Conveying and homogenizing distribution device for solid-liquid mixed fluid

A solid-liquid mixing and distributing device technology, which is used in transportation and packaging, mixers, mixers with rotary stirring devices, etc. The effect of the homogenize distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is described in further detail now in conjunction with accompanying drawing.

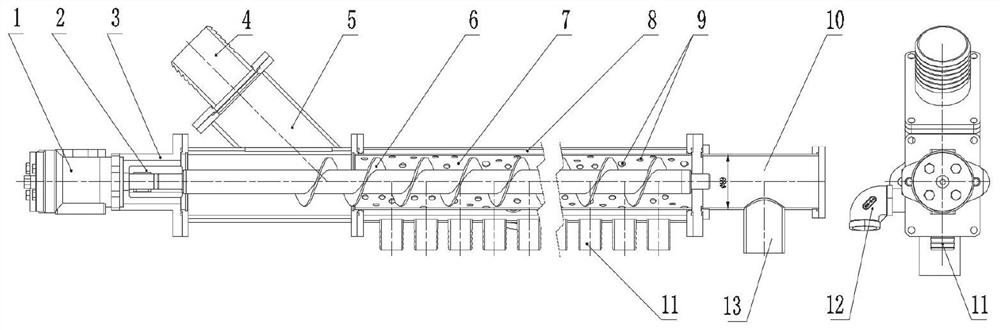

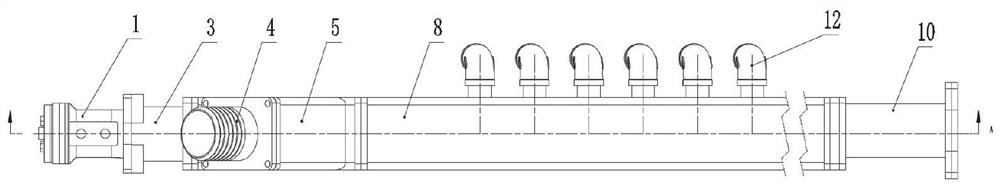

[0031] See how Figure 1-2 As shown, the present invention discloses a conveying and homogenizing distribution device for solid-liquid mixed fluid, including a helical cutting propeller 6, which is a helical shaft structure, and the solid-liquid mixture is realized through the helical blades on it. Evenly separated.

[0032] The helical cutting propeller 6 is located in the distributor housing 8, wherein as figure 1 As shown, the left part of the helical cutting propeller is located in the distributor housing 8, and the right part is located in the distribution hole tube 7, and the distribution hole tube 7 is located in the distributor housing 8 and is at a predetermined distance from the distributor housing 8. and secure the connection. The distributing orifice pipe 7 is all installed in the distributor housing 8, occupying the right part of the distributor housing 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com