Hydrodemetallization catalyst and preparation method and application thereof

A technology for hydrodemetallization and hydrogenation catalyst, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical elements of heterogeneous catalysts, etc. Removal activity and asphaltene removal activity, etc., to achieve the effect of high metal removal rate and asphaltene removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of the above hydrodemetallization catalyst, the method comprising:

[0043] (1) impregnating the hydrothermally treated carrier in an alkaline first solution containing a metal promoter compound providing the metal promoter, and then drying to obtain a carrier loaded with the metal promoter;

[0044] (2) The above-mentioned carrier loaded with the metal additive is impregnated in an acidic second solution containing an acidic additive compound providing the acidic additive, and then dried and calcined to obtain the modified hydrogenated Catalyst carrier;

[0045] (3) impregnating the modified hydrogenation catalyst carrier in a third solution containing the compound providing the active metal component, followed by drying and calcining.

[0046] According to the present invention, the above steps (1) and (2) prepare the modified hydrogenation catalyst carrier.

[0047] Wherein, in step (1), although as long as t...

preparation example 1

[0075] Take by weighing 2000 grams of dry rubber powder produced by Changling Catalyst Factory (the dry basis is 73% by weight, wherein the content of pseudoboehmite is 68% by weight, the content of alumina trihydrate is 5% by weight, and the balance is amorphous alumina ) and 60 gram sage powder (Henan Lankao tianjing rubber factory product) and mix homogeneously, then add 2400 milliliters of aqueous solution containing 32g nitric acid, and extrude into a butterfly-shaped wet bar with an outer diameter of 1.4mm on a plunger extruder. Then the butterfly-shaped wet strip was dried at 120° C. for 4 hours, and then calcined at 900° C. for 3 hours to obtain carrier Z. Measured by mercury porosimetry, carrier Z has a pore volume of 0.83mL / g and a specific surface area of 128m 2 / g, the pore structure presents a bimodal distribution, in which 5nm-20nm pores account for 45% of the total pore volume, and 100nm-300nm pores account for 23% of the total pore volume.

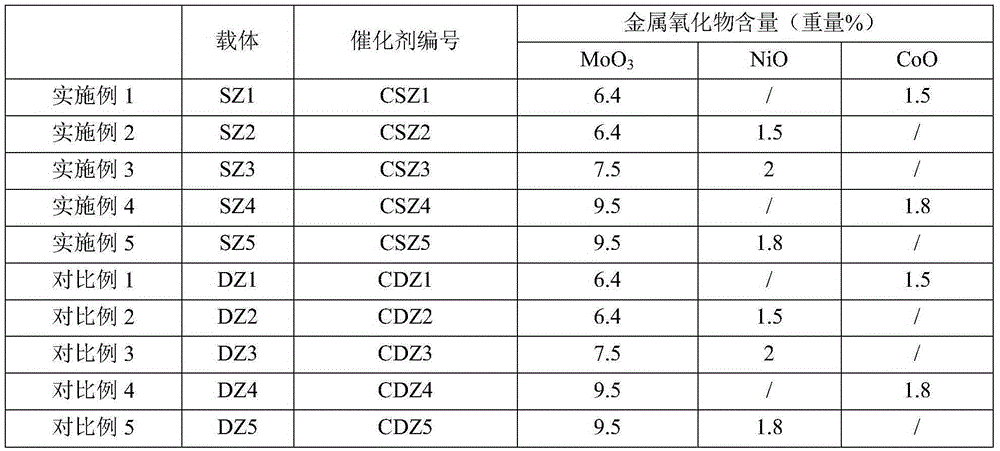

Embodiment 1

[0077] This example is used to illustrate the hydrodemetallization catalyst and its preparation method of the present invention.

[0078] (1) Take 200 grams of the carrier Z prepared in Preparation Example 1, firstly treat the carrier at 135° C. for 12 hours with hydrothermal treatment, and then use 165 milliliters of carrier Z with a temperature of 40° C. containing 15 grams / liter of Mg(NO 3 ) 2 The aqueous solution (pH value is 11) is saturated and impregnated for 1 hour, and then dried at 200 ° C for 8 hours to obtain a carrier loaded with metal additives;

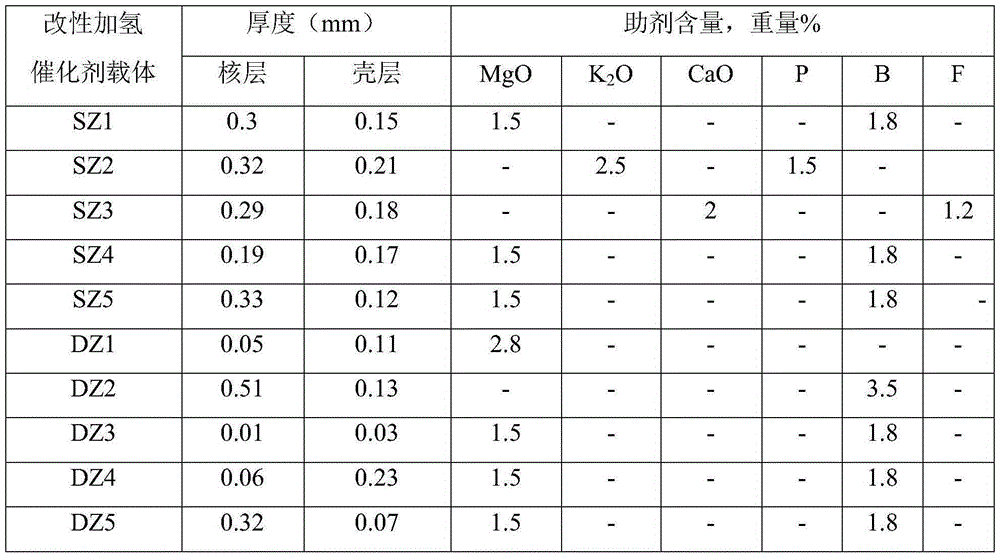

[0079] (2) The carrier obtained in step (1) is loaded with metal additives in 145 milliliters of 40 DEG C containing 10 g / L H 3 BO 3 The aqueous solution (pH value is 6) was immersed for 1 hour, then dried at 120°C for 3 hours, and then calcined at 400°C for 3 hours to obtain the modified hydrogenation catalyst carrier SZ1.

[0080] (3) Get 200 grams of carrier SZ1, use 190 milliliters of molybdenum oxide and basic c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com