Air curtain skimming device for steel-making converter

A converter steelmaking and air curtain technology, applied in the field of air curtain slag blocking device and steelmaking device, can solve the problems of increased production cost of steelmaking, inability to control slag, inconvenient implementation, etc., to optimize molten steel quality and reduce tapping The effect of low slag removal rate, new construction and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

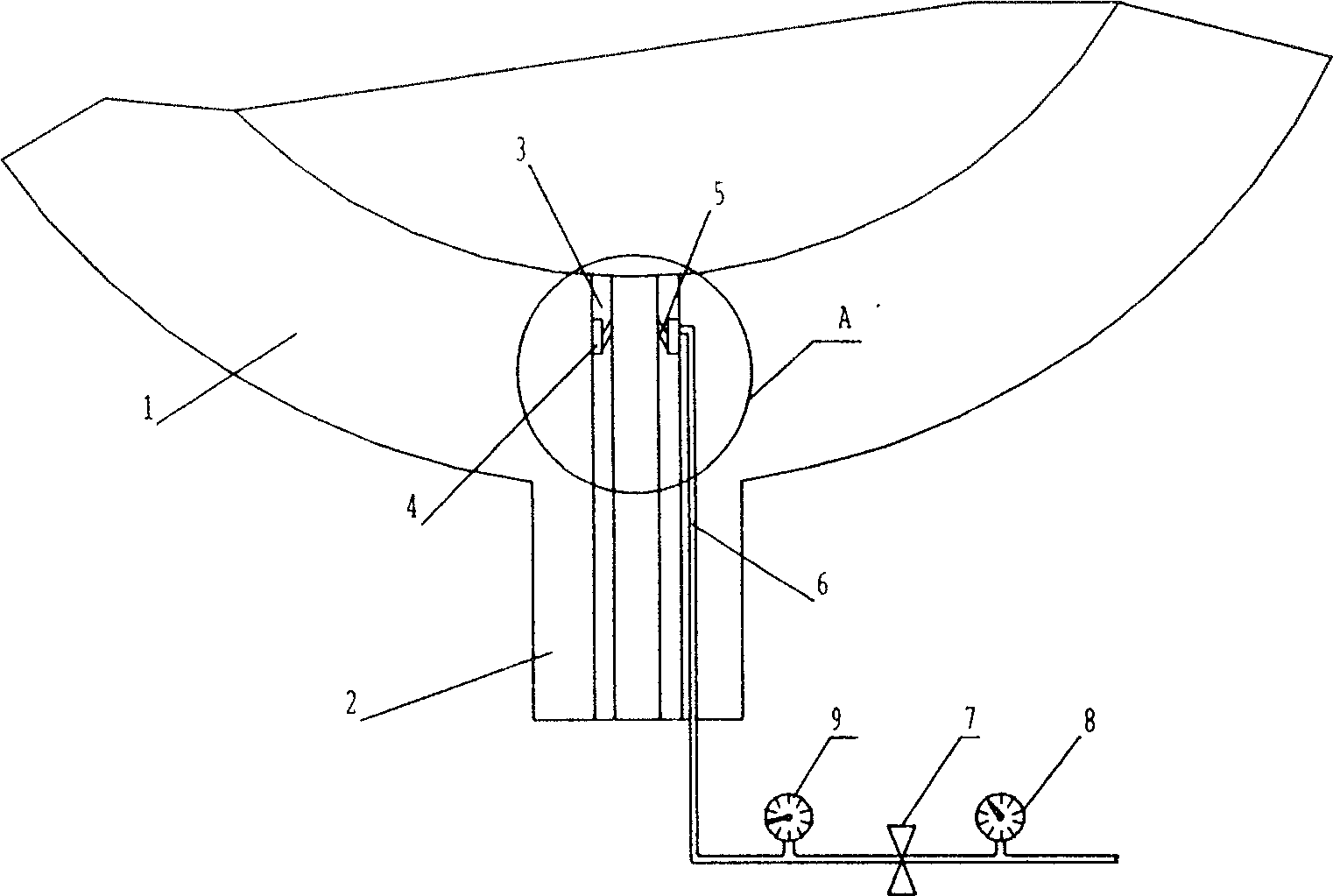

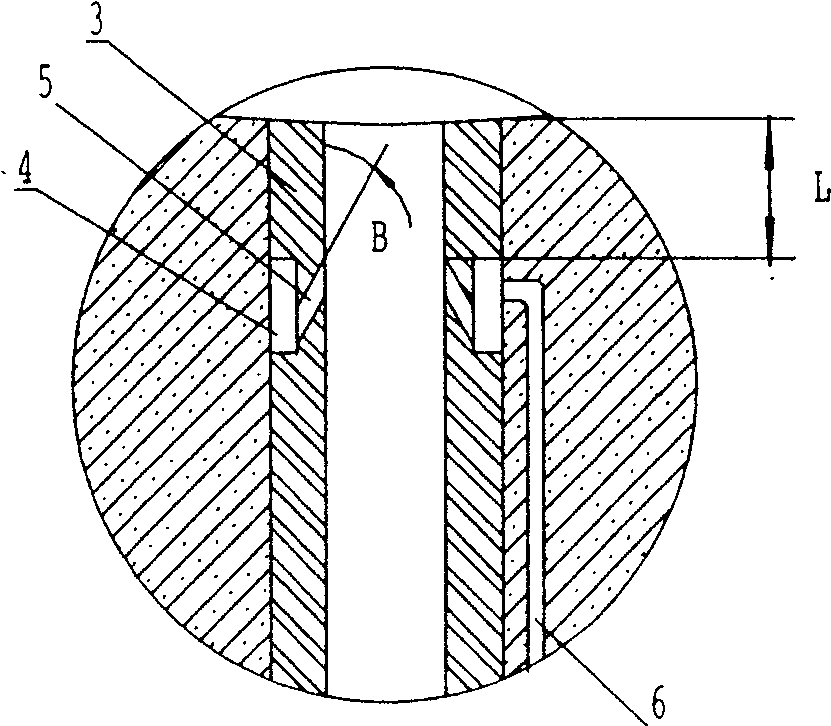

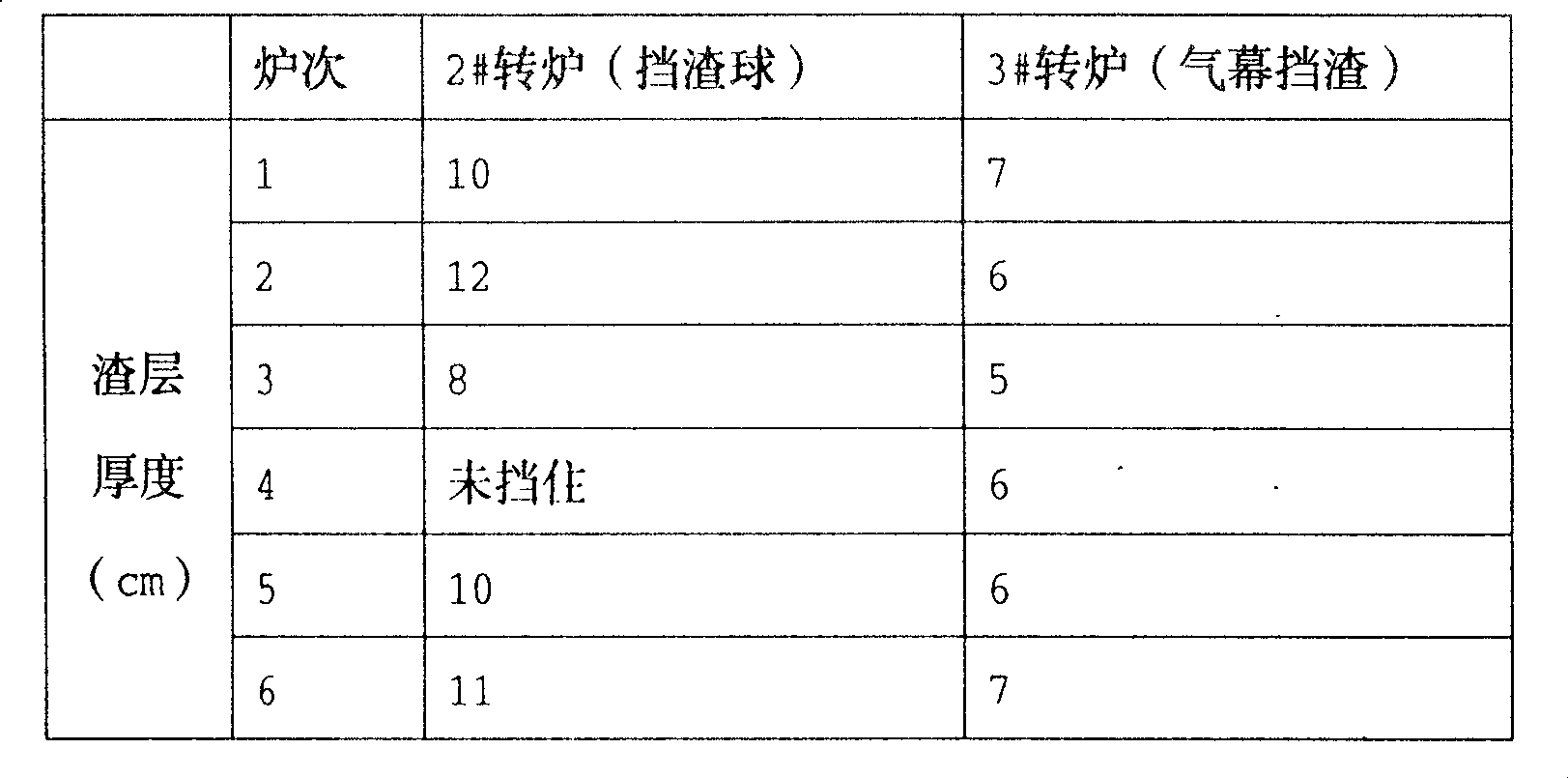

[0013] see figure 1 , figure 2 The composition of the device of the present invention includes a furnace body 1 and a tapping hole 2 arranged on the side wall of the furnace body, an annular air chamber 4 arranged at the taphole sleeve brick 3, an annular air slot 5 and an inlet connected to the annular air chamber. Air pipe 6, the annular air chamber communicates with the annular air slit, and the air inlet pipe is connected to the outside of the tapping hole and communicated with the gas source. The functions of the annular air chamber: one is to stabilize the pressure of the blowing gas, and the other is a suitable way for the air inlet pipe to communicate with the annular air slot. The optimal value of the distance L between the end of the annular air slot and the inner end of the tapping hole is R / tgB, where R is the radius of the tapping hole, and B is the angle between the annular air slot and the inner wall of the tapping hole. The L value determined according to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap