Coal tar filtering aid

A filter aid, coal tar technology, applied in the direction of filtration separation, removal of tar through water, processing, separation methods, etc., can solve the problem of few industrial applications of aids, and achieve the effect of high metal removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

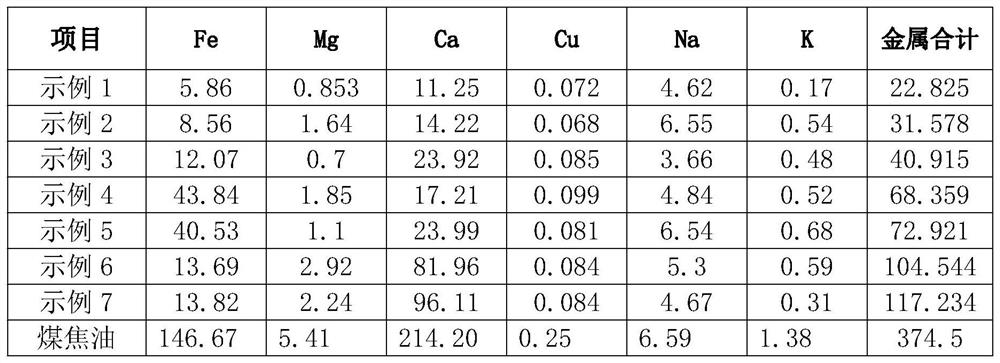

Examples

Embodiment 1

[0046] A kind of coal tar filtering aid comprises the following steps:

[0047] 1). Prepare raw materials: organic acids, inorganic acids, salts, precipitants, metal complexes, polymer flocculants, alcohols, filter aids and desalinated water. The organic acids account for 15%, and the inorganic acids 10% of salt, 20% of salt, 15% of precipitant, 15% of metal complex, 10% of polymer flocculant, and 10% of alcohol The proportion of filter aid is 3%, the proportion of filter aid is 7% and the proportion of desalinated water is 20%;

[0048] 2). Pour the organic acid into a glass container filled with water, then pour the inorganic acid into the glass container, and then mix and stir with the help of ultrasonic waves at a temperature of 20-30 ° C. The stirring time 10-15min;

[0049] 3). Place the stirred product again at a temperature of 40-50°C for heating for 2-4 minutes, then add salts, precipitants and metal complexes in sequence according to the proportion, and continue to...

Embodiment 2

[0053] A kind of coal tar filtering aid comprises the following steps:

[0054] 1). Prepare raw materials: organic acids, inorganic acids, salts, precipitants, metal complexes, polymer flocculants, alcohols, filter aids and desalted water. The organic acids account for 20%, and the inorganic acids 10% of salts, 50% of salts, 60% of precipitants, 40% of metal complexes, 5% of polymer flocculants, and 5% of alcohols 10% for filter aid, 20% for filter aid and 70% for desalinated water;

[0055] 2). Pour the organic acid into a glass container filled with water, then pour the inorganic acid into the glass container, and then mix and stir with the help of ultrasonic waves at a temperature of 20-30 ° C. The stirring time 10-15min;

[0056] 3). Place the stirred product again at a temperature of 40-50°C for heating for 2-4 minutes, then add salts, precipitants and metal complexes in sequence according to the proportion, and continue to assisted by ultrasonic waves. Next, mix and s...

Embodiment 3

[0060] A kind of coal tar filtering aid comprises the following steps:

[0061] 1). Prepare raw materials: organic acids, inorganic acids, salts, precipitants, metal complexes, polymer flocculants, alcohols, filter aids and desalinated water. The organic acids account for 30%, and the inorganic acids The proportion of salt is 20%, the proportion of salt is 60%, the proportion of precipitant is 50%, the proportion of metal complex is 60%, the proportion of polymer flocculant is 20%, the proportion of alcohol is The proportion of filter aid is 5%, the proportion of filter aid is 5% and the proportion of desalted water is 20%;

[0062] 2). Pour the organic acid into a glass container filled with water, then pour the inorganic acid into the glass container, and then mix and stir with the help of ultrasonic waves at a temperature of 20-30 ° C. The stirring time 10-15min;

[0063] 3). Place the stirred product again at a temperature of 40-50°C for heating for 2-4 minutes, then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com