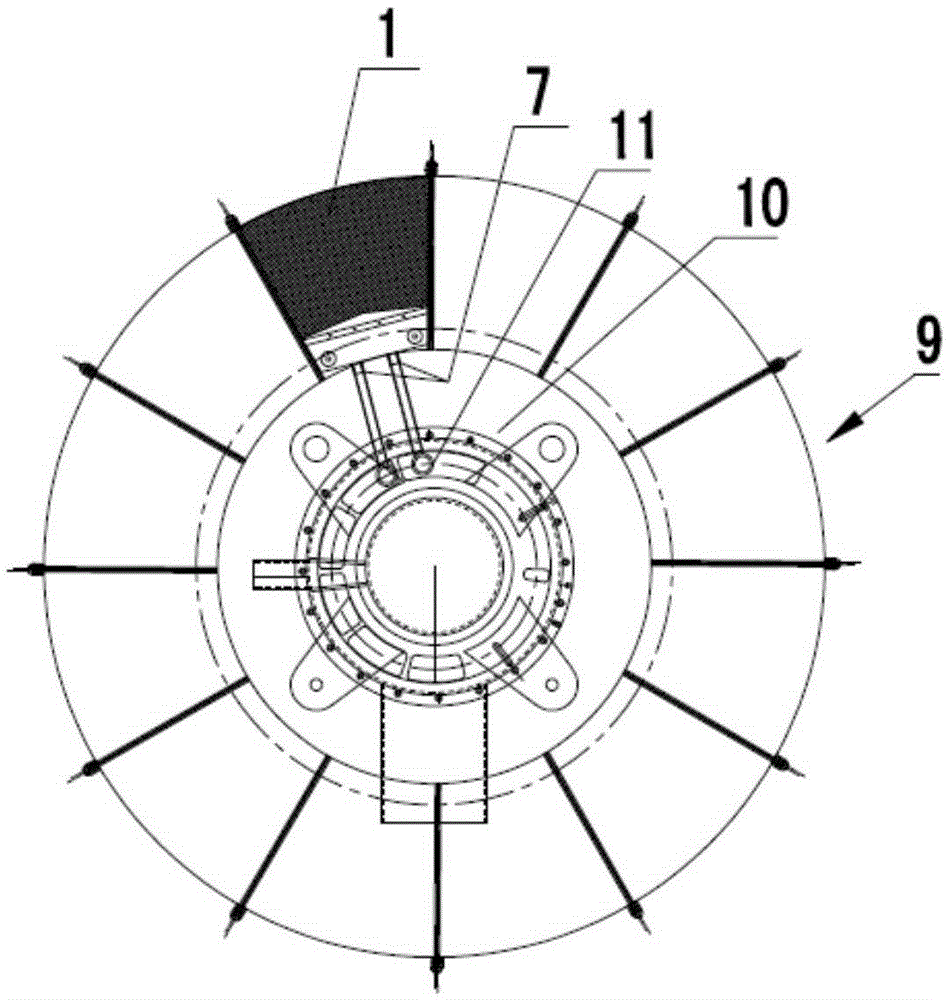

[0067] The filter plate 1 of the present invention is a functional component unit performing a filtering function, and adopts a closed structure of an independent unit, which is convenient for use, maintenance and replacement. figure 1 , figure 2 and Figure 4 , Figure 5 Respectively represent two different forms of filter plates 1 . Such as figure 1 and Figure 4As shown in the exploded diagram of the assembly, the assembly direction is marked in the direction of the arrow in the figure. The filter plate 1 is a closed body composed of two pieces of filter cloth 2, two pieces of support layer 3, assembled by screws 6, and has a steam-water flow pipe 7 , the assembled filter plate 1 as figure 1 and Figure 4 As shown in the molding diagram, it includes a cavity 8 inside it, and the filter cloth 2 is fixed on the outer surface of the filter plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com