Siphon for toilets

A technology for siphons and toilets, applied in the field of siphons, which can solve problems such as parts damage, loss, and inability to complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

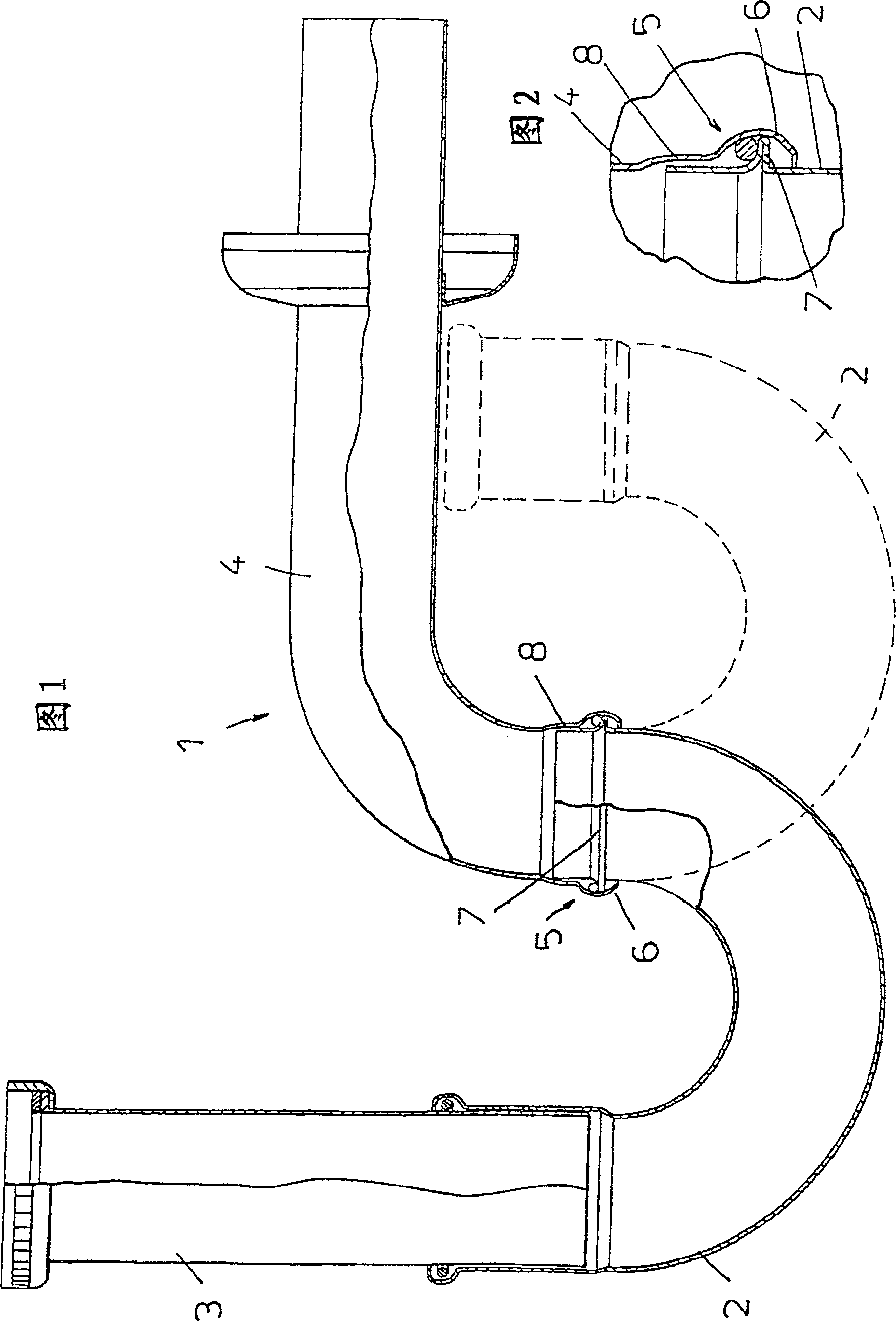

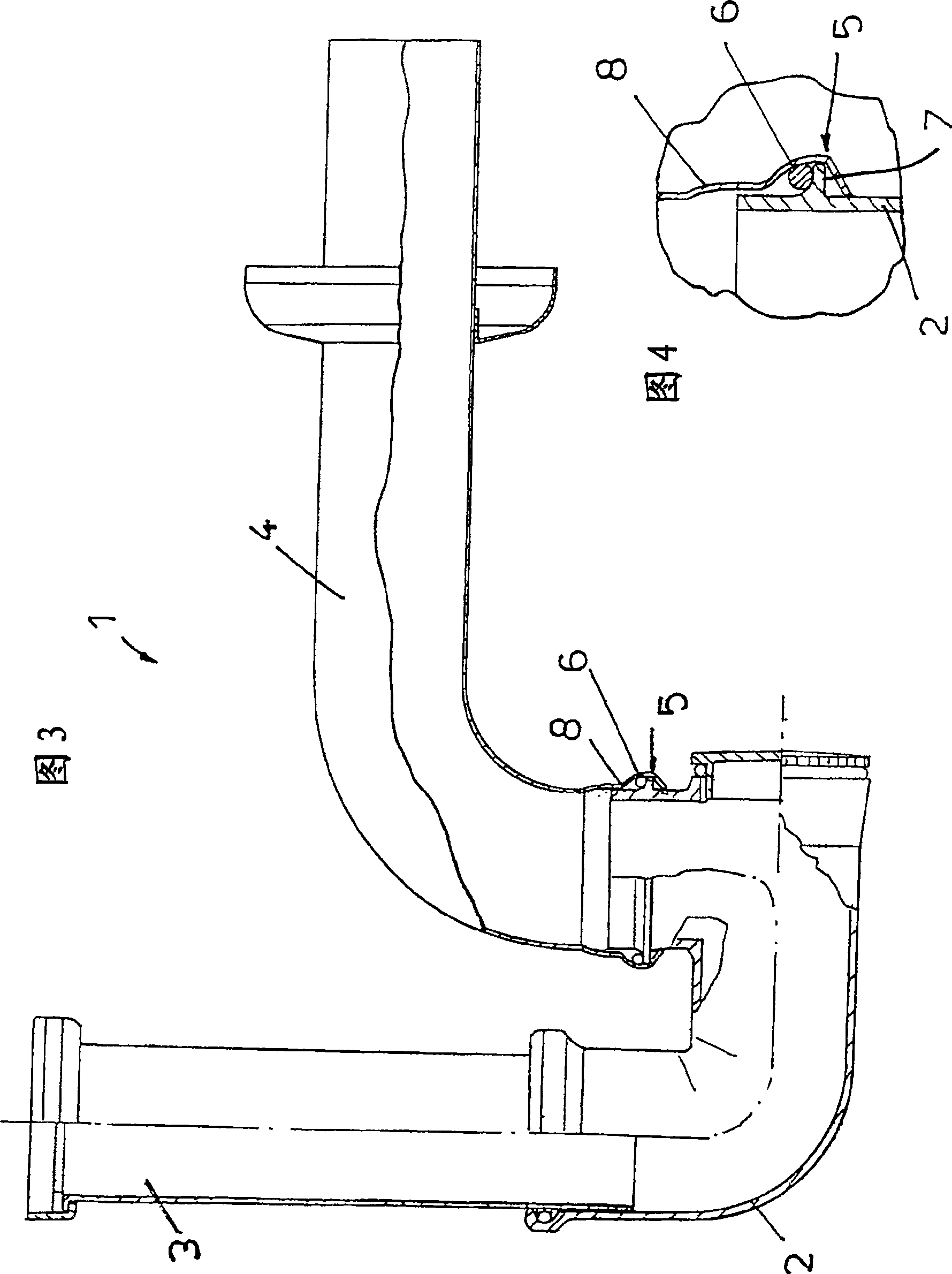

[0022] Referring to the attached drawings, a siphon for a toilet shown in the figures is indicated with the reference numeral 1 throughout.

[0023] The siphon 1 comprises a first tubular element 2 for connection to the toilet drain 3 and a second tubular element 4 for connection to the wall drain.

[0024] Advantageously, the first tubular element 2 and the second tubular element 4 are connected together watertight in a rotational manner, thereby enabling a small volume transfer position (indicated by dashed lines in FIG. 1 ) and an installation position in which the tubular elements 2, 4 extend (indicated by a continuous line in Figure 1) between rotations.

[0025] The second tubular element 4 has at one of its ends at least one circular base 5 into which one end of the first tubular element is inserted and vice versa, that is, the circular base can be A seat 5 is provided at the end of the first tubular element 2 .

[0026] The circular base 5 comprises a first widening ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap