Anti-erosion high-quality casting blank long-service-life slab nozzle

A high-quality, anti-erosion technology, used in foundry equipment, casting melt containers, metal processing equipment, etc., can solve the problems of affecting delivery quality, large molten steel flow, waste of resources, etc., to improve production quality, save resources, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In view of the deficiencies in the prior art, the case has been studied for a long time and a large amount of practice, and the technical scheme of the present invention can be proposed. The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

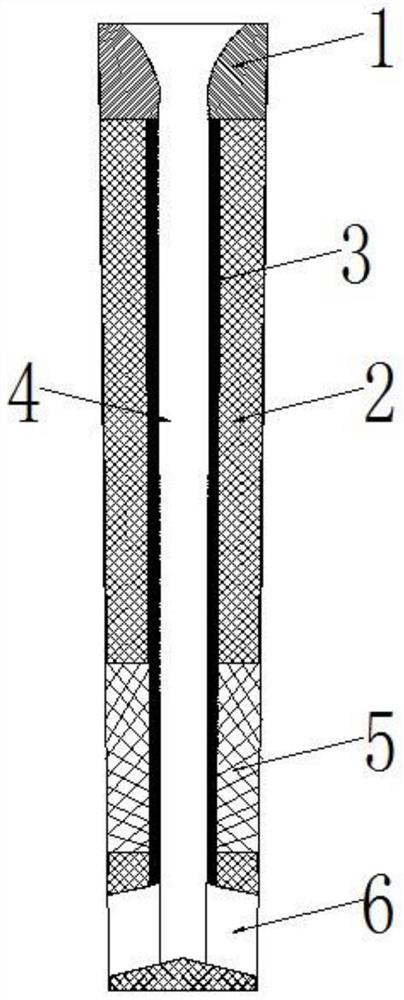

[0013] figure 1 It is a schematic diagram of the corrosion-resistant high-quality cast slab long-life slab nozzle structure provided in the embodiment of the present invention, such as figure 1 As shown, an anti-corrosion high-quality cast slab long-life slab nozzle provided in the embodiment of the present invention includes a bowl 1, a slab nozzle body 2, a lining 3, a molten steel channel 4, a slag line 5 and a side hole 6 , the inner lining 3 is located inside the slab nozzle body 2, the center lines of the molten steel channel 4, the inner lining 3 and the slab nozzle body 2 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap