Stop ring with support eye for hanging stop or binding

A technology of stop ring and stopper, which is applied in the direction of load hanging components, connecting components, threaded fasteners, etc., to save space and prevent pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

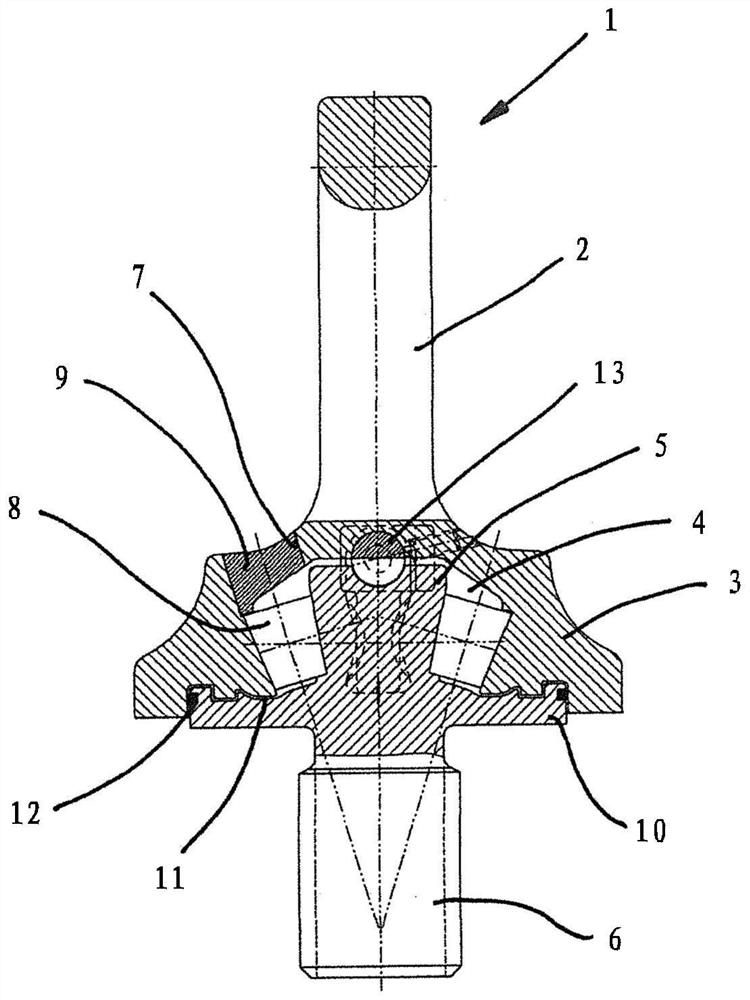

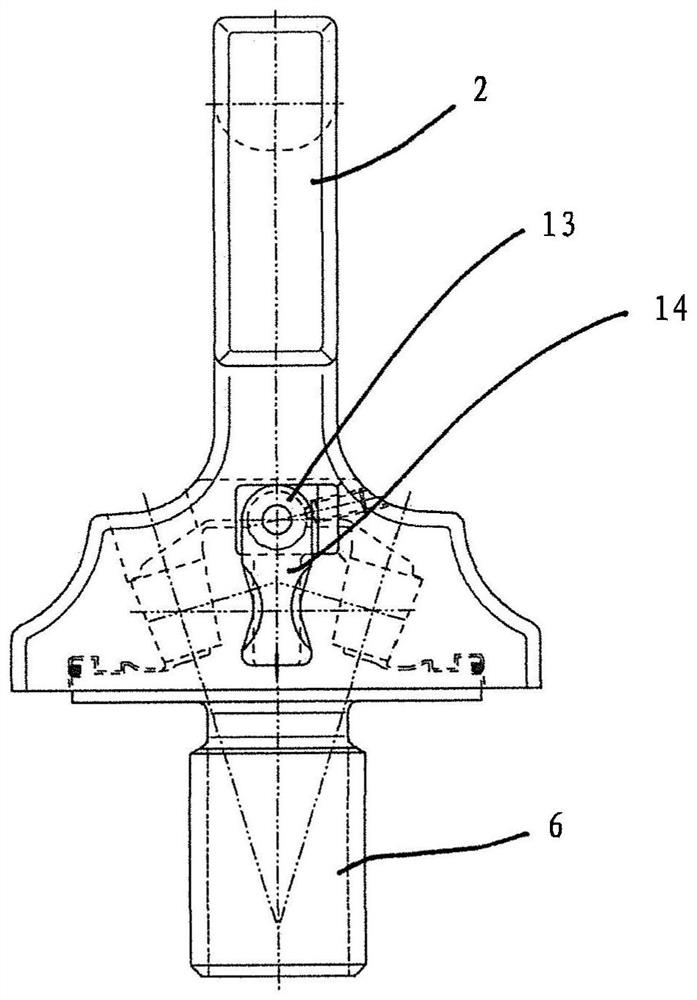

[0020] figure 1 A stop ring 1 is shown with a support eye 2 and a base 3 configured as a bearing bore 4 , in which a journal 5 of a threaded bolt 6 is arranged. In order to achieve a form-fitting connection and to support a smooth rotational movement of the bearing eye 2 relative to the threaded bolt 6 , bearing rollers 8 are inserted between the