Outer-side-rotation rotor for dynamo-electric machines

A rotating electrical machine, externally rotating technology, applied in synchronous motors with stationary armatures and rotating magnets, manufacturing stator/rotor bodies, electromechanical devices, etc. Inability to carry out sufficient reinforcement and fixation, etc., to achieve the effect of stabilizing dimensional characteristics and electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

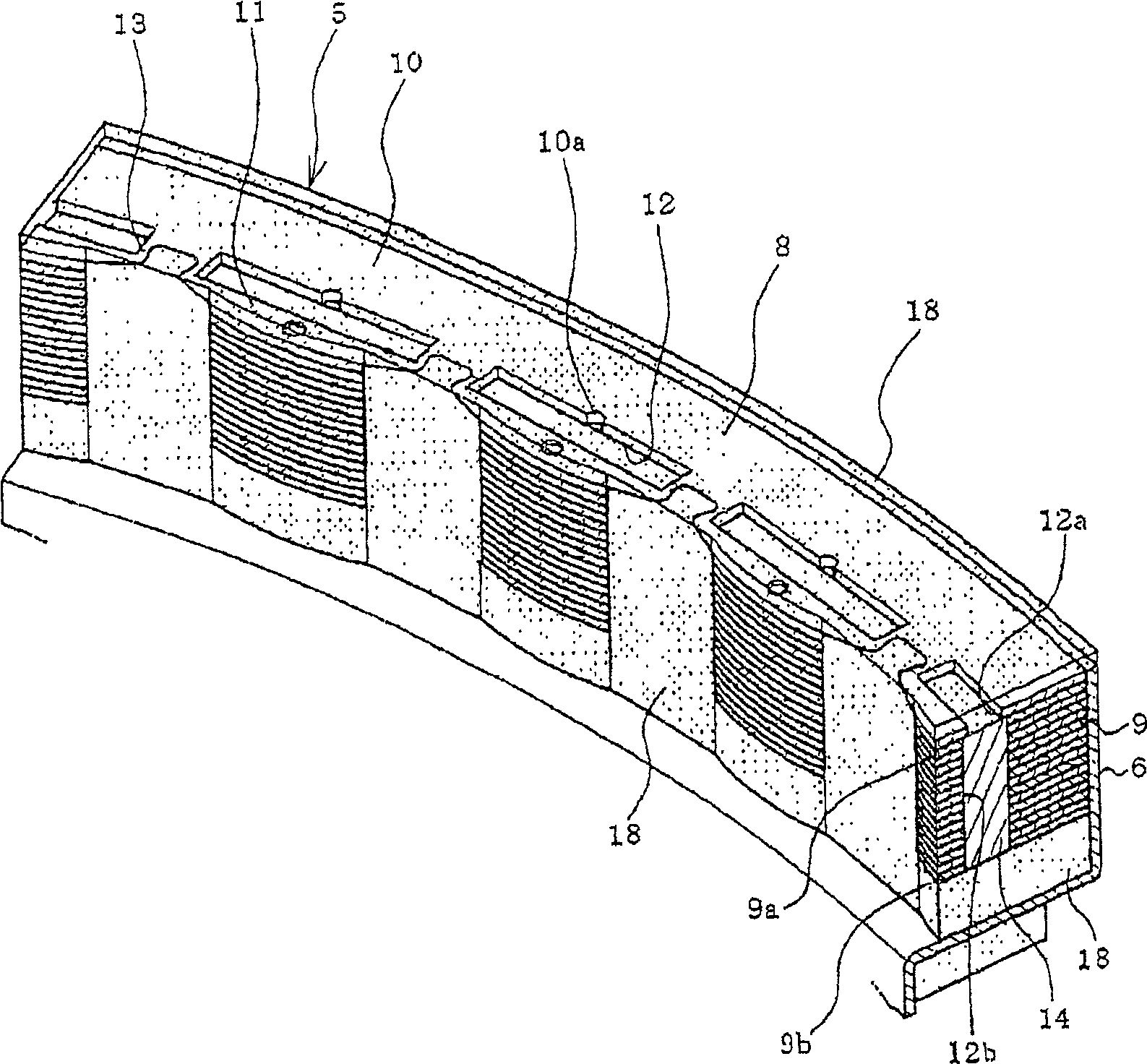

