A kind of aluminate non-Newtonian continuous casting mold powder and its preparation method

A continuous casting mold and mold powder technology, which is applied in the field of aluminate non-Newtonian continuous casting mold mold powder and its preparation, can solve the problems of crystallizer system alarm phenomenon, high viscosity, and inability to take into account matching, and achieve a solution Inconsistent viscosity requirements, improved billet lubrication, and reduced slag entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Composition of aluminate non-Newtonian continuous casting mold flux, by mass parts CaO 46.36 parts, Al 2 o 3 38.64 parts, Li 2 O 10 parts, B 2 o 3 0 copies. The slag is equipped with carbonaceous material as a melting rate regulating component, and the carbonaceous material accounts for 5 parts, wherein the carbonaceous material is graphite.

[0051] The preparation method is:

[0052] The corresponding slag is prepared according to the chemical composition mass parts of the above-mentioned aluminate non-Newtonian continuous casting mold flux composition, wherein, Li 2 10 parts of O is based on the added raw material as Li 2 CO 3 Carry out, mix evenly and heat to 1500±10°C for high temperature pre-melting. After the slag sample is completely melted, it is water-quenched and then dried to obtain a pre-melted slag material. Grind and sieve the premelted material to make the particle size less than 0.074mm, then add the pre-prepared carbonaceous material, mix th...

Embodiment 2

[0057] The composition of aluminate non-Newtonian continuous casting mold flux contains 42 parts by mass of CaO, Al 2 o 3 35 parts, Li 2 O 10 parts, B 2 o 3 10 servings. The slag is equipped with carbonaceous material, which is a melting rate regulating component, and the carbonaceous material accounts for 3 parts. The carbonaceous material is graphite. The preparation method is the same as in Example 1.

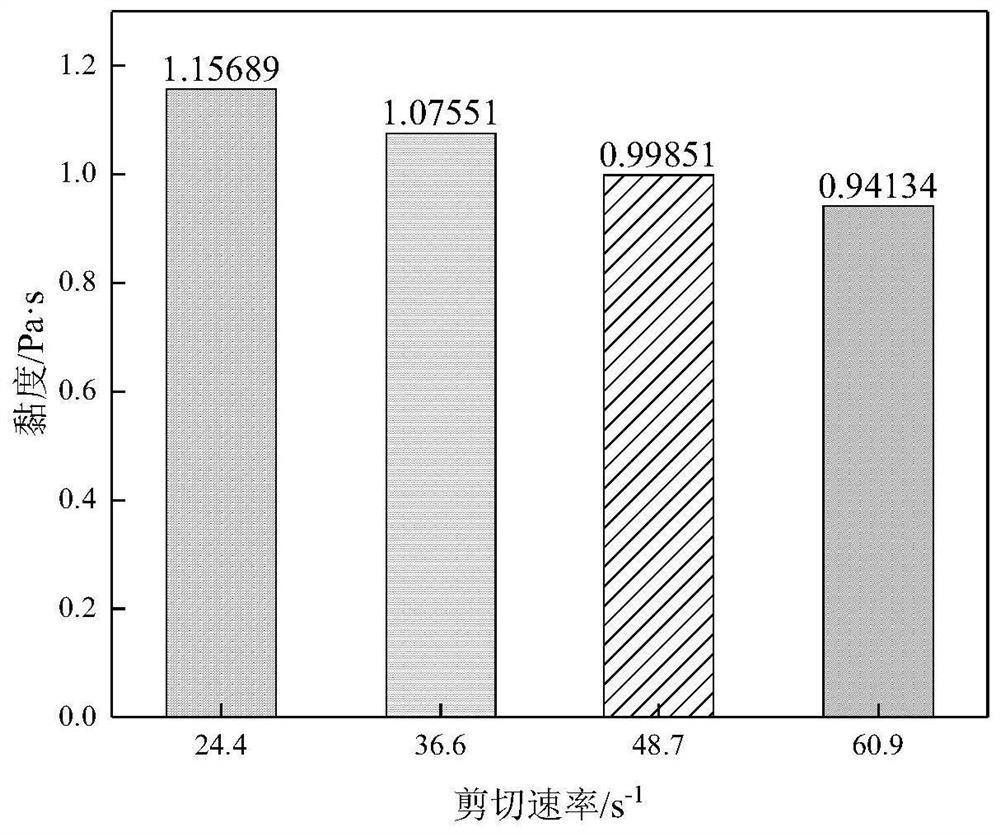

[0058] The shear rate of the aluminate non-Newtonian continuous casting mold powder at 1200°C was measured by the rotating cylinder method controlled by a high-precision rheometer from 24.4s to 24.4s -1 increased to 36.6s -1 When the viscosity decreases, the shear thinning rate is 1.04%; the shear rate is changed from 36.6s -1 increased to 48.7s -1 When the viscosity decreases, the shear thinning rate is 0.73%; the shear rate is changed from 48.7s -1 increased to 60.9s -1 When the viscosity decreases, the shear thinning rate is 0.33%. Viscosity as a function of...

