Maching station, maching device and method of positioning workpiece on the maching unit

A technology of processing unit and processing equipment, applied in metal processing equipment, metal processing mechanical parts, metal processing and other directions, can solve the problems of high cost, unsuitable to achieve high efficiency, etc., to achieve cost reduction, high suitability and flexibility, Pause reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

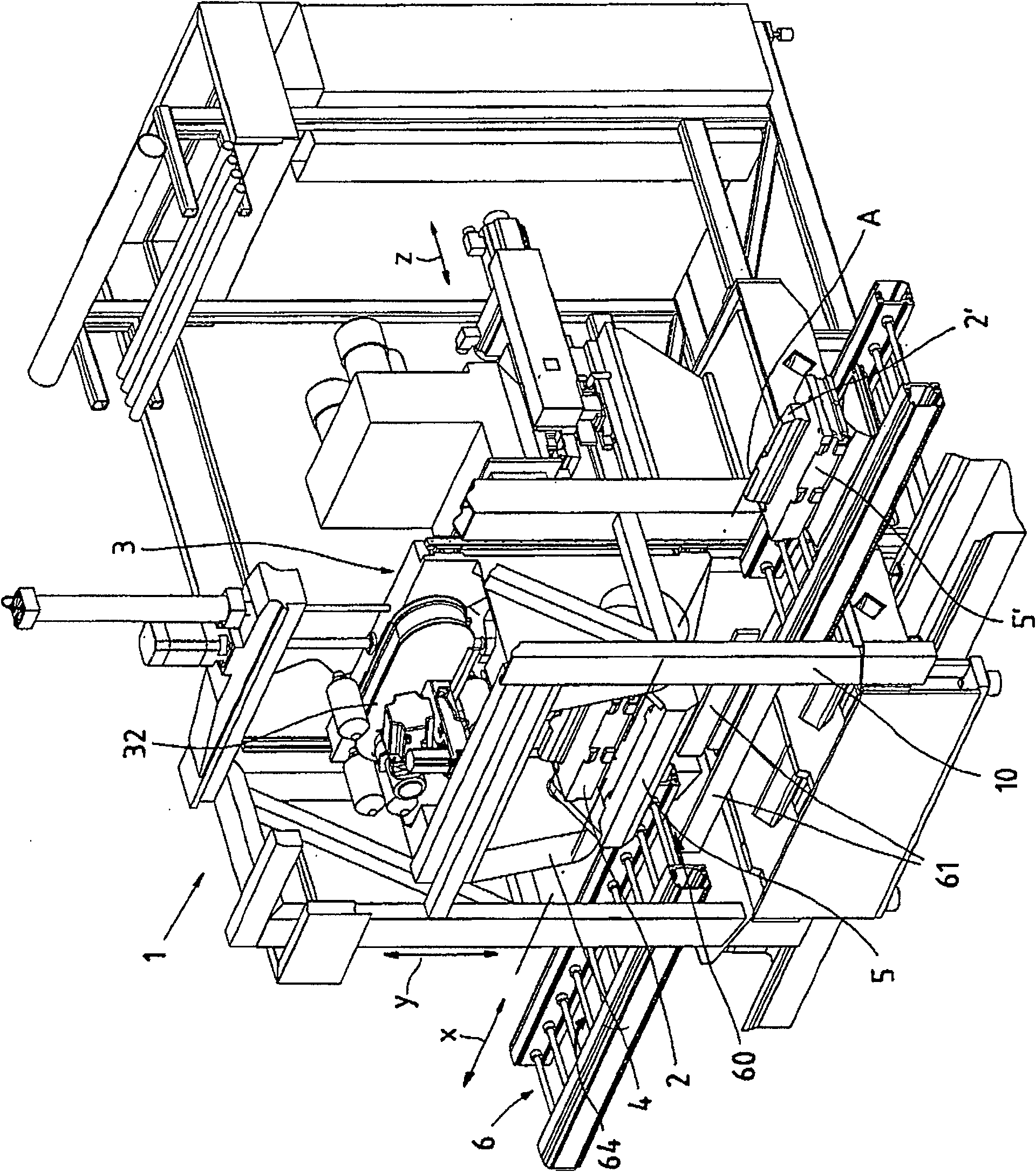

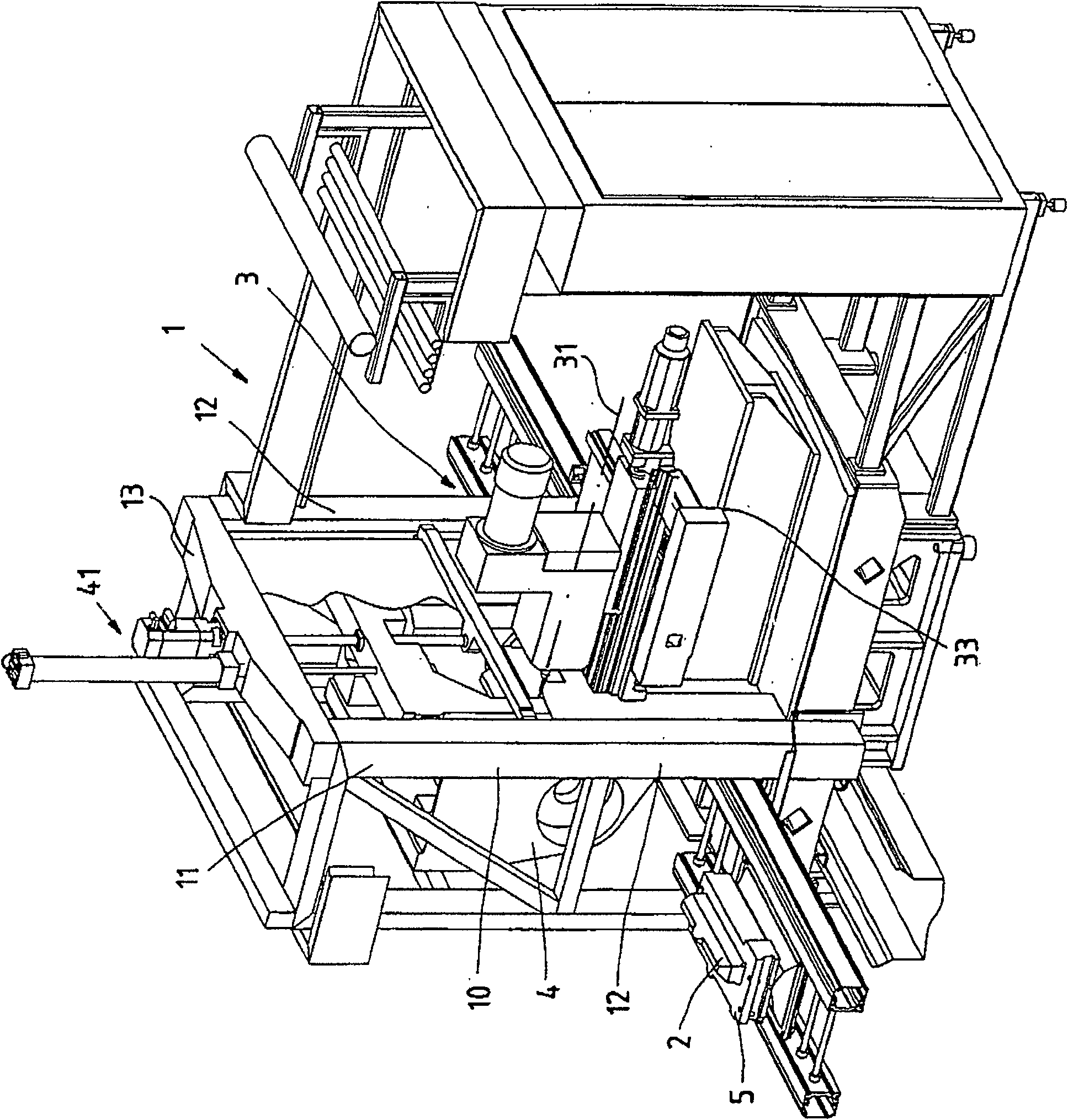

