Combined fly wheel loading unit capable of reconstructing

A loading device, combined technology, applied in the direction of measuring device, testing of machine/structural components, force/torque/work measuring instrument, etc., can solve the requirements that it is difficult to meet the requirements of brake test standards, and the simulation of the actual driving state of the vehicle is not enough. , the flywheel assembly and disassembly process is complicated and other problems, to achieve the effect of precise adjustment, easy operation, accurate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

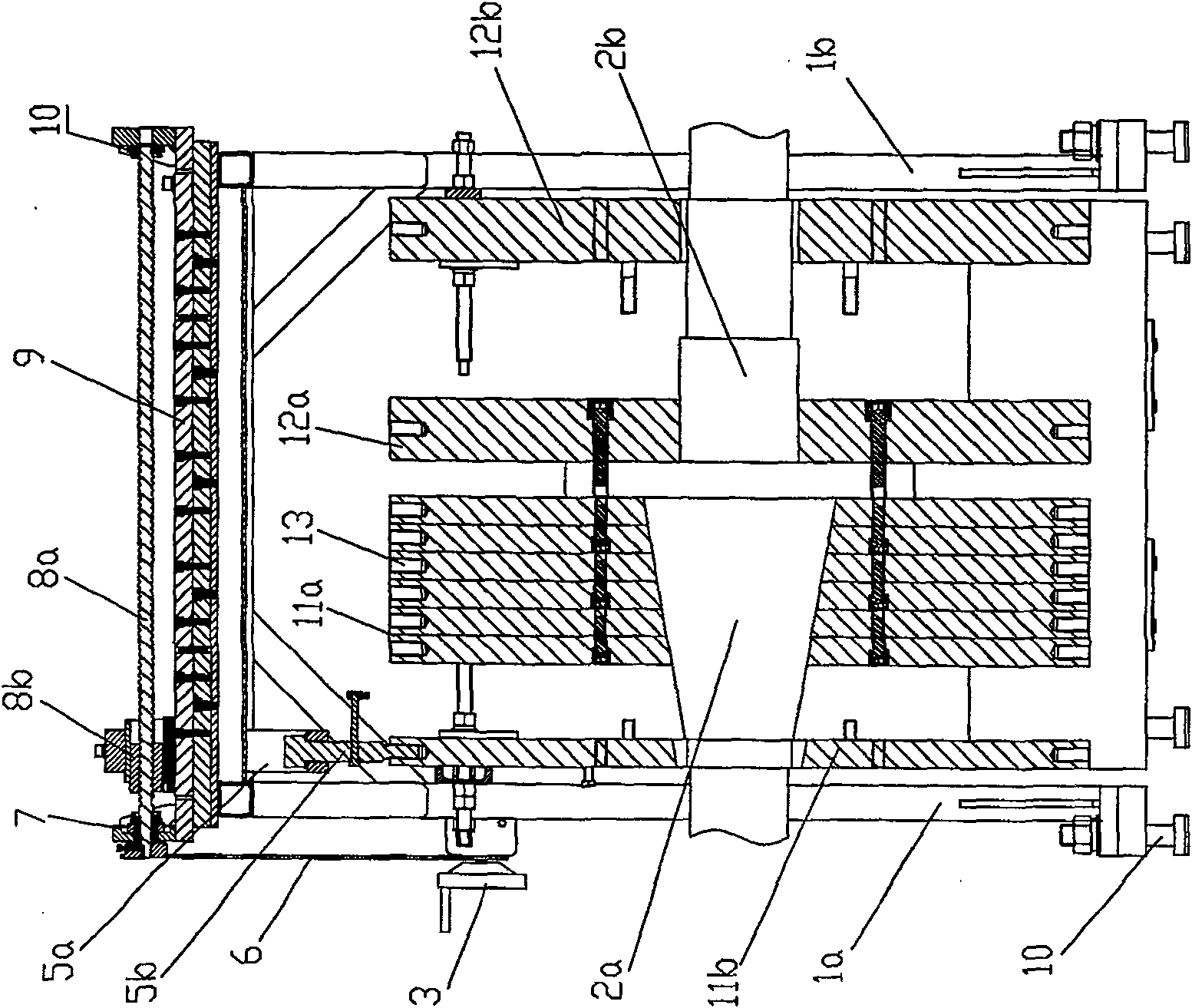

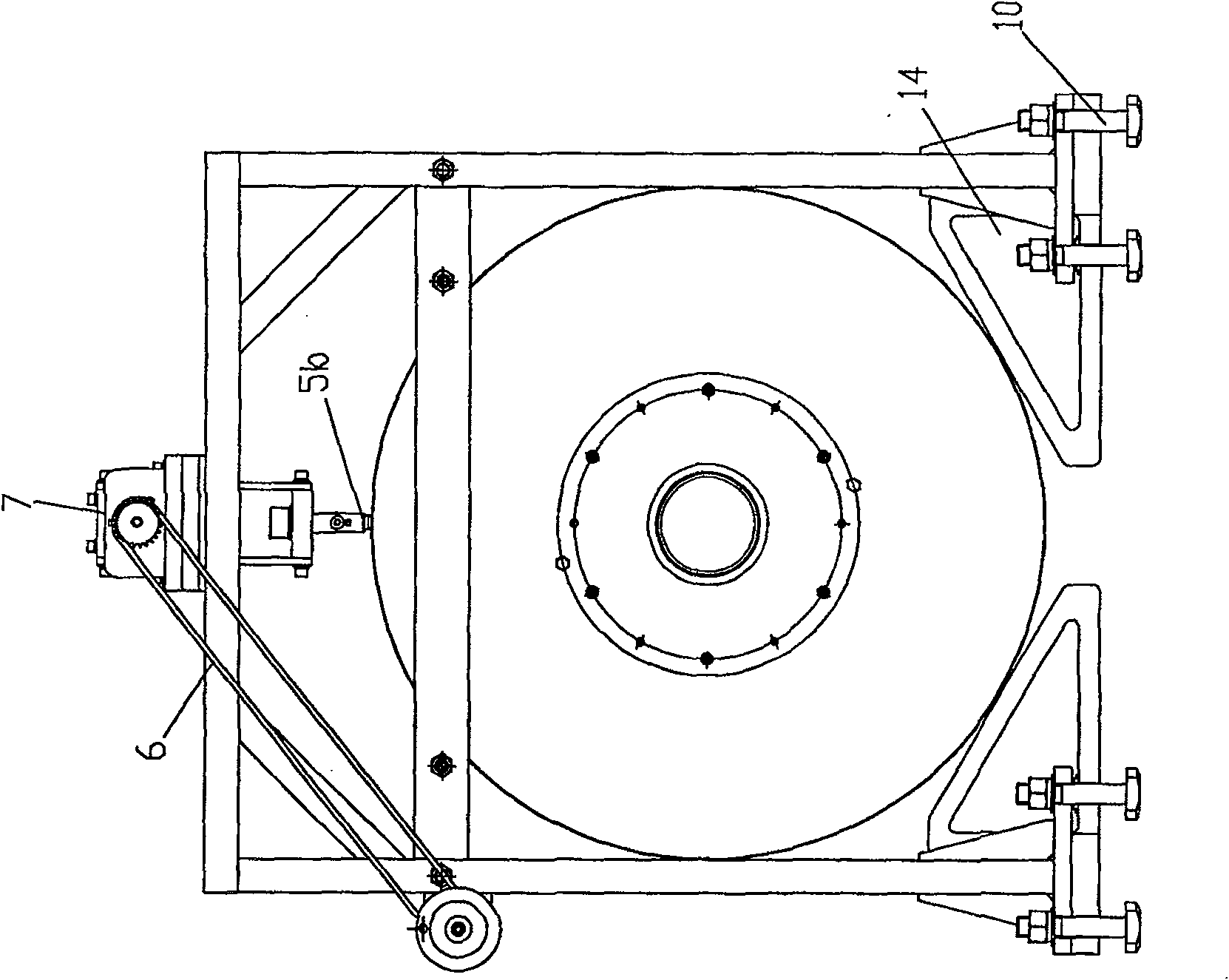

[0022] Referring to the accompanying drawings, in this embodiment, a portal frame consisting of a left side frame 1a, a right side frame 1b and a horizontal top frame is provided. In the portal frame, a plurality of flywheel pieces constitute a flywheel group, and each flywheel piece Set in a series on the rotating shaft in sequence, fixedly set the connecting plate on the rotating shaft, the flywheels for use are sequentially fixed on the connecting plate through the inner hexagonal screws, the idle flywheels are separated from the connecting plate, and are attached to the door frame in sequence The side frame of the side frame, the rotating shaft at the position of the idle flywheel is smaller in diameter than the rotating shaft at the position of the flywheel, and the idle flywheel is supported on the "V" bracket 14 at the bottom of the frame ( figure 2 shown).

[0023] The rotating shaft is centered on the connection plate. The flywheel on the right side of the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com