Automobile shock absorber

A shock absorber and automobile technology, applied in the field of auto parts, can solve problems such as oil leakage, shock absorber failure, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

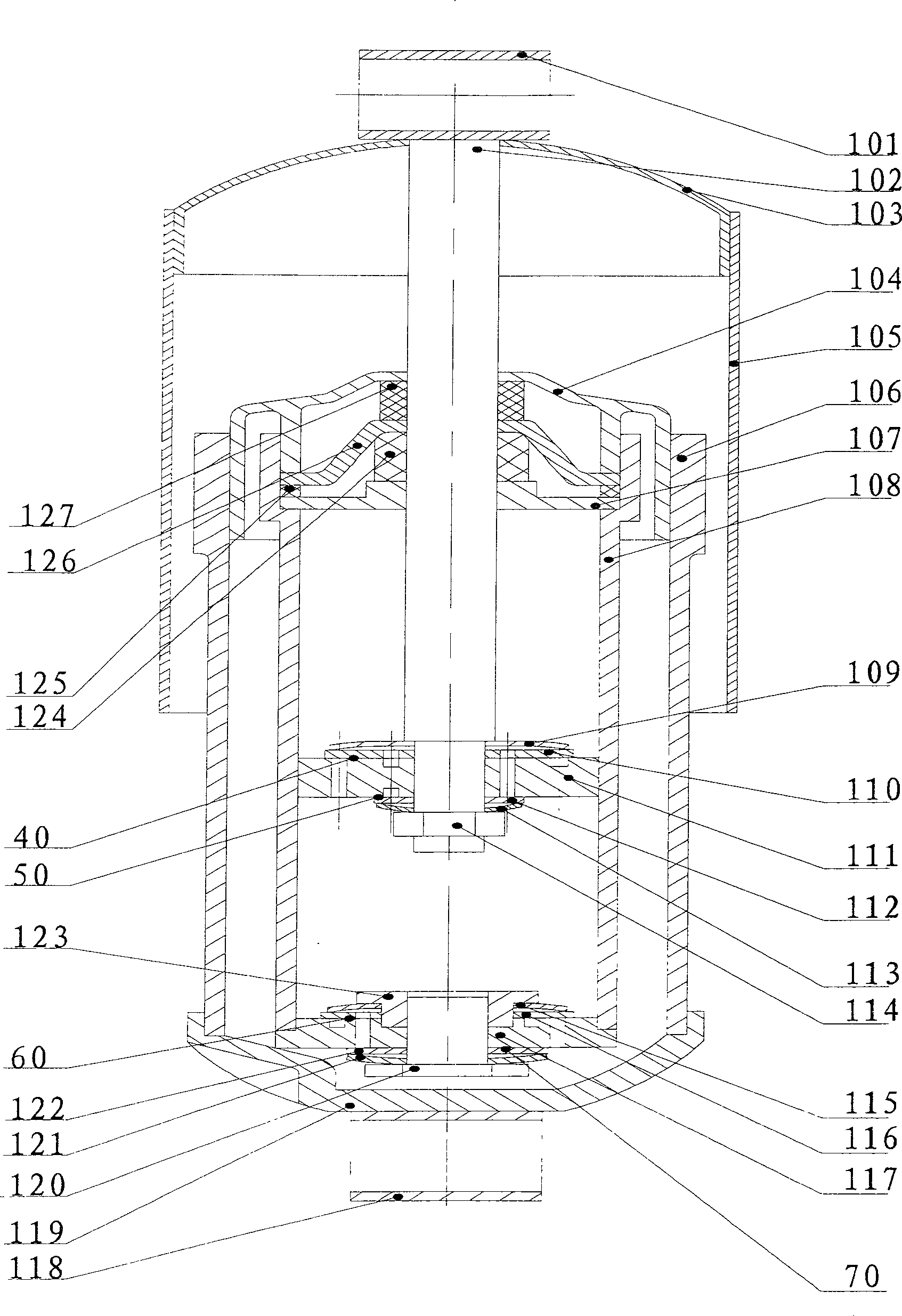

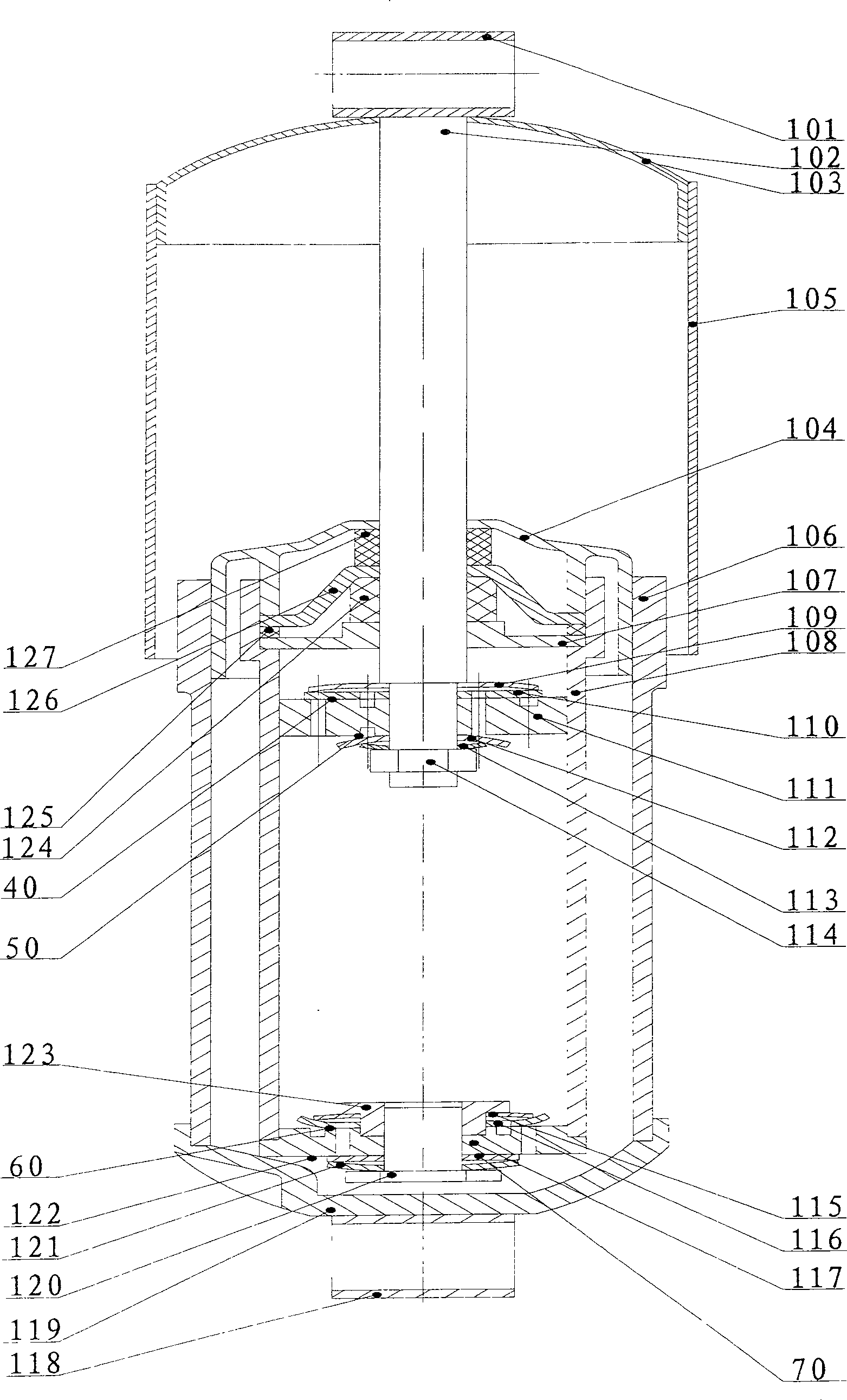

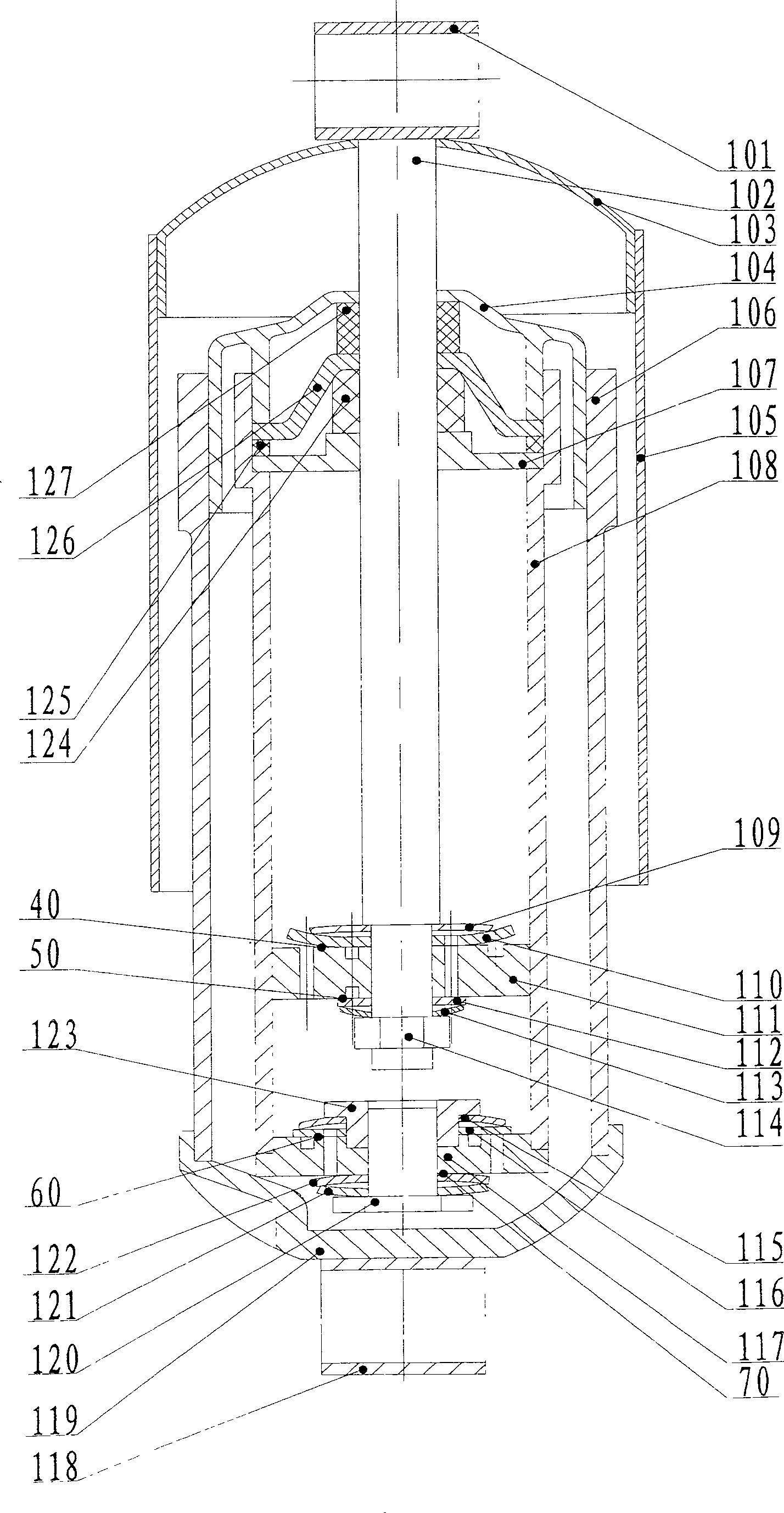

[0021] The structure of the automobile shock absorber is as follows: Figure 4As shown: it is mainly composed of upper connecting ring 1 (connected with the vehicle body, not shown in the figure), piston rod 2, upper cover 3 and upper cover outer cylinder 5, oil storage cylinder nut 4, liquid storage cylinder 6, Piston rod guide seat 7, working cylinder 8, disc spring 9, circulation valve disc 10, piston 11, stretch valve disc 12, disc spring 13, compression nut 14, disc spring 15, compensation valve disc 16 , working cylinder base 17, lower connecting ring 18 (connected with vehicle frame or steering knuckle, not shown in the figure), oil storage cylinder seat 19, compression bolt 20, disc spring 21, compression valve valve plate 22, compression nut 25, lower fixed plate 26, grease trap 27, grease nozzle 28 and grease nozzle cover 29 etc. are formed. Wherein: disc spring 9 , flow valve valve plate 10 , piston 11 etc. constitute flow val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com