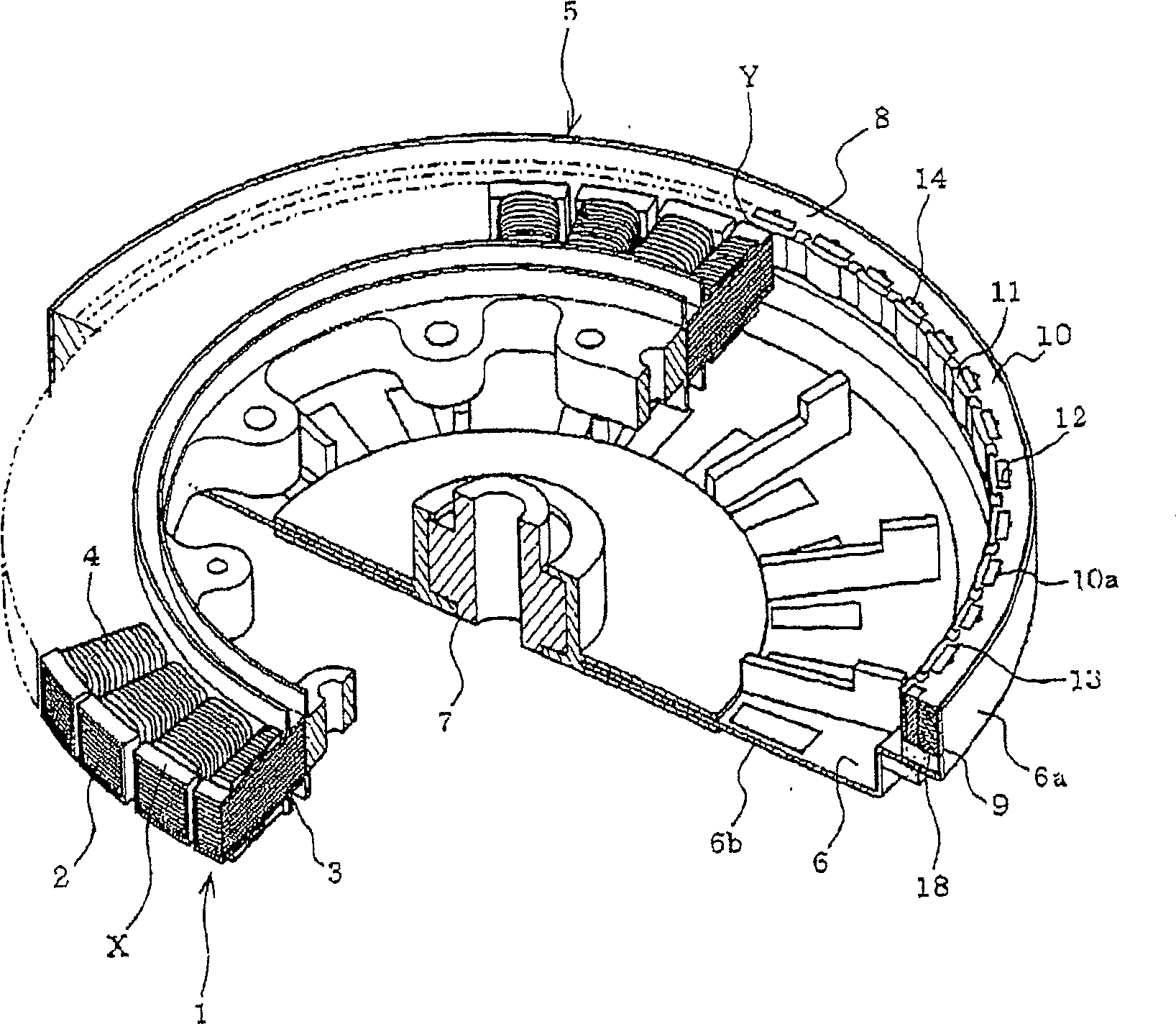

[0020] Next, an embodiment in which the present invention is applied to an externally rotating permanent magnet motor (rotating electric machine) will be described with reference to the drawings.

[0021] figure 2 It is a perspective view showing a part of the motor cut away. exist figure 2 Among them, the stator 1 includes: a stator core 3 having a plurality of teeth 2 radially; a stator resin X provided to cover the stator core 3 ; and a stator winding 4 wound around each tooth 2 .

