Large area VHF-PECVD reaction chamber electrode capable of obtaining even electric field

A uniform electric field, large area technology, applied in the field of electrode design of large area VHF-PECVD reaction chamber, can solve the problems affecting the uniformity of potential distribution, etc., to solve the uniformity of potential distribution, suppress the logarithmic singularity effect, and improve the electric field distribution The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

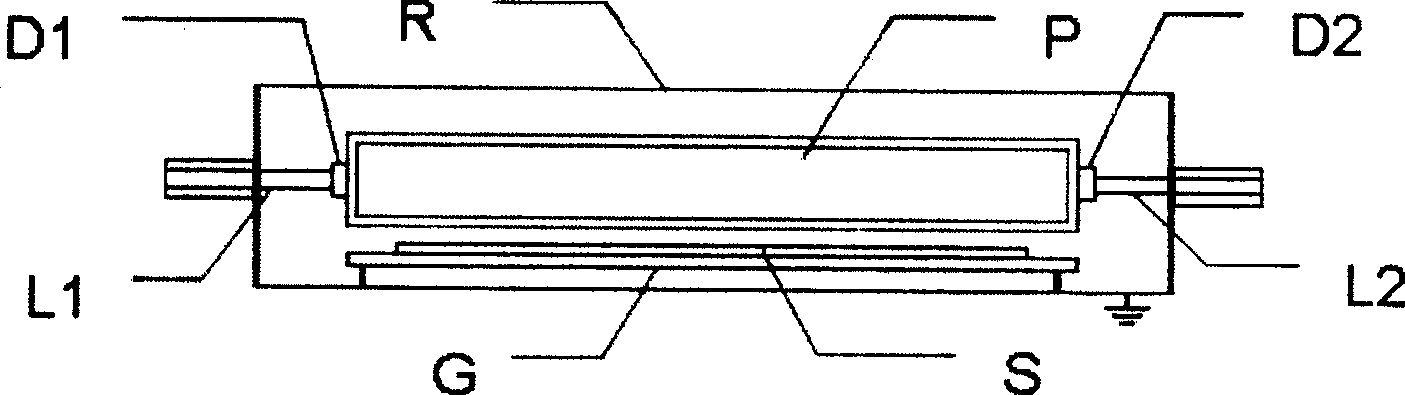

[0042] A set of grooved electrode structures with symmetrical ends ( Figure 5 shown).

[0043] In this example, the length of the rectangular parallel plate hollow electrode is L=120cm, the width W=40cm, the height H=10cm, and the thickness of the electrode wall is 1cm; the side feed-in method at both ends of the electrode is adopted, and the two power feed-in ports are located on the side of the wide side of the electrode The center position of the power feed port, that is, the side close to the substrate, is engraved with two rectangular slots. The length of the slot is 38cm, the width is 1cm, and the interval between the two slots is 1.5cm. The depth is 1cm and communicates with the inside of the electrode. The excitation frequency power supply of 40.68MHz is applied to carry out equal phase and equal amplitude power feeding at both ends. Using the PECVD reaction chamber with the electrode structure of this example, the theoretical calculation of the electric field distr...

