Elastic vibration reduction towing mechanism of track vehicle

A technology for rail locomotives and traction devices, which is applied in the directions of traction devices, transportation and packaging, railway car body parts, etc. and other problems, to achieve the effect of reliable transmission, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

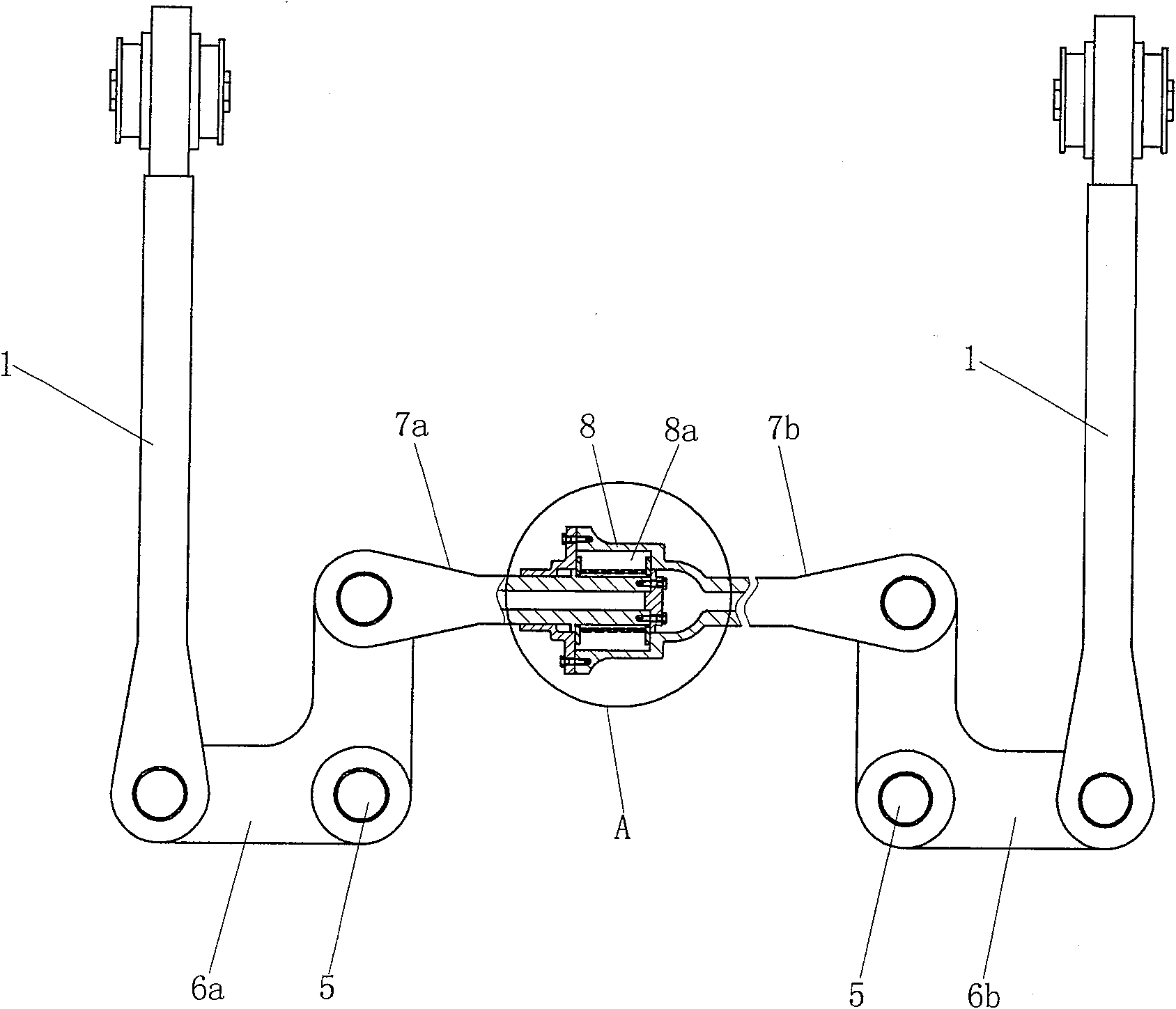

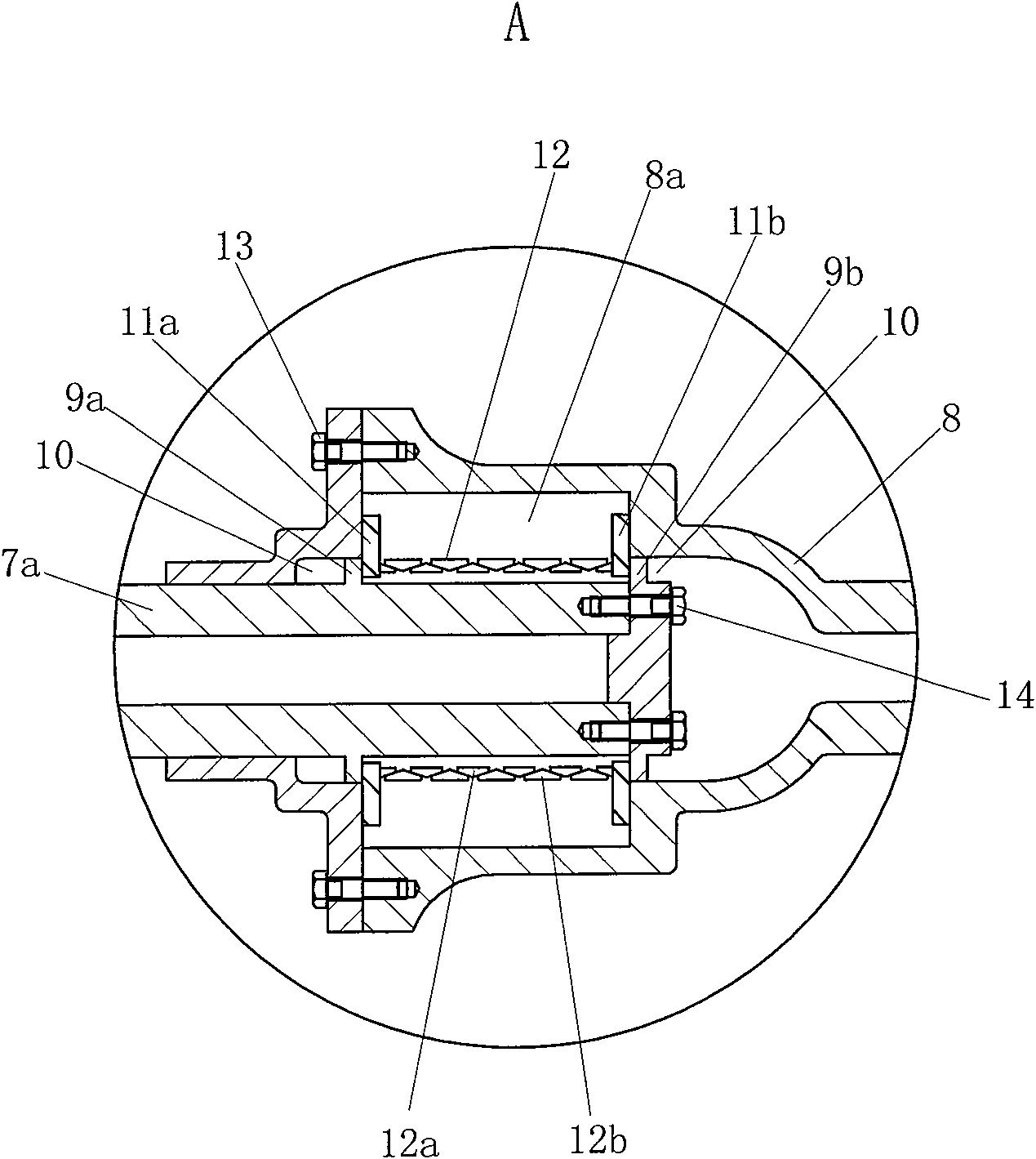

[0021] figure 1 , 2 Shown, a specific embodiment of the present invention is: a kind of rail locomotive vehicle elastic damping traction device, comprises the left and right draw bar 1 that is connected with car body, and the left and right draw bar 1 that are hinged with left and right draw bar 1 respectively The crank arms 6a, 6b, the corners of the left and right crank arms 6a, 6b are connected to the bogie frame through the crank arm pin 5. The left and right swing arms 6a, 6b are connected by elastic connectors, and the elastic connectors are specifically formed as follows: the left end of the left connecting rod 7 is hinged with the left swing arm 6a, and the right part of the left connecting rod 7a is covered with a spring chamber 8a. Spring guide cylinder 8, the right end of spring guide cylinder 8 links to each other with right connecting rod 7b, and the right end of right connecting rod 7b is hinged with right turning arm 6b; The end positions are respectively prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com