bearing hole 4 and the journal 5 through the opening 7 in the bottom 3 of the bearing eye 2 . between. The opening 7 is closed by a closing plug 9 . The plug 9 can be pressed in, wedged in or glued on. In order to protect the bearing against contamination, the ring washer 10 of the threaded bolt 6 is equipped with a labyrinth seal 11 and a sealing ring 12 . stop pin 13 in figure 1 is shown in the initial position.

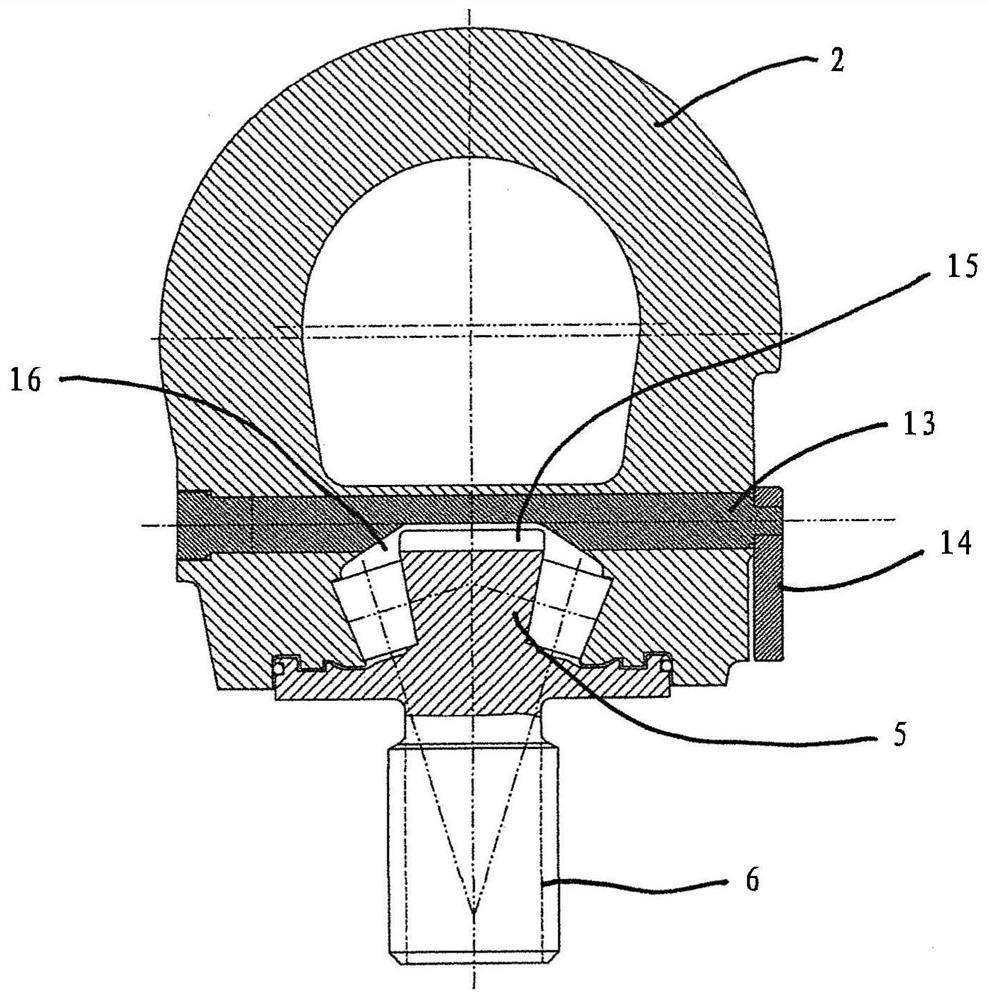

[0021] exist figure 2 shows the locking mechanism between the support eye 2 and the threaded bolt 6 by means of the locking pin 13 . The head of the journal 5 of the threaded bolt 6 is equipped with a groove 15 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com