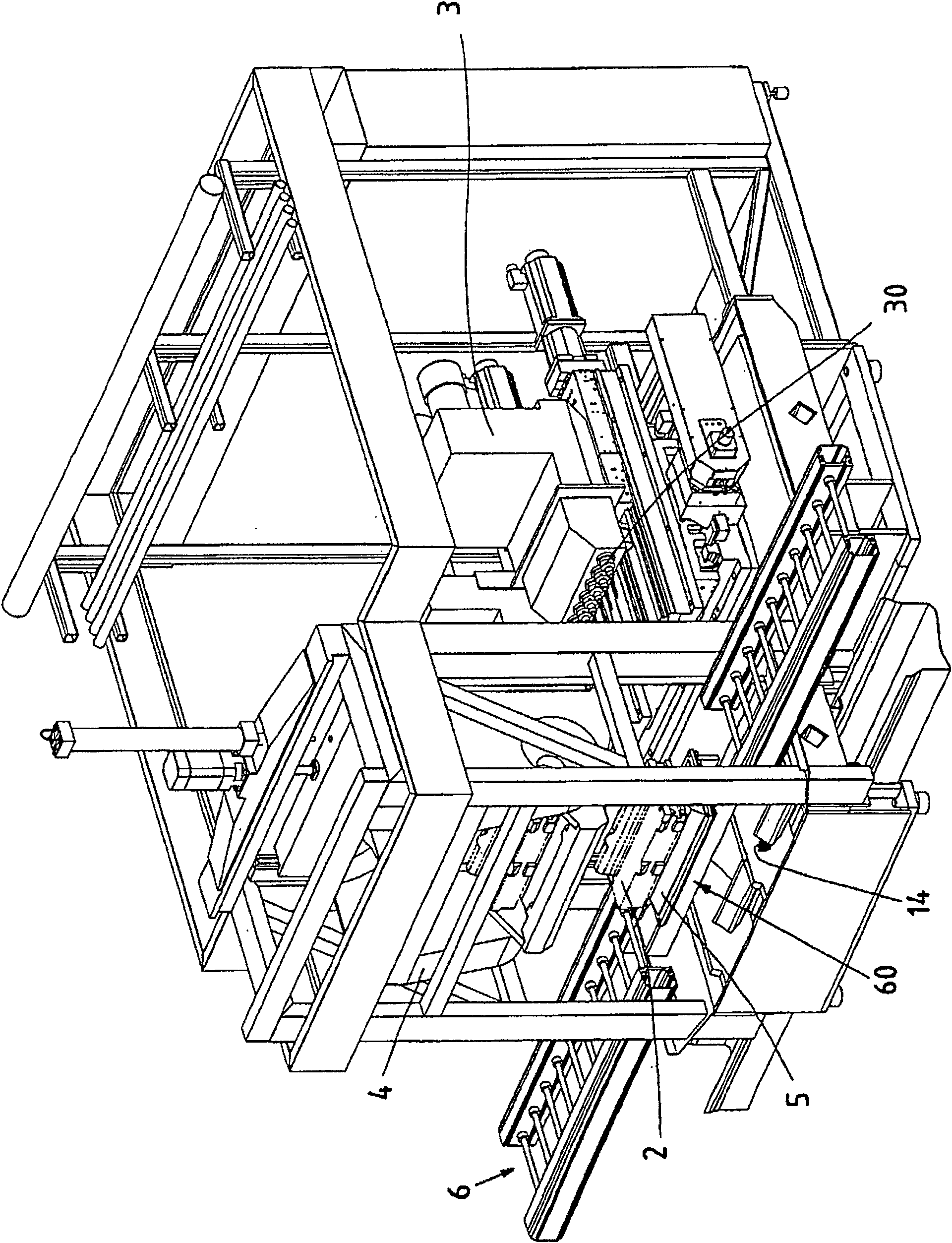

[0100] A processing station 1 according to the invention is shown, for example, in figure 1 middle. The machining station basically comprises a machining unit 3 for machining workpieces 2 . The machining unit 3 has a mobility along the Z axis, which is parallel to the spindle axis and, if necessary, also perpendicular thereto along the X axis. wherein the Z-axis and the X-axis are oriented horizontally or substantially horizontally. The vertical axis (Y axis) is provided by the workpiece slide 4 carrying the workpiece 2 , in particular during or for machining.

[0101] The processing station according to the invention is often part of a processing plant which is also according to the invention, for example a conveyor line. A plurality of processing stations arranged in succession are connected to one another by means of a conveyor track 6 . The area of the transport track 6 where the workpieces 2 are fed is marked here with 64 . figure 1 The situation is shown in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com