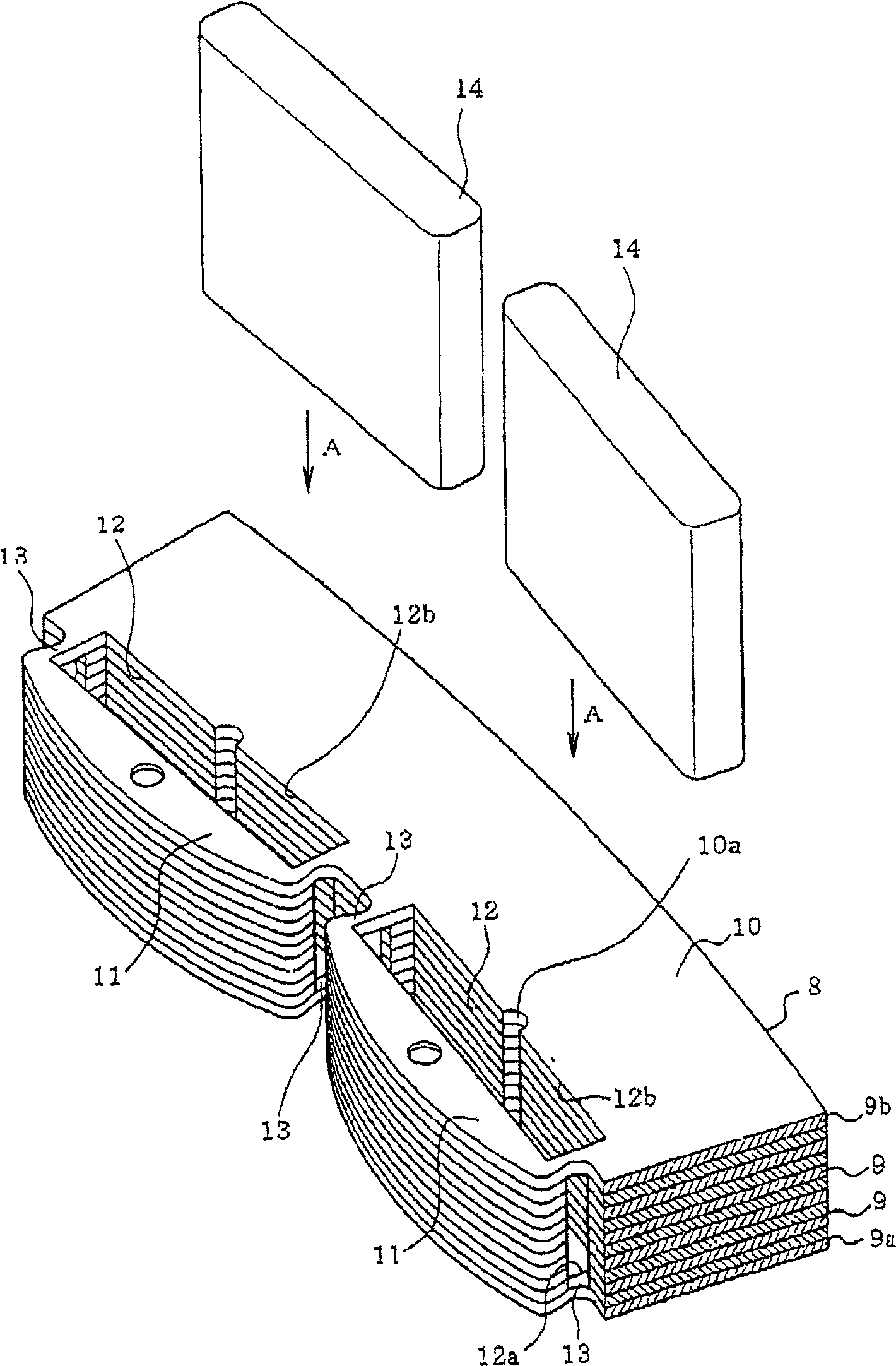

[0022] The outwardly rotating rotor 5 has a frame 6 made of a magnetic body in the shape of a circular container with an open top. A shaft support body 7 is fixed to the central portion of the frame 6 . An annular wall 6a is provided on the opening side of the outer peripheral portion of the frame 6, and the rotor core 8 is arranged along the inner periphery of the annular wall 6a. The rotor core 8 is formed by punching out an electromagnetic steel sheet to form a punched plate 9 and stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com