Interconnecting assembly for motor

A component and winding technology used in the field of interconnected components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

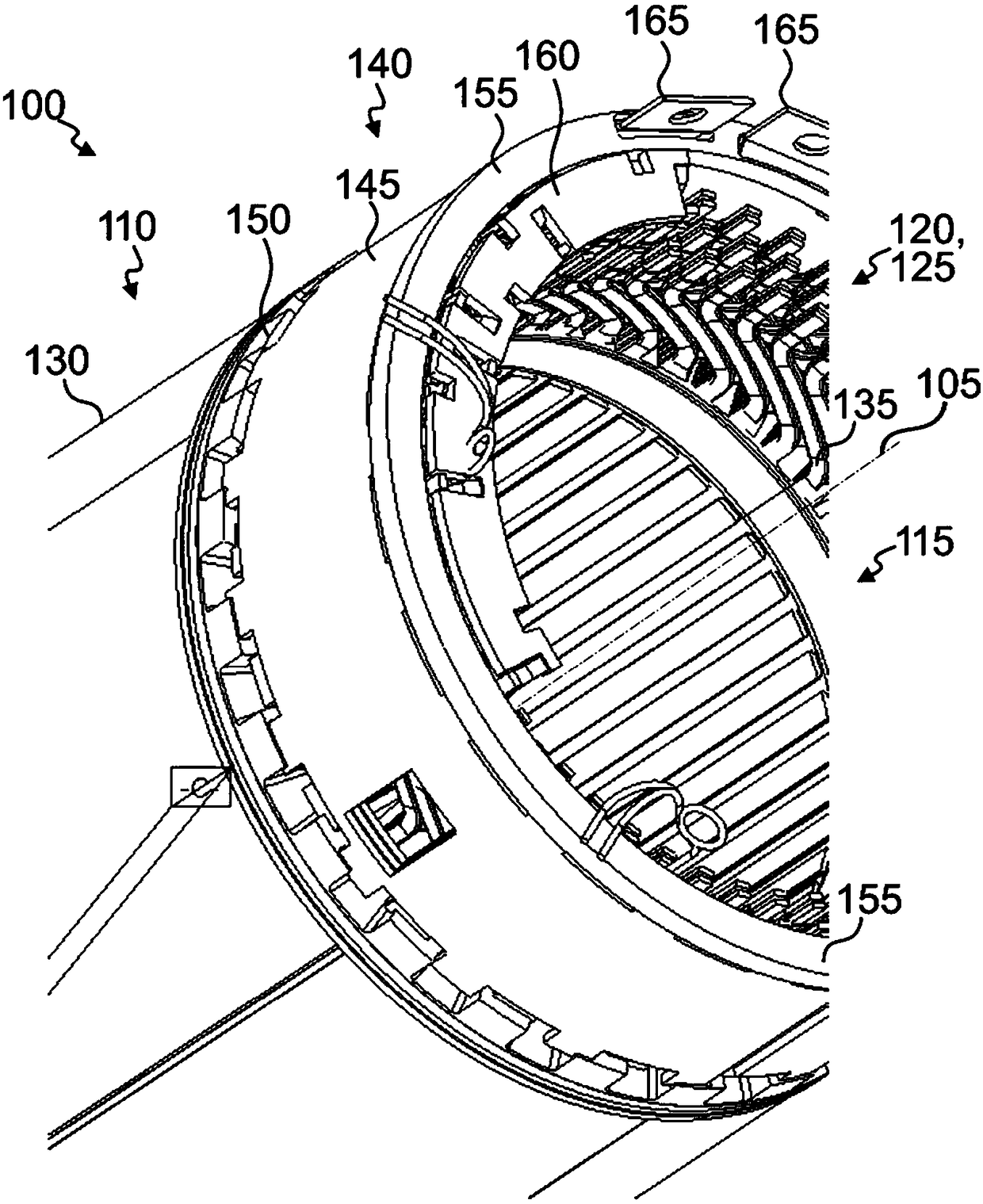

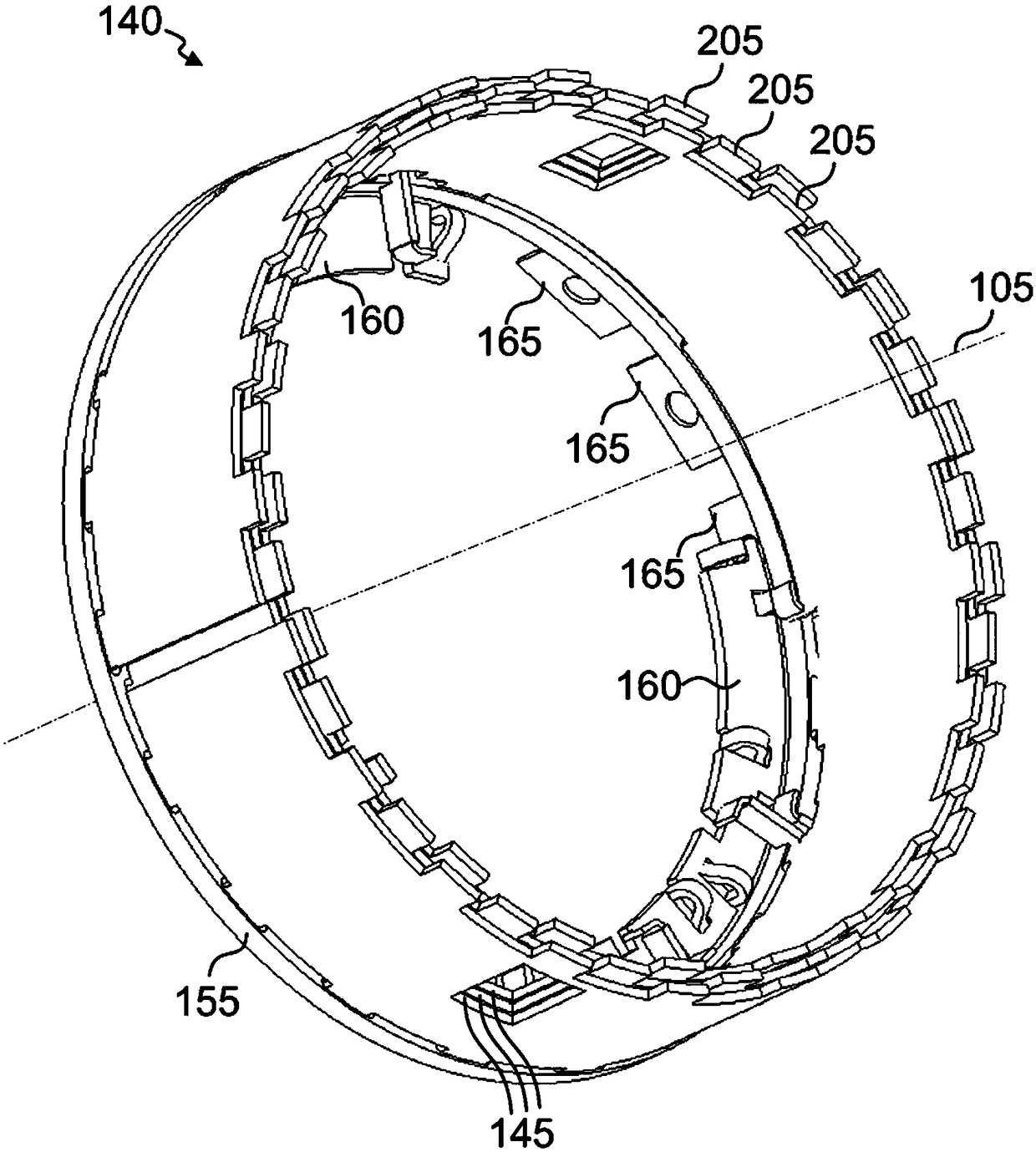

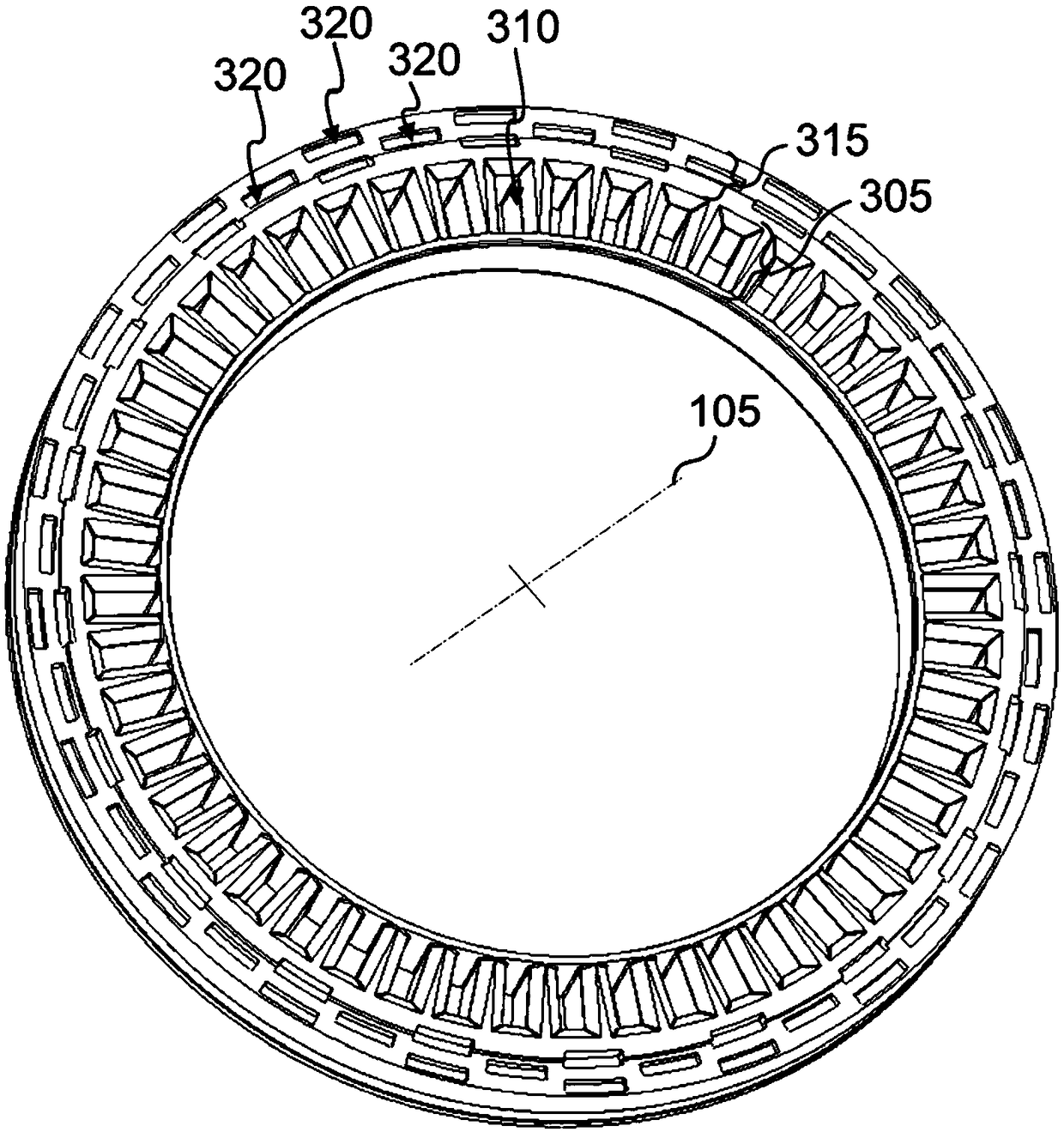

[0031] figure 1 An exemplary electric machine 100 is shown, which comprises an axis of rotation 105 about which a stator 110 is arranged relative to a rotatably mounted rotor 115 (not shown). In this document, the descriptions of polarity always refer to the axis of rotation 105 of the electric machine 100 unless otherwise stated. The electric machine 100 is designed as a permanent magnet synchronous machine by way of example with a radially outer stator 110 and an inner rotor 115 , but other embodiments are also conceivable.

[0032] A plurality of windings 120 are arranged on the stator 110 , which are each assigned to one of the three phases 125 . Winding 120 is preferably designed as a hairpin winding with hairpin elements 135 . The hairpin element 135 is bent substantially in a U-shape and includes two conductor segments spaced apart from each other and a bend section therebetween. The magnetic conducting element 130 can in particular be configured as an axial stack of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com