Embodiment 2

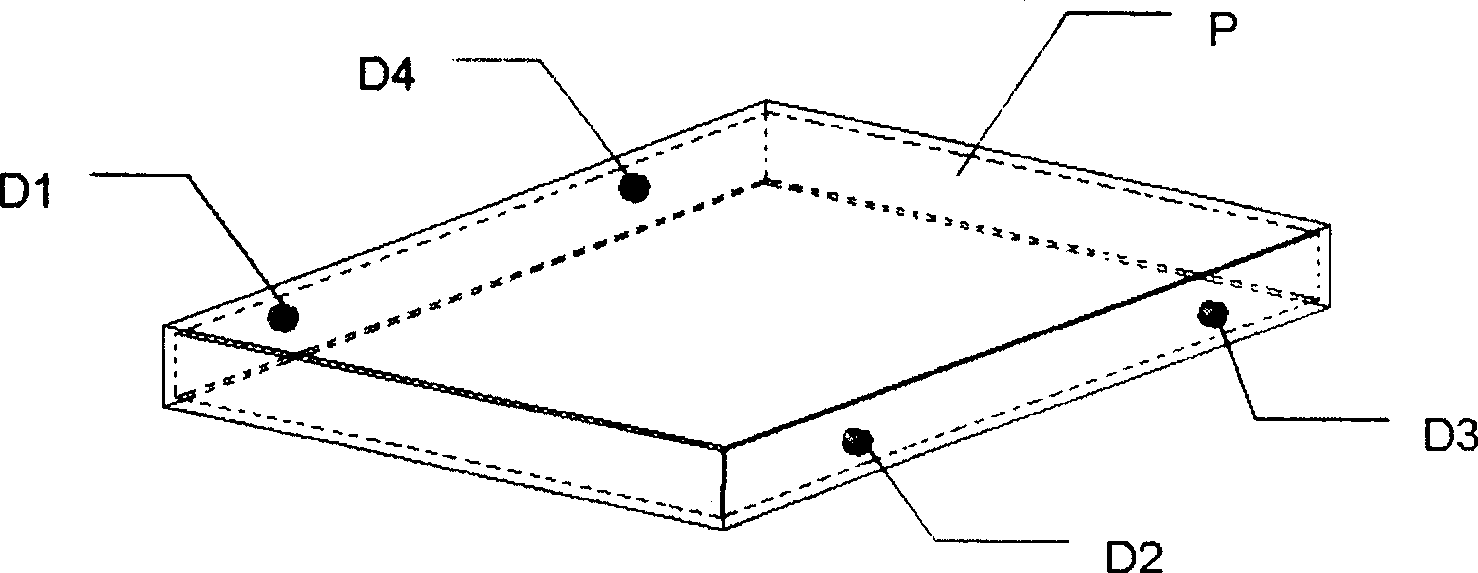

[0045] Point contact feed-in port, intermittent multi-slot electrode structure ( Figure 7 shown).

[0046] In this example, the length of the rectangular parallel plate hollow electrode is L=120cm, the width W=80cm, the height H=10cm, and the thickness of the electrode wall is 1cm; the side four-terminal symmetrical feed-in method is adopted, and the four power feed-in ports are located on the long side of the electrode L The horizontal midline position on the side, the distance between the centers of the two ports is 70cm; grooves are carved on the side of the power feed port close to the substrate, and two rectangular grooves are carved on one side of each port. The length of the groove is 30cm, the width is 1cm, and the distance between the two grooves 2cm, the depth of the groove is 1cm, and it communicates with the inside of the electrode. The excitation frequency power supplies of 40.68MHz and 54.24MHz were applied respectively, and the four-terminal equal-phase and eq...

Embodiment 3

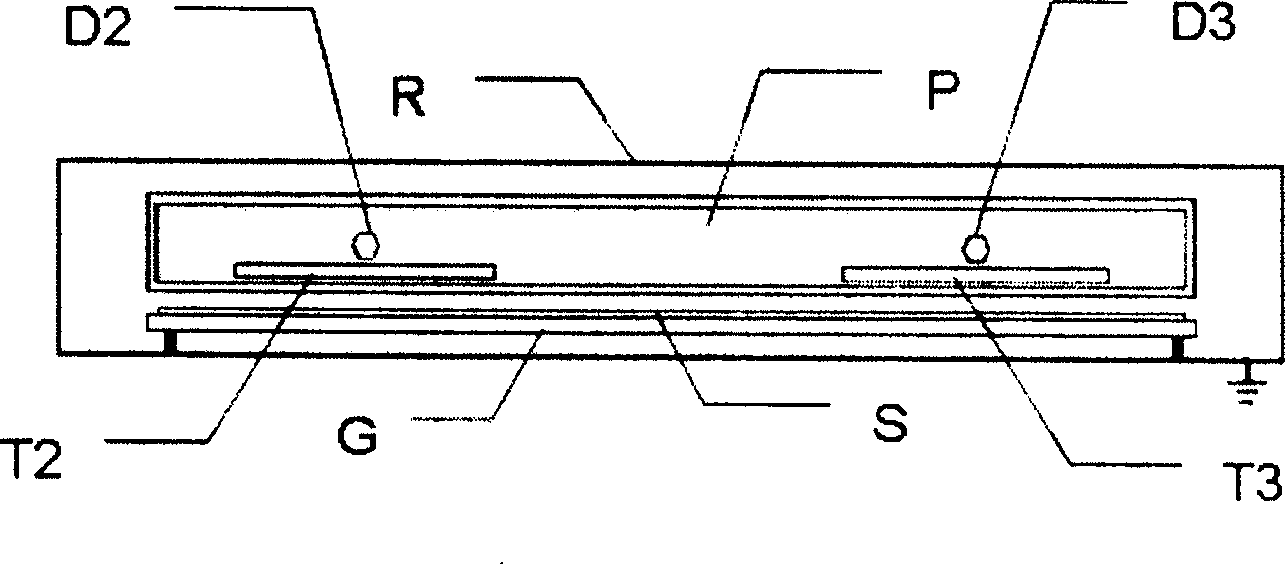

[0048] Line contact feed-in port, continuous multi-slot electrode structure ( Figure 10 shown).

[0049] In this example, the length of the rectangular parallel plate hollow electrode is L=120cm, the width W=80cm, the height H=19cm, and the thickness of the electrode wall is 1cm; the four-terminal symmetrical side feeding method of the electrode is adopted, and the power feeding port is strip-shaped, strip-shaped The port width is 7cm and its thickness is negligible. The four strip-shaped power feed-in ports are located on the midline of the two L long sides of the electrode, and the distance between the centers of the two ports on the same side is 63 cm; four rectangular slots are engraved on the side of the power feed-in port adjacent to the substrate. The length of the groove is 110cm, the width is 1cm, the distance between the two grooves is 2cm, the depth of the groove is 1cm, and it is connected with the inside of the electrode. 40.68MHz excitation frequency power sup...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap