A kind of residual oil hydrogenation catalyst and preparation method thereof

A residue hydrogenation and catalyst technology, used in the petroleum industry, hydrocarbon oil treatment, refining to remove heteroatoms, etc., can solve the problem of low metal removal rate and desulfurization activity, low conversion rate of heavy oil or residual oil, and low catalytic activity problems, to achieve high metal removal rate and desulfurization activity, improve catalytic activity, and low coking rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

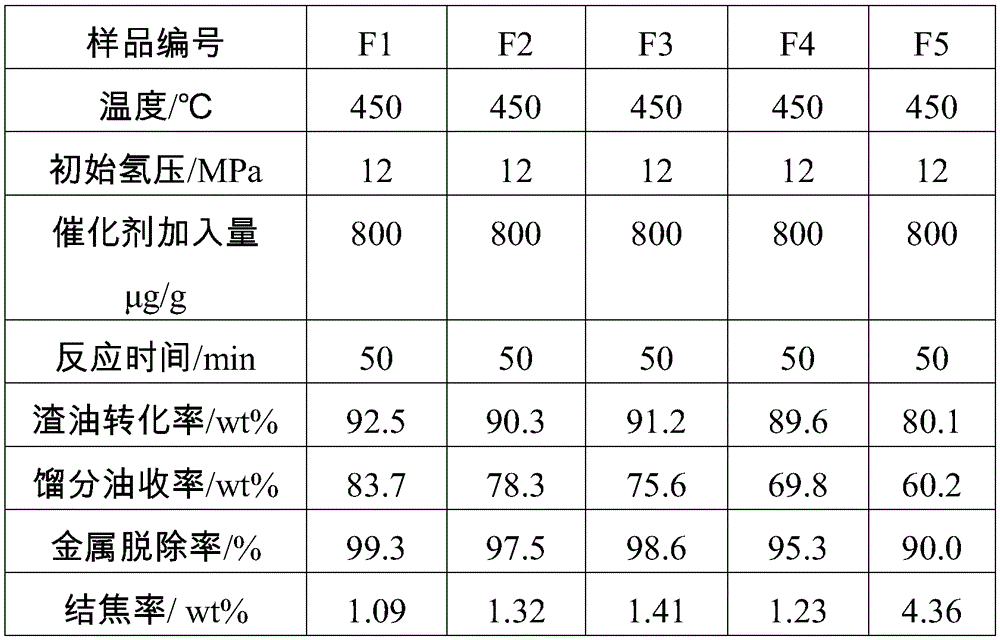

Embodiment 1

[0028] The present embodiment provides a kind of residual oil hydrogenation catalyst, it comprises following components:

[0029] Active molybdenum sulfide, 70g;

[0030] Graphitized pore-expanding blue carbon, 30g;

[0031] Wherein, the graphitized pore-expanding blue carbon is prepared by the following method:

[0032] (1) Pulverize the semi-coke, pass through a 300-mesh sieve, dry the water at 120°C, perform graphitization treatment in nitrogen at 1500°C for 8.0 hours, and take it out after the temperature drops to room temperature to obtain graphitized blue-coke;

[0033] (2) Take graphitized blue carbon and pore-enlarging agent KOH according to the mass ratio of 1:2 and mix them uniformly, and perform pore-enlarging treatment in a mixed gas atmosphere composed of nitrogen and oxygen at a volume ratio of 1:9 at a temperature of 500°C After 12 hours, the product after the pore expansion treatment was acid-washed and washed with water, centrifuged, and dried at 100°C for 3...

Embodiment 2

[0038] The present embodiment provides a kind of residual oil hydrogenation catalyst, it comprises following components:

[0039] Active molybdenum sulfide, 60g;

[0040] Activated coal activated carbon, 40g;

[0041] Wherein, the activated coal-based activated carbon is prepared by the following method:

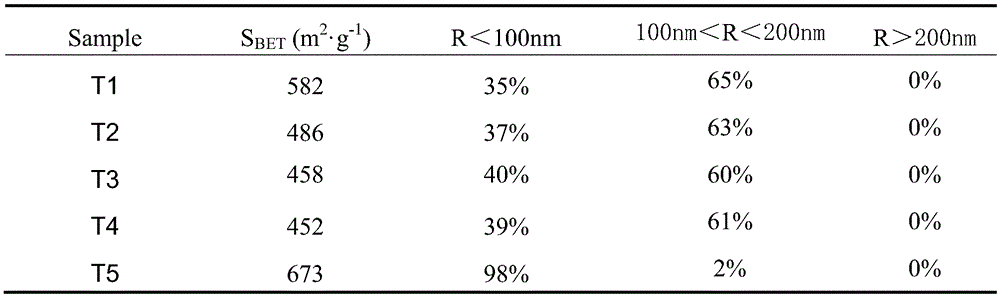

[0042] Coal activated carbon (specific surface area 659m 2 / g, radius is that the hole of 100-200nm accounts for 3% of total number of holes, and the hole with radius less than 100nm accounts for 97% of total number of holes) is immersed in the alkali solution that mass concentration is 25%, described coal activated carbon and described alkali The mass ratio of the solution was 1:5, and activation treatment was carried out at 400° C. for 5 hours to obtain the activated coal-based activated carbon.

[0043] Further, the residue hydrogenation catalyst is prepared by the following method:

[0044] (1) The waste Mo-Ni / γ-Al 2 o3 The catalyst is pulverized, washed with dilute...

Embodiment 3

[0047] The present embodiment provides a kind of residual oil hydrogenation catalyst, it comprises following components:

[0048] Active molybdenum sulfide, 50g;

[0049] Graphitized pore-expanding blue carbon, 50g;

[0050] Wherein, the graphitized pore-expanding blue carbon is prepared by the following method:

[0051] (1) Pulverize the semi-coke, pass through a 200-mesh sieve, dry the water at 100°C, and conduct graphitization treatment in argon at 1900°C for 0.5h, and take it out after the temperature drops to room temperature to obtain graphitized blue-coke ;

[0052] (2) Take graphitized blue carbon and pore-enlarging agent KOH according to the mass ratio of 1:6 and mix them evenly, and expand the pores in a mixed gas atmosphere composed of oxygen and carbon dioxide at a volume ratio of 1:9 at a temperature of 1000°C After treatment for 0.5h, pickling and water washing were carried out on the product after the pore expansion treatment, and then centrifuged and dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com