Rotor housings for disconnecting mechanisms of switching devices for electrical switchgear

A technology for rotor shells and electrical switches, which is applied in the direction of electrical switches, circuit breakers with excessive current, electrical components, etc., can solve the problems of costly locking, high complexity, and complexity limitations, and achieve reduced friction and high mechanical efficiency. Effects of stability, reduced complexity and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

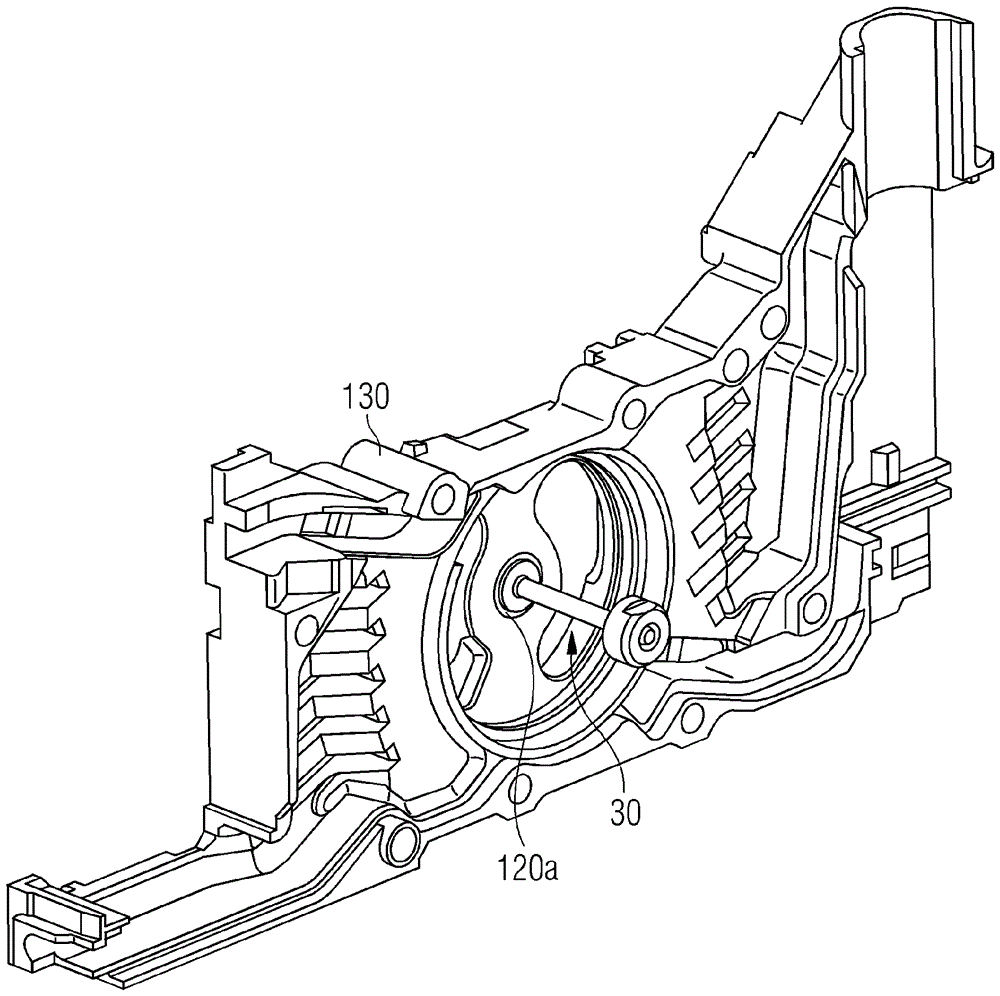

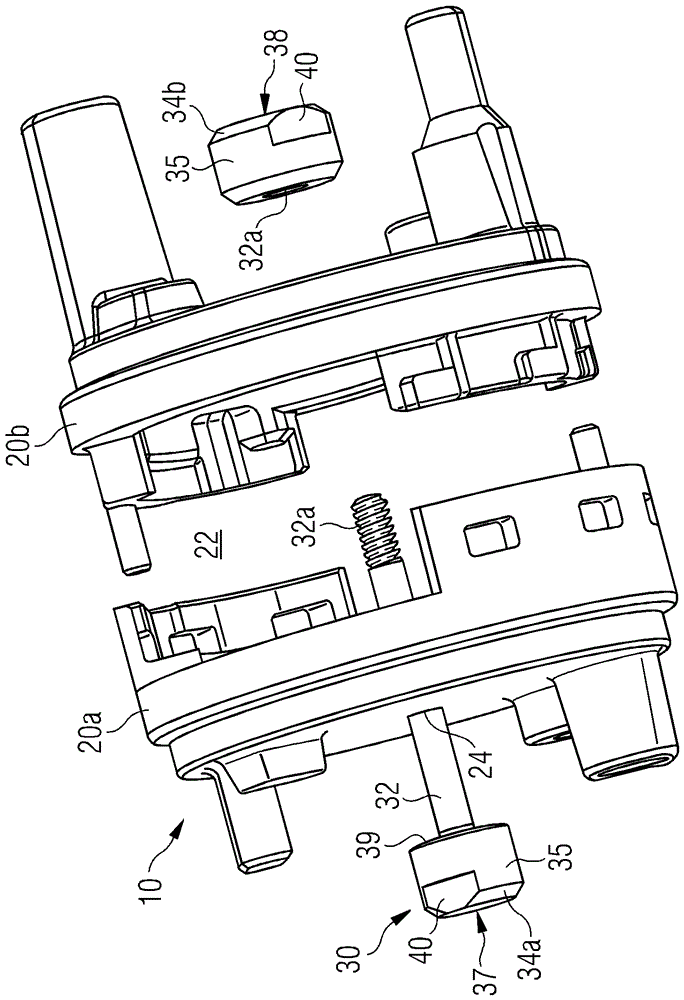

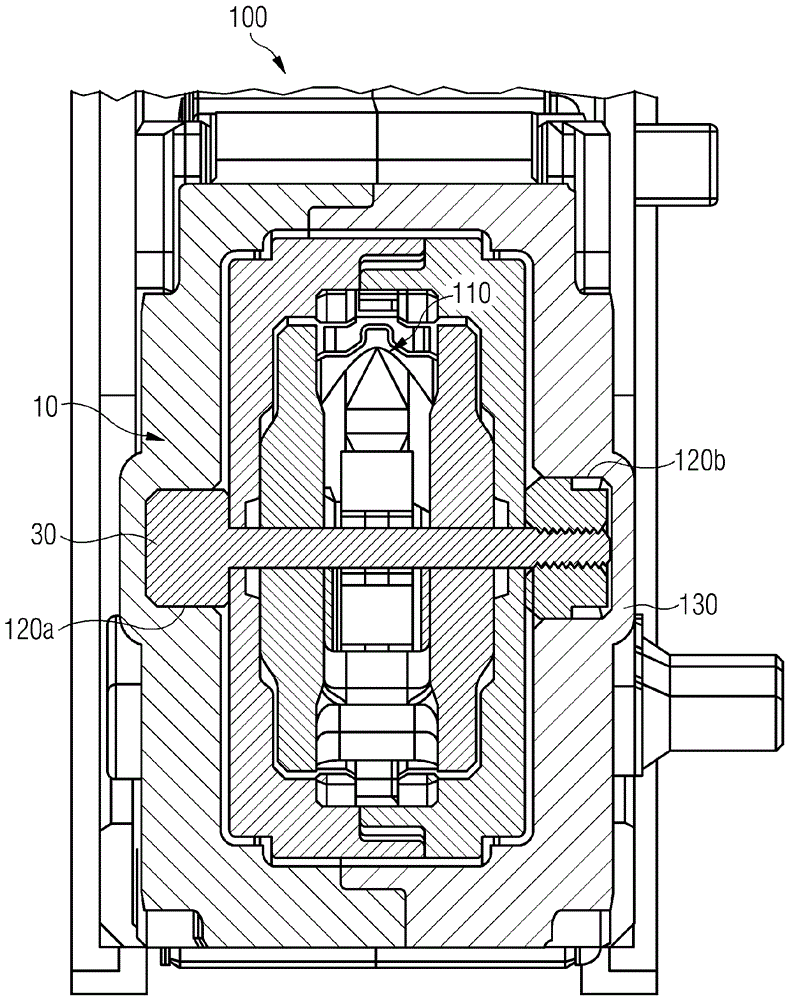

[0064] figure 1 with 2 A first embodiment of a rotor housing 10 according to the invention is shown. The rotor housing 10 has two housing elements 20a and 20b, for example figure 2 can be separated from each other as shown. Furthermore, a connecting element 30 is provided, the shaft section 32 of which passes through the interior of the rotor housing 10 , ie the housing interior 22 . As a result, the shaft section 32 is located in the housing interior 22 , for example Figure 4 The swivel support structure forming part of the breaking mechanism 110 as shown in FIG.

[0065] To locally fix the two housing elements 20 a and 20 b relative to one another, the connecting element 30 has a head section 37 and a base section 38 . The head section 37 and the base section 38 each have a contact surface 39 which bears on the outer side of the respective housing element 20a and 20b. if available in Figure 3a with 3b As seen in , since the connecting element 30 has a mounting mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com