A steady flow device for continuous casting crystallizer

A technology of continuous casting crystallizers and flow stabilization devices, which is applied in the field of flow stabilization devices, can solve problems such as the failure of the optimized flow field effect, and achieve the effects of uniform and reasonable speed distribution, long working hours, and reduced inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

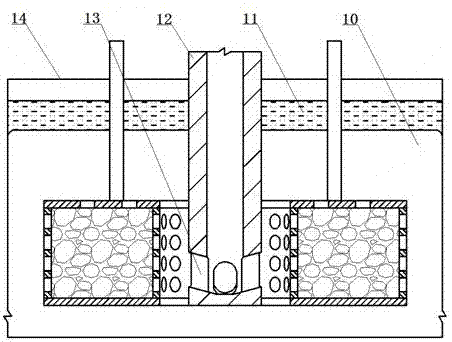

[0028] The utility model relates to a constant flow device for a continuous casting crystallizer. This example image 3 As shown, the continuous casting mold 14 is used to produce 600mm round billet. The outer diameter of the four-hole submerged nozzle 12 used in conjunction with the continuous casting crystallizer 14 is 100 mm, and the immersion depth of the four-hole submerged nozzle 12 is 150 to 200 mm during the pouring process.

[0029] Such as image 3 As shown, the present embodiment is immersed in molten steel 10 at a height of 150-200 mm below the meniscus at the level of the outlet hole 13 of the four-hole submerged nozzle 12 in the continuous casting crystallizer 14. The surface of molten steel 10 is covered with mold slag 11 .

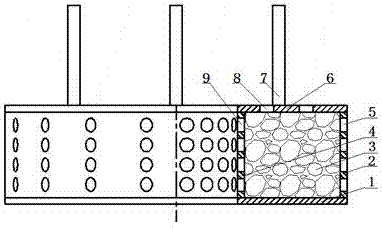

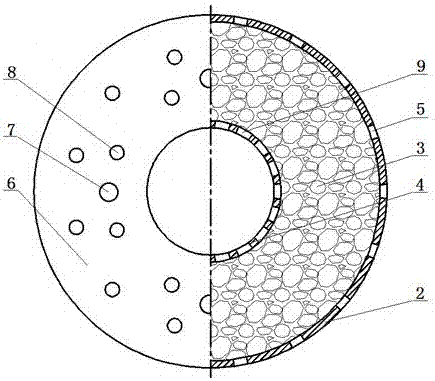

[0030] This example figure 1 with figure 2 As shown, the flow stabilization device is composed of a base 1 , an outer casing 2 , an inner casing 4 , a cover plate 6 , a lifting rod 7 and a filling material 3 . The lower end of the ou...

Embodiment 2

[0039]The utility model relates to a constant flow device for a continuous casting crystallizer. Present embodiment except following technical parameters, all the other are with embodiment 1:

[0040] This embodiment is used to produce a continuous casting crystallizer of 150×150mm billet. The outer diameter of the double-hole submerged nozzle used in conjunction with the continuous casting crystallizer is 20mm, and the immersion depth of the double-hole submerged nozzle is 100-150mm during the pouring process. in:

[0041] The outer sleeve 2 is square tubular, and the inner diameter of the inner sleeve 4 is 0.2 to 0.5 times the diagonal of the square tube;

[0042] The thickness of the base 1, the thickness of the cover plate 6, the wall thickness of the inner casing 4 and the outer casing 2 are the same, all of which are 10-30mm;

[0043] The height of the outer casing 2 is 100-200mm;

[0044] The diameters of the outer diversion hole 5, the inner diversion hole 9 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap