Joint terminal

A terminal and electric wire technology, applied in connection, conductive connection, contact manufacturing, etc., can solve problems such as troublesome installation and complexity, and achieve the effect of good easy contact, reliable support and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

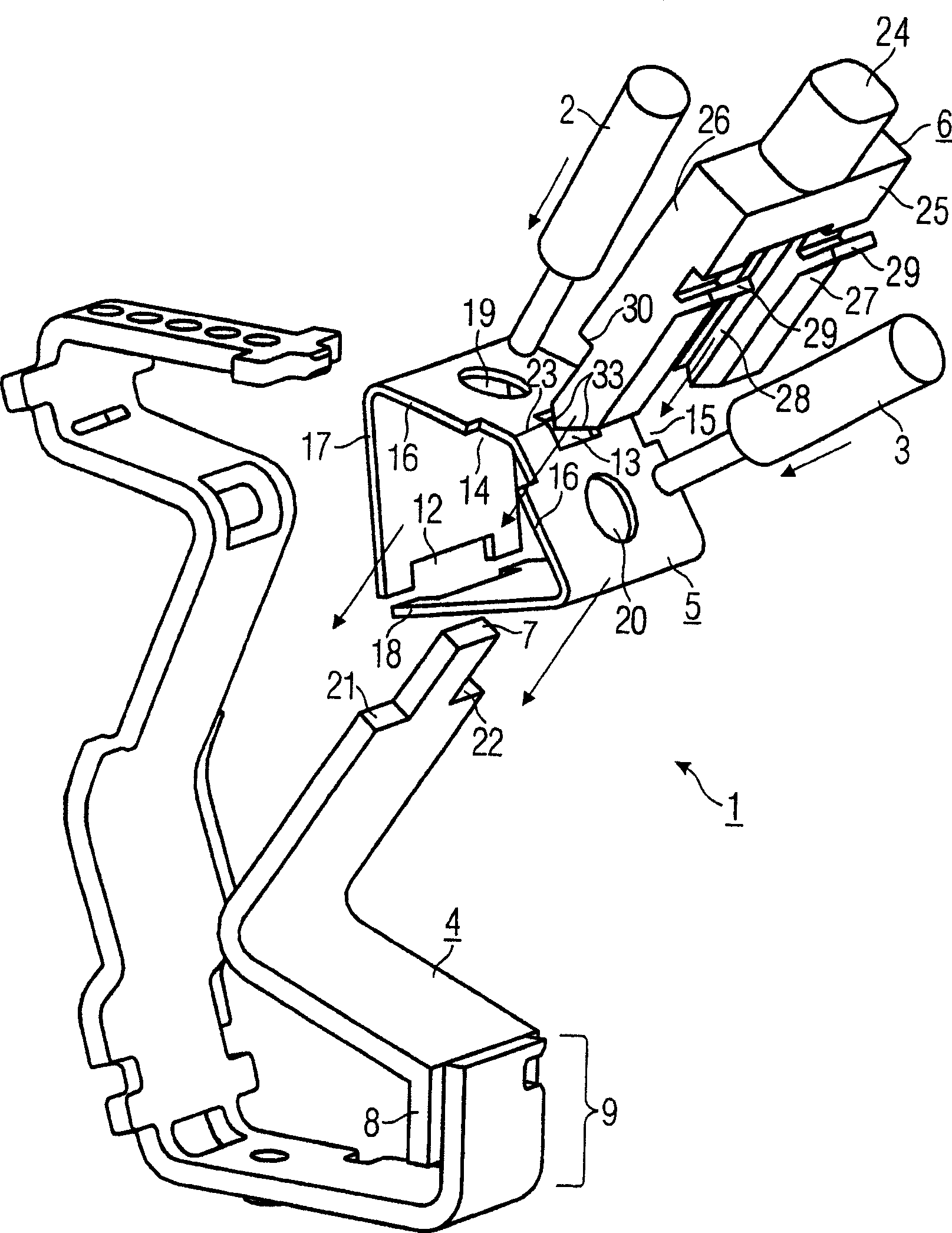

[0024] exist figure 1 shows a bolt-free elastic terminal 1 in a three-dimensional exploded view. In this case, the connection terminal 1 or plug terminal is used to connect a first partially stripped electrical conductor 2 and a partially stripped second electrical conductor 3 . The assembly of the connection terminal 1 has a support element 4 , a spring element 5 and an actuating element 6 , which can be assembled to form an assembly by mutual plug-in connections along the direction arrows. The component can thus be temporarily stored as a functionally reliable pre-assembled structural unit until further use.

[0025] Support elements 4 in accordance with figure 1 It is part of a bimetal support, which can be a one-piece, that is to say continuous or two-piece structure. In a two-part construction, the support element 4 has, at its fastening end 8 opposite the free end 7 , a connection point 9 which can be designed, for example, as a welding point.

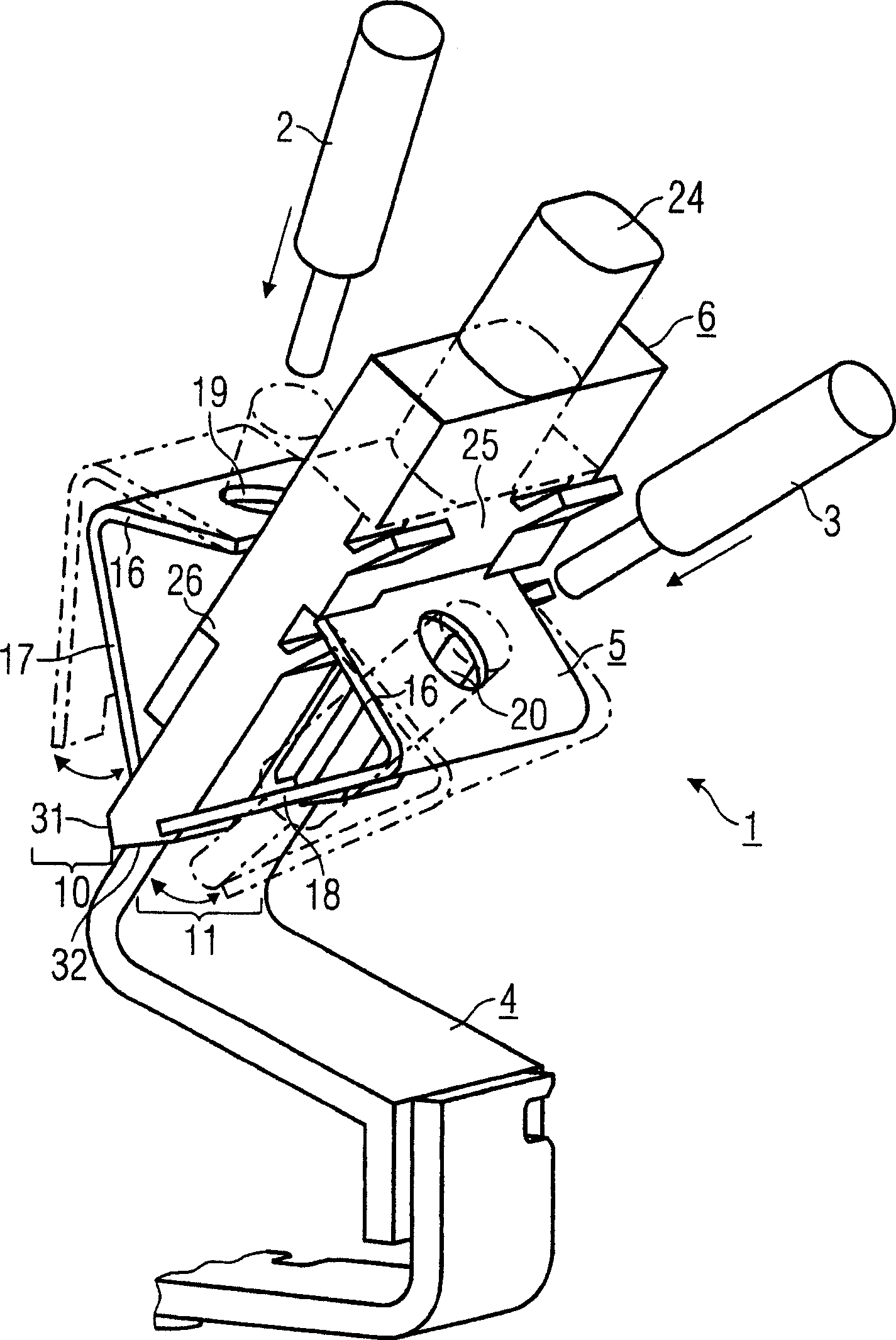

[0026] exist figure...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap