Thin film transistor module base board and its making method

A technology of a thin film transistor and a manufacturing method, applied in the field of liquid crystal display components, can solve problems such as environmental pollution, and achieve the effects of improving quality and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

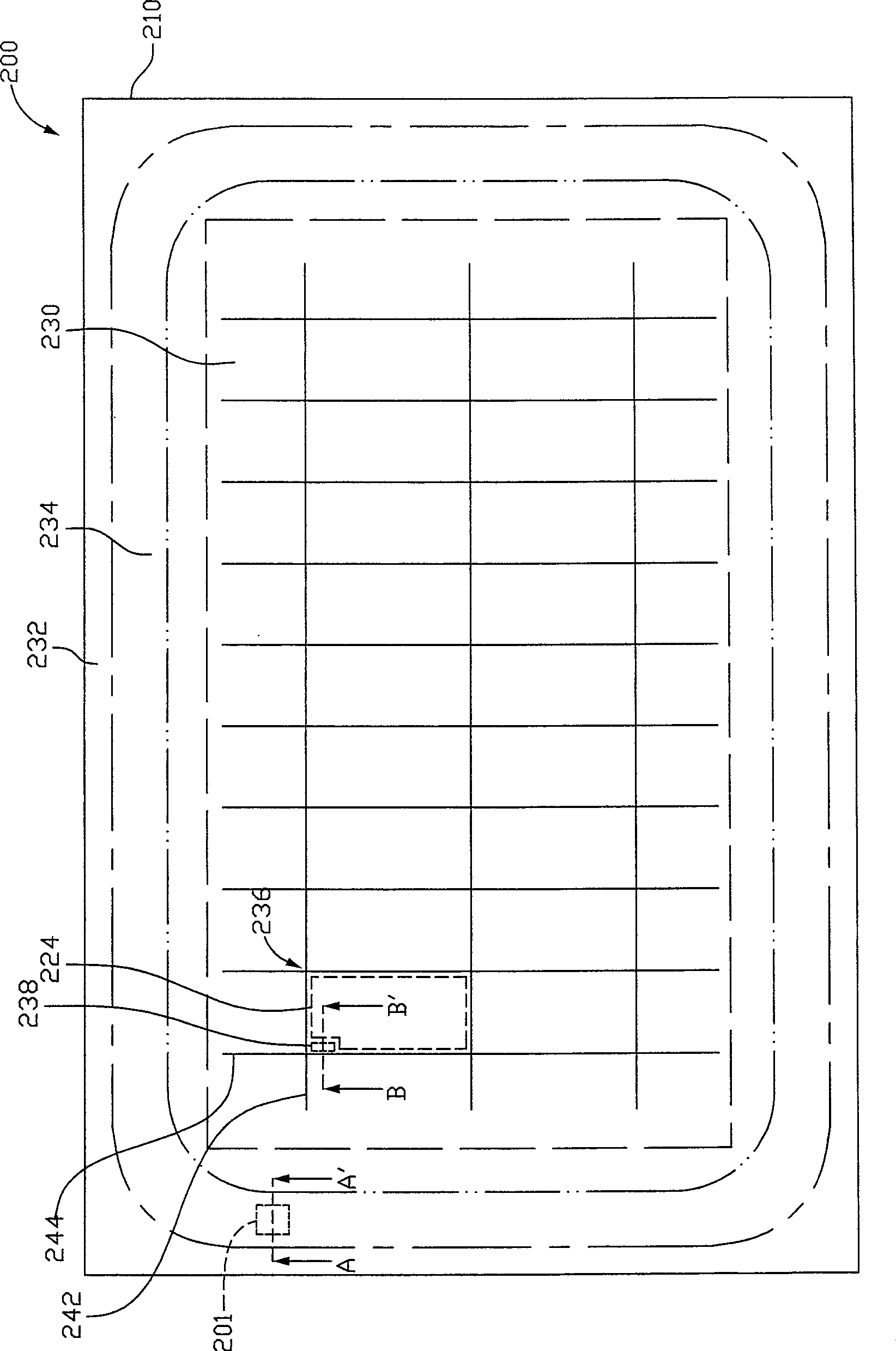

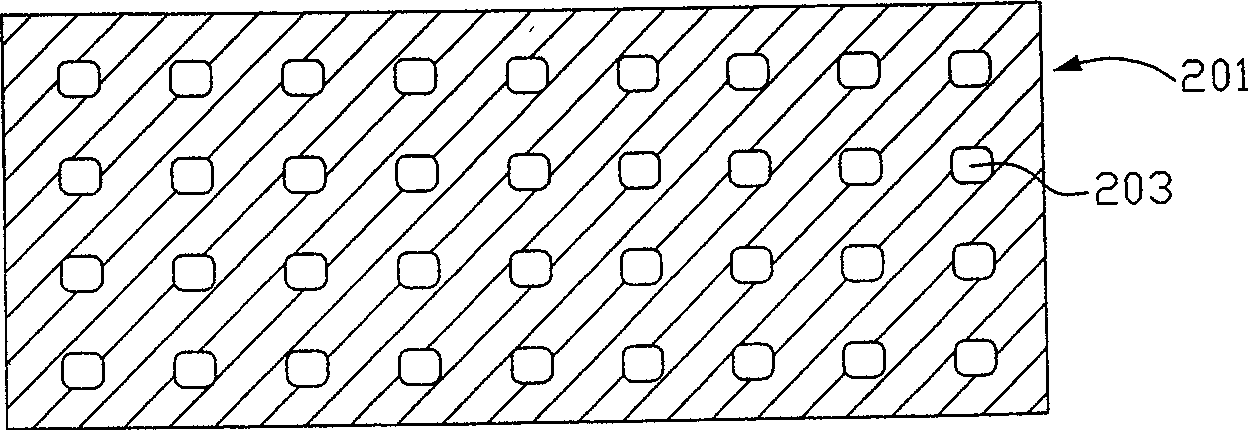

[0050] figure 2 A schematic top view of a thin film transistor array substrate according to a preferred embodiment of the present invention is shown. Please refer to figure 2, the thin film transistor array substrate 200 has a display area 230 and a non-display area 232, and includes a transparent substrate 210, a plurality of pixel units 236 and a light shielding structure 234, wherein the pixel unit 236 is arranged in the display area 230, and includes a TFT 238 and a pixel electrode 224 . The light shielding structure 234 is located in the non-display area 232 of the TFT array substrate 200 .

[0051] More specifically, the transparent substrate 210 is, for example, a glass substrate, the display area 230 is, for example, a rectangular area located in the center of the glass substrate, and the non-display area 232 is, for example, a frame-shaped area surrounding the display area 230 . A plurality of data lines 244 and scan lines 242 parallel to each other are disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com