Embodiment 3

[0062] The composition of aluminate non-Newtonian continuous casting mold flux contains 43.2 parts by mass of CaO, Al 2 o 3 28.8 parts, Li 2 O 5 parts, B 2 o 3 15 servings. The slag is equipped with carbonaceous material, which is a melting rate regulating component, and the carbonaceous material accounts for 8%. The carbonaceous material is graphite. The preparation method is the same as in Example 1.

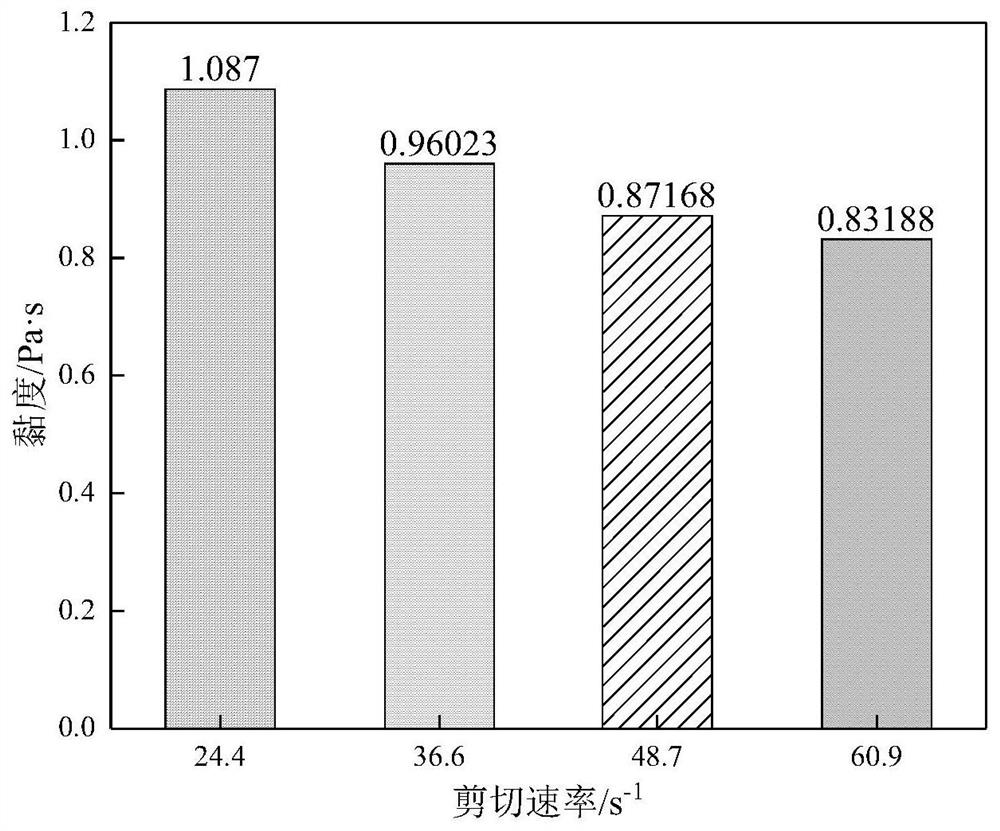

[0063] Aluminate-based non-Newtonian continuous casting mold flux at 1200°C, the shear rate is changed from 24.4s -1 increased to 36.6s -1 When the viscosity decreases, the shear thinning rate is 0.10%; the shear rate is changed from 36.6s -1 increased to 48.7s -1 When the viscosity decreases, the shear thinning rate is 0.13%; the shear rate is changed from 48.7s -1 increased to 60.9s -1 When the viscosity decreases, the shear thinning rate is 0.08%. Its viscosity varies with the shear rate as shown in Figure 5 As shown, in this case, when the mold powder slag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap