Automatic welding process and device for long pipe joint in boiler pipe header

A long pipe and pipe welding machine technology, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as unstable welding quality and leakage accidents of fillet welds, improve product quality and labor productivity, and ensure welding Quality, the effect of improving the level of automatic welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

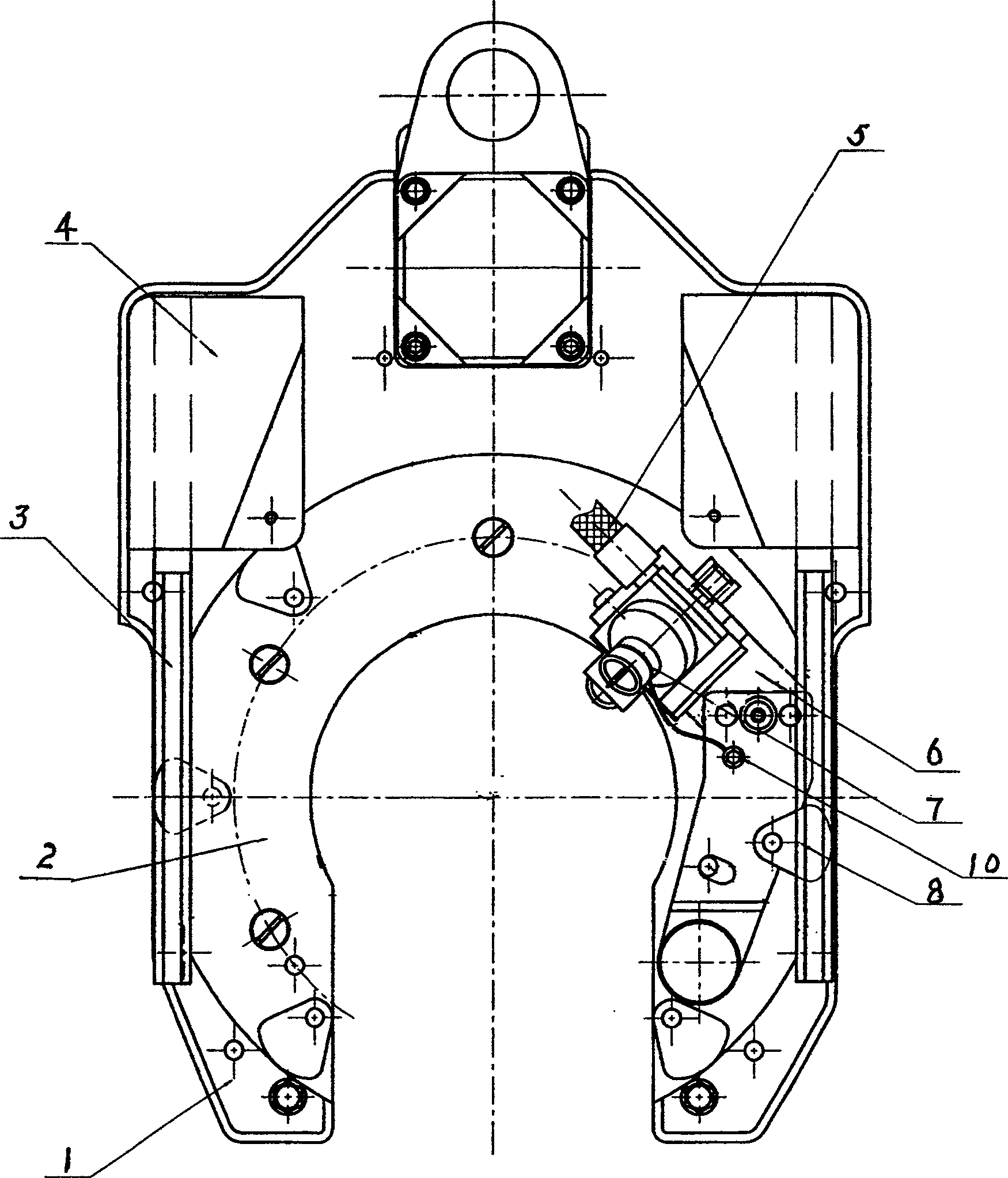

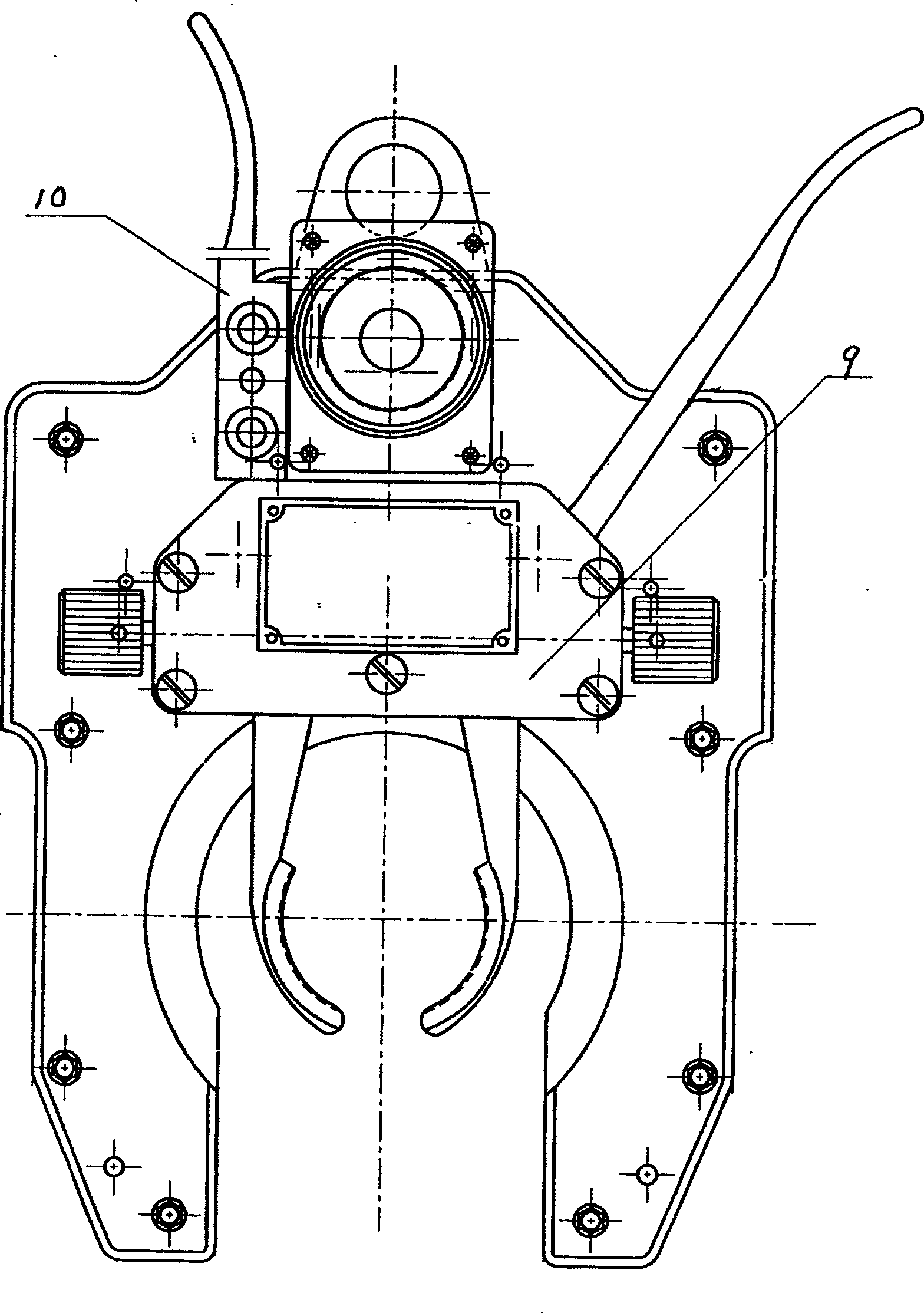

[0016] Such as figure 1 , 2 As shown, it is a structural schematic diagram of a pipe welding machine. The pipe welding machine is characterized in that it consists of a base plate 1, a rotating mechanism 2, a positioning plate 3, a vertical positioning device 4, a cable 5, a welding machine 6, a welding head 7, and a winding Line column 8, clamping device 9, handle 10 are formed.

[0017] Two positioning plates 3 are installed on both sides of the base plate 1 respectively, and two vertical positioning devices 4 are respectively installed on the upper ends of the two positioning plates 3. When the clamping device 9 clamps the pipe, the two vertical positioning devices 4 can clamp The female pipe at the lower end of the pipe is positioned to make the pipe more fixed.

[0018] The rotating mechanism 2 is installed on the bottom plate 1, the rotating mechanism 2 and the bottom plate 1 are in the shape of concentric arcs, the welding machine 6 is installed on the rotating mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com